Processing method for preventing secondary muddying of wild blueberry clear juice

A wild blueberry and processing method technology, applied in the field of food processing, can solve the problems of low anthocyanin retention rate, low blueberry juice yield, poor turbidity stability, etc., to improve clarity and stability, improve appearance quality, and prevent secondary cloudy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

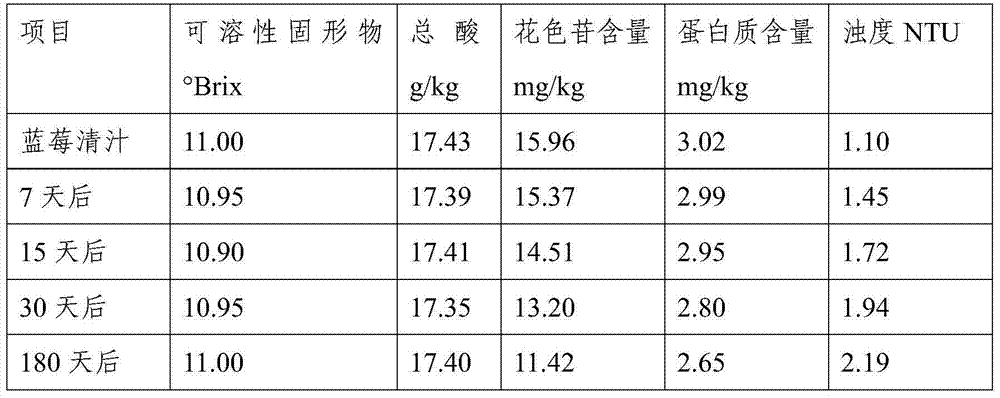

Examples

Embodiment 1

[0031] A processing method for preventing secondary turbidity of clear wild blueberry juice, comprising the following steps:

[0032] (1) Material preparation: take 20kg of fresh wild lowbush blueberries that are free from rot, deterioration and pests, rinse them with clean water and drain;

[0033] (2) Pulping: The wild lowbush blueberries cleaned in step (1) were beaten and crushed, and 10 g of vitamin C (VC) was added after crushing, and the pulp was continued for 3 minutes to obtain blueberry pulp.

[0034] (3) Enzymolysis: Heat the blueberry pulp prepared in step (2) to 50°C, add 10g of pectinase UltraColor, and keep enzymatic hydrolysis at 50°C for 1 hour;

[0035] (4) Juicing: put the blueberry pulp after the enzymatic hydrolysis in step (3) into a press and squeeze directly to obtain blueberry squeeze liquid and squeeze residue;

[0036] (5) Secondary enzymatic hydrolysis: heat the blueberry squeeze liquid obtained in step (4) to 85°C to inactivate the enzyme, and the...

Embodiment 2

[0042] A processing method for preventing secondary turbidity of clear wild blueberry juice. The processing method is the same as that described in Example 1, except that the continuous beating time in step (2) is 2 minutes.

Embodiment 3

[0044]A processing method for preventing secondary turbidity of clear wild blueberry juice, the processing method is as described in Example 1, the difference is that the continuous beating time in step (2) is 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com