Nanometer composite heat resisting fluid loss reducing agent and its prepn

The technology of a fluid loss reducer and nano-composite material is applied in the field of fluid loss reducer and its preparation, which can solve the problems of unsatisfactory fluid loss reduction effect, poor resistance to salt and calcium pollution, etc., and improve physical and mechanical properties. , Eliminate hydration swelling, improve the effect of salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of organic montmorillonite

[0035]Based on the cation exchange capacity (CEC) of the montmorillonite base slurry, prepare a corresponding concentration of cetyltrimethylammonium chloride (CTAC) solution, mix it with the montmorillonite base slurry in a beaker, and place it in a water bath at 80°C. Stir vigorously in medium for 2-4 hours (hours), let it stand overnight, remove the upper layer solution, filter, wash with deionized water until there is no Cl- (tested with a solution with a concentration of 0.01mol / L AgNO3), dry in a vacuum oven, and crush 200-300 mesh sieve to obtain organic montmorillonite (O-MMT).

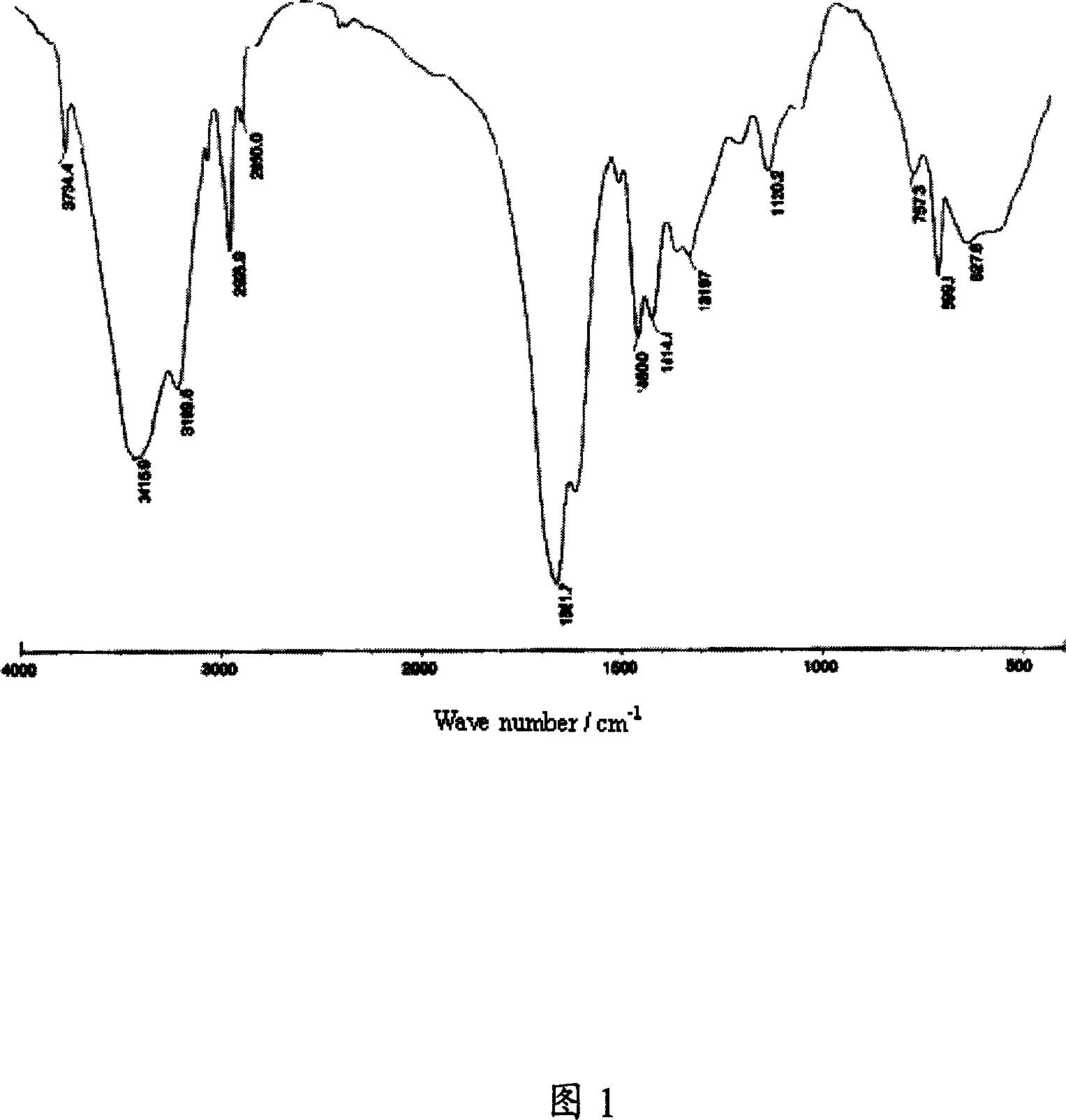

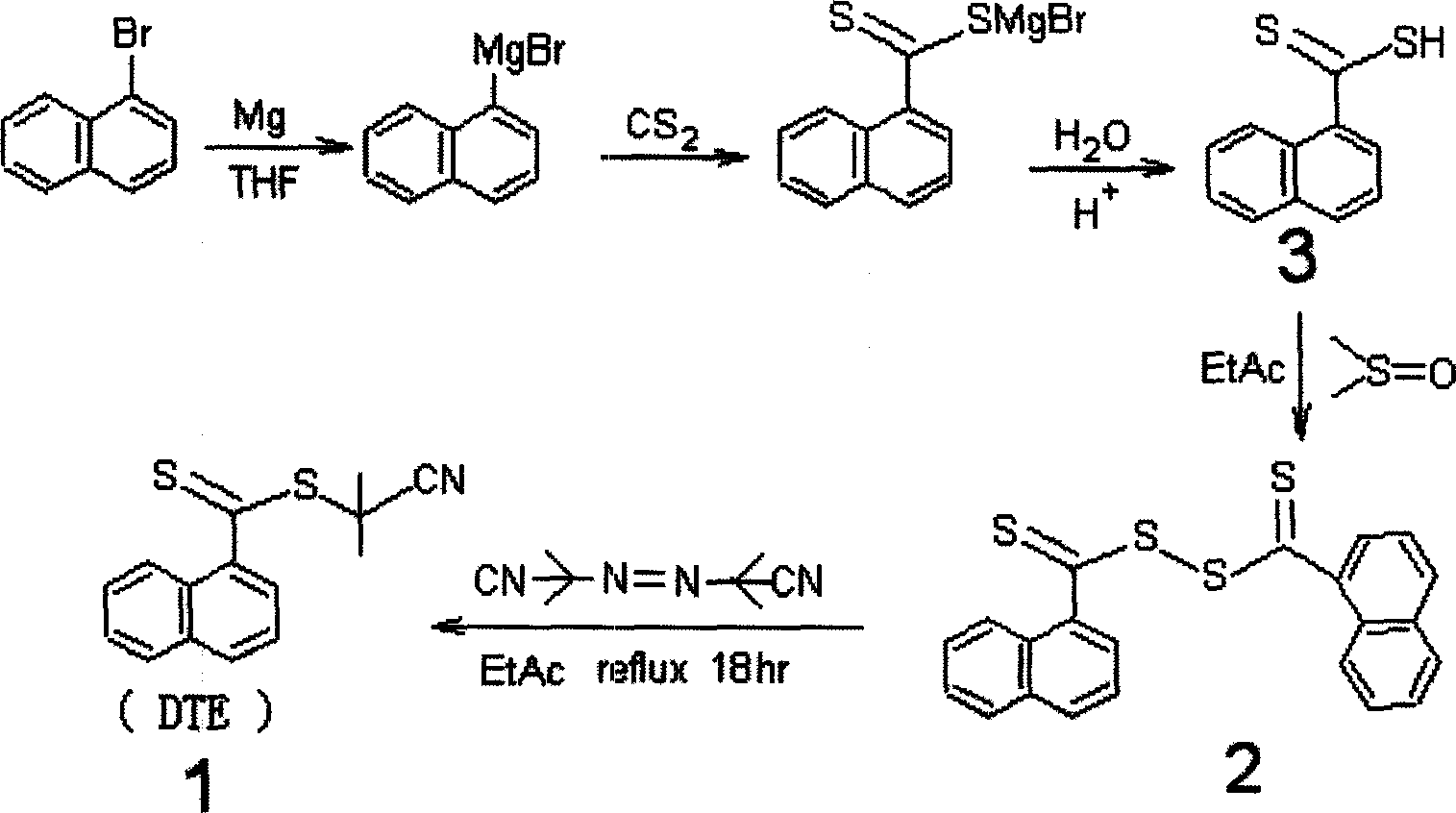

[0036] 2. Synthesis of dithioα-naphthoic acid isobutyronitrile (DTE) chain transfer agent

[0037] Its synthetic route is:

[0038]

[0039] ①In a dry 250mL three-necked bottle, add 2.67g (0.11mol) of magnesium chips, install a condenser tube with anhydrous calcium chloride drying tube, plug the other port of the three-necked bottle, and ...

Embodiment 2

[0046] The preparation and synthesis of organic montmorillonite and dithioα-naphthoic acid isobutyronitrile (DTE) chain transfer agent are the same as in Example 1.

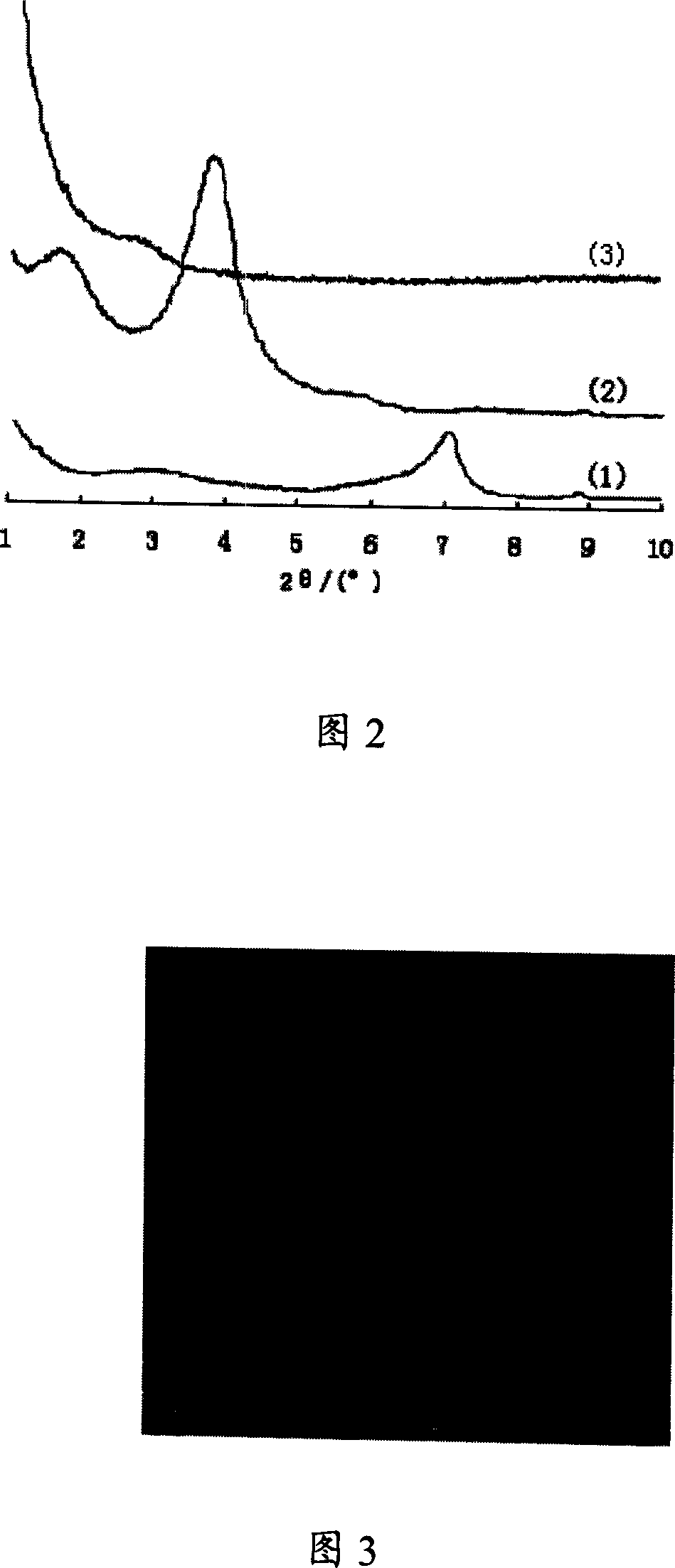

[0047] ①In a three-necked flask equipped with a thermometer and a mechanical stirrer, the molar ratio of St, DTE and AIBN is 200:1:0.2, and O-MMT is added in a ratio of 2% by mass of styrene monomer. After sealing, , the air in the system was removed by freezing and vacuuming, filled with nitrogen, and circulated for 3 times, fully stirred under the protection of nitrogen, and reacted in an oil bath at 150°C. After reacting for 2 hours, the reaction system was cooled with an ice-water bath, and the product was precipitated in acetone, filtered, and then vacuum-dried to obtain a polystyrene / montmorillonite (PSt / O-MMT) nanocomposite macromolecular chain transfer agent.

[0048] ②In a three-necked flask equipped with a thermometer and a mechanical stirrer, add the PSt / O-MMT nanocomposite macromolecular chain transfe...

Embodiment 3

[0050] The preparation and synthesis of organic montmorillonite and dithioα-naphthoic acid isobutyronitrile (DTE) chain transfer agent are the same as in Example 1.

[0051] ①In a three-necked flask equipped with a thermometer and a mechanical stirrer, the molar ratio of St, DTE and AIBN is 600:1:0.6, and O-MMT is added in a ratio of 10% by mass of styrene monomer. After sealing, , the air in the system was removed by freezing and vacuuming, filled with nitrogen, circulated 3 times, fully stirred under the protection of nitrogen, and reacted in an oil bath at 100°C. After reacting for 4 hours, the reaction system was cooled with an ice-water bath, and the product was precipitated in a methanol / water mixed solution (volume ratio 90 / 10), filtered and then vacuum-dried to obtain a polystyrene / montmorillonite (PSt / O-MMT) nanocomposite type macromolecular chain transfer agent.

[0052] ②In a three-necked flask equipped with a thermometer and a mechanical stirrer, add the PSt / O-MMT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com