Construction structure and construction method for strengthening stratum at end of shield tunnel

A technology of shield tunnel and construction method, which is applied to tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of inability to carry out mixing piles and rotary jetting piles, construction, and the reinforcement structure is not strong, so as to prevent water leakage and sand leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

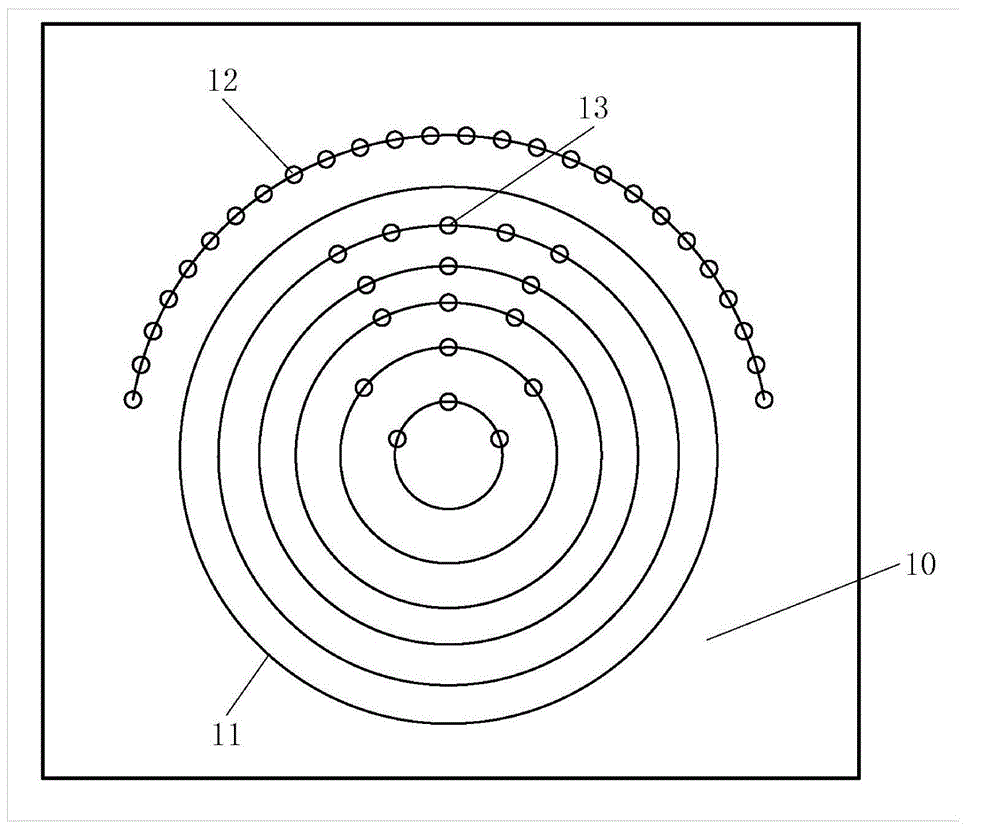

[0044] figure 1 It is a schematic plan view of the construction structure of Embodiment 1 to strengthen the strata at the end of the shield tunnel, as figure 1 As shown, a construction structure for strengthening the strata at the end of a shield tunnel provided in this embodiment includes:

[0045] A working well surface 10, the working well surface 10 includes a working well opening 11 to be operated by the shield machine, which is equal in radius to the shield machine;

[0046] A plurality of advanced grouting long pipe sheds 12 are arranged perpendicular to the working well surface 10 to be shielded to be operated on the top of the door 11 of the working well to be shielded. The vertical distances between the centers of the working well portals 11 are equal, and the ring spacing between the adjacent long pipe sheds 12 for the advanced grouting is equal;

[0047] A plurality of horizontal grouting pipes 13 are arranged vertically to the working well surface 10 to be shiel...

Embodiment 2

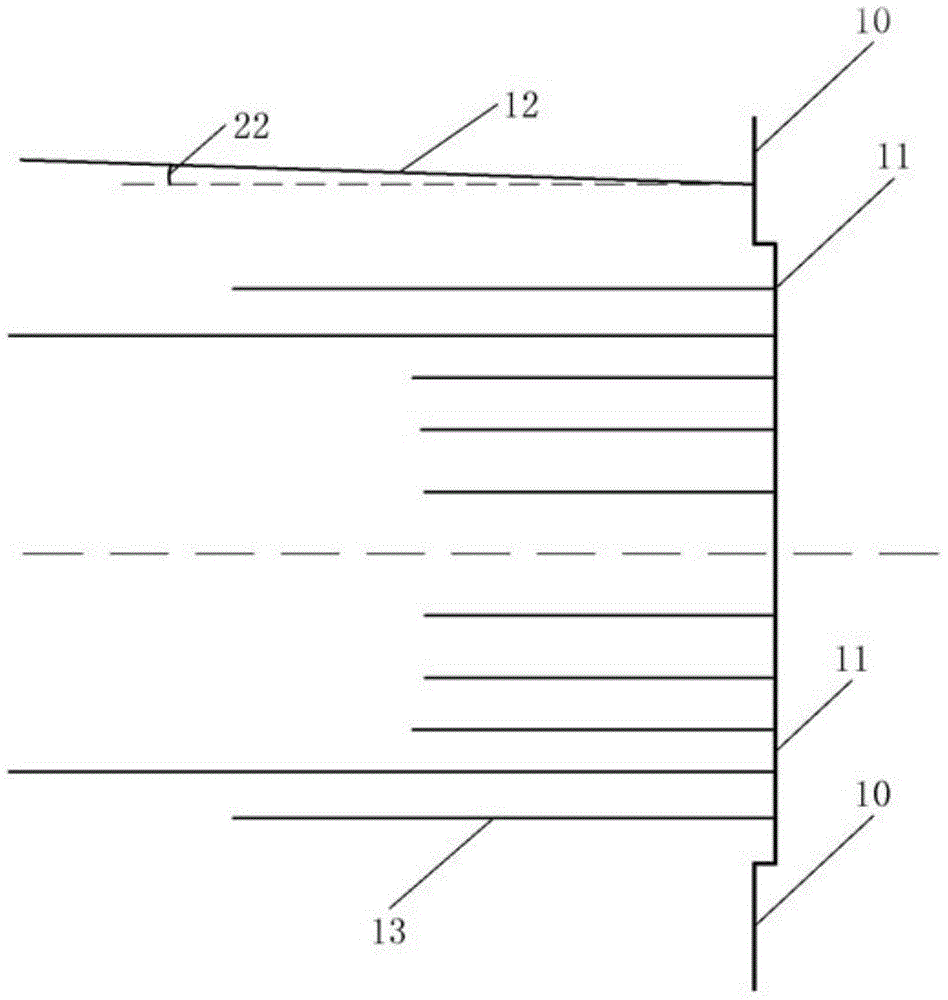

[0054] figure 2 It is the cross-sectional view of the construction structure of embodiment two reinforcement shield tunnel head formations, as figure 2 As mentioned above, on the basis of the first embodiment, the plurality of advanced grouting long tube sheds 12 are arranged above the door 11 of the working well to be shielded to be operated at an angle 22 of a certain size upward with the horizontal line. For example, the included angle 22 may be set to 1°.

[0055] The above-mentioned technical scheme, by setting a certain angle between multiple long pipe sheds with advanced grouting and the horizontal line, avoids the front end drooping into the tunnel operation area due to the gravity of the pipe shed itself when installing the pipe shed, which affects the construction quality and operation safety .

Embodiment 3

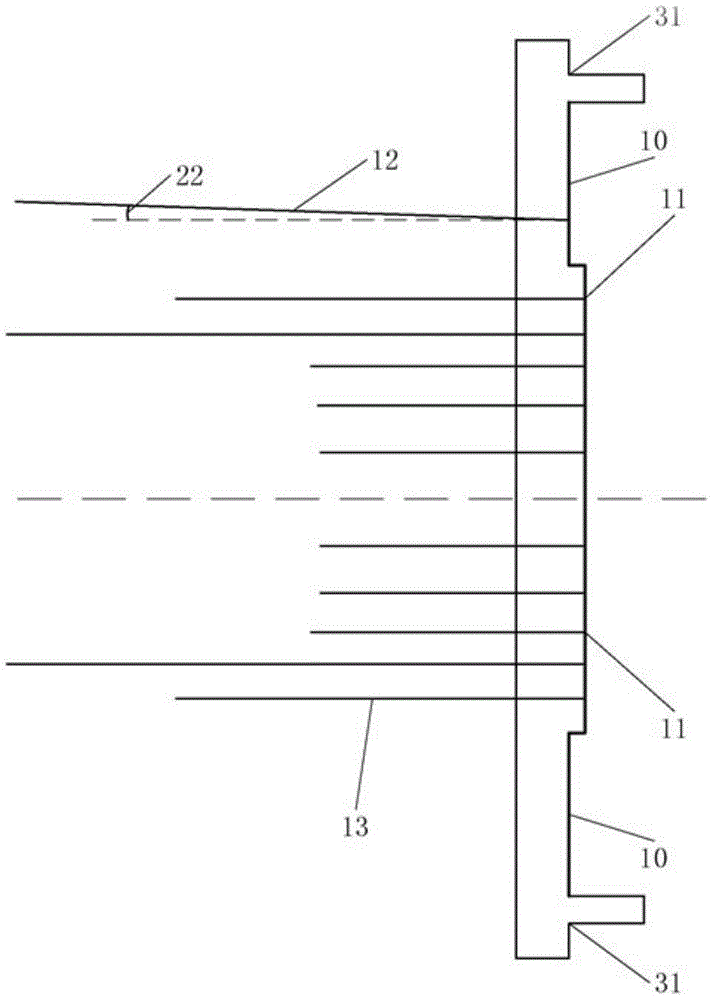

[0057] image 3 It is the sectional view of the construction structure of embodiment three reinforcement shield tunnel end formations, as image 3 As shown, each of the advanced grouting long pipe sheds has the same length, and the length can be set to 12m. Each of the said advanced grouting long pipe sheds is composed of a variety of steel pipes with different specifications, and grouting holes are drilled on the steel pipes. The length of the steel pipe sections of different specifications can be 1.0m, 1.5m, 2.0m or 3.0m respectively.

[0058] On the basis of the above-mentioned embodiments, specifically, the working well surface is also fixed with a working well enclosure structure 31, and then the steel pipes in each of the advanced grouting long pipe sheds 12 are placed on the working well enclosure structure 31. No grouting holes are drilled within a certain distance on one side, and the certain distance may be within 1m.

[0059] The above technical scheme, by setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com