Method for treating heavy metal-containing acidic wastewater in nonferrous metal industry

A technology of acid wastewater and treatment method, which is applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, neutralized water/sewage treatment, etc., and can solve the problem of insufficient compactness of sediment, large amount of precipitated sludge, unfavorable disposal, etc. problems, achieve the effect of reducing the use of chemicals, the operation process is simple, and the investment is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking the pretreated acidic wastewater containing heavy metals from a nonferrous metal smelting enterprise as the research object, the concentration of nickel in the wastewater is 1.84mg / L, the concentration of copper is 3.09mg / L, the concentration of lead is 3.36mg / L, and the concentration of arsenic is 3.36mg / L. The concentration is 24.46mg / L, the concentration of cadmium is 0.46mg / L, the pH is 1.06, and the COD is 290mg / L.

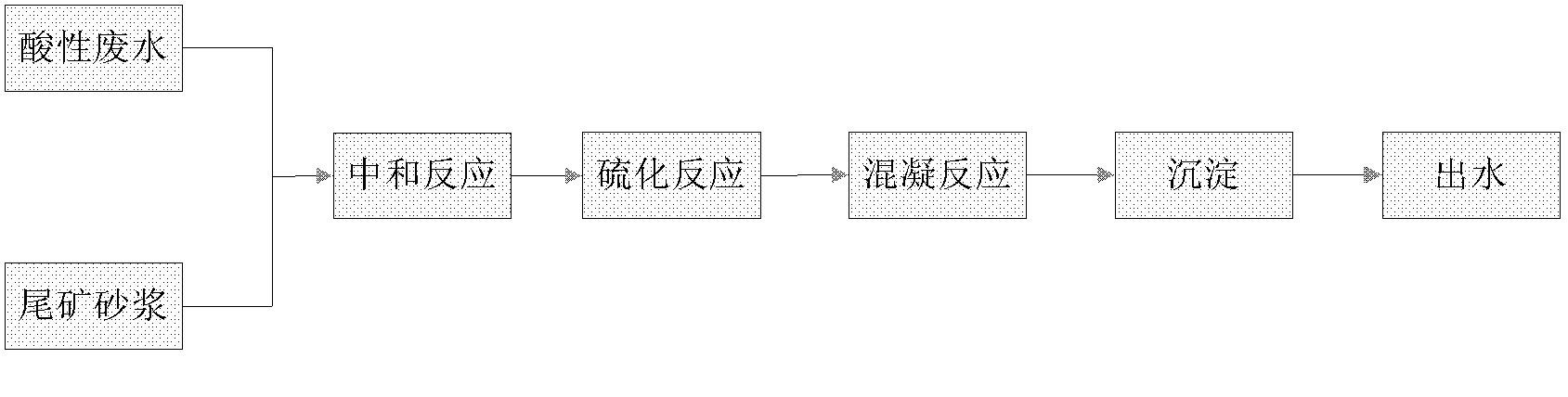

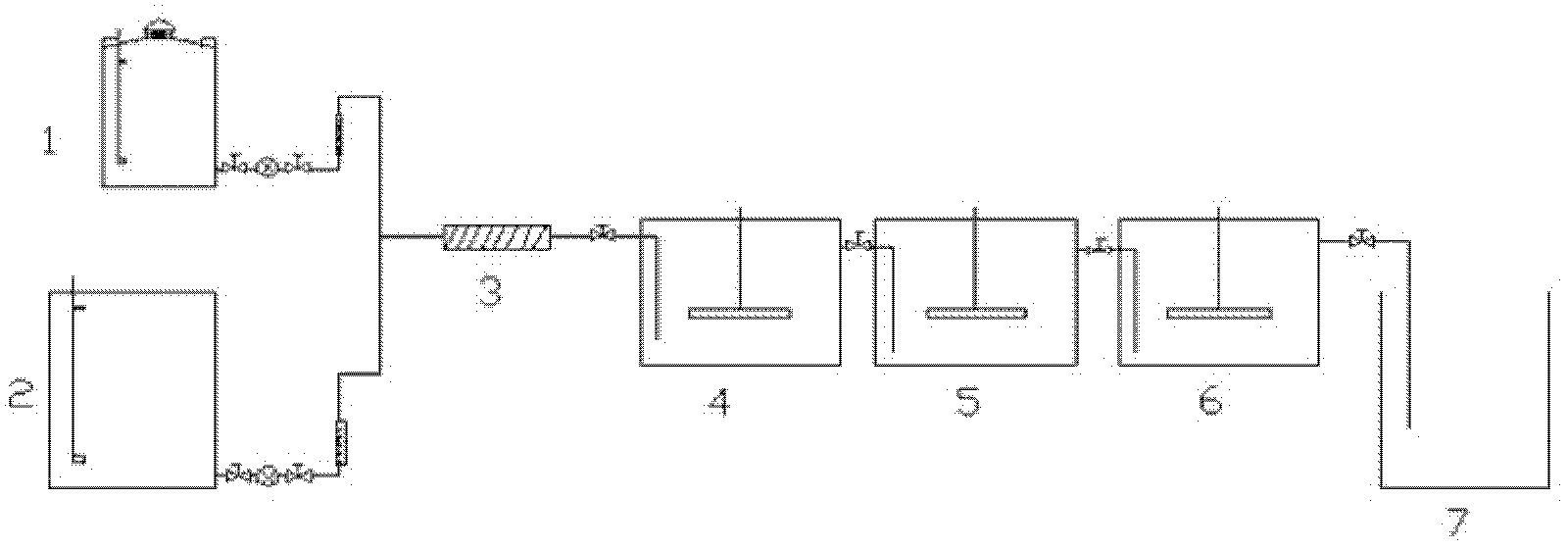

[0035] Please combine figure 1 and figure 2 .

[0036] 1) Mix the acid wastewater in the acid wastewater storage tank 1 and the tailings mortar in the tailings mortar storage tank 2 at a volume ratio of 12:1 through a proportional pipe mixer 3 (DN50) for neutralization.

[0037] 2) The mixed solution of the neutralization reaction enters 1# reaction tank 4, and Na 2 S solution and mechanical stirring for vulcanization reaction; Na 2 The mass concentration of S is 5%, and the proportion with acidic wastewater is 0.3; there is no strict requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com