Automatic bread machine

A bread machine, automatic production technology, applied in baking workshops, kitchen utensils, household utensils, etc., can solve the problem of not being able to make soft rice flour bread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

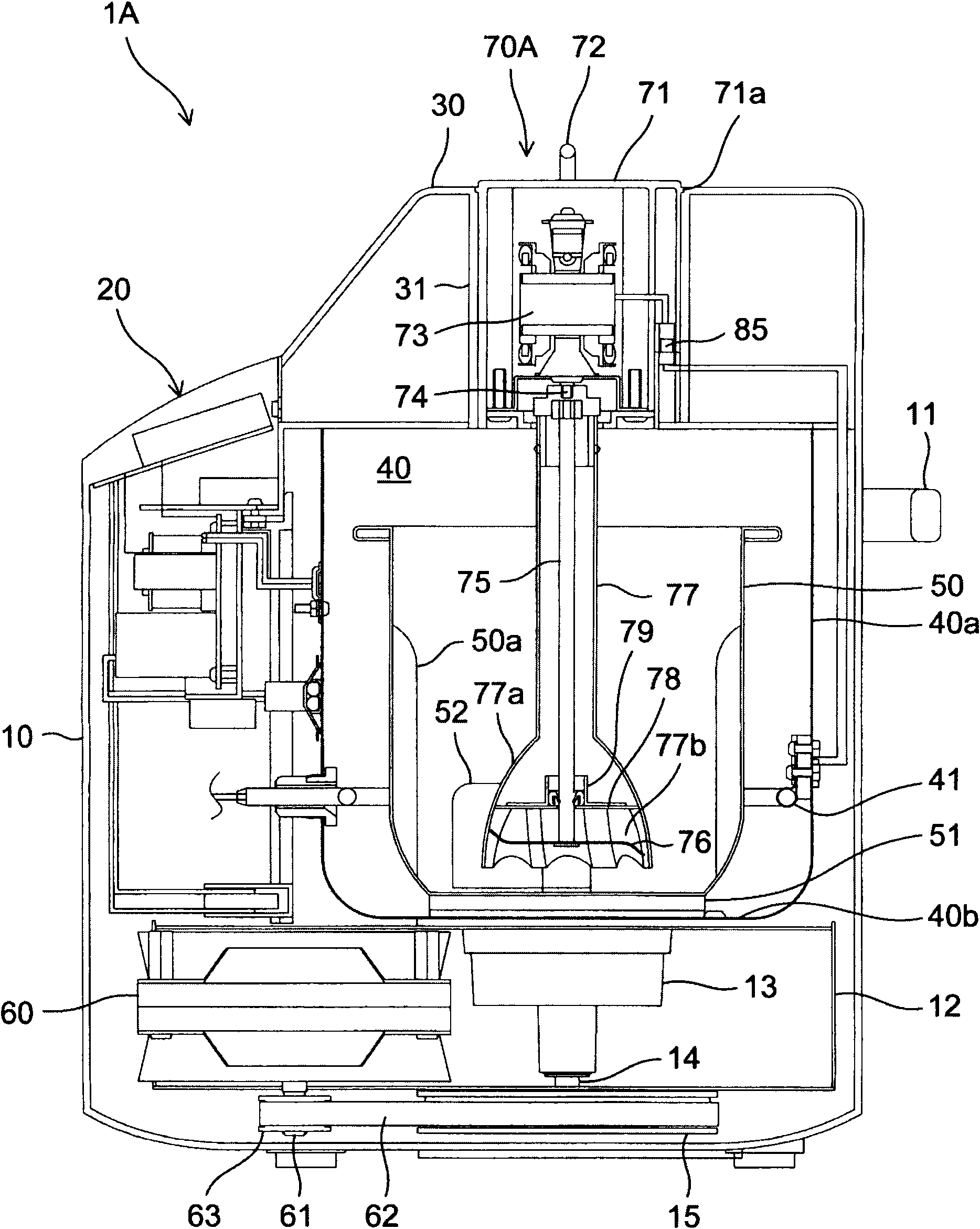

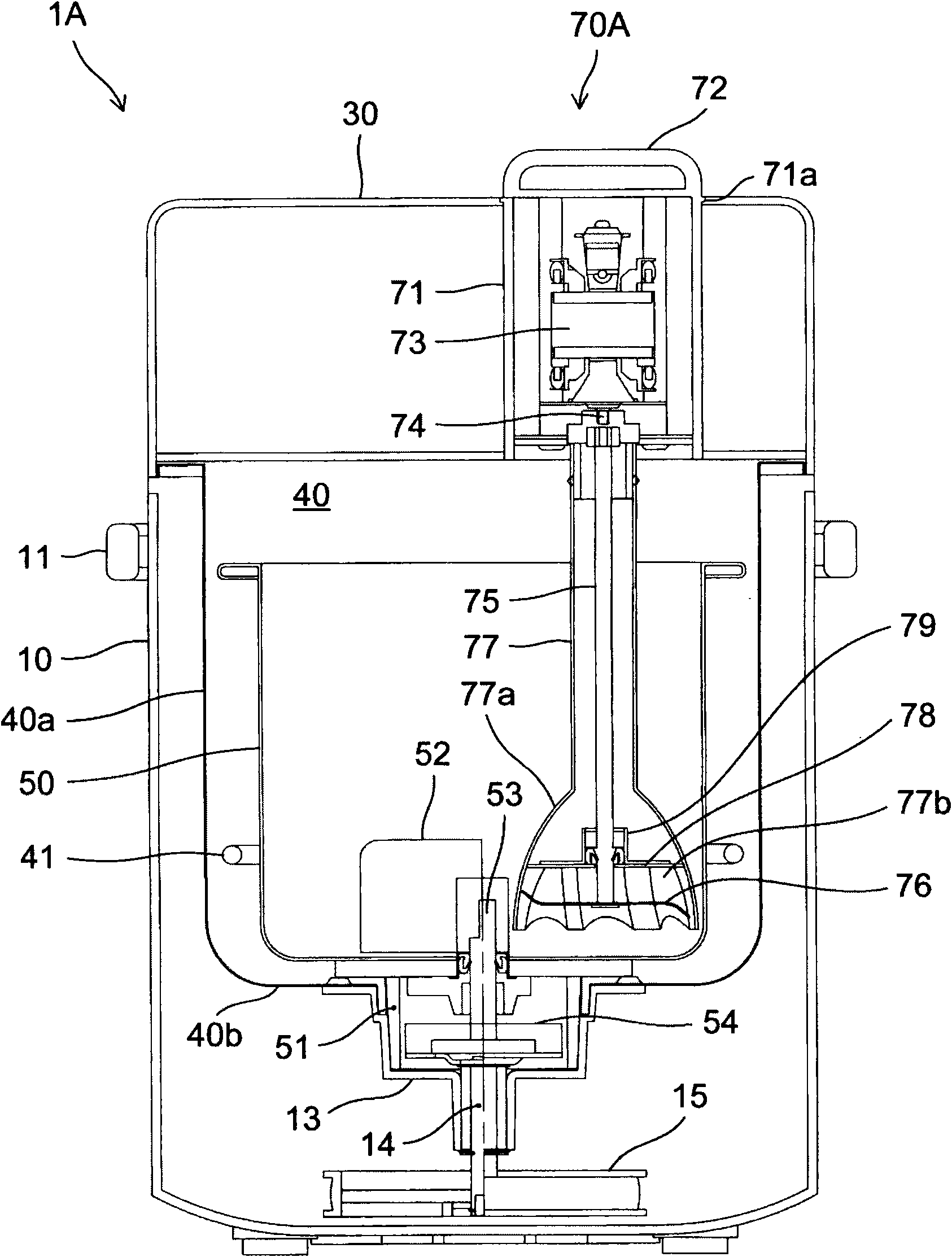

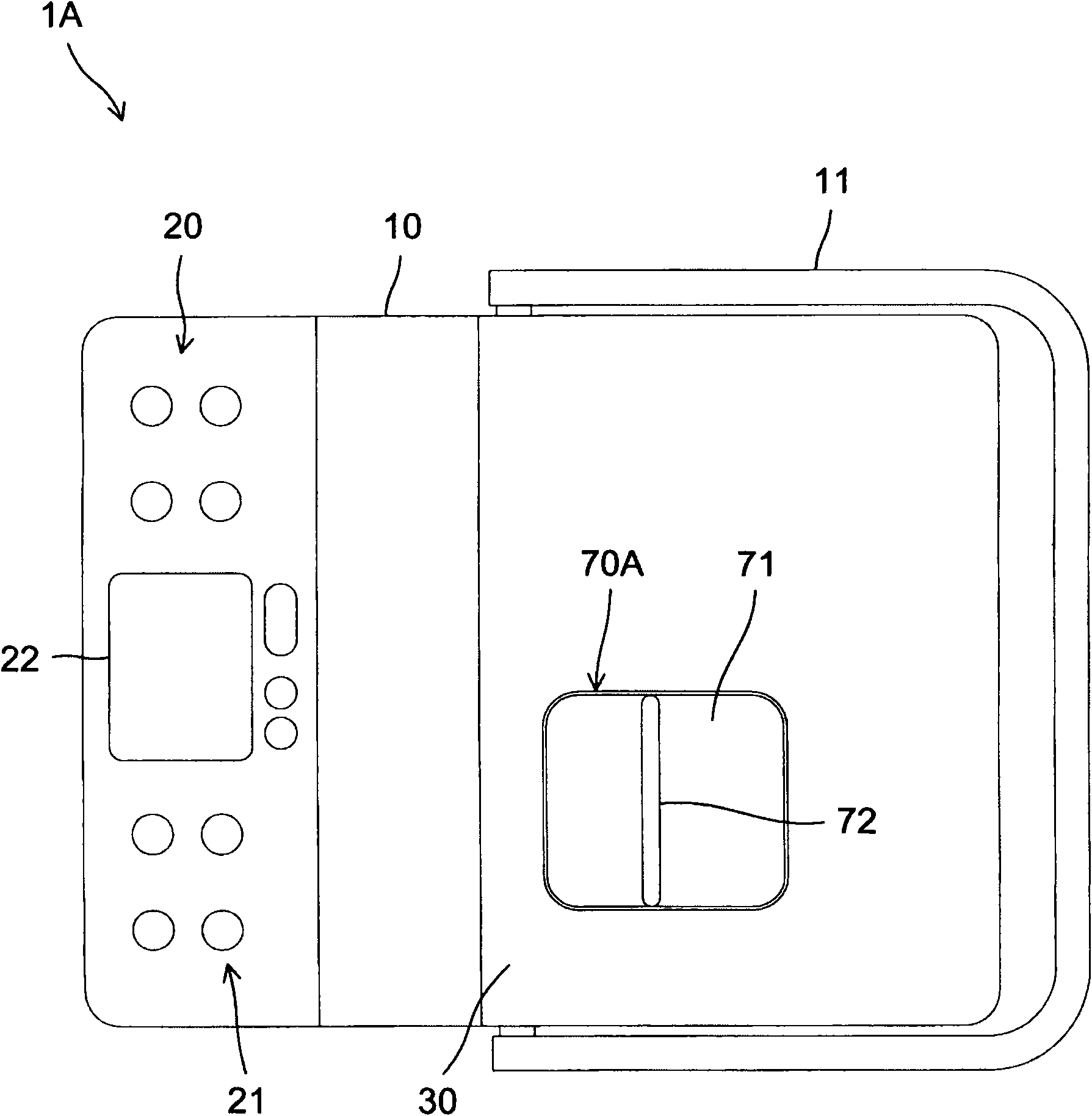

[0105] reference from Figure 1 to Figure 18 The accompanying drawings describe the automatic bread maker 1A of the first embodiment. exist figure 1 and image 3 In the drawing, the left side of the figure is the front (front) side of the automatic bread maker 1A, and the right side of the figure is the back (rear) side of the automatic bread maker 1A. In addition, when the observer faces the automatic bread maker 1A from the front, the left hand side is the left side of the automatic bread maker 1A, and the right hand side is the right side of the automatic bread maker 1A.

[0106] The automatic breadmaker 1A has a box-shaped body 10 . The main body 10 has a synthetic resin shell, and is provided with a "U"-shaped synthetic resin handle 11 whose two ends are connected to the left side and the right side, so that the handle 11 can be carried.

[0107] An operation portion 20 is formed on the front portion of the upper surface of the body 10 (for example, refer to image 3...

no. 2 Embodiment approach

[0165] refer to Figure 25 to Figure 35 The accompanying drawings describe an automatic bread maker 100 according to a second embodiment. exist Figure 25 as well as Figure 35 In the drawing, the left side of the figure is the front (front) side of the automatic bread maker 100, and the right side of the figure is the back (rear) side of the automatic bread maker 100.

[0166] Such as Figure 25 as well as Figure 26 As shown, the automatic bread maker 100 has a box-shaped main body 110 provided with a synthetic resin casing. The upper surface of the main body 110 is covered with a cover 120 made of synthetic resin. The cover 120 is installed on the edge of the back side of the main body 110 through the hinge shaft 121, and rotates in a vertical plane with the hinge shaft 121 as a fulcrum.

[0167] Inside the main body 110, a baking chamber 130 is provided, and the baking chamber 130 has a peripheral side wall 130a and a bottom wall 130b. The structure of the baking ch...

no. 3 Embodiment approach

[0193] refer to Figure 36 to Figure 41 The accompanying drawings describe an automatic bread maker 200 according to a third embodiment. exist Figure 38 and Figure 40 In the drawing, the left side of the figure is the front (front) side of the automatic bread maker 200, and the right side of the figure is the back (rear) side of the automatic bread maker 200. Furthermore, when the observer faces the automatic bread maker 200 from the front, the left-hand side is the left side of the automatic bread maker 200 , and the right-hand side is the right side of the automatic bread maker 200 .

[0194] The automatic breadmaker 200 has a box-shaped body 210 . On the left side of the front of the main body 210, there is an opening to communicate with the baking chamber described later, and a door 211 for closing the opening (refer to Figure 36 ). The door 211 rotates in a vertical plane with its lower end as a fulcrum, and has a handle 212 at its upper end, and has an observatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com