Polymer-containing sludge depolymerization agent and preparation method thereof

A depolymerization agent and sludge technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of increased amount of crude oil terminal sludge, no patent publications, and insufficient processing capacity, etc., to reduce emulsification, Good dehydration and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

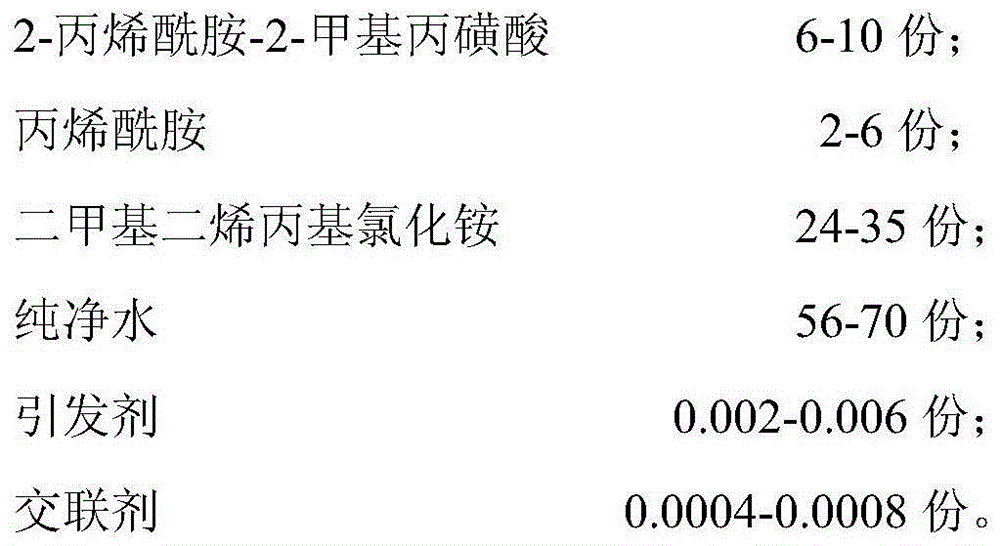

[0031] A kind of polymer-containing sludge depolymerization agent, its composition and parts by weight are:

[0032]

[0033] The preparation method of above-mentioned polymer-containing sludge depolymerization agent, the steps are as follows:

[0034] (1) Add 550kg of water to a 1.5-square reaction stirred tank.

[0035] (2) Slowly add 80kg of AMPS (powder) and 40kg of AM (powder) into the reaction stirring tank until they are completely dissolved.

[0036] (3) Add 280kg of DMDAAC into the reactor, slowly heat up to 40°C, and feed nitrogen (99.9%) into the reactor at a rate of 1m 3 / Hour.

[0037] (4) Add the initiator ammonium persulfate solution (40kg pure water+40g ammonium persulfate) dropwise, and drop it in 10 minutes.

[0038] (5) Add the cross-linking agent methylenebisacrylamide solution (10 kg of pure water + 6 g of methylenebisacrylamide) dropwise, and finish dropping in 30 minutes.

[0039] (6) Raise the temperature to 50°C to 55°C and stir for 4 hours to r...

Embodiment 2

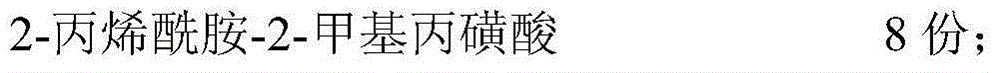

[0057] A kind of polymer-containing sludge depolymerization agent, its composition and parts by weight are:

[0058]

[0059] The preparation method of above-mentioned polymer-containing sludge depolymerization agent, the steps are as follows:

[0060] (1) Add 662.5kg of water to a 1.5-square reaction stirred tank.

[0061] (2) Slowly add 60kg of AMPS (powder) and 30kg of AM (powder) into the reaction stirring tank until they are completely dissolved.

[0062](3) Add 280kg of DMDAAC into the reactor, slowly heat up to 40°C, and feed nitrogen (99.9%) into the reactor at a rate of 1m 3 / Hour.

[0063] (4) Add the initiator ammonium persulfate solution (30kg pure water+30g ammonium persulfate) dropwise, and finish dropping in 10 minutes.

[0064] (5) Add the cross-linking agent methylenebisacrylamide solution (7.5kg of pure water + 4.5g of methylenebisacrylamide) dropwise, and finish dropping in 30 minutes.

[0065] (6) Raise the temperature to 50°C to 55°C and stir for 4 ...

Embodiment 3

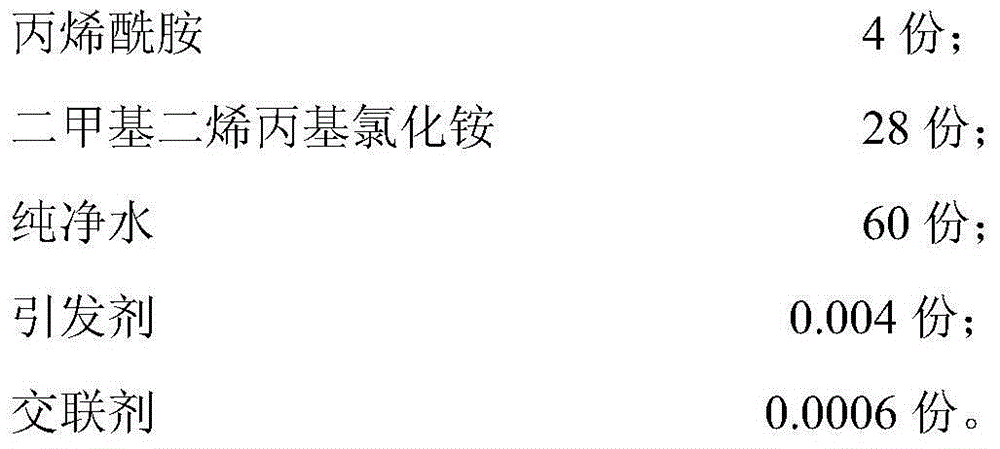

[0083] A kind of polymer-containing sludge depolymerization agent, its composition and parts by weight are:

[0084]

[0085] The preparation method of above-mentioned polymer-containing sludge depolymerization agent, the steps are as follows:

[0086] (1) Add 487.5kg of water to a 1.5-square reaction stirred tank.

[0087] (2) Slowly add 100kg of AMPS (powder) and 50kg of AM (powder) into the reaction stirring tank until they are completely dissolved.

[0088] (3) Add 350kg of DMDAAC into the reactor, slowly heat up to 40°C, and feed nitrogen (99.9%) into the reactor at a rate of 1m 3 / Hour.

[0089] (4) Add the initiator ammonium persulfate solution (50kg pure water+50g ammonium persulfate) dropwise, and finish dropping in 10 minutes.

[0090] (5) Add the cross-linking agent methylenebisacrylamide solution (12.5kg of purified water + 7.5g of methylenebisacrylamide) dropwise, and finish dropping in 30 minutes.

[0091] (6) Raise the temperature to 50°C to 55°C and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com