Device for measuring transverse stress of pipeline

A transverse stress and stress measurement technology, applied in measurement devices, force/torque/work measuring instruments, and measurement of properties using piezoelectric devices, etc. And effective detection and other problems, to achieve the effect of accurate measurement, high measurement efficiency, and reduce the interference of equipment to the original stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

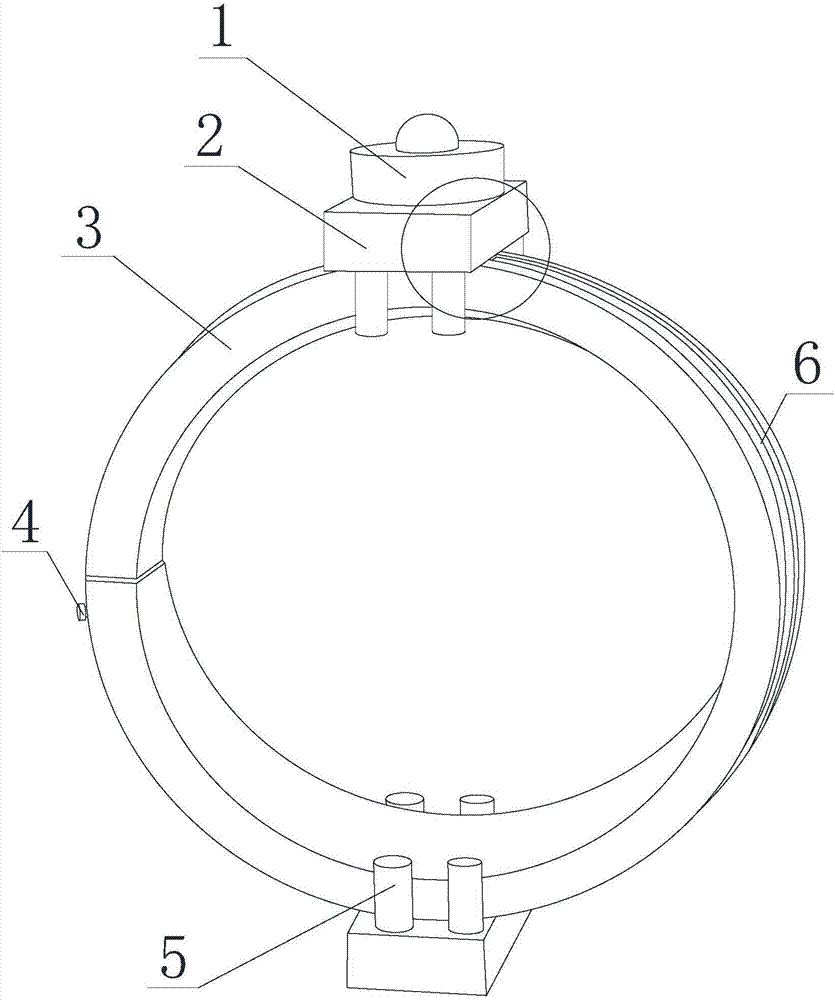

[0021] Such as figure 1 , figure 2 As shown, the device based on the measurement of the lateral stress of the pipeline includes a fixing strip 3 for fastening in the radial direction of the pipeline. The two ends of the fixing strip 3 have different sizes, and the larger end is open and has a cavity, and can Ensure that the smaller end can be inserted into the cavity of the larger end to form a ring structure, and change the insertion depth of the end of the fixing strip 3 according to the diameter of the pipeline at the measurement point, and then change the diameter of the ring structure, so that the fixing strip 3 It can form full contact with the outer wall of the pipeline, realize the firmness of the fixation, and ensure the accuracy of the measurement without moving during the measurement. Two sets of stress measurement devices 1 are installed on the fixing bar 3, which are symmetrical along the center of the pipeline during use. The stress measurement device 1 can mov...

Embodiment 2

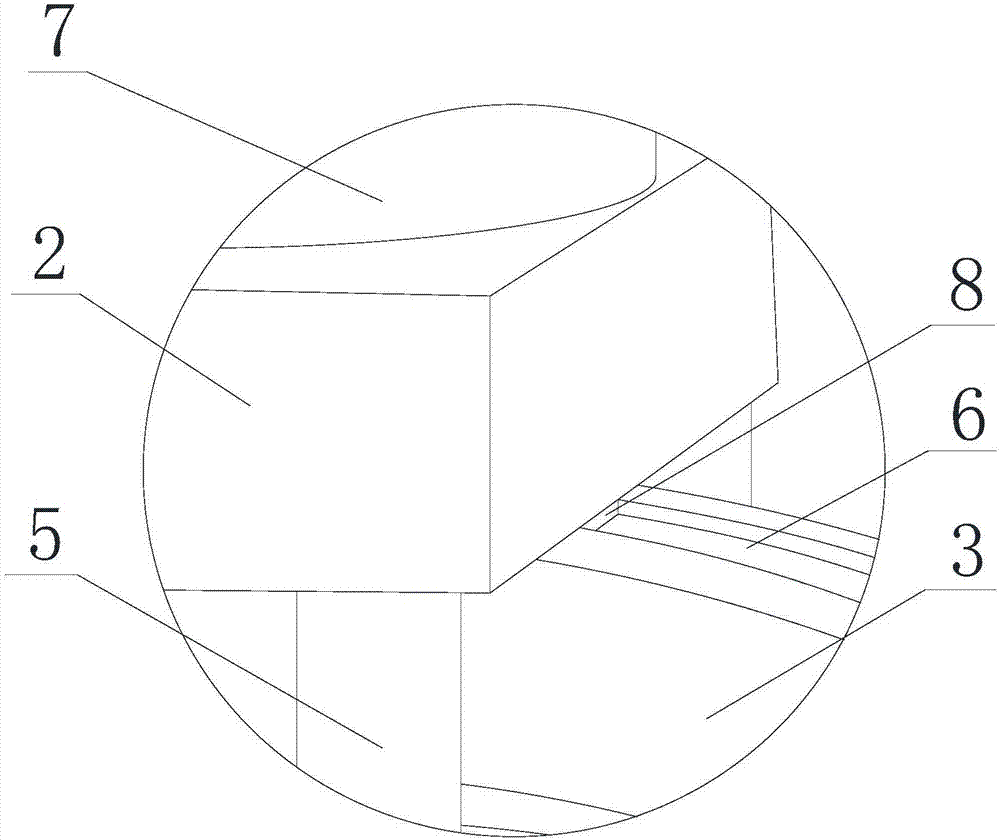

[0023] Such as figure 1 , figure 2 As shown, on the basis of Embodiment 1, the outer wall of the ring structure formed by the fixing bar 3 is concavely formed to form a mounting groove 6 , and the stress measuring device 1 is inserted into the mounting groove 6 and can move along the mounting groove 6 . The stress measurement device 1 includes a mounting plate 2, several measuring heads 5 are arranged below the mounting plate 2, the fixing strip 3 is arranged between the areas formed by the measuring heads 5, and the axes of the measuring heads 5 pass through the center of the ring structure, and the mounting plate 2 A guide block 8 is provided toward one end of the fixing bar 3. The guide block 8 is inserted into the installation groove 6 and can move along the installation groove 6. In order to ensure the firmness of the stress measurement device 1 and the convenience of movement, the guide block 8 and the mounting groove 6 should form a structure that matches each other. ...

Embodiment 3

[0027] Such as figure 1 , figure 2 As shown, on the basis of the above embodiment, the outer wall of the fixing bar 3 is equipped with locking pins 4, and when the fixing bar 3 forms a ring structure, the locking pins 4 are inserted into the outer walls of both ends of the fixing bar 3 at the same time. In order to prevent interference in the structure, the locking position of the locking pin 4 needs to be strictly designed. At the outer wall of the end with a larger size, the locking pin 4 should be inserted from close to the end and interact with the installation groove 6. No interference, no interference with the movement of the stress measuring device 1 on the fixing bar 3, so that the stress measuring device 1 can complete the measurement of all points of the ring structure on the pipeline, and the direction of the locking pin 4 inserted into the fixing bar 3 is towards the pipeline In this way, it is firm and not easy to fall off when fixed, so that after the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com