Mechanical shaft-forming method of shield cutterhead maintenance shaft in tunnel and underground construction

A shield cutter head and underground engineering technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as increased construction costs and construction periods, high construction safety risks, and complicated construction techniques, achieving shortened construction periods, Reduce construction risk and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiment of the present invention is described in conjunction with accompanying drawing:

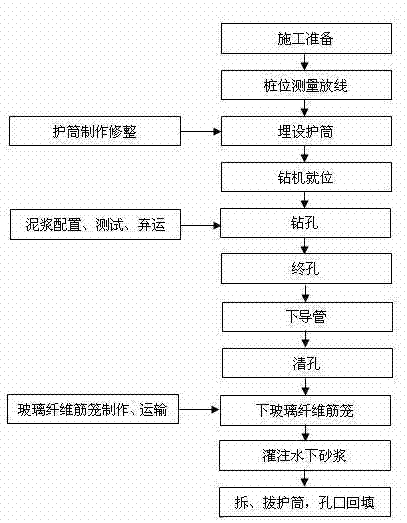

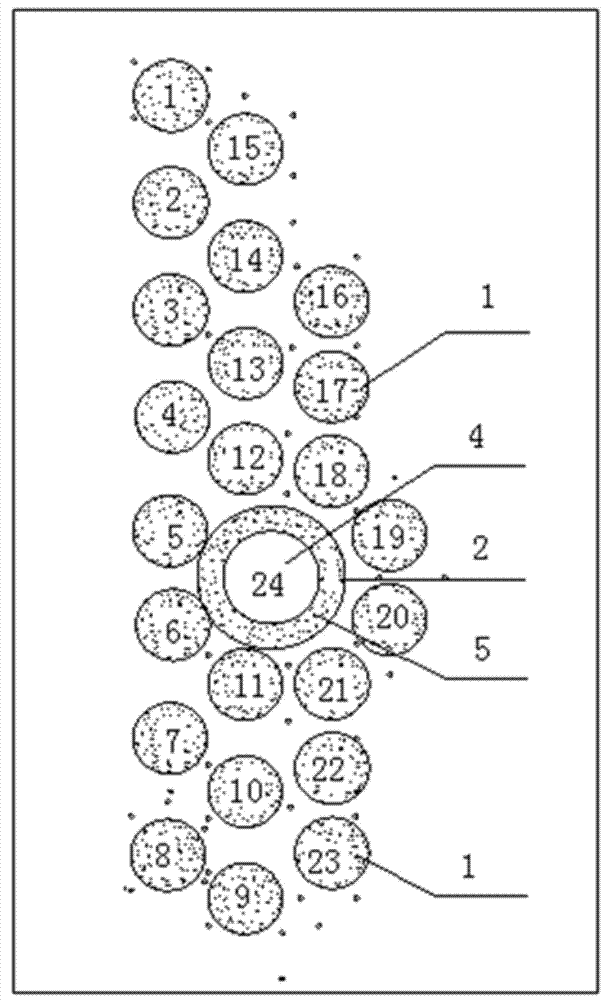

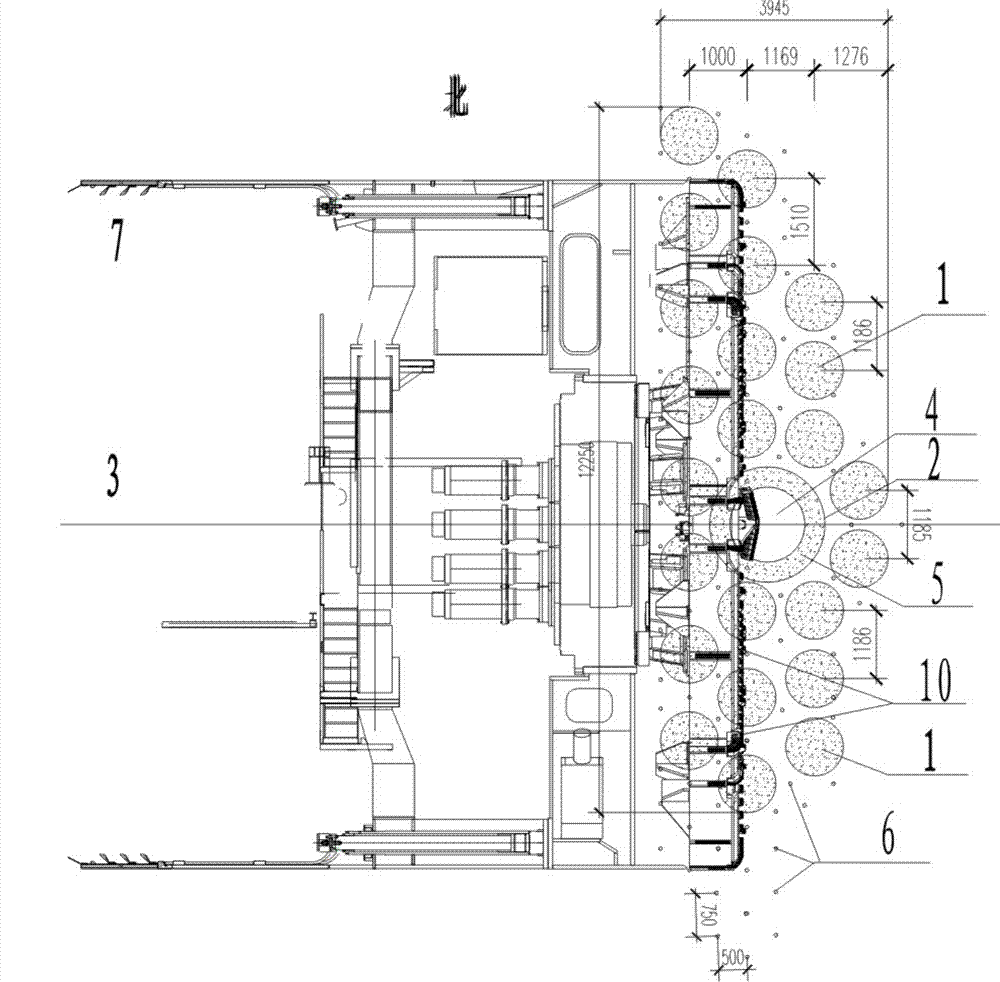

[0029] Such as figure 1 , 2 , 3, 4, and 5, a method for mechanical well-forming of shield cutter head maintenance well in tunnels and underground engineering, the steps are as follows:

[0030] 1) Firstly, at the position where the cutter head needs to be repaired in the shield tunnel, use geophysical prospecting and manual excavation to find out the underground pipeline (11) in the construction area, and mark the underground pipeline (11);

[0031] 2), and then carry out retreat grouting reinforcement on the 5m deep strata within the reinforcement range of bored piles,

[0032] 3), and then use the rotary drilling drill to construct 3 rows of φ1.0m glass fiber reinforced cast-in-place piles (1) in the reinforcement range of the shield tunnel with the pre-stop position as the center;

[0033] 4) Finally, on the tunnel axis (3) of the shield machine (6), a large-diameter (φ2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com