Technique for extracting grease from oil-tea camellia seed by enzyme method

A technology of enzymatic extraction and camellia oleifera seed, which is applied in the field of enzymatic extraction of oil from camellia oleifera seed, can solve problems such as unfavorable process operation, damage to cell structure, emulsification, etc., to reduce process links, increase oil yield, The effect of preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

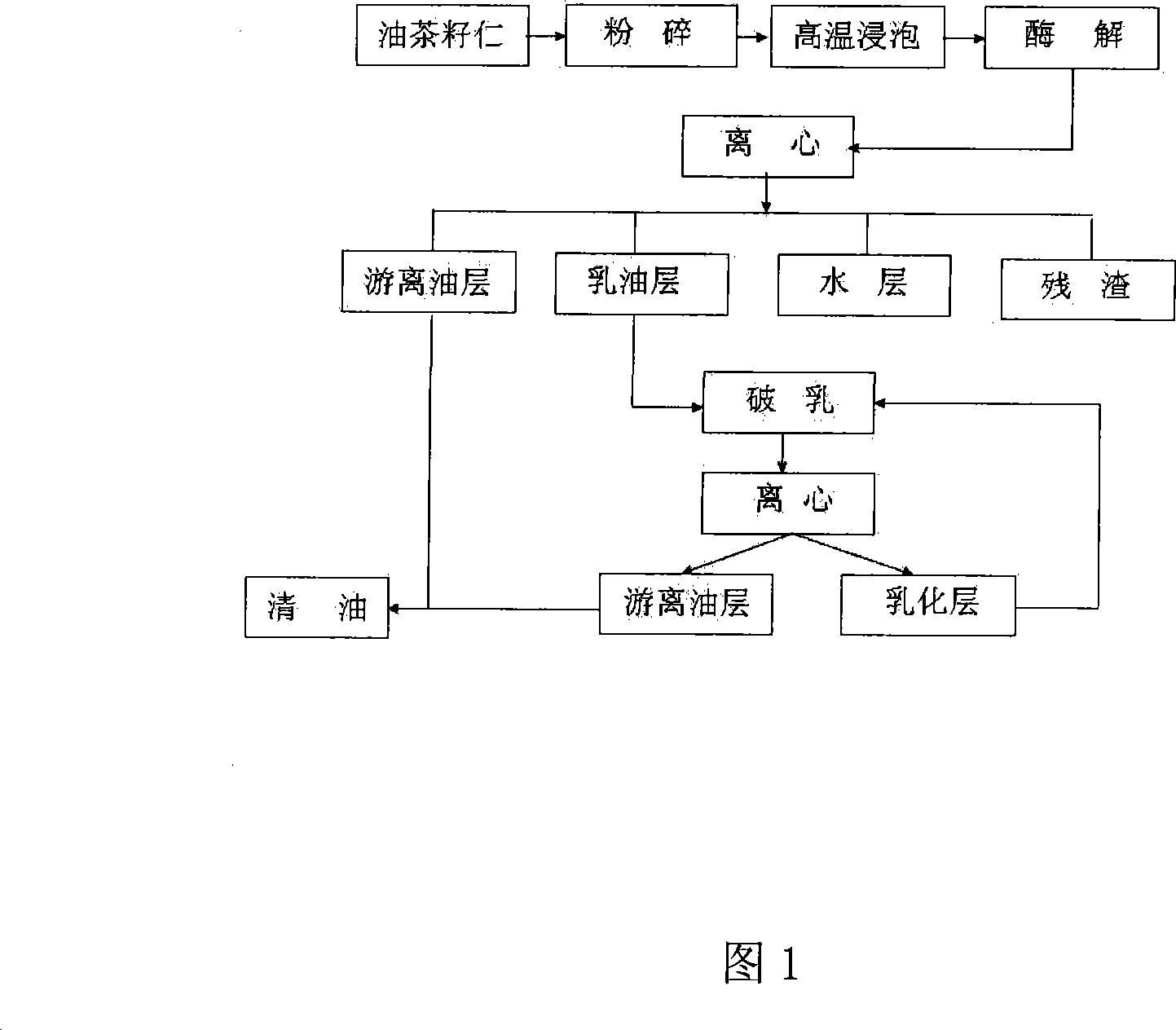

[0032] Take 1kg of air-dried tea oil seed kernels, crush them through a 100-mesh sieve, add 3L of ordinary pure water, soak at 90°C for 30 minutes, add 0.4g of acid protease, extract at 50°C for 4 hours, centrifuge at 4000 rpm for 30 minutes, from top to bottom Divided into free oil layer, emulsifiable oil layer, water layer and residue layer; take out the free oil layer, heat treat the emulsifiable oil layer at 90°C for 10 minutes, centrifuge at 5000 rpm for 30 minutes, take the upper oil layer and combine it with the clean oil layer to obtain a clean oil of about 250 grams.

example 2

[0034] Take 1.5kg of air-dried Camellia oleifera seeds, crush them through a 100-mesh sieve, add 5L of ordinary pure water, soak at 90°C for 30 minutes, add 0.6g of acid protease / vitaminase (3:1), and extract at a constant speed of 50°C for 4 hours , centrifuge at 4000 rpm for 30 minutes, and divide it into free oil layer, emulsifiable oil layer, water layer and residue layer from top to bottom; take out the net oil layer, freeze the emulsifiable oil layer at -20°C, then thaw at 90°C for 10 minutes, Centrifuge for 30 minutes, let it stand, take the upper oil layer and combine it with the net oil layer to obtain about 370 grams of net oil.

example 3

[0036] Take 1.5kg of air-dried Camellia oleifera seeds, crush them through a 100-mesh sieve, add 5L of ordinary pure water, soak at 90°C for 30 minutes, add 0.6g of acid protease / vitaminase (1:1), and extract at a constant speed of 50°C for 4 hours , centrifuge at 4000 rpm for 30 minutes, and divide it into free oil layer, emulsifiable oil layer, water layer and residue layer from top to bottom; take out the clean oil layer, treat the emulsifiable oil layer at 90°C for 10 minutes, centrifuge at 5000 rpm for 30 minutes, and let it stand. Take the upper oil layer and combine it with the net oil layer to obtain about 370 grams of net oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com