Method for placing vacuum glass supporter

A vacuum glass and support technology, which is applied in the field of vacuum glass support placement, can solve problems such as warping and deformation, affecting the appearance, inconsistent displacement direction and size, etc.

Inactive Publication Date: 2016-02-10

黄家军

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

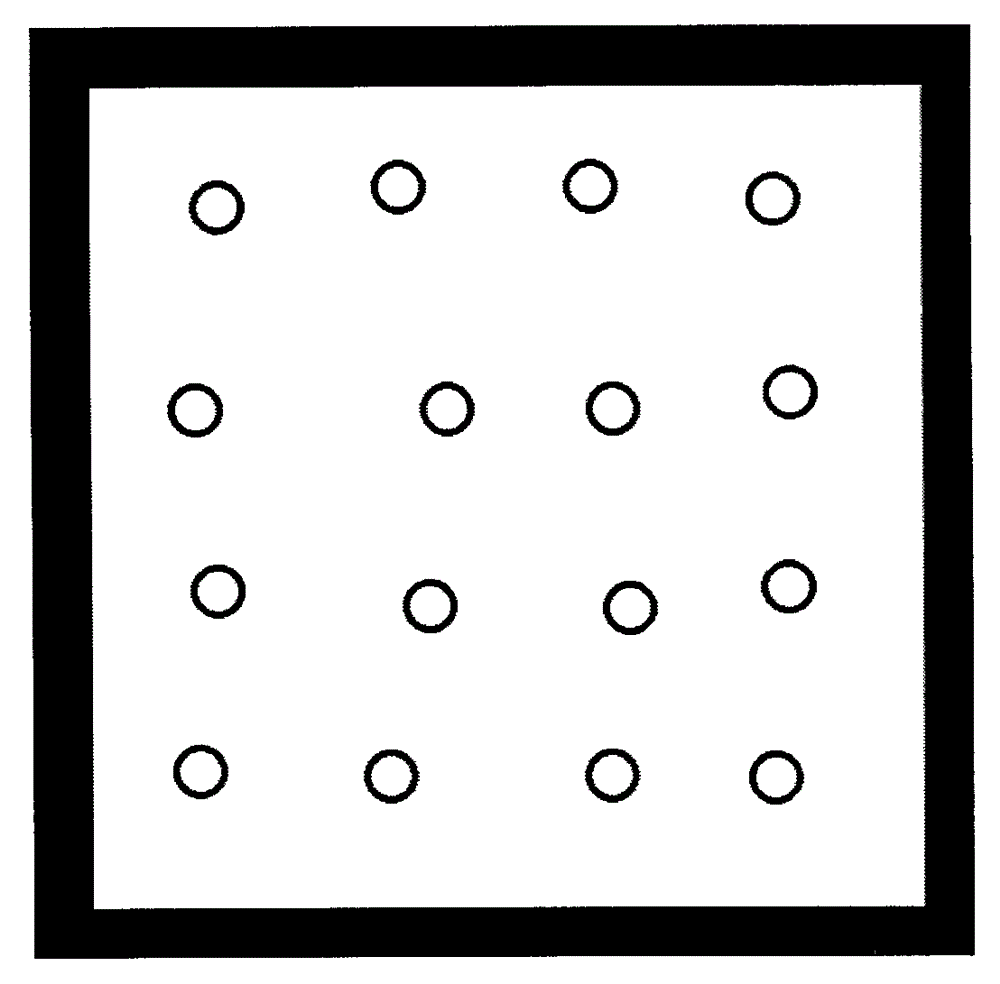

The support fixed with organic sealant, the sealant is heated and melted, the upper and lower glass plates are compressed in the middle under the action of external force, and the glass plate will warp and deform under the action of external force, which will generate a lateral thrust on the support , causing the support to move. Although the movement is only 1-2 mm, it has no effect on the heat insulation and sound insulation effect of the vacuum glass, but this movement affects the appearance, such as figure 1 As shown, when the upper row of supports is initially placed, the supports are on a straight line. After compression, the displacement directions and sizes of each support are inconsistent, and the upper row of supports is not on a straight line. This affects beautiful

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

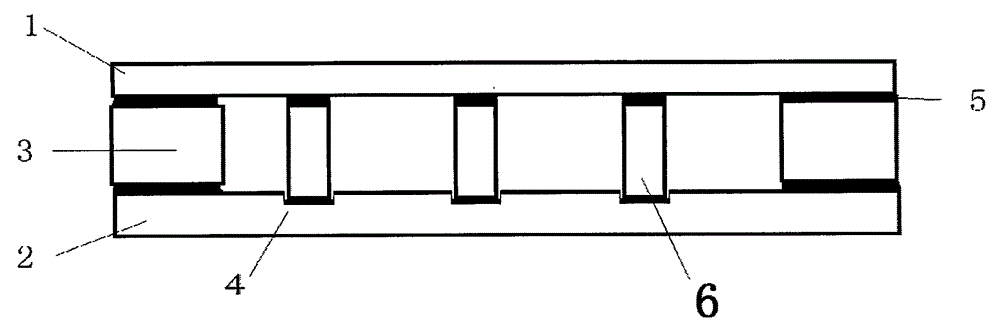

[0010] like figure 2 As shown, before placing the support, open a 1 mm deep groove 4 on the lower glass plate 2 at the position where the support will be placed, then put the support into the groove, then place the auxiliary sealing strip 3 and seal Glue 5, and then cover the upper glass plate 1. Then put the vacuum glass original plate into the vacuum heating furnace for heating and sealing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention aims at providing a method for placing a vacuum glass supporter. The method is used for preventing the supporter from lateral movement. The method for placing the vacuum glass supporter is characterized by comprising the steps of firstly, forming a groove, which is slightly greater than the outside diameter of the supporter, in the surface of a glass sheet where the supporter is required to be placed, and then, placing the supporter in the groove.

Description

technical field [0001] The invention relates to the field of vacuum glass manufacturing, in particular to a method for arranging vacuum glass supports. Background technique [0002] Supports are used in the vacuum glass manufacturing process. The support fixed with organic sealant, the sealant is heated and melted, the upper and lower glass plates are compressed in the middle under the action of external force, and the glass plate will warp and deform under the action of external force, which will generate a lateral thrust on the support , causing the support to move. Although the movement is only 1-2 mm, it has no effect on the heat insulation and sound insulation effect of the vacuum glass, but this movement affects the appearance, such as figure 1 As shown, when the upper row of supports is initially placed, the supports are on a straight line. After compression, the displacement directions and sizes of each support are inconsistent, and the upper row of supports is not ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C27/06

Inventor 黄家军

Owner 黄家军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com