Method for improving quality of tobacco leaves by adding enzyme preparation, glucose and citric acid

An enzyme preparation, citric acid technology, applied in tobacco, tobacco processing, application and other directions, can solve the problems of changing the aroma style of tobacco leaves, high irritation, poor aftertaste, etc., to reduce the irritation and miscellaneous gas of smoke, and reduce the protein content. , the effect of increasing usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

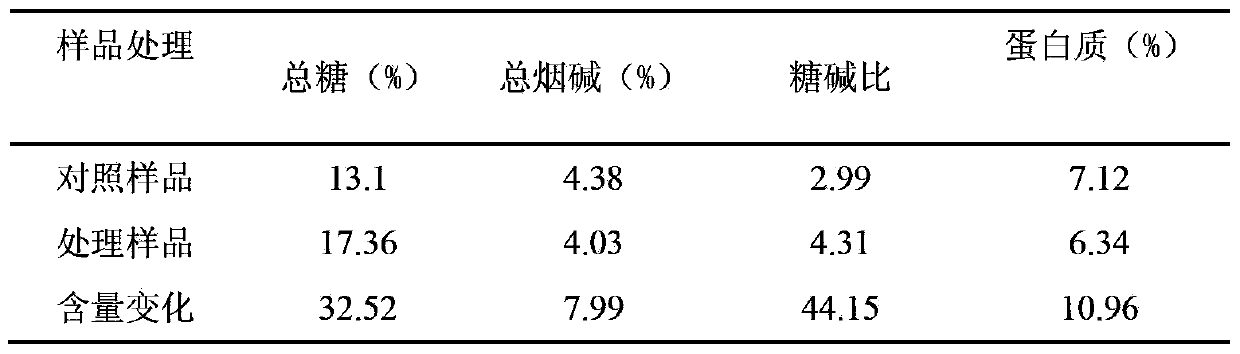

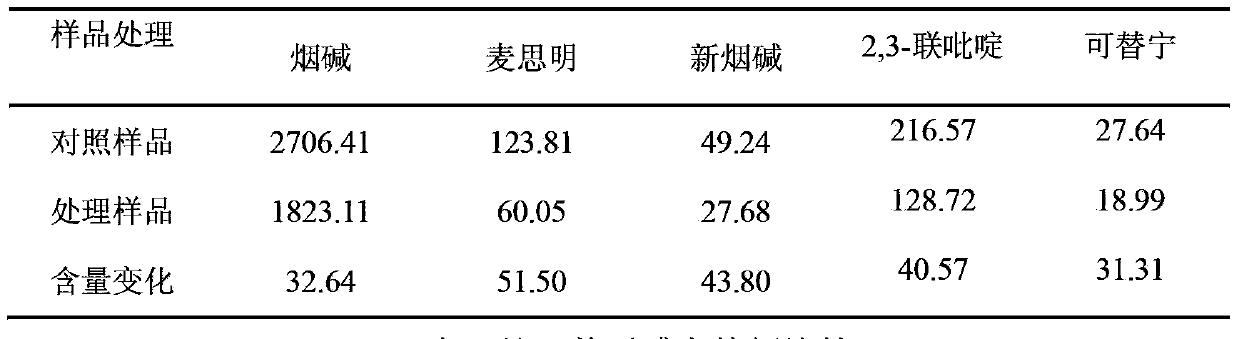

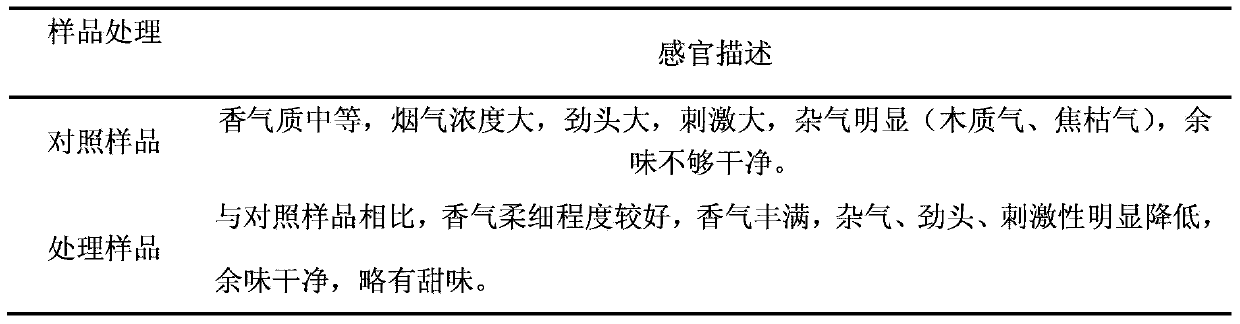

Embodiment 1

[0023] Select Shangjuer (B2F) tobacco leaf raw material in Shaoyang, Hunan Province, spread the tobacco sheets, remove tobacco stems, sundries, etc.; spray deionized water to moisturize the leaves, so that the moisture content (w / w) is 18% to 20%, and carry out once Adding materials, spraying xylanase solution (dissolved in deionized water, and adjusting pH = 8.0 with potassium acetate) according to the amount of 0.05% of the weight of the treated tobacco leaves, after the spraying, at a temperature of 60°C and a humidity of 60%. After 4 hours of leaf storage; perform secondary feeding, that is, spray acid protease (dissolved in deionized water, and adjust pH=3.5 with citric acid) at an amount of 0.1% of the weight of the treated tobacco leaves. Store the leaves for 6 hours under the condition of 60%; then add compound material (composed of 2.0% glucose and 0.5% citric acid according to the weight of the treated tobacco leaves, dissolved in deionized water.), at a temperature o...

Embodiment 2

[0034]Select Shangjuer (B2F) tobacco leaf raw material in Shaoyang, Hunan Province, spread the tobacco sheets, remove tobacco stems, sundries, etc.; spray deionized water to moisturize the leaves, so that the moisture content (w / w) is 18% to 20%, and carry out once Feeding, spraying xylanase solution (dissolved in deionized water, and adjusting pH = 8.0 with potassium citrate) at an amount of 0.1% of the weight of the treated tobacco leaves, after spraying, at a temperature of 55°C and a humidity of 50% After storing leaves for 10 hours, carry out secondary feeding, that is, spray acid protease in an amount of 0.4% of the weight of treated tobacco leaves (dissolved in deionized water, and adjust pH=3.5 with acetic acid at the same time). Store the leaves for 3 hours under the condition of 50%; then add compound material (consisting of 4.0% glucose and 1.0% citric acid according to the weight of the treated tobacco leaves, dissolved in deionized water), store at a temperature of...

Embodiment 3

[0045] Select Shangjuer (B2F) tobacco leaf raw material in Shaoyang, Hunan Province, spread the tobacco sheets, remove tobacco stems, sundries, etc.; spray deionized water to moisturize the leaves, so that the moisture content (w / w) is 18% to 20%, and carry out once Adding materials, spraying xylanase solution (dissolved in deionized water, and adjusting pH = 8.0 with potassium citrate) according to the amount of 0.08% of the weight of the treated tobacco leaves, after the spraying, at a temperature of 50 ° C, humidity 55% After storing leaves for 8 hours, carry out secondary feeding, that is, spray acid protease in an amount of 0.3% of the weight of treated tobacco leaves (dissolved in deionized water, and adjust pH=3.5 with acetic acid at the same time). Store leaves for 5 hours under the condition of 55%; then add composite material (3.0% by weight of treated tobacco leaves, composed of glucose and 0.8% citric acid, dissolved in deionized water), store at a temperature of 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com