Pressure vessel vented boss with sintered metal plug

A technology for pressure vessels and sintered metals, applied in the direction of pressure vessels, vessel discharge methods, vessel filling methods, etc., capable of solving problems such as weakening the connection between the liner 20 and the boss 16

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

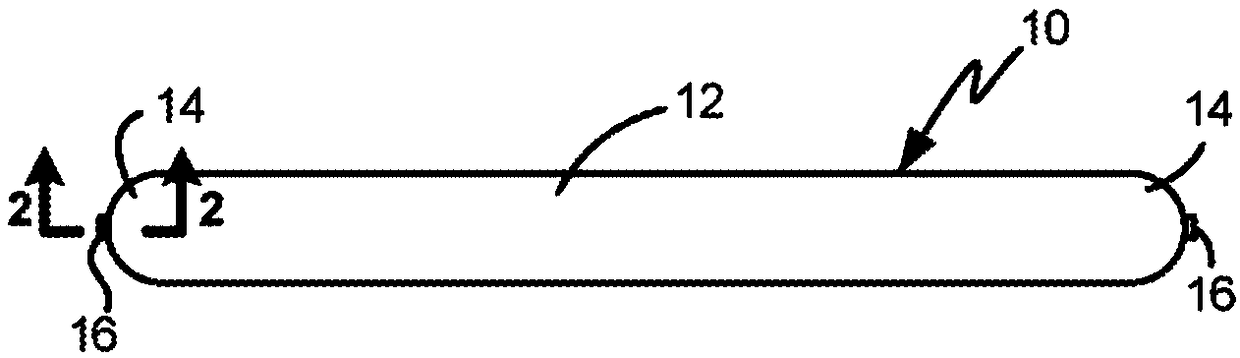

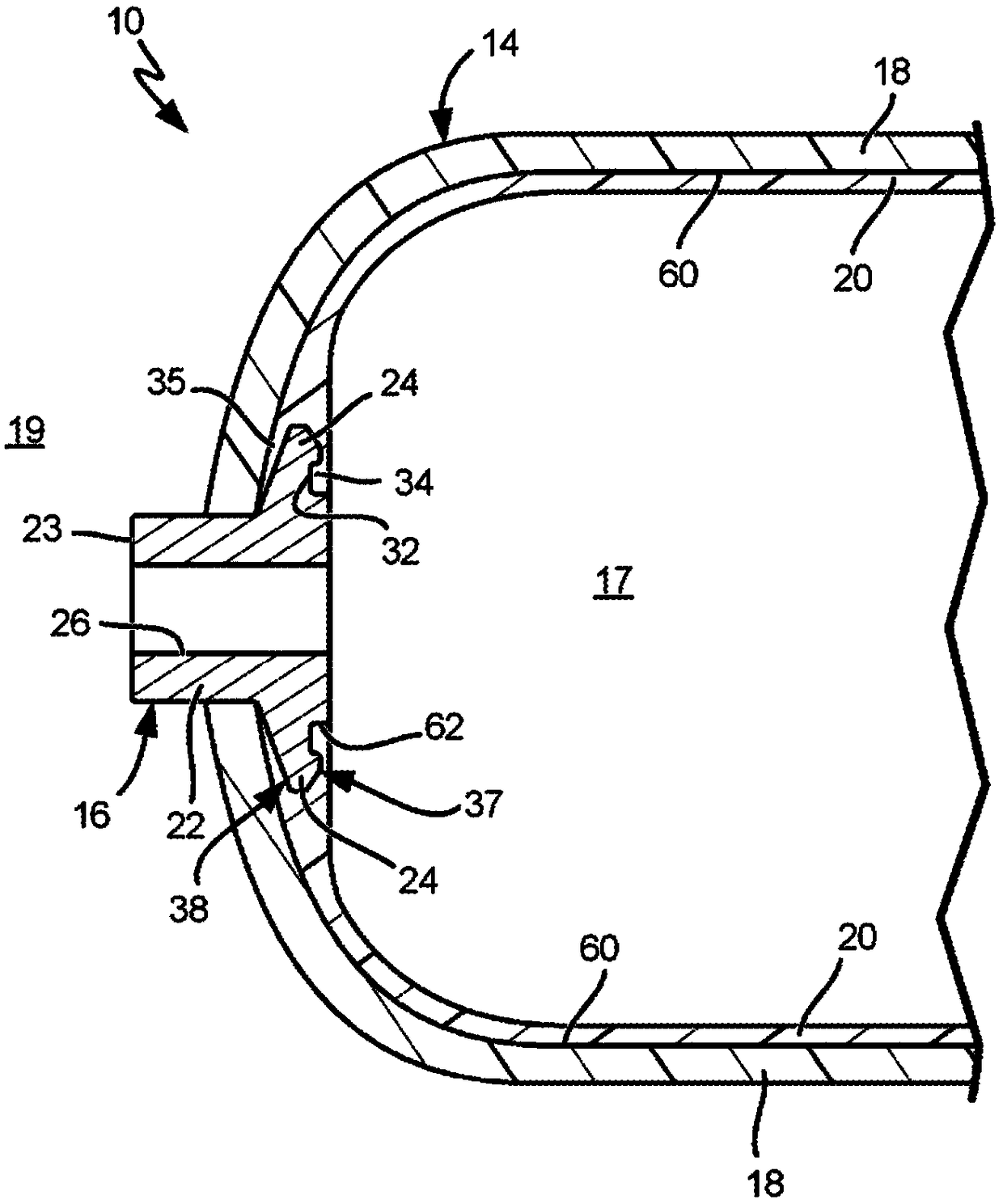

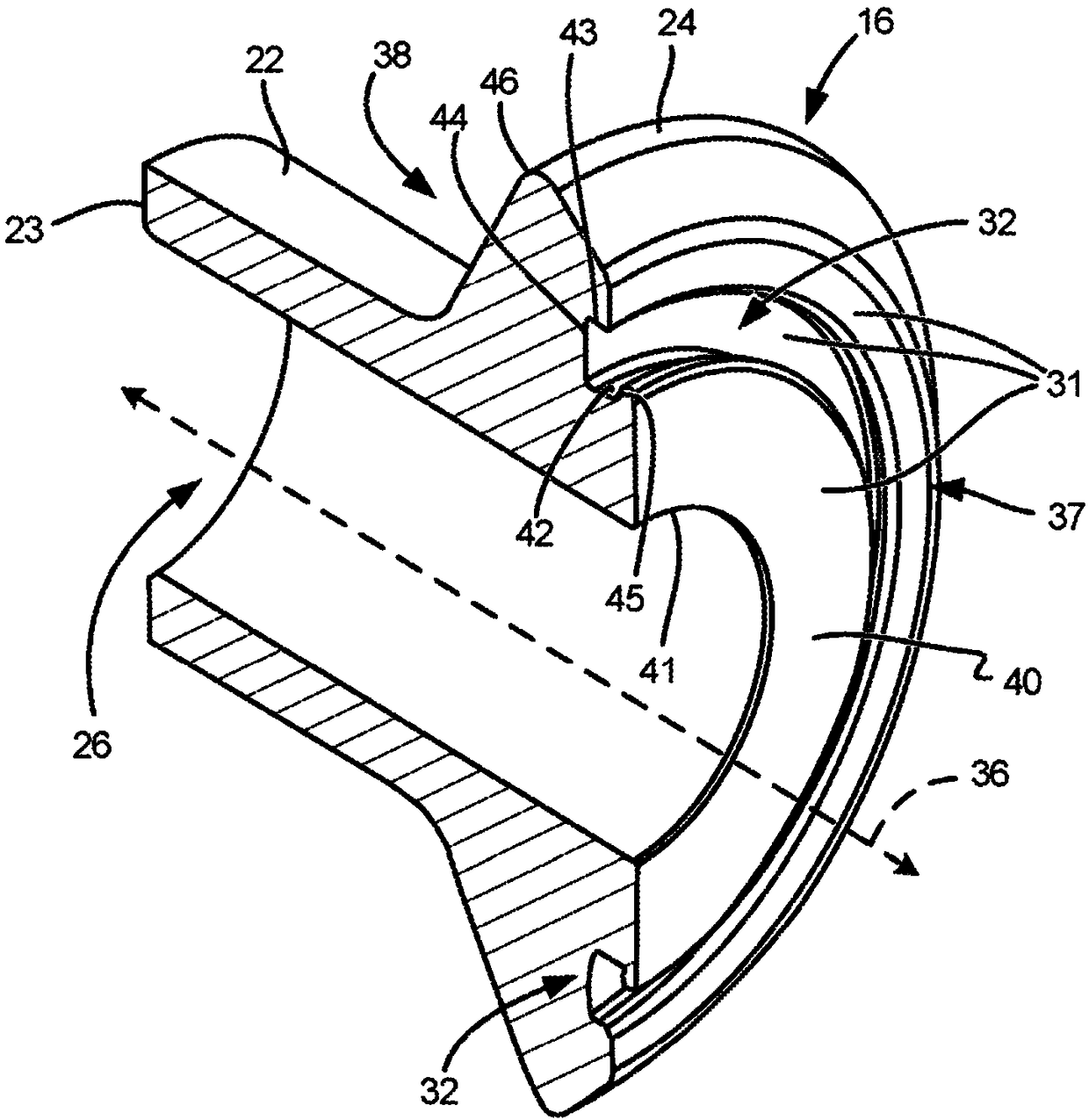

[0064] The present disclosure describes exemplary gas vent structures for use in pressure vessels and methods for producing such vent structures. The gas vent structure may be embedded in the boss of the pressure vessel such that the exemplary structure prevents separation of the liner from the boss and / or the liner from the shell under pressure. The gas vent structure allows gas trapped between the liner and the shell (or boss) to be vented, such as gas trapped between the liner and the interior surface of the shell that engages the liner. In one aspect, the present disclosure relates to combining at least one of the exemplary gas vent structures with the boss 16 of the pressure vessel 10 . In some embodiments, the vent structure is configured as a plug or insert positioned in a corresponding cavity of the boss. Each of the exemplary gas vent structures has features that allow gas accumulated between the liner 20 and the casing 18 (or boss 16 ) to vent to the internal enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com