Novel fire grate segment

A new type of grate and grate technology, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve the problems of large manpower and material resources, simple precision casting, high labor costs and economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

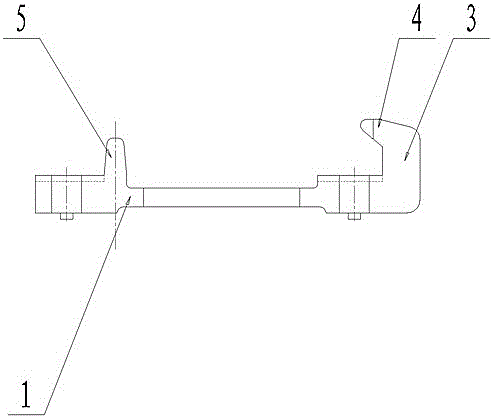

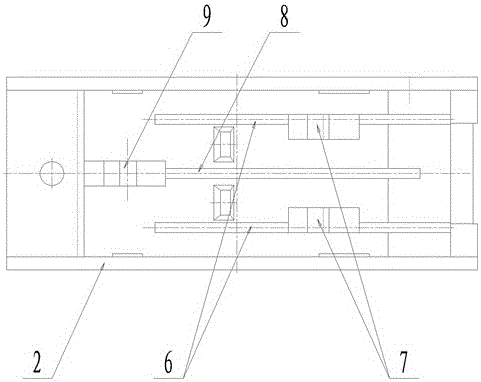

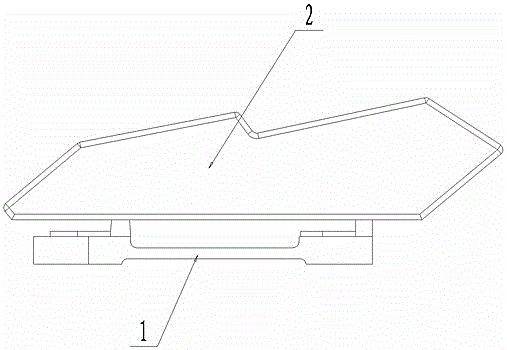

[0012] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 4 Shown: a new type of grate piece, which is composed of two parts, the base 1 and the upper shell 2, the rear end of the base 1 is provided with a connecting part 3, and the top of the connecting part 3 is provided with an inclined part 4, And the end (i.e. the outer edge) of the inclined part 4 is a smooth curved surface, a board 5 is provided at the front of the base 1, and two reinforcing ribs 6 on both sides are symmetrically provided in the upper housing 2, and these two The ribs 6 on both sides are distributed along the axial direction of the upper shell 2, and the first groove 7 matching the inclined part 4 is opened on the ribs 6 on both sides. The middle reinforcement rib 8 distributed along the axis, on which there is a second groove 9 matched with the board 5;

[0013] The above-mentioned upper shell 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com