Community organic matter in-place digestion degradation biogas preparation electrical power generating system, and applications thereof

A technology of biogas power generation and organic matter, which is applied in fuel systems, machines/engines, biochemical equipment and methods, etc., can solve the problems of increasing the cost of organic waste treatment, the effect of anaerobic digestion, the environmental pollution of stacking space, etc., and achieve the treatment cost Low, short process, the effect of improving the effect of anaerobic digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

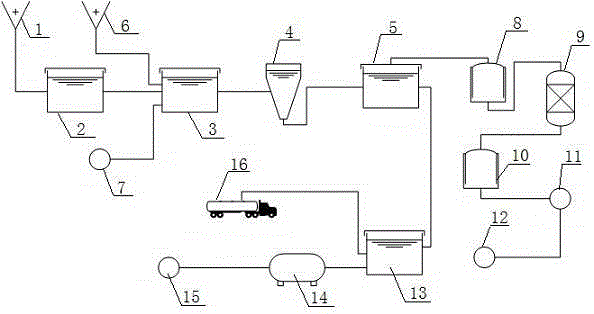

[0032] This embodiment provides a figure 1 The shown biogas power generation system by in-situ digestion and degradation of organic matter in the community includes a buffer tank 2, a mixing tank 3, a concentration tank 4 and an anaerobic digestion tank 5 connected in sequence; the feed port of the buffer tank 2 is connected to the community kitchen drainage main , the community kitchen drainage mains are respectively connected to the kitchen sewers in the community, and the kitchen sewers in the community are respectively provided with garbage breakers 1, and the mixing pool 3 inlet is connected to the outlet of the buffer pool 2 and the community The toilet flushing wastewater drainage main pipe is connected to each toilet 6 in the community. The upper part of the anaerobic digestion tank 5 is provided with an exhaust pipe, and the exhaust pipe is connected to the desulfurization tower 9 feed ports. The desulfurization tower The outlet of the tower 9 is connected to a gas in...

Embodiment 2

[0047] On the basis of embodiment 1, the present embodiment provides a resident community of 10,000 people, which produces 1.44 tons of excrement every day on average, 3.6 tons of kitchen waste, and 100 kg of green waste. figure 1 The specific implementation process of processing it is shown in the technological process.

[0048] The food waste of various companies is crushed by the food waste crusher 1 to form materials with a particle size of about 2mm, which is easier to hydrolyze. The food waste crusher 1 adopts a commercially available civil waste crusher; the processed food The kitchen waste is collected through the community kitchen drainage main and enters the buffer pool 2 for hydrolysis. The time is about 10 days, and the volume of the buffer pool 2 is 300m 3 about.

[0049] The hydrolyzed wastewater, toilet flushing wastewater and green waste are mixed in the mixing pool 3, the mixing time is about 6-12 hours, and the volume of the mixing pool 3 is 450m 3 about. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com