[0003] 1. Since the

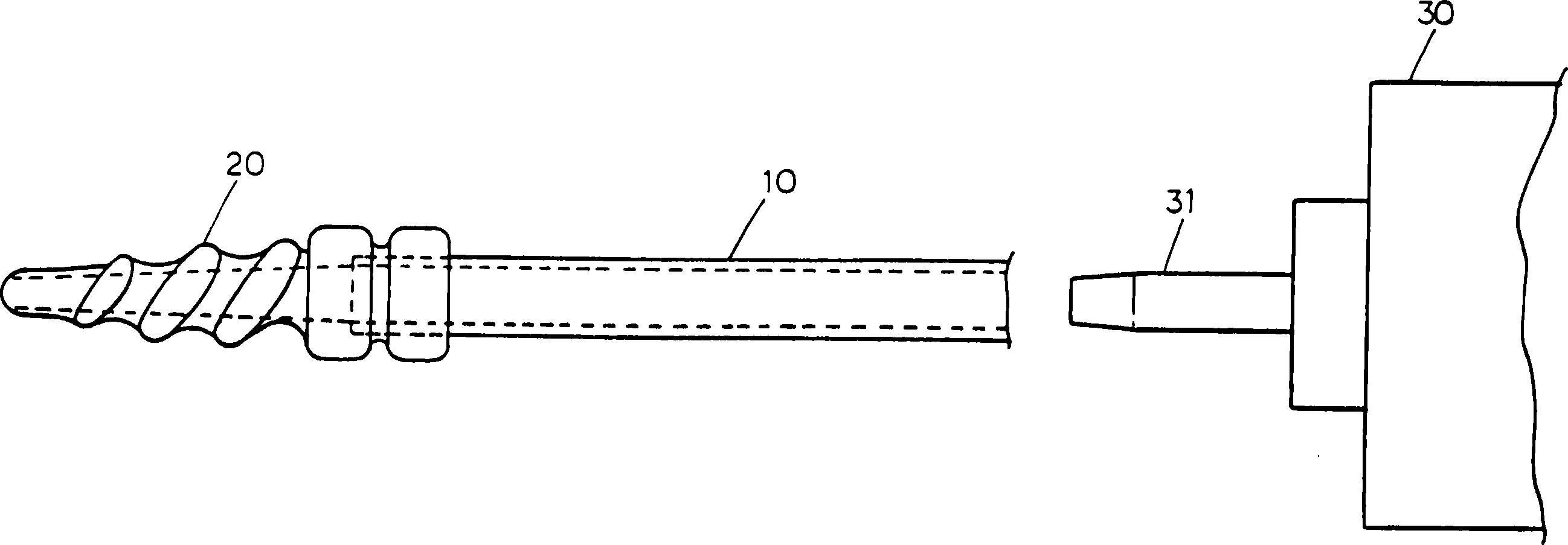

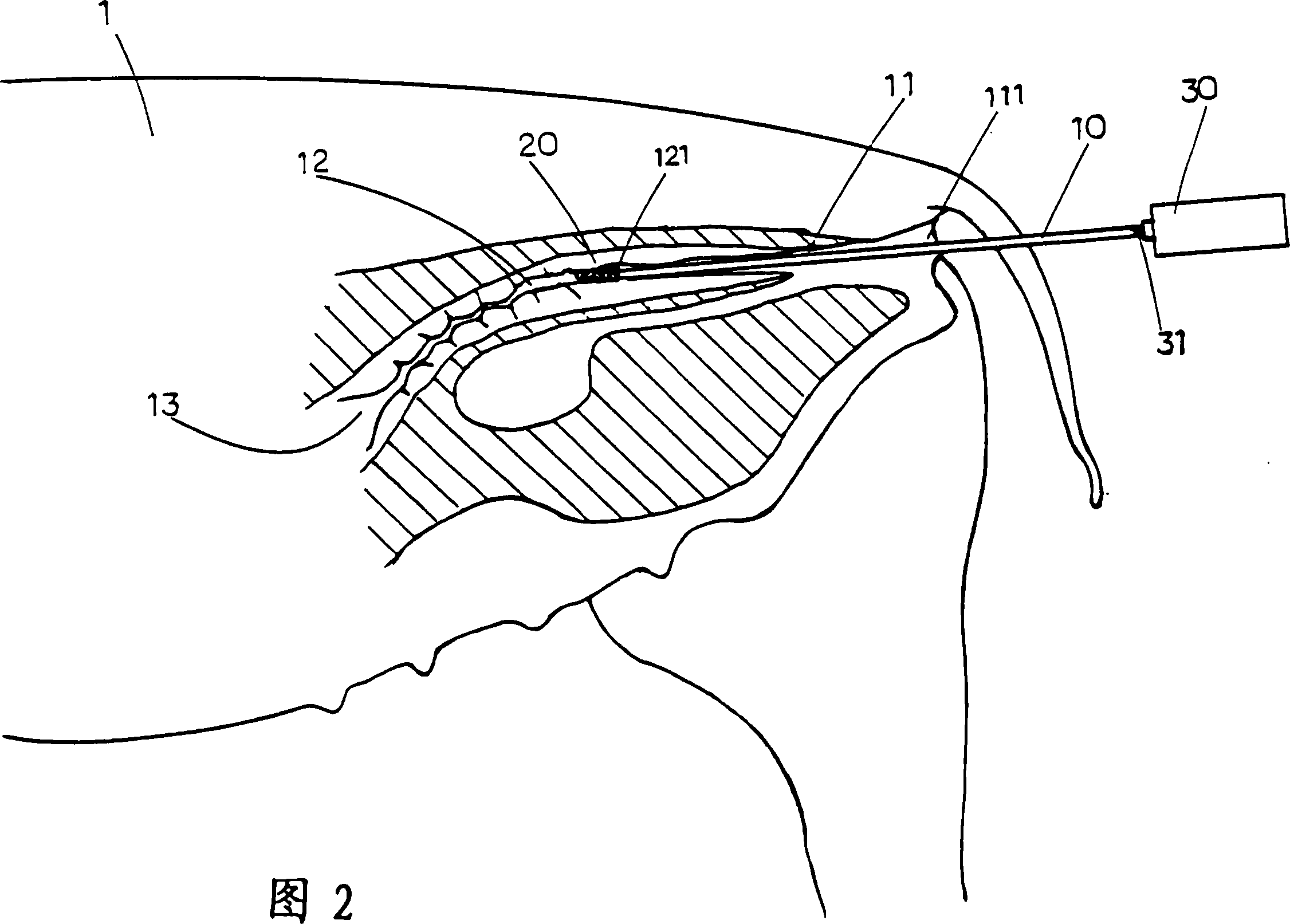

catheter 10 extends behind the

vagina 11 of the animal mother, the

nozzle 20 at the front end is pushed to the position of the first cervical ring 121 of the

cervix 12. However, the first cervical ring 121 and the uterus 13 must be There is still a distance, so although the uterus 13 can introduce semen from the

cervix 12 through contraction, the large amount of semen ejected from the

nozzle 20 must first accumulate at the position of the first cervical ring 121, and cannot flow in instantly In the case of the uterus 13, the most common occurrence is that the semen accumulated in the first cervical ring 121 will flow back and flow out from the

vulva 111. In this way, not only the uneconomical

disadvantage of

wasting semen, but also the inflow The semen of uterus 13 will be relatively reduced and the probability of successful insemination will be reduced

[0004] 2. As mentioned above, in response to the phenomenon that semen is easy to

reflux, usually the industry will dilute the semen used in a large amount (generally 5cc diluted to 50-120cc), and also set the inner

diameter of the

catheter 10 to be larger, so as to provide And accommodate more semen for insemination, but the large amount of diluted semen will obviously reduce the

pregnancy rate and the number of conceptions, and the use of more semen also has the uneconomical

disadvantage of direct waste

[0005] 3. As mentioned above, since the semen of the

catheter 10 is directly released from the

nozzle 20, and when the nozzle 20 extends from the outside of the animal mother 1 to the

cervix 12, it is unavoidable that the

dirt from the outside or the

vagina 11 will be accidentally discharged. In this way, it is very easy to cause the risk of bacterial infection and

inflammation in the animal's

vagina, cervix, and even the uterus during the process of artificial insemination, and at the same time, it also endangers the

biological safety of the uterus. sex

[0006] 4. As mentioned above, in order to improve the success rate and safety of artificial insemination, the operation of artificial insemination procedures for animals usually needs to be performed by professionals (such as veterinarians or professional technicians), and this is not the case for raising many

livestock. (Such as raising pigs) For the industry, this is obviously a heavy economic load and even has the

disadvantage that manpower cannot fully cooperate

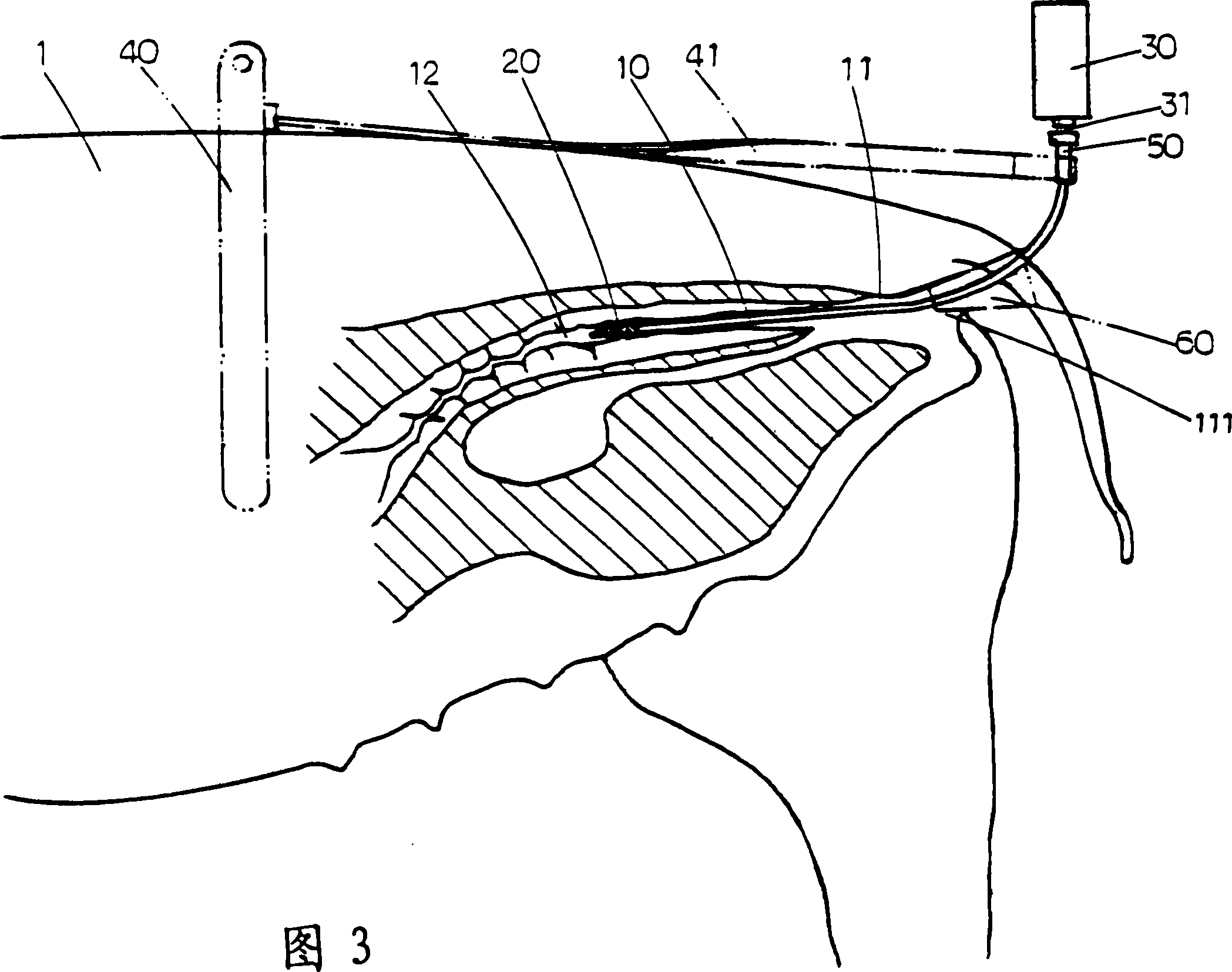

[0007] 5. As mentioned above, when the operator extends the catheter 10, that is, the nozzle 20, into the vagina 11 of the animal mother, that is, the cervix 12, he must hold the rear end of the catheter 10 with one hand, and hold and squeeze it with the other hand. The semen

bottle 30 obviously has the disadvantages of troublesome, inconvenient, troublesome and time-consuming inefficiency in operation

[0010] 1. Since the film 410 is inserted through the front opening 421 of the catheter 420 and fixed with the nozzle 440 by the guide edge 412, the nozzle 440 must be added first when the tip 411 is extruded from the inside to the outside by the force of semen

extrusion. The channel length B (shown in Figure 6) can enter the animal cervix, so, in order to make the film 410 can enter the animal uterus smoothly, the film 410 must have a longer length, however, the longer the length of the film, then Desire to push it out so that the extruding force exposed to the nozzle must be greater, and this obviously has a relatively troublesome situation; If the

bottle or

syringe, then in the implementation of more limited disadvantages

[0011] 2. When the guide edge 412 of the film 410 is buckled back and combined with the positioning ring 422 of the conduit 420, the film 410 is tightly bound to the

peripheral surface of the front end of the conduit 420 in a tension state of a certain degree of tightness, and the nozzle 440 is connected in a tight shape. The most common occurrence is that the film 410 is stuck and combined on the

peripheral surface of the film 410. When the film 410 in tension is pushed by the stuck nozzle 440, it is very easy to push and break at the

front edge of the conduit 420. hole situation (c as shown in Figure 6), and then, when the semen is squeezed into the catheter 420, the hole will cause air leakage, and the film 410 will not be able to be squeezed out smoothly and quickly poor artificial insemination efficiency or even failure

[0012] 3. As mentioned in the above item, since the perforation c of the film 410 is completely concealed by the nozzle 440, when the authenticity detection cannot be implemented, there are great variables in the quality of its production. It will also greatly reduce the effect of using

[0013] 4. Since the film 410 is inserted inwardly from the opening 421 of the catheter 420, the inner

diameter of the catheter 420 (i.e. the hollow space 424) is set to be relatively large for the smoothness of the

insertion operation. However, the larger

diameter However, it will directly increase the amount of semen used, which is the same as the conventional wisdom, and obviously cannot achieve the economic benefit of saving semen

[0014] 5. In order to reduce the injury of the animal mother during the artificial insemination procedure, usually the nozzles are all set as soft bodies. During the artificial insemination procedure, due to factors such as improper application of force during operation or animal disturbances, it is easy for those skilled in the art to cause injuries. The front end of the nozzle is squeezed, deformed or bent to block the passage, and this, for the film 410 built in the catheter 420, it is very easy to be unable to smoothly extrude for artificial insemination

[0015] This shows that the above-mentioned existing artificial insemination device for animals obviously still has inconvenience and defects in structure and use, and needs to be further improved urgently.

In order to solve the problems existing in artificial insemination devices for animals, relevant manufacturers have tried their best to find a solution, but no suitable design has been developed for a long time, and there is no suitable structure for general products to solve the above problems. This is obviously a problem that relevant industry players are eager to solve

Login to View More

Login to View More  Login to View More

Login to View More