Intelligent continuous dynamic compaction machine

A technology of dynamic compaction machine and frame, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of high risk of construction personnel or inspection personnel, large influence of surrounding buildings, low compaction power of road rollers, etc. To achieve the effect of convenient connection, stability and reliability, flexible and convenient construction, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

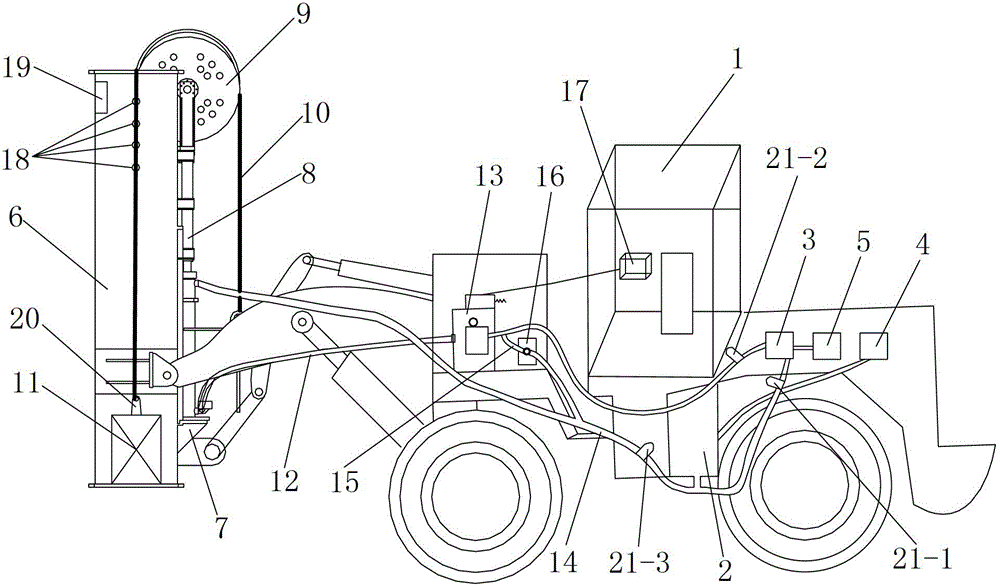

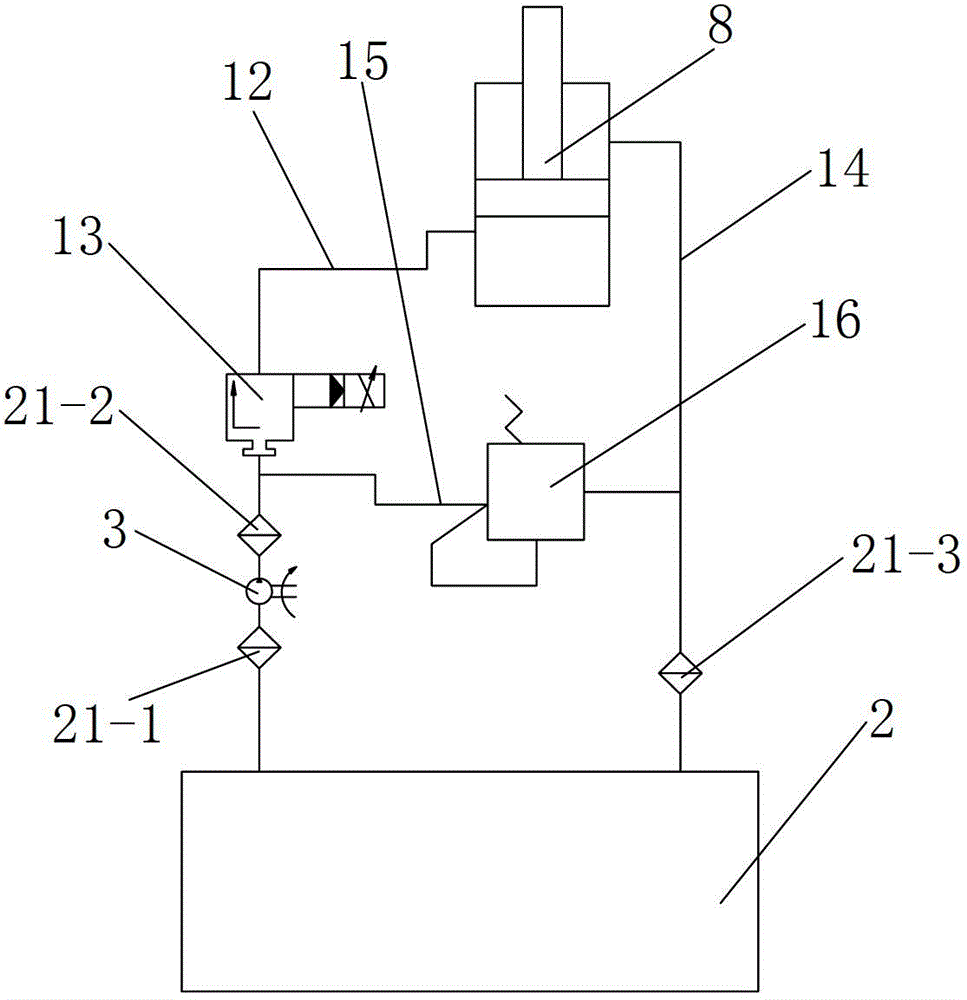

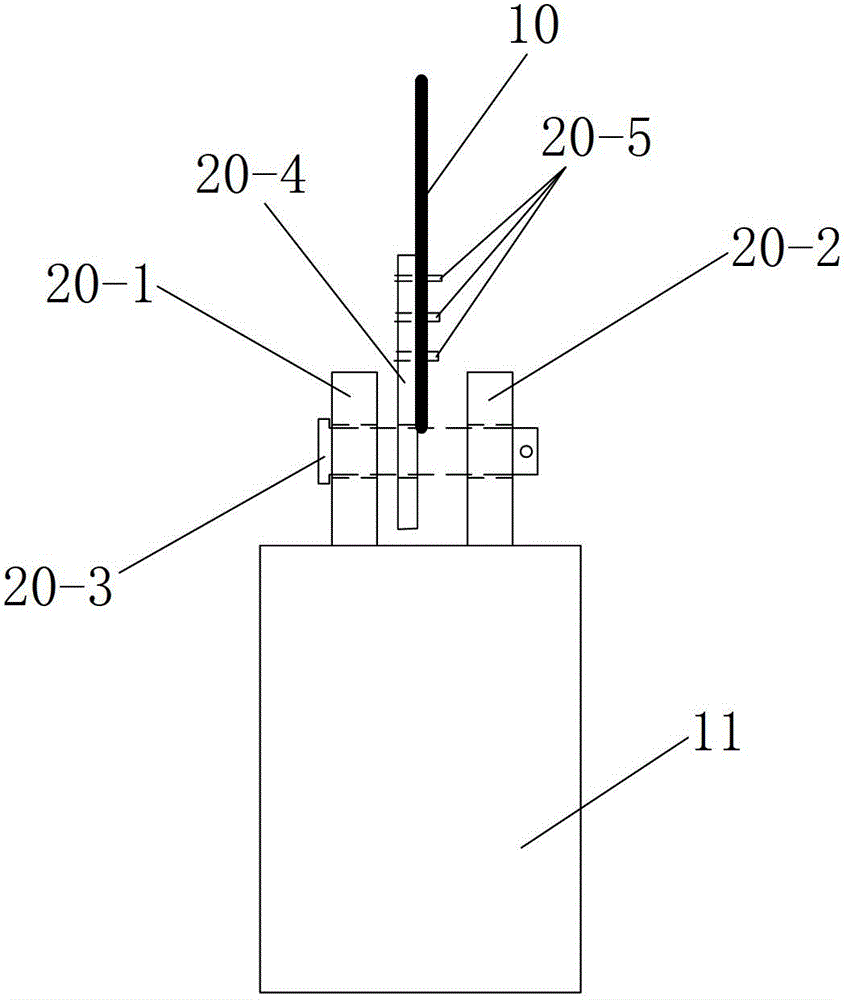

[0044] Such as figure 1As shown, the present invention includes a loader 1 and a tamping mechanism connected to the loader 1, the loader 1 is provided with an oil tank 2, an oil pump 3 connected to the oil tank 2 and a radiator 4, and a pump connected to the oil pump 3 The loader power system formed by the engine 5 is characterized in that: the tamping mechanism includes a frame 6, an oil cylinder support plate 7 connected to the frame 6 and an oil cylinder 8 connected to the oil cylinder support plate 7, and the cylinder 8 The piston rod protrudes upwards and the top end of the piston rod of the oil cylinder 8 is connected with a movable pulley 9, the movable pulley 9 is wound with a flexible connecting body 10, and one end of the flexible connecting body 10 is fixedly connected with the frame 6, the The other end of the soft connector 10 is connected with a tamper 11; the frame 6 is provided with a tamping condition detection system for detecting the tamping condition of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com