Bletilla striata polysaccharide extract and preparation method thereof

The technology of Bletilla striata polysaccharide and extract is applied to the field of Bletilla striata polysaccharide extract and its preparation, which can solve the problems of difficulty in removing impurities such as protein and starch, and reduce the extraction purity of Bletilla striata polysaccharide, and achieves low destructiveness, low protein content and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

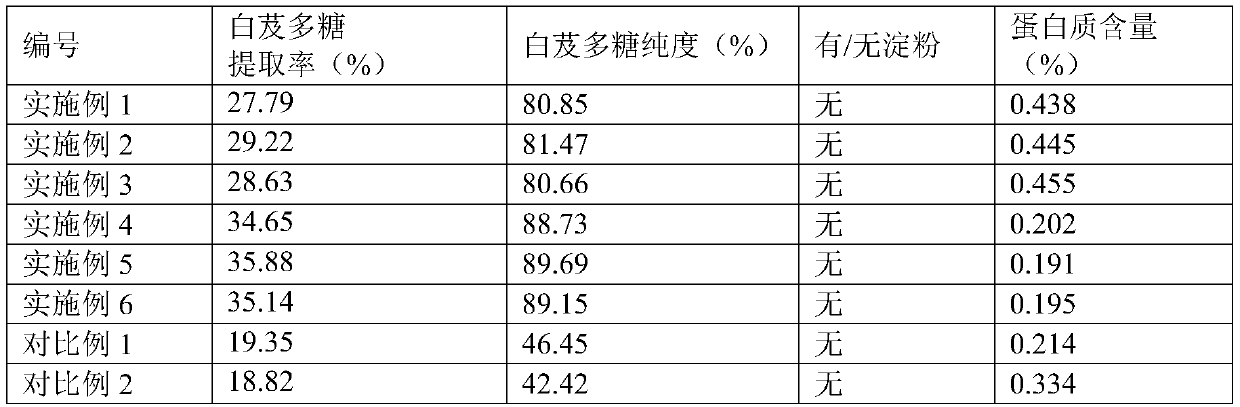

Examples

Embodiment 1

[0044] The Bletilla striata medicinal material was crushed through a 40-mesh sieve, 50 g of the powdered Bletilla striata powder was weighed, added into 3500 mL of water under stirring, and ultrasonically extracted for 9 hours at a stirring speed of 27 r / min and an ultrasonic frequency of 28 kW, centrifuged, Filter to obtain the water extract of Bletilla striata.

[0045] Concentrate the bletilla striata water extract obtained above to a crude drug concentration of 0.1 g / mL, add absolute ethanol to 60% ethanol concentration under unidirectional stirring, let stand at 4°C for 12 hours, filter with suction, and successively wash with absolute ethanol , acetone and ether, and then vacuum-dried at 20°C to obtain the crude polysaccharide of Bletilla striata.

[0046] Add the above-mentioned Bletilla striata crude polysaccharide into deionized water to dissolve, centrifuge, take the supernatant and filter it with a microfilter (0.22 μm), take the microfiltrate at a pressure of 0.10 ...

Embodiment 2

[0048] The bletilla striata medicinal material was crushed through an 80-mesh sieve, 50 g of the pulverized bletilla striata powder was weighed, added into 4500 mL of water under stirring, and ultrasonically extracted for 5 hours at a stirring speed of 27 r / min and an ultrasonic frequency of 28 kW, centrifuged, Filter to obtain the water extract of Bletilla striata.

[0049] After concentrating the bletilla striata water extract obtained above to a crude drug concentration of 0.1 g / ml, add absolute ethanol under unidirectional stirring until the ethanol concentration is 40%, place it at 10° C. for 24 hours, filter with suction, and successively wash with absolute ethanol , acetone and ether, and then vacuum-dried at 50°C to obtain the crude polysaccharide of Bletilla striata.

[0050] Add the above-mentioned crude polysaccharide of Bletilla striata into deionized water to dissolve, centrifuge at high speed, take the supernatant and filter it with a microfilter (0.45 μm), take ...

Embodiment 3

[0052] The bletilla striata medicinal material was crushed through a 100-mesh sieve, and 50 g of the pulverized bletilla striata powder was weighed, added into 250 mL of water under stirring, and ultrasonically extracted for 0.5 hours under the conditions of a stirring speed of 27 r / min and an ultrasonic frequency of 28 kW, centrifuged, Filter to obtain the water extract of Bletilla striata.

[0053] Concentrate the bletilla striata water extract obtained above to a crude drug concentration of 0.1 g / ml, add absolute ethanol to an ethanol concentration of 80% under unidirectional stirring, place it at 30°C for 72 hours, filter with suction, and successively wash with absolute ethanol , acetone and ether, and then vacuum-dried at 40°C to obtain the crude polysaccharide of Bletilla striata.

[0054] The above-mentioned crude polysaccharide of Bletilla striata was dissolved in deionized water, centrifuged at high speed, and the supernatant was filtered with a microfilter (0.8 μm)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com