Emulsion type rubber pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, emulsion type technology, used in adhesives, adhesive types, graft polymer adhesives, etc. The application range of pressure-sensitive adhesives, etc., to achieve the effect of improving water resistance, high peel strength, and overcoming fogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

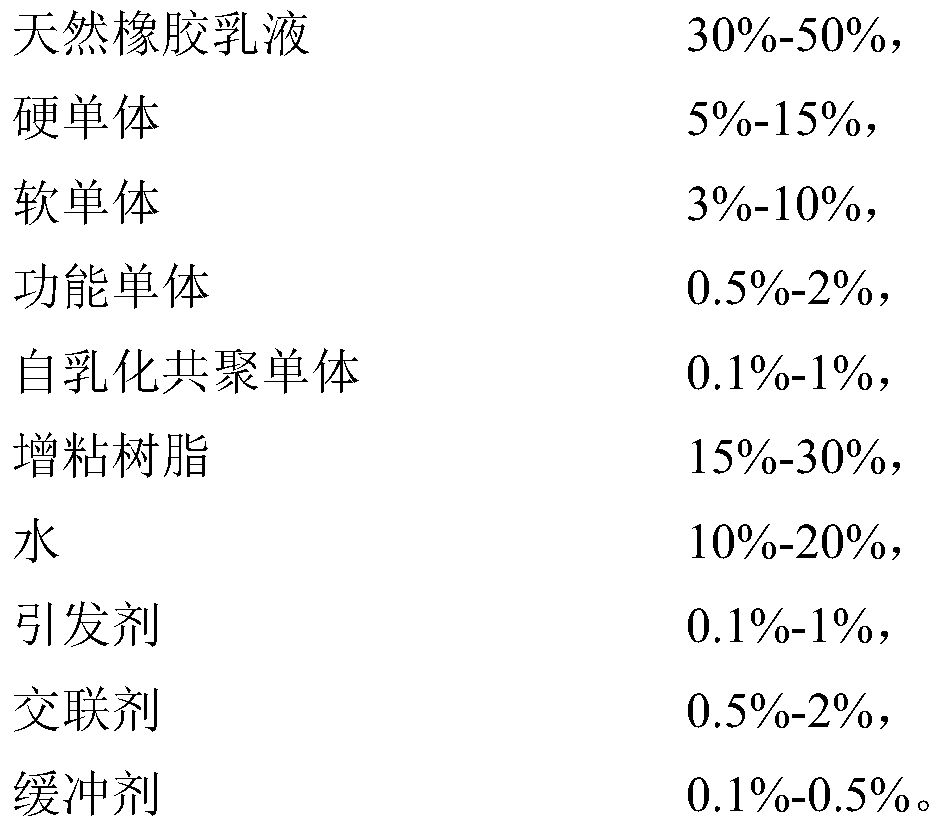

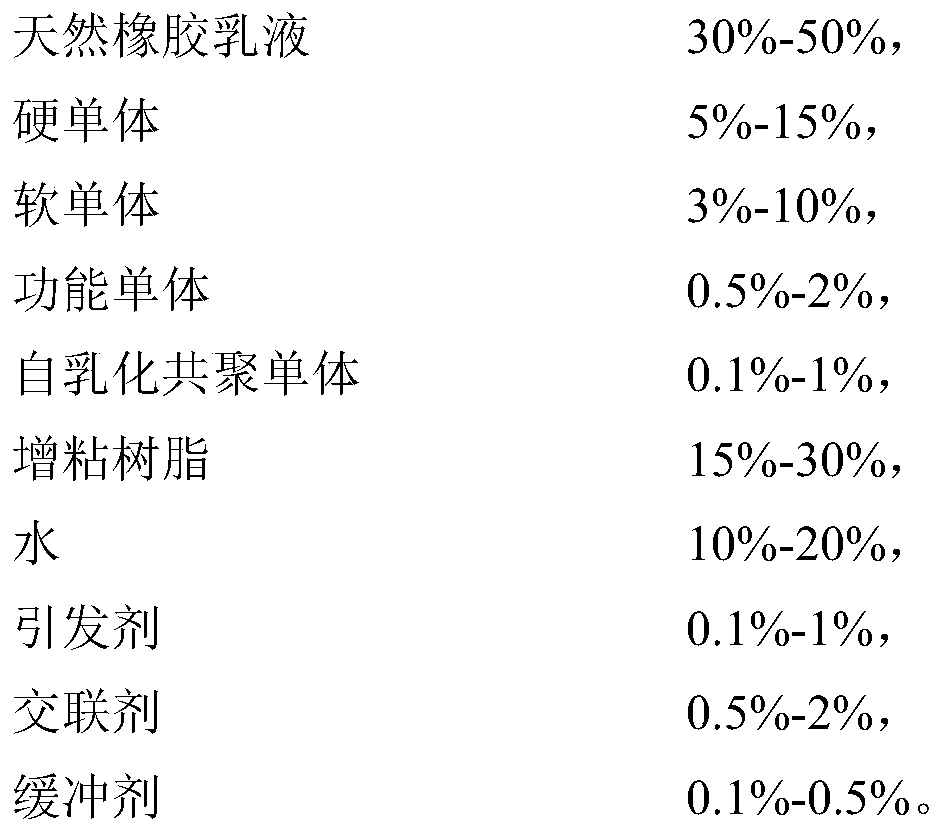

Method used

Image

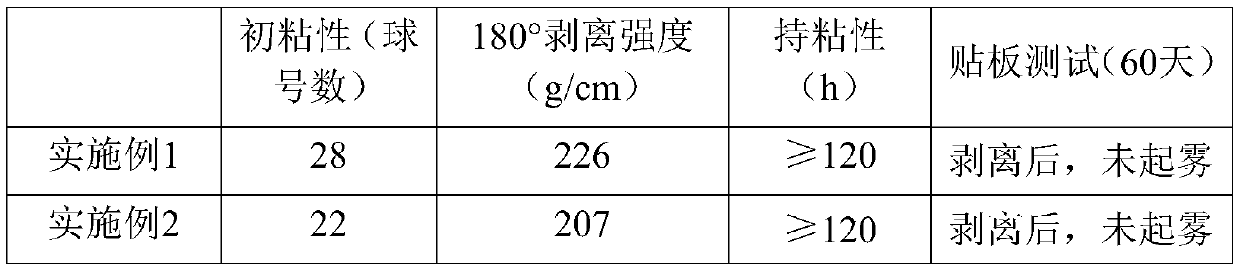

Examples

Embodiment 1

[0028] An emulsion type rubber pressure-sensitive adhesive, prepared by the following method:

[0029] (1) Preparation of pre-emulsion: 80 kg of methyl methacrylate, 60 kg of butyl acrylate, 10 kg of acrylic acid, 3 kg of sodium styrene sulfonate, and 150 kg of deionized water are placed in a pre-emulsification kettle, fully stirred, Prepare a pre-emulsion;

[0030] (2) Polymerization reaction: Add 430 kg of natural rubber emulsion, 3 kg of sodium bicarbonate, and 4 kg of ammonium persulfate into the reaction kettle, mix well, start to add the pre-emulsion liquid dropwise, stir while adding dropwise, and heat up to 65°C Carry out the polymerization reaction, complete the dropwise addition in 6 hours, keep the temperature for 3 hours, cool down to about 40°C, and filter to obtain the modified rubber emulsion;

[0031] (3) Preparation of pressure-sensitive adhesive: put the modified rubber emulsion, 250 kg of terpene resin and 10 kg of amino resin in a stirring tank, and stir e...

Embodiment 2

[0033] An emulsion type rubber pressure-sensitive adhesive, prepared by the following method:

[0034] (1) Preparation of pre-emulsion: 100 kg of methyl acrylate, 50 kg of acrylonitrile, 100 kg of ethyl acrylate, 20 kg of methacrylic acid, 5 kg of propyl sulfonate sodium methacrylate, 5 kg of ethyl methacrylate Sodium sulfonate and 200 kilograms of deionized water are placed in a pre-emulsification kettle and fully stirred to obtain a pre-emulsion;

[0035] (2) Polymerization reaction: Add 300 kg of natural rubber emulsion, 5 kg of sodium hydrogen phosphate, and 8 kg of potassium persulfate into the reaction kettle, mix well, start adding the pre-emulsion liquid dropwise, stir while adding dropwise, and raise the temperature to 70°C Carry out the polymerization reaction, complete the dropwise addition in 5 hours, keep the temperature for 3 hours, cool down to about 35°C, and filter to obtain the modified rubber emulsion;

[0036] (3) Preparation of pressure-sensitive adhesive...

Embodiment 3

[0038] An emulsion type rubber pressure-sensitive adhesive, prepared by the following method:

[0039] (1) Preparation of pre-emulsion: 50 kg of acrylamide, 30 kg of butyl methacrylate, 5 kg of hydroxyethyl acrylate, 2 kg of sodium methacrylate, and 175 kg of deionized water were placed in a pre-emulsification kettle. Stir fully to obtain a pre-emulsion;

[0040] (2) Polymerization reaction: Add 500 kg of natural rubber emulsion, 1 kg of ammonium bicarbonate, and 2 kg of ammonium persulfate into the reaction kettle, mix well, start to add the pre-emulsion liquid dropwise, stir while adding, and raise the temperature to 80°C Carry out the polymerization reaction, complete the dropwise addition in 4 hours, keep the temperature for 3 hours, cool down to about 30°C, and filter to obtain the modified rubber emulsion;

[0041] (3) Preparation of pressure-sensitive adhesive: Put the modified rubber emulsion, 230 kg of petroleum resin and 5 kg of hexamethylene diisocyanate in a stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com