Method for preparing high-content fenugreek gum

A fenugreek gum, high-content technology, applied in the field of separation, can solve the problems of easy carbonization of protein, easy protein corruption, skin allergies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1~9

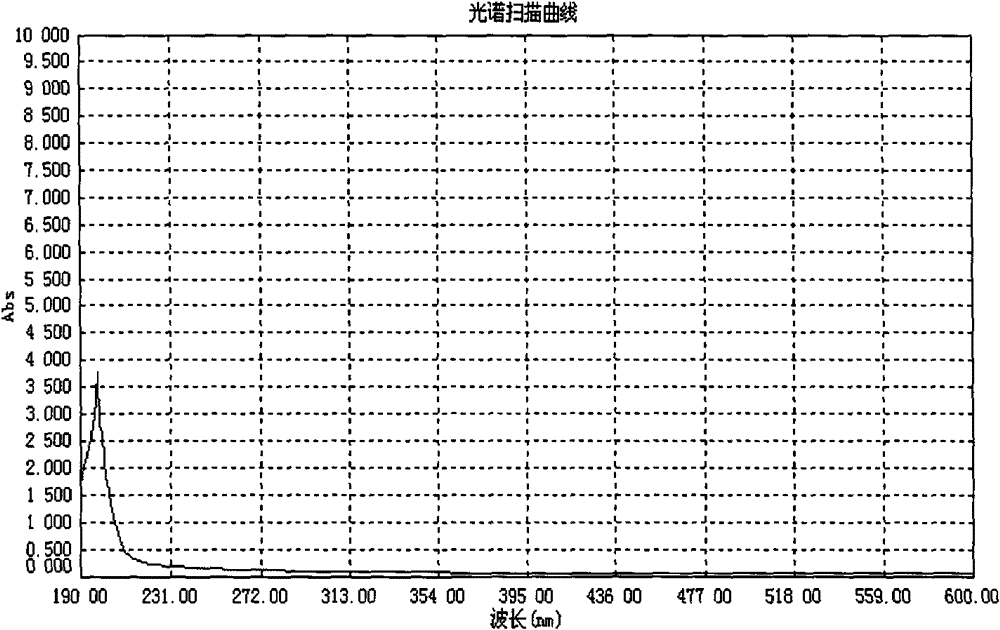

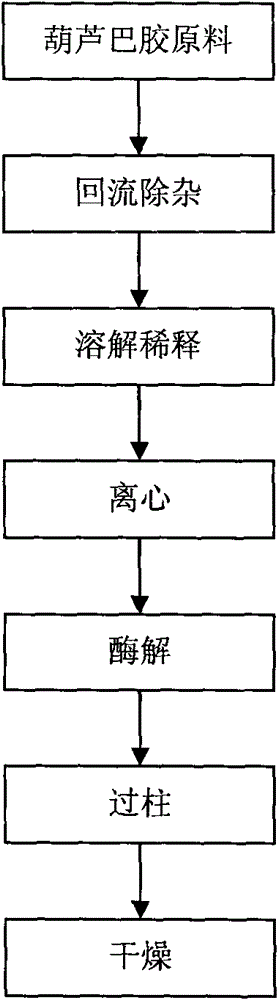

[0045] Examples 1-9 of the present invention use industrial-grade fenugreek gum powder as raw material, with a polysaccharide content of 55% and a protein content of 6.5%. Use 6-10 times the amount of 70%-90% ethanol as the medium, reflux extraction at 80-90°C for 1-3 hours, remove steroidal saponins, trigonelline, flavonoids and other impurities, and then use 5-15 times the amount of petroleum ether 70 ℃~80℃ Reflux extraction for 2h to remove fatty oil.

[0046] The raw materials after impurity removal are dried, and the organic solvent is volatilized. Take 1 part of the processed raw material and add 5 parts of 50% ethanol, stir well, add purified water to dissolve, and prepare 0.5% fenugreek colloid. Centrifuge to remove the supernatant. The supernatant was heated to 45°C, and 30u / mg of low-level protease was added for enzymatic hydrolysis for 4.5 hours. The liquid after enzymatic hydrolysis is pressurized and passed through 1.2 times the volume of ion resin, and the dra...

Embodiment example 10~18

[0052] Examples 10-19 of the present invention use industrial-grade fenugreek gum powder as raw material, with a polysaccharide content of 55% and a protein content of 6.5%. Use 8 times the amount of 80% ethanol as the medium, reflux extraction at 85°C for 2 hours, remove alcohol-soluble impurities such as steroidal saponins, trigonelline, flavonoids and other impurities, and then reflux extraction with 8 times the amount of petroleum ether at 70°C for 2 hours to remove fatty oil Wait.

[0053] The raw materials after impurity removal are dried, and the organic solvent is evaporated. It is measured that the polysaccharide content in the processed fenugreek gum is 68.5%, and the protein content is 6.7%. The processed raw materials were divided into 9 parts, 5 times the amount of 50% ethanol was added to each part, fully stirred evenly, purified water was added to dissolve, and 0.5% fenugreek colloid was prepared. Centrifuge to remove the supernatant.

[0054] Heat the supern...

Embodiment example 19

[0059] Take 100 g of fenugreek gum powder as the raw material, add 8 times the amount of 85% methanol, and extract twice at 80°C for 2 hours each time. Extract once more with 8 times the amount of petroleum ether at 75°C. filter. drying. Add 2 times the amount of 99% ethanol and stir evenly, then quickly add 10,000ml of purified water, continue to add 20,000ml of purified water after stirring evenly, centrifuge, heat the supernatant to 45°C, add activated protease solution, the amount of protease is 30u / mg substrate amount, after enzymatic hydrolysis for 3 hours, the liquid was passed through 1.6 times ion resin, and the lost liquid obtained was spray-dried.

[0060] The polysaccharide content in the finished product is 95.6%, the protein content is 0.13%, and the viscosity is 5,710mPaS

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com