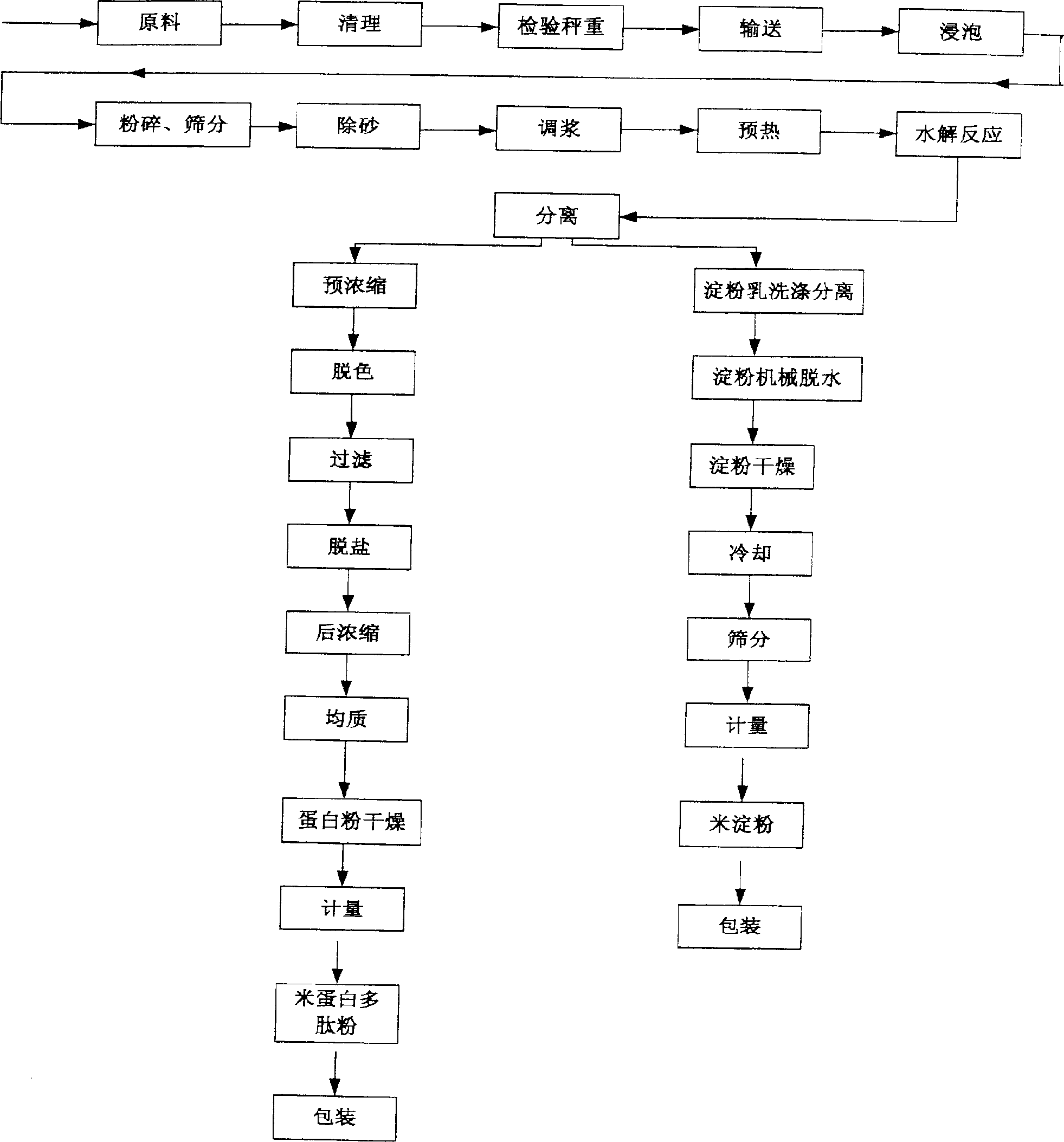

Production of rice-starch and rice-protein polypeptide powder by composite enzyme method

A compound enzyme method and rice starch technology, applied in the direction of fermentation, can solve the problems of low quality of rice starch and rice protein products, low yield of rice starch and rice protein, high production cost and high energy consumption, and achieve complete protein hydrolysis. , the effect of high value of by-products and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The raw material can be finished rice (or broken rice), weigh a certain amount of rice, pass through a 100-mesh sieve to get rice flour, put it into a jacketed beaker, add water with a mass ratio of 1:1 to rice flour for soaking (to make the material absorb water and swell, reduce Small crushing resistance), stirring at the same time, the stirring speed is 10 ~ 20r.p.m; the jacketed beaker is connected with a super constant temperature water bath. Add water, adjust the temperature of the feed liquid to 50-55°C, then add sodium hydroxide to adjust the pH to 10 for pulping, and then add 200,000 active compound enzymes according to 4‰ of the dry basis. The compound enzyme is alkaline protease [2709 alkaline Protease (2709 Alkaline Protease)], neutral protease [AS1398 Neutral Protease (AS1398 Neutral Protease)], acid protease [537 Acidic Protease (537 Acidic Protease)] and flavor protease [flavor protease 500MG (Flavourzyme 500MG)] by 6:2 : The ratio of 1:1 is used for hydr...

Embodiment 2

[0053] Weigh a certain amount of rice, pass through a 100-mesh sieve to get rice flour, put it into a jacketed beaker, add water with a mass ratio of 1:4 to the rice flour for soaking (to make the material absorb water and expand, and reduce the crushing resistance), while stirring, the stirring speed is 10~20r.p.m; the jacketed beaker is connected to a super constant temperature water bath. At this time, the temperature of the material liquid is controlled at about 60°C. After soaking for 6 hours, add water at a mass ratio of 1.5:4 to the rice flour to adjust the temperature of the material liquid to 50-55 ℃, then add sodium hydroxide to adjust the pH to 10 for pulping, and then add 200,000 active compound enzymes according to 8‰ of the dry basis. [AS1398 Neutral Protease (AS1398 Neutral Protease)], acidic protease [537 Acidic Protease (537 Acidic Protease)] and flavored protease [flavored protease (500MGFlavourzyme 500MG)] carry out the hydrolysis reaction according to the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com