Method for extracting maize germ oil and recovering protein by water enzyme method

A technology of corn germ oil and protein, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of low oil yield, high production cost, and failure to meet market requirements, and achieve easy refining, easy handling, The effect of increasing the processing power of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

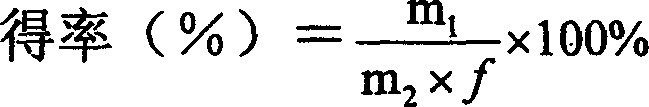

[0042]Weighing moisture content is 54.44% wet corn germ 6585.30g (dry corn germ is 3000g) and soaks in the citric acid solution of 0.01mol / L of 18L, carries out heat treatment in YX-400A double-deck vertical electric steam sterilizer, Control the temperature at 120°C, treat for 65 minutes, drain, and grind the drained material twice with a grinding wheel at a material-to-water ratio of 1:6 (dry basis) and add water. Add 2.5% (enzyme / dry matter) acid protease at natural pH (range about 3-3.5) at 40°C for 7 hours of enzymolysis; raise the temperature to 50°C, adjust the pH to 5.0, add 1.5% (enzyme / dry matter) Substance) cellulase, enzymolysis 12h. Direct centrifugation, free oil, emulsified layer, hydrolyzate and residue are obtained after centrifugation, and the yield of free oil can reach 87-91%.

[0043] Combine the hydrolyzate obtained by centrifugation with the soaking solution obtained after draining, and use a cut-off with a relative molecular mass of 150Da and an effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com