Composite enzyme prepn for degrading agricultural waste effectively and its prepn process

A technology for compound enzyme preparation and agricultural waste is applied in the field of high-efficiency degradation of agricultural waste compound enzyme preparation and its preparation, which can solve the problems of low fermentation temperature, insufficient fermentation, incomplete killing of harmful organisms, etc. The effect of biogas production, energy saving, and promotion of digestion and absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] A compound enzyme preparation for efficient degradation of agricultural waste, which includes the following enzyme species and activities: xylanase, whose enzyme activity is ≥100,000 U / g; β-glucanase, whose activity is ≥80,000 U / g ; Cellulase, whose enzyme activity is ≥28,000 U / g; acid protease, whose enzyme activity is ≥56,000 U / g; lipase, whose enzyme activity is ≥15,000 U / g pectinase, whose enzyme activity is ≥0.6 million U / g; α-amylase, whose enzyme activity is ≥12,000 U / g.

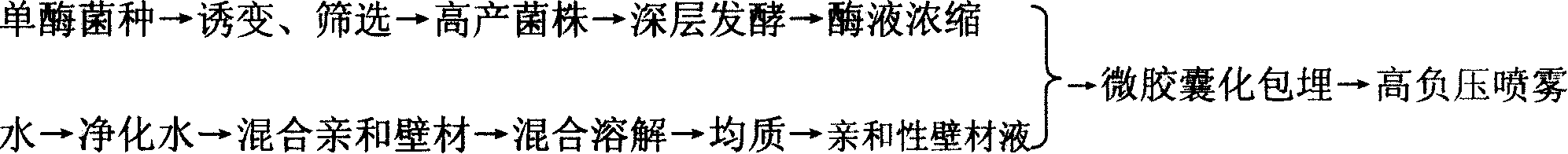

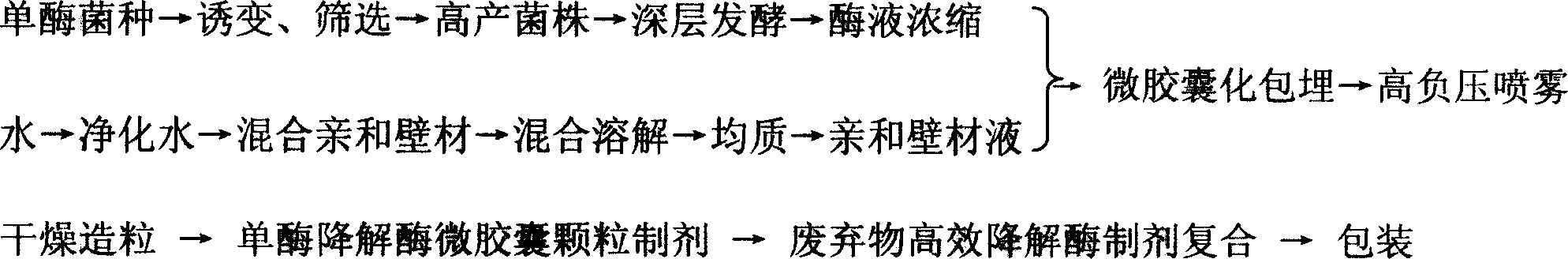

[0014] The preparation method of the high-efficiency degradation compound enzyme preparation of the above-mentioned agricultural waste, the method comprises the following process steps:

[0015] 1. Strain preparation:

[0016] Xylanase, glucanase, cellulase, acid protease, lipase, pectinase, α-amylase, etc. are all used in vitro directed evolution of enzyme molecules to produce high-yield enzyme live strains.

[0017] Using the theory of molecular breeding, using the directional screening tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com