Single-feed-cylinder capillary rheometer

A capillary rheometer and capillary technology, applied in the field of polymer rheology testing, can solve the problems of high cost, complex structure, and low accuracy of data results, so as to improve accuracy, eliminate inlet pressure drop, and reduce the influence of human factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

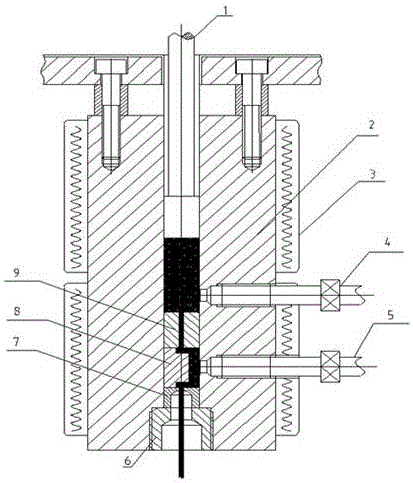

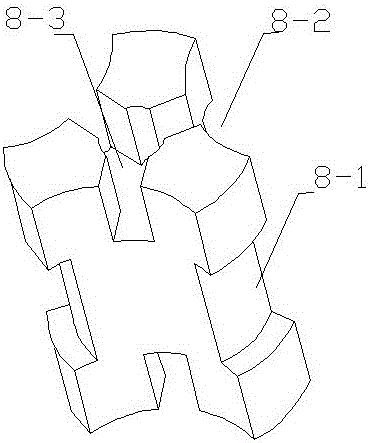

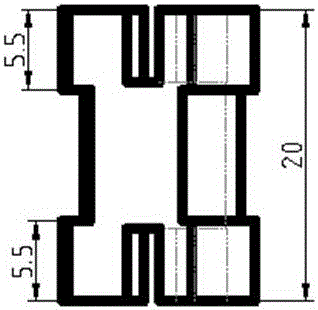

[0019] like Figure 1 to Figure 4 As shown in , a single-barrel capillary rheometer includes a barrel 2, the front end of the barrel 2 is provided with a plunger 1, the rear end is provided with a movable nut 6, and an electric heater 2 is arranged around it. Long capillary die 9, support member 8 and zero-length capillary die / short capillary die 7, the upper end of described plunger 1 is connected with servo motor, also comprises first pressure sensor 4 and second pressure sensor 5, described The first pressure sensor 4 is close to the upper end of the long capillary die, the second pressure sensor is close to the support member 8, the long capillary die 9 and the zero long capillary die / short capillary die 7 are in series, A supporting part 8 is connected between the two kinds of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com