The method of replacing the main drive seal in muddy water shield in complex formation

A technology of complex strata and muddy water shield, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem of lack of replacement of the main drive seal, and achieve the effect of reducing replacement risk and improving safety and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

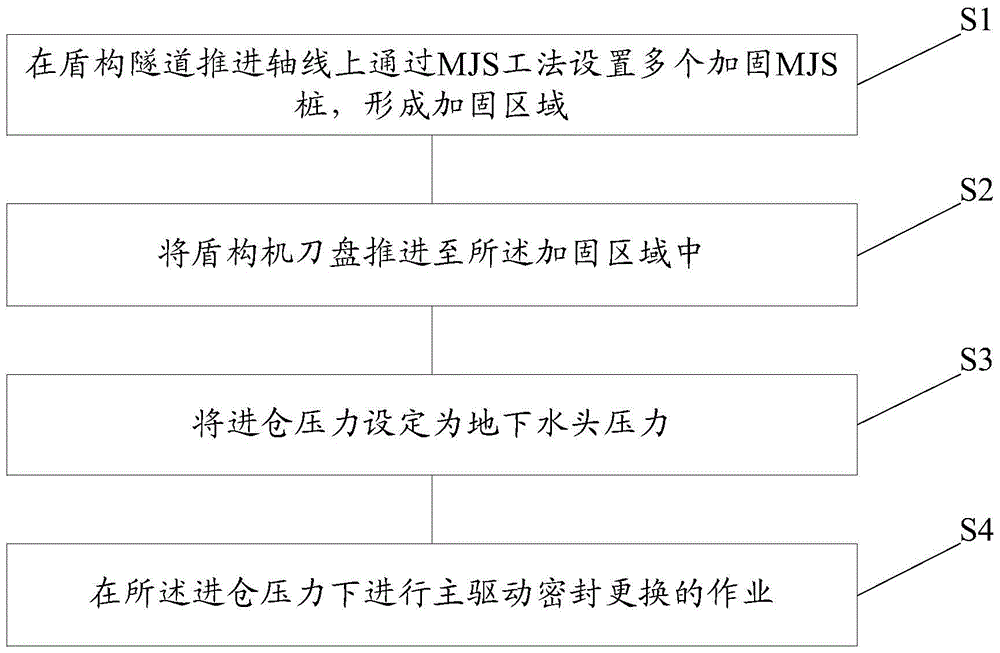

[0026] refer to figure 1 As shown, the present invention provides a method for replacing the main drive seal of a muddy water shield in complex formations, comprising the following steps:

[0027] S1, setting multiple reinforced MJS piles on the advancing axis of the shield tunnel through the MJS construction method to form a reinforced area;

[0028] S2, pushing the cutter head of the shield machine into the reinforcement area;

[0029] S3, setting the inlet pressure as the groundwater head pressure;

[0030] S4, performing the operation of replacing the seal of the main drive under the pressure of entering the chamber.

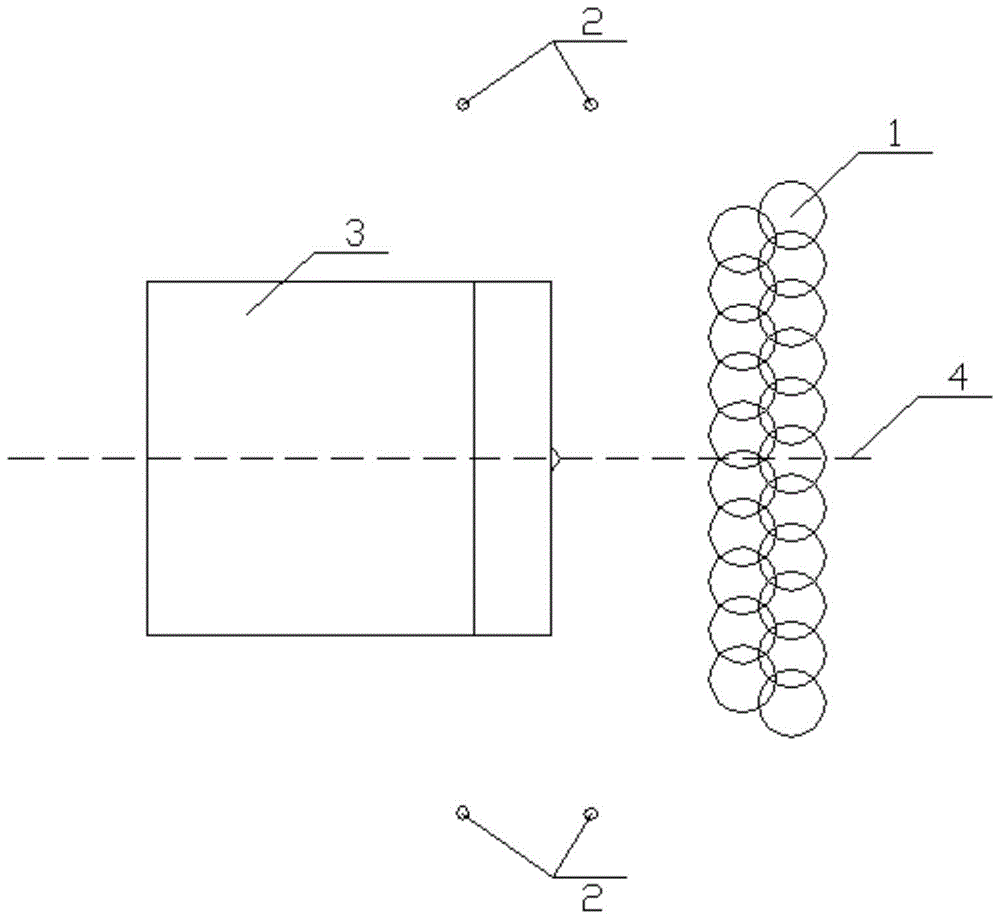

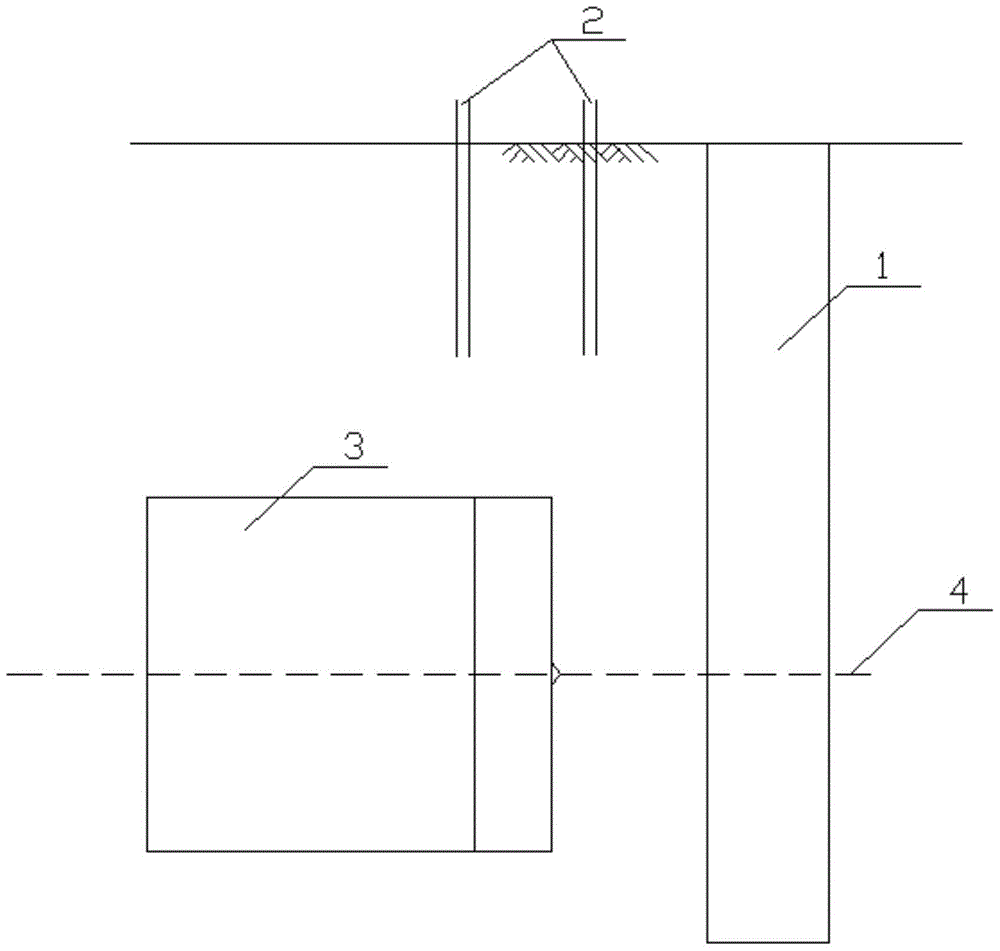

[0031] Specifically, in step S1 and step S2, please refer to figure 2 , image 3 , Figure 4 and Figure 5 , figure 2 A plan view of the reinforcement area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com