Efficiency monitoring of a compressor

A compressor and efficiency technology, which is applied in the field of compressor efficiency monitoring, can solve the problems of limited estimated accuracy and working parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

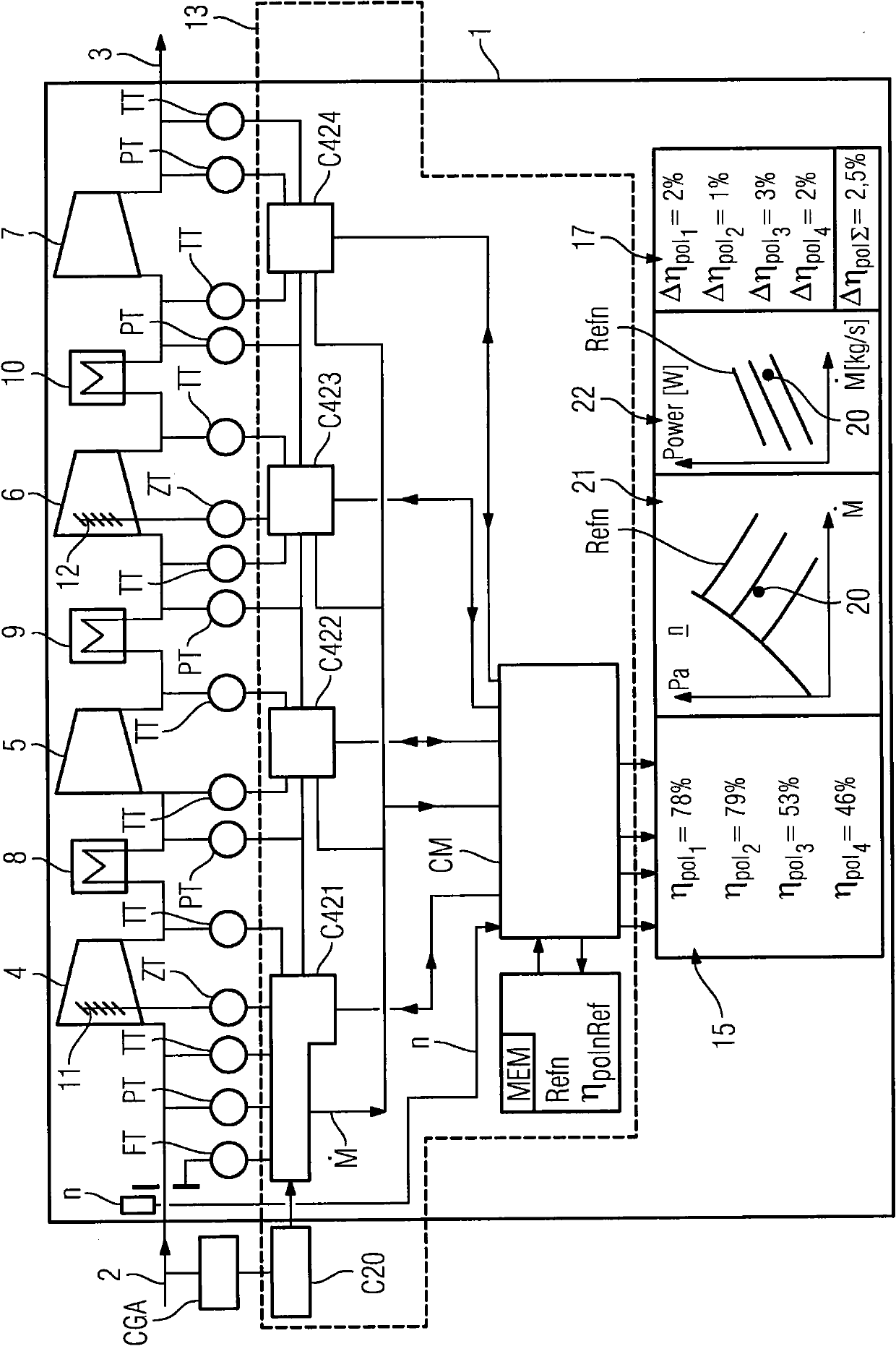

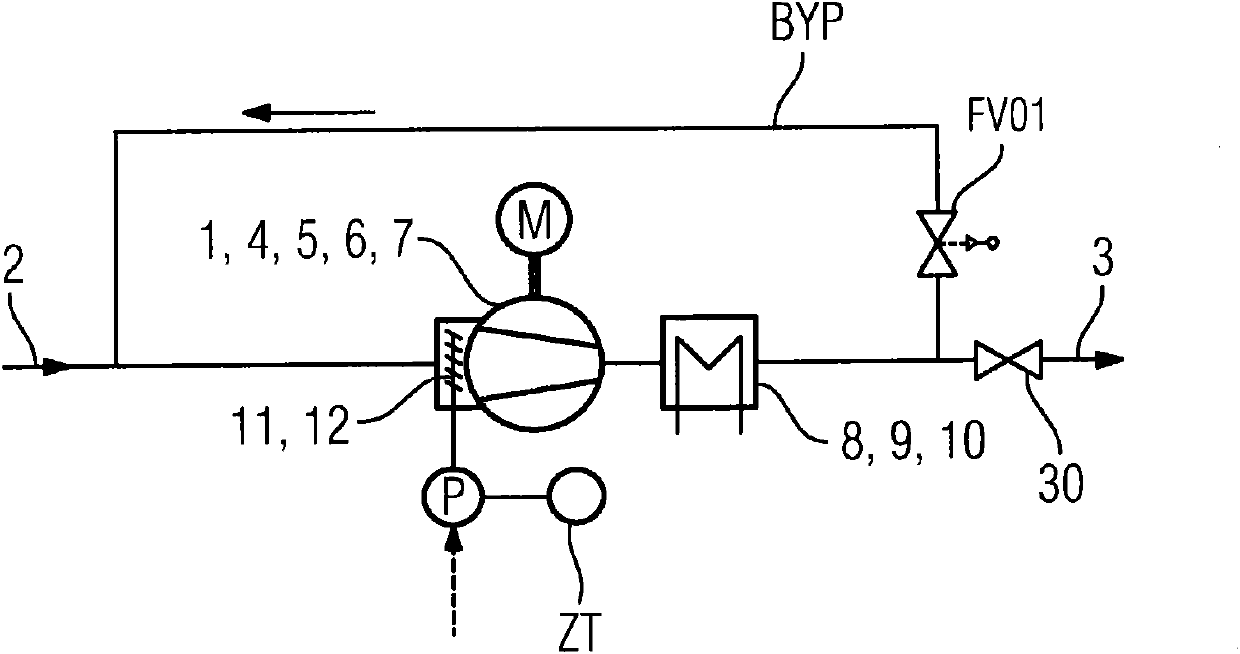

[0032] figure 1 A compressor 1 is shown schematically, on which the method according to the invention for monitoring the efficiency is to be applied. Mass flow in compressor 1 (measured as ) enters as incoming mass flow 2 and exits as outgoing mass flow 3 . The compressor 1 has four stages 4, 5, 6, 7 (from left to right respectively the first stage 4 to the fourth stage 7), through which the incoming mass flow 2 flows, wherein intercooling is provided in each case between the stages Devices 8, 9, 10 (Necessary corrections shall be made to the numbering method).

[0033] Before entering each stage 4 , 5 , 6 , 7 and after exiting each stage 4 , 5 , 6 , 7 the pressure is measured by means of the pressure measuring point PT and the temperature is measured by means of the temperature measuring point TT. Because apart from a small and understandable pressure loss in the intercooler 8 , 9 , 10 , the pressure before the intercooler 8 , 9 , 10 and the pressure after the intercooler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com