Method for preparing lime raw material and SO2 by decomposing phosphogypsum from high sulphur refinery coke

A calcareous raw material, high-sulfur petroleum technology, applied in chemical instruments and methods, removal of sulfur compounds, solid wastes, etc., can solve the problems of increasing production costs, long sintering time at high temperature, and high production costs, reducing production costs, reducing Reaction temperature, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

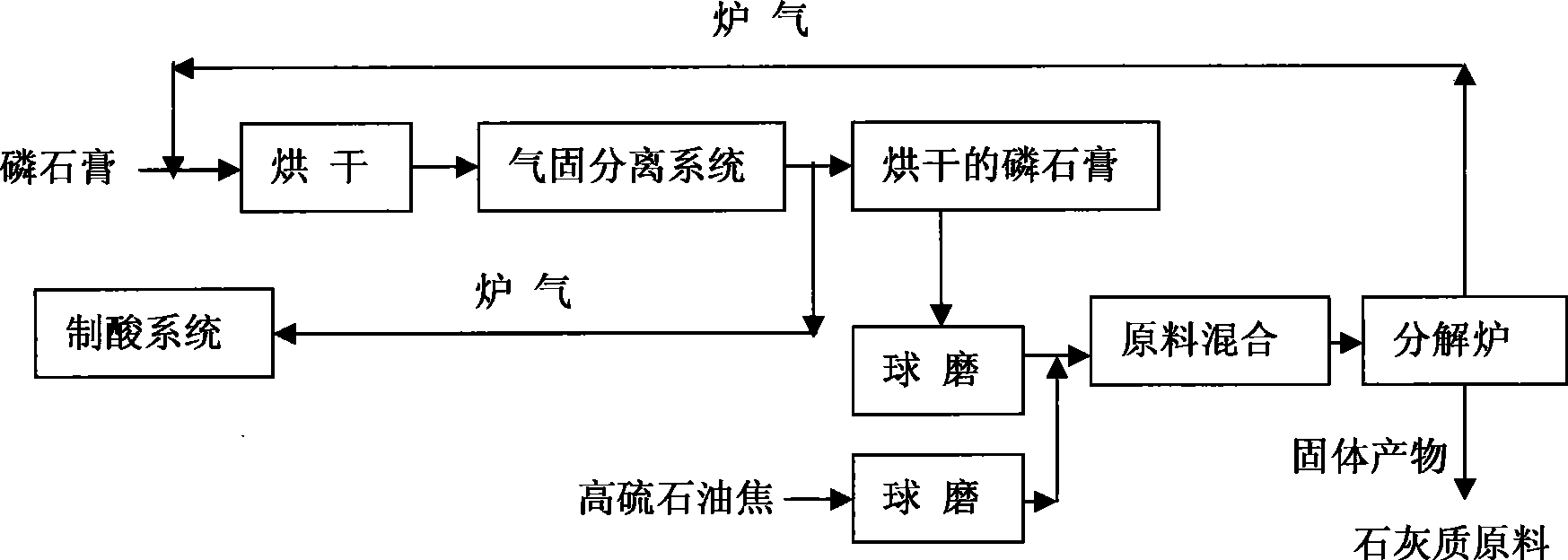

Image

Examples

Embodiment 1

[0034] First, take 1000 g of phosphogypsum powder that has been dried and ground to 100 mesh, and 100 g of 100 mesh high-sulfur petroleum coke, and mix them evenly, and then send them into the reduction and decomposition furnace. Heat the reduction and decomposition furnace, control the temperature at 1.150~1250°C, and the reduction and decomposition reaction time is 1 to 2 hours. Use the flue gas analyzer to continuously detect the volume content of sulfur dioxide in the furnace gas online to be 15~18%. SO 2 Provide qualified raw material gas for acid production process. After the reaction is completely stopped and heated, after natural cooling, the obtained solid product is taken out for analysis and calculation, and the decomposition rate of phosphogypsum is 96%, the desulfurization rate is 92%, and the calcium oxide content in the generated solid product is 51%, which can be directly used as limestone. Raw materials for the production of cement clinker.

Embodiment 2

[0036] First, take 1000g of 120-mesh phosphogypsum powder after drying and grinding, and 130g of 120-mesh high-sulfur petroleum coke, mix them evenly, send them into the reduction and decomposition furnace, heat the reduction and decomposition furnace, control the temperature at 1100~1200°C, and the reduction and decomposition reaction time is For 1 to 2 hours, use a flue gas analyzer to continuously detect the volume content of sulfur dioxide in the furnace gas online to be 16 to 19%, and the SO produced during the reaction 2 Provide qualified raw material gas for acid production process. After the reaction is completely stopped and heated, after natural cooling, the obtained solid product is taken out for analysis and calculation, and the decomposition rate of phosphogypsum is 97%, the desulfurization rate is 93%, and the calcium oxide content in the generated solid product is 57%, which can be directly used as limestone. Raw materials for the production of cement clinker. ...

Embodiment 3

[0038] First, take 1000g of 160 mesh phosphogypsum powder after drying and grinding, and 200g of 160 mesh high-sulfur petroleum coke, mix them evenly, send them into the reduction and decomposition furnace, heat the reduction and decomposition furnace, control the temperature at 1050~1100°C, and the reduction and decomposition reaction time is For 1 to 2 hours, use a flue gas analyzer to continuously detect the volume content of sulfur dioxide in the furnace gas online to be 17 to 21%, and the SO produced during the reaction 2 Provide qualified raw material gas for acid production process. After the reaction is completely stopped and heated, after natural cooling, the obtained solid product is taken out for analysis and calculation, and the decomposition rate of phosphogypsum is 98%, the desulfurization rate is 94%, and the calcium oxide content in the generated solid product is 60%, which can be directly used as limestone. Raw materials for the production of cement clinker. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com