Morinda officinalis pure powder ultrafine decoction pieces and preparation method thereof

A kind of Morinda officinalis meat, ultra-micro technology, applied in the direction of pharmaceutical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of reduced content of active ingredients, low bioavailability, low dissolution rate, etc., to achieve odor and Improved taste, high bioavailability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

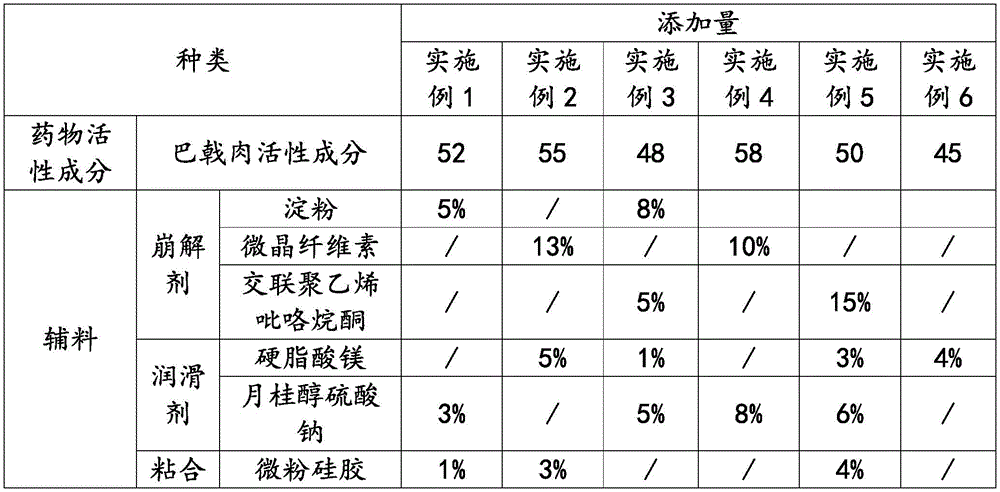

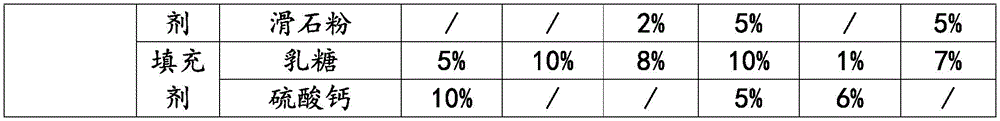

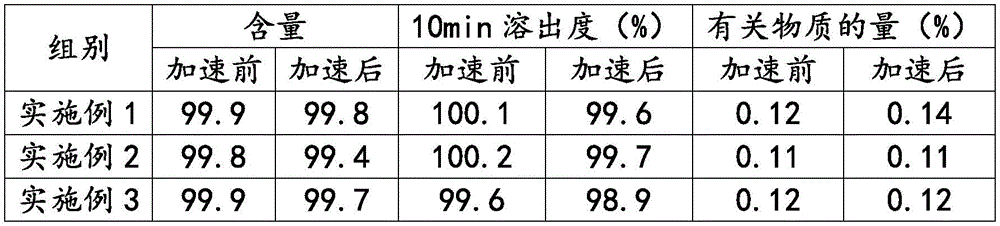

Examples

Embodiment 1-3

[0032] The preparation method of Morinda officinalis extract in embodiment 1-3 comprises the following steps:

[0033] The active ingredient of Morinda officinalis is extracted according to the following extraction method: dry the Morinda officinalis, then crush it to 40-80 mesh, place it in a supercritical extraction kettle, add entraining agent, and convert carbon dioxide into a supercritical fluid through a high-pressure pump , the first secondary extraction under the first pressure for 2-4 hours, extract the extracted solution under reduced pressure and analyze the first crude extract, disperse the first crude extract in hot water, and concentrate under reduced pressure to 1 / 8 of the original volume , then left to stand for crystallization, repeated 2-3 times, and then the first extract was obtained; the kettle was extracted under the second pressure for 3-4 hours, and the extract was decompressed and analyzed to obtain the second crude extract, which was then extracted Di...

Embodiment 1

[0036] Preparation Process:

[0037] The dried active ingredient of Morinda officinalis meat is pulverized to a particle size of less than 300 microns, sterilized by radiation, and then ultrafinely pulverized to 40 microns in a jet mill, and 90% of the particles with a particle size of less than 65 microns accumulate to obtain Morinda officinalis Meat pure powder superfine drink slices.

[0038]Among them, the temperature of vacuum drying is 100°C, and the pressure is 0.1mpa; the conditions of ultrafine pulverization are: pulverization temperature 20°C, pressure when entering the ultrafine pulverizer is 1.5Mpa, pulverization pressure 3Mpa, air velocity 220m / s, pulverization The time is 1.5h;

[0039] The prepared ultrafine decoction pieces and auxiliary materials meeting the pharmaceutical requirements are prepared into tablets, capsules, or other oral constant-release dosage forms.

Embodiment 2

[0041] Preparation Process:

[0042] Grinding the dried active ingredients of Morinda officinalis meat to a particle size of less than 300 microns, microwave sterilization, and then superfinely pulverizing to 50 microns in a jet mill, and accumulating 95% of the particles with a particle size of less than 65 microns to obtain Morinda officinalis Meat pure powder superfine drink slices.

[0043] Among them, the temperature of vacuum drying is 90°C, and the pressure is 0.2mpa; the conditions of ultrafine pulverization are: pulverization temperature 20°C, pressure when entering the ultrafine pulverizer is 1.5Mpa, pulverization pressure 5Mpa, air velocity 260m / s, pulverization The time is 1.5h;

[0044] The prepared ultrafine decoction pieces and auxiliary materials meeting the pharmaceutical requirements are prepared into tablets, capsules, or other oral constant-release dosage forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com