Shield segment structure and shield tunnel

A technology of shield segments and shield tunnels, which is applied in tunnels, mining equipment, and earthwork drilling and mining, and can solve the problems of small effective use area of circular sections, small size of rectangular sections, and poor mechanical performance of rectangular sections. Achieve the effect of reducing the excavation depth of the structure, improving the reliability of the connection, and improving the safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

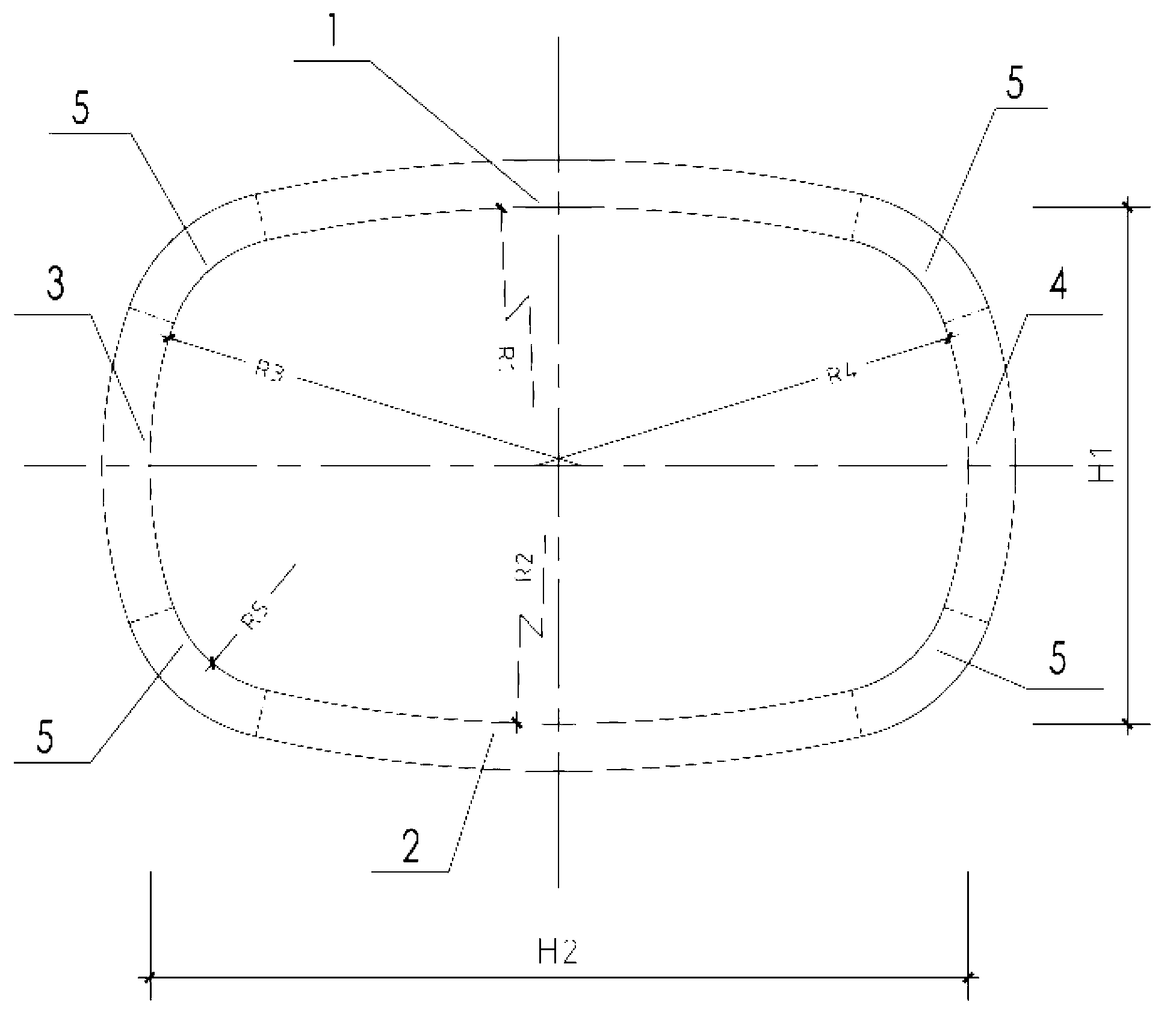

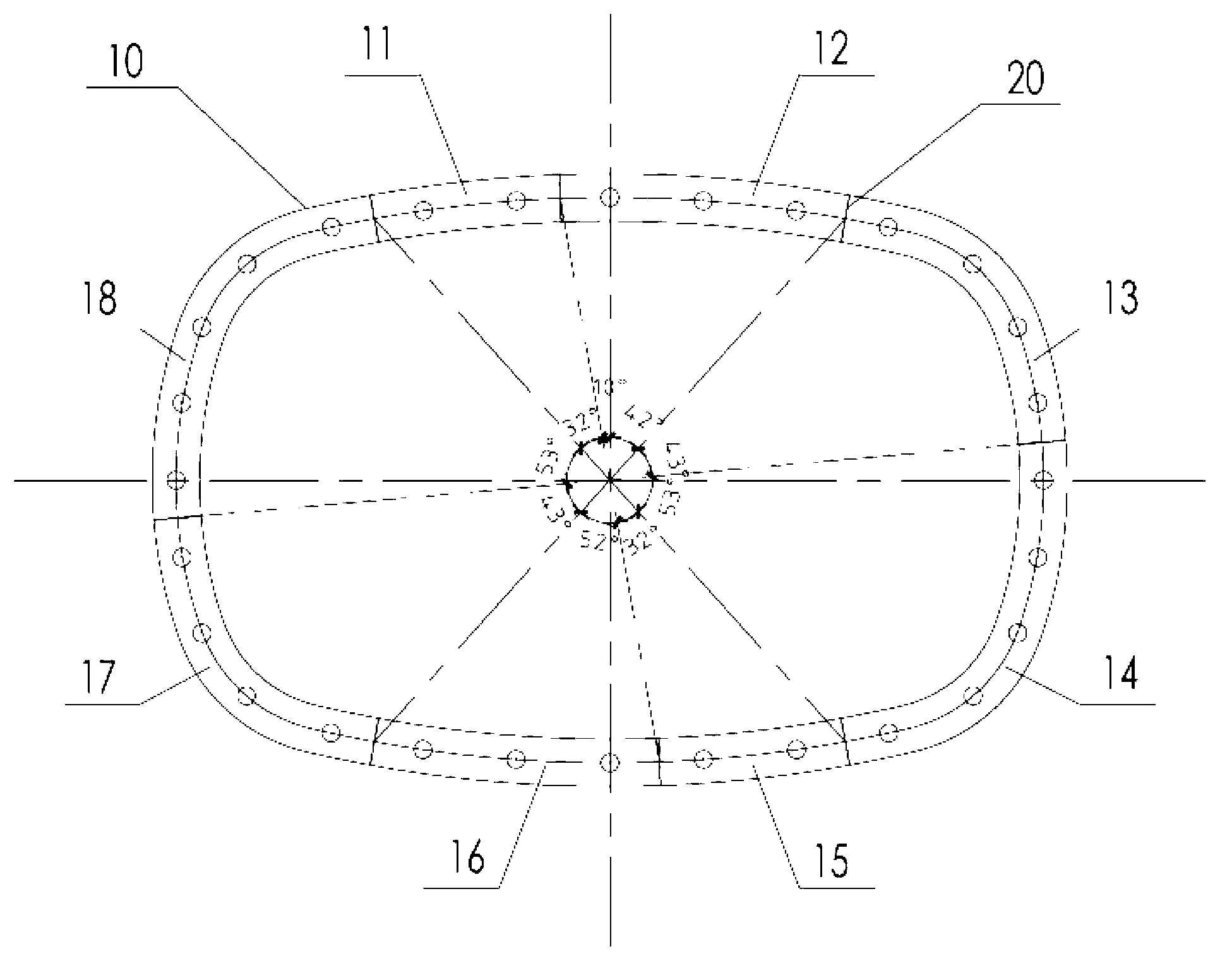

[0030] figure 1 It is a schematic diagram of the cross-sectional structure of the shield segment structure in Embodiment 1. like figure 1 As shown, a shield segment structure according to a specific embodiment of the present invention includes a plurality of segment segments 10, and the segment segments 10 are surrounded and spliced to form a complete ring. Among them, such as figure 2 As shown, the cross-section of the entire ring is a center-symmetric and axisymmetric special-shaped surface, and the special-shaped surface is formed by enclosing eight sections of inferior arcs, which are respectively the top inverted arch 1 and the bottom inverted arch 2, which are arranged symmetrically up and down. The left arch 3 and the right arch 4 arranged opposite to each other symmetrically, and the four corners 5 . The two ends of the top inverted arch 1 are respectively connected to the two upper ends of the left arch 3 and the right arch 4 through a corner 5, and the two ends...

Embodiment 2

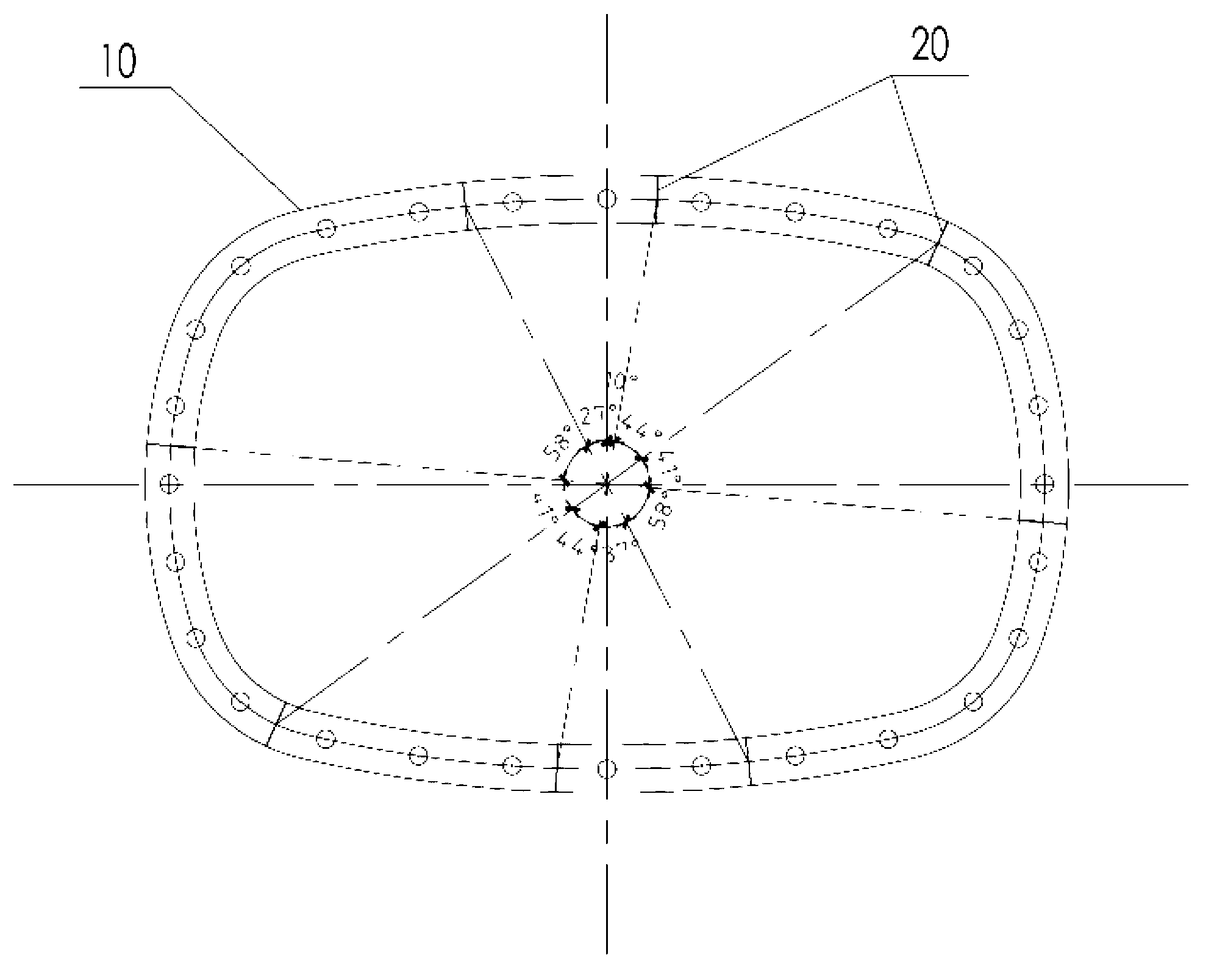

[0035] image 3 It is a schematic diagram of the cross-sectional structure of the shield segment structure of the second embodiment. like image 3 As shown, the shield segment structure of the second embodiment differs from the first embodiment in that the central angle of the segment 10 is different, and the position of the splicing seam 20 of adjacent segments is changed.

[0036] Of course, in other embodiments, the number of segments and their central angles can be selected according to the needs of the shield segment structure, which will not be repeated here.

Embodiment 3

[0038] Figure 4 It is a structural schematic diagram of the shield tunnel of the third embodiment. like Figure 4As shown, the shield tunnel of this embodiment includes the above-mentioned shield segment structure, and several shield segment structures are docked to form the shield tunnel, and the adjacent segments 10 of the shield segment structure 20 seams are set in a staggered manner. A positioning hole 30 for longitudinally extending connection is provided in the segment 10 , and several shield segment structures are sequentially connected in series by piercing the connecting piece in the positioning hole 30 .

[0039] Exemplarily, the shield tunnel of this embodiment adopts the shield segment structures of Embodiment 1 and Embodiment 2 to be assembled in series at longitudinal intervals to form a flat rectangular-like tunnel assembled in the form of staggered joints as a whole. According to the size of the segments 10, the screw holes are evenly distributed as the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com