Temperature-resistant and salt-resistant latex blocking agent and preparation method thereof

A technology of temperature and salt resistance and plugging agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of insufficient temperature and salt resistance of plugging agents, decreased performance and stability of drilling fluid, and plugging Unsatisfactory effect and other problems, to achieve good plugging and reduce water loss, improve salt resistance and temperature resistance, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The application also provides a method for preparing a temperature-resistant and salt-resistant latex plugging agent, the method comprising:

[0053] Mix and stir 10-100 parts by weight of hydrophobic monomer, 0-20 parts by weight of hydrophilic monomer, 0.05-5 parts by weight of emulsifier and 20.1-50.6 parts by weight of deionized water to prepare a first mixed solution;

[0054] mixing the remaining parts by weight of the hydrophobic monomer, the remaining part by weight of the hydrophilic monomer, 0.03-3 parts by weight of an emulsifier and 11.4-50.2 parts by weight of deionized water and stirring at a high speed to form a second mixed solution;

[0055] Mixing 3.4 to 8.6 parts by weight of deionized water and all initiators to prepare a third mixed solution;

[0056] Add buffer, molecular weight modifier, protective agent, remaining deionized water and emulsifier into the reactor and mix well. The temperature of the reactor is raised to 75° C., under an inert atmo...

Embodiment 1

[0071] Add the following raw materials into a 250ml beaker: styrene 40g, methyl methacrylate 30g, butyl acrylate 30g, deionized water 35.6g, fatty alcohol oxyethylene ether sulfosuccinate sodium salt 0.75g, alkyl glycoside 0.55g , high-speed stirring to obtain the first mixed solution;

[0072] Add the following raw materials into a 50ml beaker: 2g of acrylamide, 3g of N-vinylpyrrolidone, 5g of sodium vinylsulfonate, 0.25g of sodium salt of fatty alcohol oxyethylene ether sulfosuccinate, 20.1g of deionized water, and Stir to obtain the second mixed solution;

[0073] Add the following raw materials into a 10ml beaker: 5g of deionized water, 0.6g of ammonium persulfate, and stir well to obtain the third mixed solution;

[0074] Add the following raw materials into a 250ml stirred three-port reactor: 15g of deionized water, 0.3g of alkyl glucoside, 0.5g of sodium bicarbonate, 0.1g of dodecyl mercaptan, 0.13g of polyvinyl alcohol, mix and stir evenly, and heat up To 75°C, add t...

Embodiment 2

[0082] Add the following raw materials into a 100ml beaker: 70g methyl methacrylate, 5g ethyl methacrylate, 5g butyl methacrylate, 1g acrylic acid, 0.15g fatty alcohol alkyloxyethylene ether phosphate, isomerized alcohol polyoxyethylene Ether 0.12g, deionized water 69g, high-speed stirring to obtain the first mixed solution;

[0083]Add the following raw materials to a 200ml beaker: 10g methyl methacrylate, 5g ethyl methacrylate, 5g butyl methacrylate, 5g 2-acrylamide-2-methylpropanesulfonic acid, 22g deionized water, Fatty alcohol alkyloxyethylene ether phosphate 0.3g, isomerized alcohol polyoxyethylene ether 0.5g, high-speed stirring to obtain the second mixed solution;

[0084] Add the following raw materials into a 50ml beaker: 8.5g of deionized water, 1.2g of ammonium persulfate, and stir well to obtain the third mixed solution;

[0085] Add the following raw materials into a 250ml stirred three-port reactor: 5.2g sodium bicarbonate, 6.4g polyvinylpyrrolidone, 4.2g tert-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

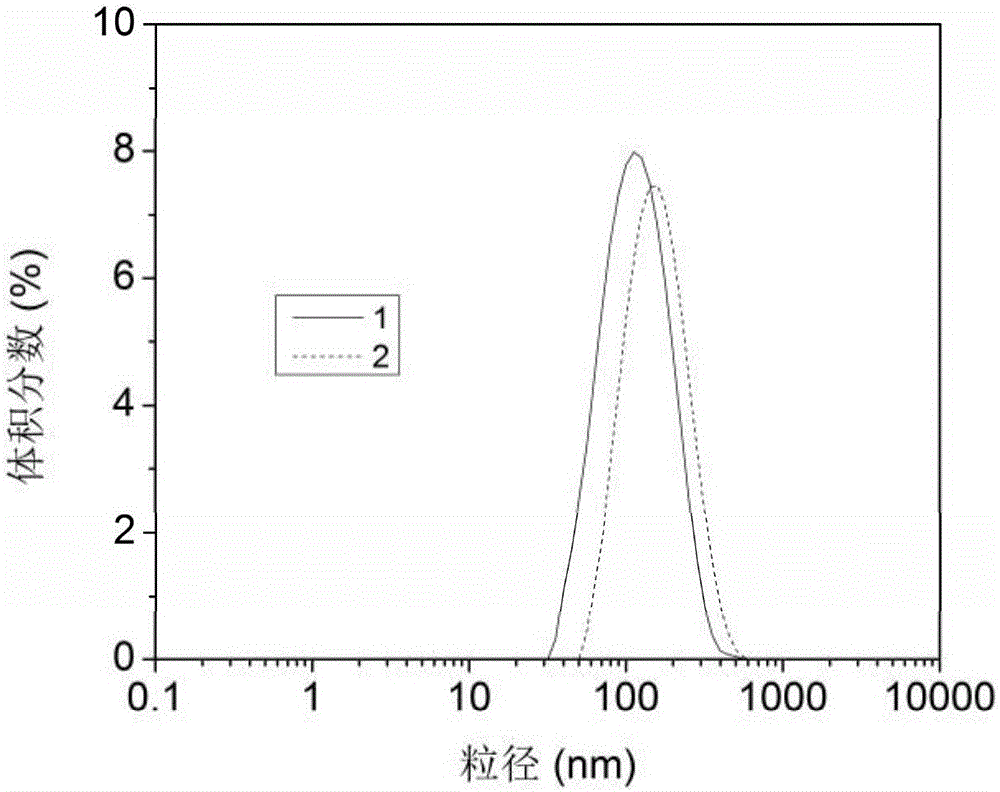

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com