Weft selection apparatus for a weaving machine

A technology of looms and traction devices, applied in the directions of looms, textiles, textiles, and papermaking, to achieve the effect of reducing additional loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

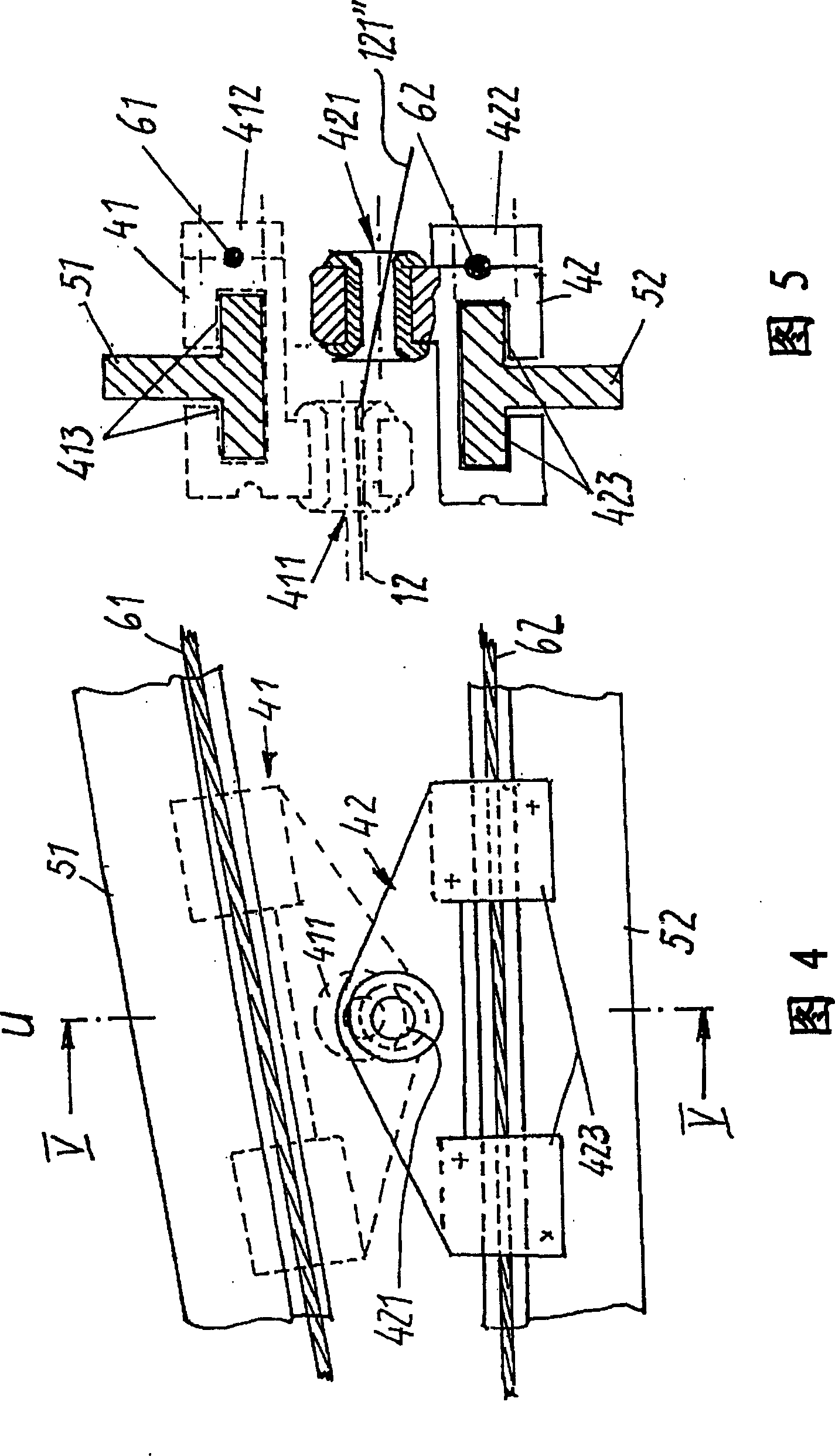

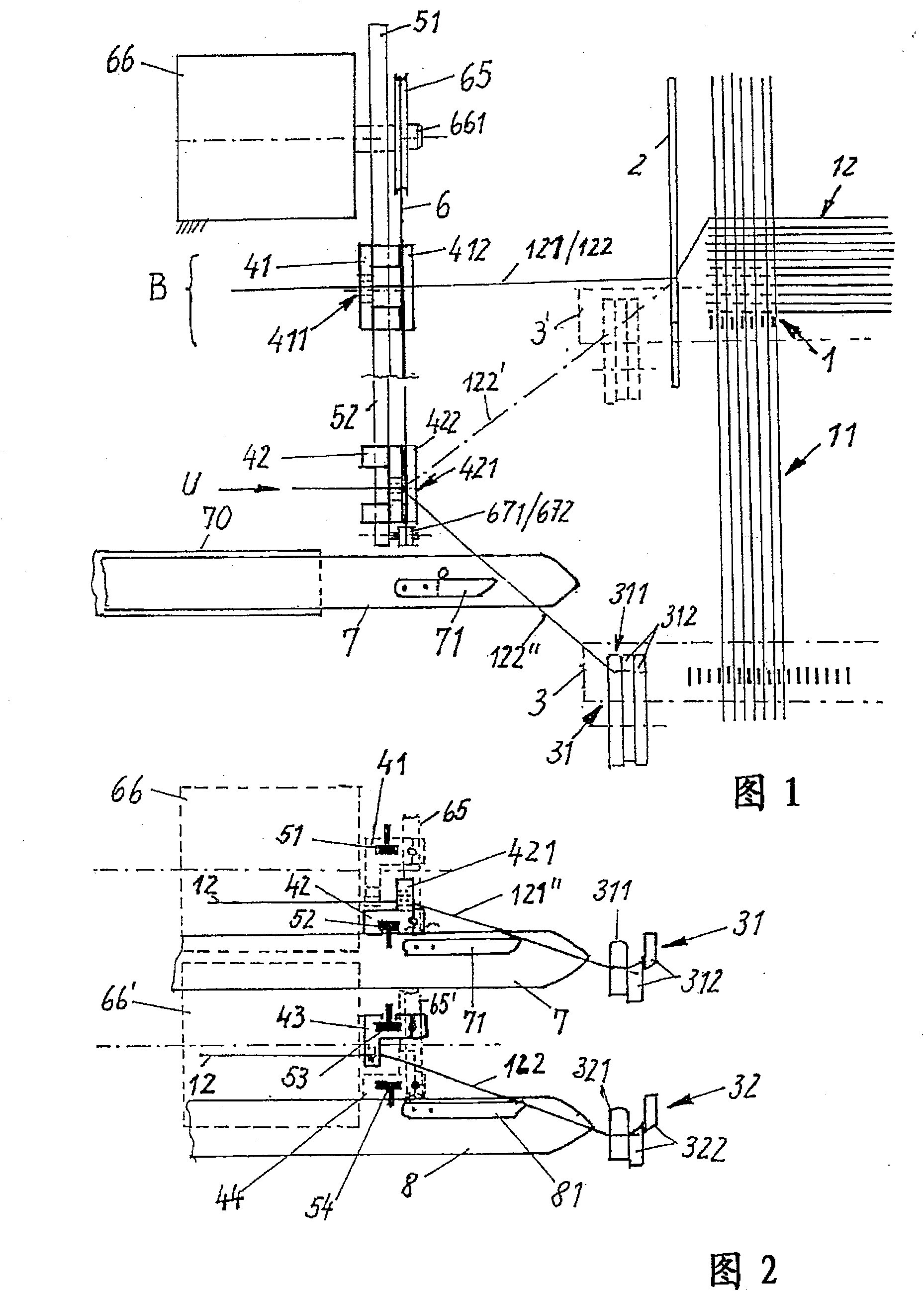

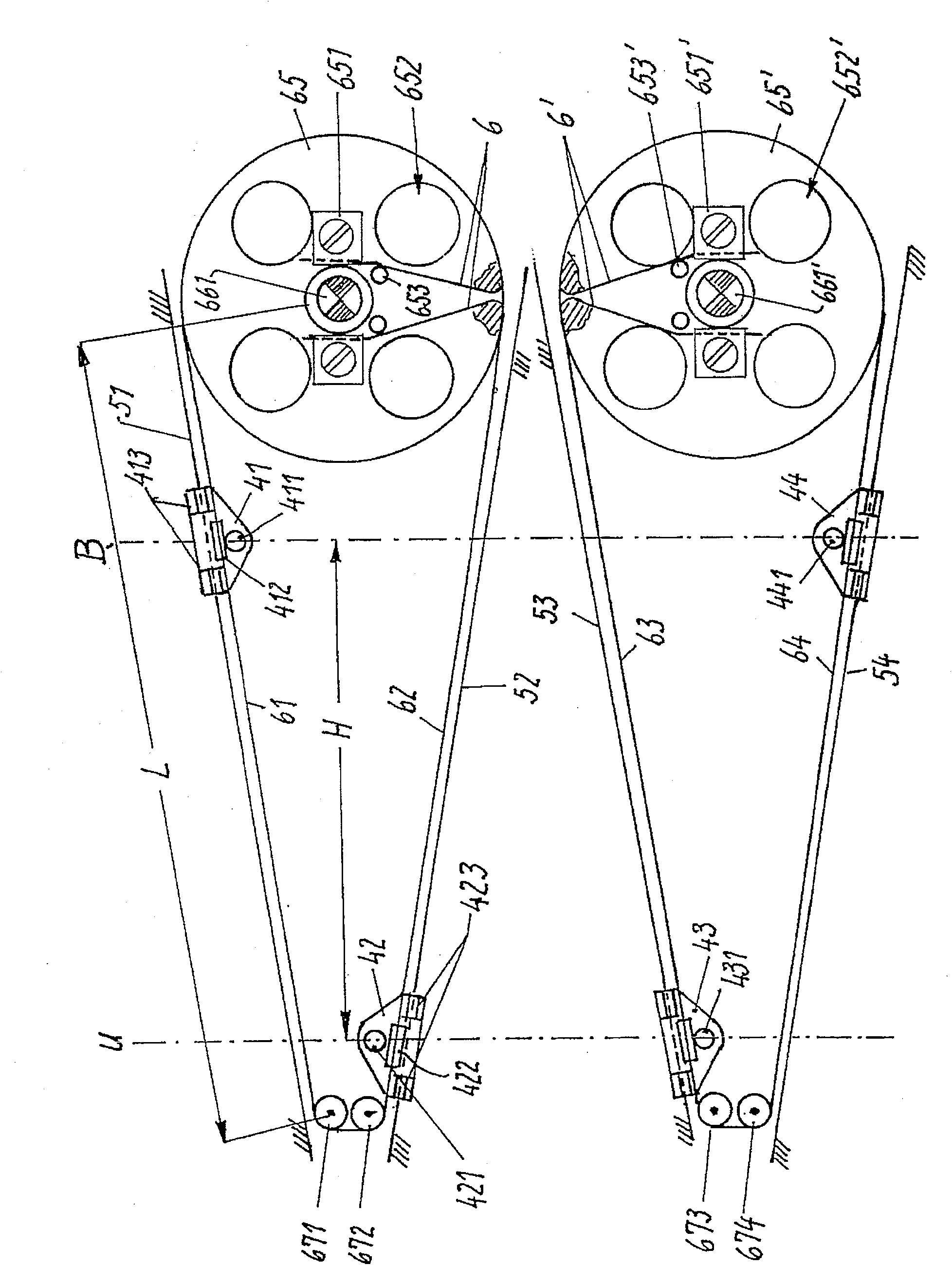

[0022] The weft changing device according to the invention is illustrated by means of a double shed loom with two weft insertion planes placed one above the other.

[0023] The coil transfer position U and the standby position B are arranged substantially in a common horizontal plane.

[0024] figure 1 In the right-hand region is indicated the supply of warp threads 11 which, together with the weft threads 12 introduced, produce a base fabric 1 of double-faced fleece after the fabric has been beaten up.

[0025] During the stage of weft insertion by means of the clamping bar 7 with a tucking clamp 71, the sley 3 with the weaving reed is in its final position. A controllable clamping and cutting device 31, 32 for the weft thread 12 is arranged on the sley 3 laterally outside the weaving reed. The clamps 311, 321 and the blades of the scissors 312, 322 are driven in a manner known per se. The driving structure is not shown.

[0026] Laterally on the outside of the base fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com