A long-distance large-diameter concrete pipe manual jacking process in complex strata

A technology for complex strata and concrete pipes, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems affecting the guiding accuracy of guide rails, increasing pipeline deviation, guide rail offset, etc., to achieve Improve visual visibility, reduce pipeline deviation, and improve installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

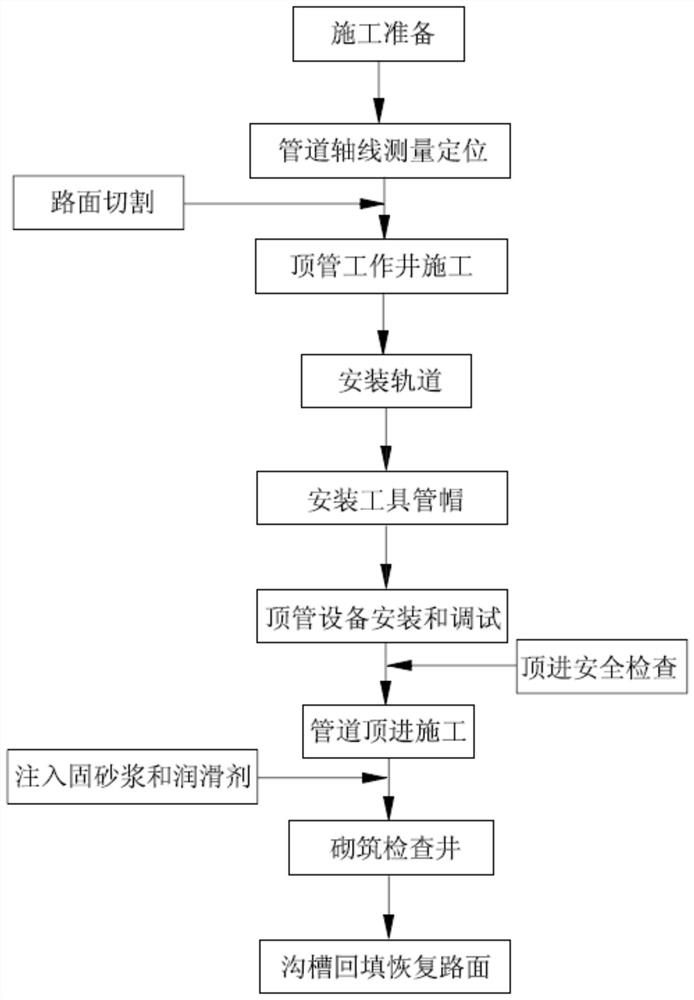

[0028] Such as figure 1 As shown, a long-distance large-diameter concrete pipe artificial jacking process in complex formations includes the following steps:

[0029] (1) Construction preparation: According to the construction requirements, the construction site has reached water, electricity, road access and site leveling, and the construction materials and machinery are prepared for use; at the same time, the material storage site and the project department office are put in place, The main machinery enters the site and conducts pre-construction inspections.

[0030] (2) Measurement and positioning of the pipeline axis: a. Firstly, the control network is laid out. The control network layout includes the plane control network layout through the pipeline engineering plane control measurement method and the elevation control network l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com