Tackifier for drilling fluid, and preparation method and application thereof

A technology of viscosifier and drilling fluid, which is applied in the field of viscosifier for drilling fluid and its preparation. It can solve the problems of increasing viscosity of viscosifier, drilling fluid viscosity, low shear force, and poor performance, so as to increase molecular weight and viscosity, Good anti-saturation salt performance, and the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

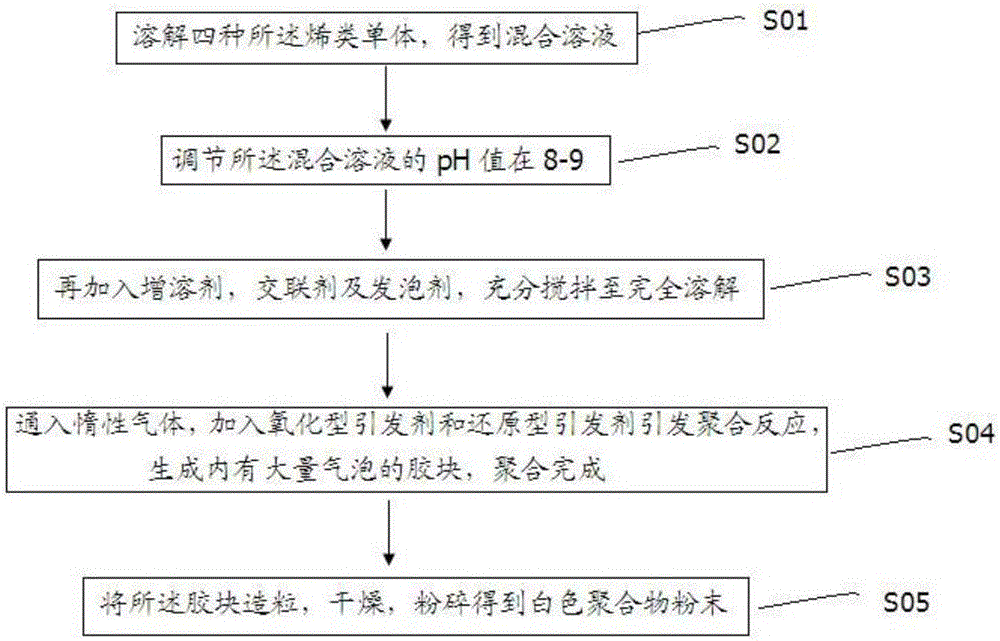

[0036] Such as figure 1 As shown, the preparation method of the drilling fluid viscosifier in the embodiment of the present invention comprises the following steps:

[0037] S01: dissolving the four kinds of ethylenic monomers to obtain a mixed solution;

[0038] S02: adjust the pH value of the mixed solution at 8-9;

[0039] S03: Then add solubilizer, crosslinking agent and foaming agent, and stir until completely dissolved;

[0040] S04: Pass in an inert gas to remove oxygen, add an oxidizing initiator and a reducing initiator as a redox initiating system to initiate a polymerization reaction, and generate a rubber block with a large number of bubbles in it, and the polymerization is completed;

[0041] S05: Granulating the rubber block, drying, and pulverizing to obtain a white polymer powder.

[0042] In order to better understand the above technical solution, the above technical solution will be described in detail below in conjunction with specific implementation manner...

Embodiment 1

[0044] Pour 300mL of deionized water into a 1L beaker, and then take 2-acrylamido-2-methylpropanesulfonic acid, vinylpyrrolidone, acrylic acid, and acrylamide in a mass ratio of 30:20:40:10 Add a total of 300g of the four monomers into the beaker and dissolve completely; then use 30% sodium hydroxide solution to adjust the pH value of the monomer mixed solution to 8-9, and then add additives: solubilizer ethylene glycol 2%, cross-linking Agent N-methylolacrylamide 1%, foaming agent sodium dodecylbenzene sulfonate 1%, stir well until it is completely dissolved, and after deoxygenation by passing nitrogen for 30 minutes at room temperature, add 0.1g of oxidized initiator Agent ammonium persulfate and 0.1g reducing initiator sodium bisulfite are used as a redox initiator system to initiate a polymerization reaction, and a rubber block with a large amount of air bubbles is generated, that is, the polymerization is completed; the resulting polymer rubber block is cut into small piec...

Embodiment 2

[0059] Take 300mL of deionized water and pour it into a 1L beaker, and then take four kinds of vinylpyrrolidone, maleic acid, fumaric acid and methacrylamide according to the mass ratio of 35:15:40:10 Add a total of 300g of monomers into the beaker and dissolve completely; then use 30% potassium hydroxide solution to adjust the pH value of the monomer mixed solution to 8-9, and then add additives: solubilizer sodium dodecylbenzenesulfonate 5% , cross-linking agent diacetone acrylamide 1%, foaming agent sodium bicarbonate 2%, stir well until it is completely dissolved, and after passing nitrogen for 30 minutes at room temperature, add 0.15g oxidized initiator potassium persulfate and 0.15g The reduction initiator ferric sulfite is used as a redox initiator system to initiate the polymerization reaction, and a rubber block with a large number of bubbles is generated, that is, the polymerization is completed; the obtained polymer rubber block is cut into small pieces by a cutting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com