Small-radius shield tunnel construction technology

A construction technology, small radius technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as low deviation correction sensitivity, difficult construction, quality, safety, and even difficult progress guarantees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

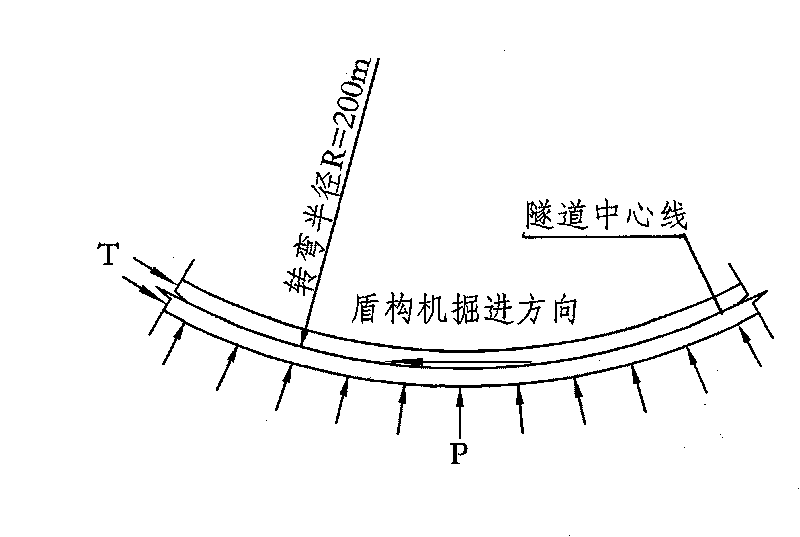

[0019] 1. Application of super digging knife

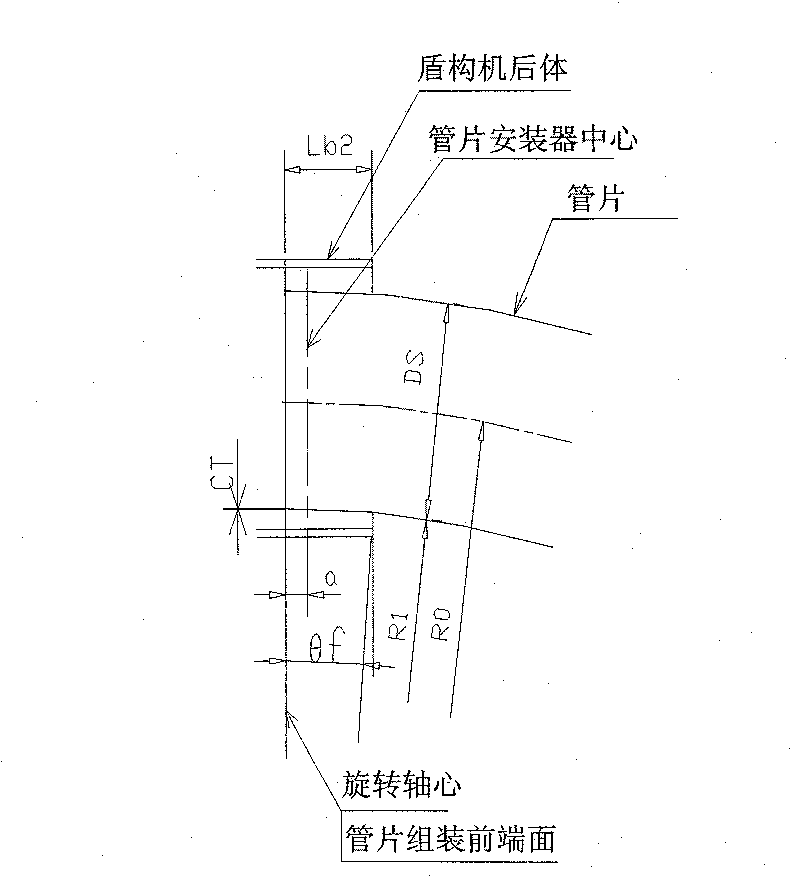

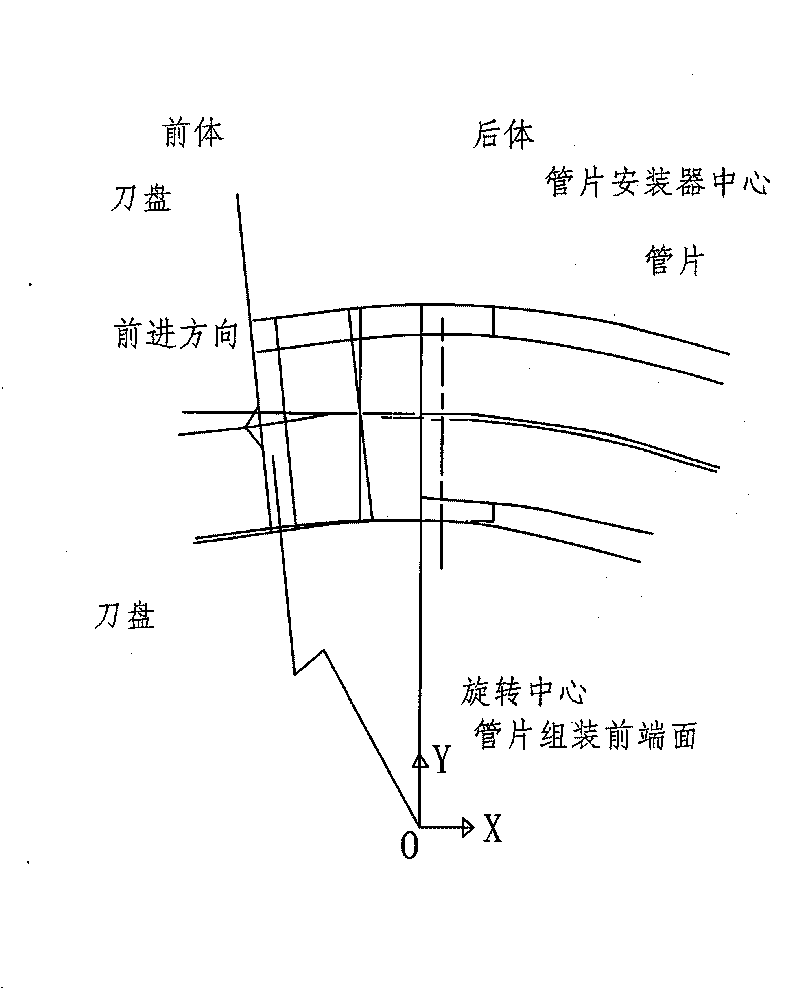

[0020] See Table 1 for the calculations of the shield tail clearance, the overbreak amount of the overcut knife, and the minimum turning radius during the construction of this section.

[0021] Table 1

[0022] mark

value

Explanation of symbols

K

2

Type number of shield machine: muddy water type K=1, earth pressure type K=2

R0

200m

Tunnel Plane Turning Radius

Ds

6000mm

Segment outer diameter

Bs

1200mm

Segment Width

D

6280mm

Shield machine cutter head outer diameter

L s

4173mm

The length from the cutterhead surface of the shield machine to the hinge center

[0023] mark

value

Explanation of symbols

L b

3997mm

Body length of shield machine back (from hinge center to shield tail)

L b1

1562mm

The length from the front of the first ring segment to the hinge center

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com