Pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to carbonate reservoir

A technology of carbonate rock reservoirs and process methods, which is applied in the field of high acid fracturing process for pump stop, sand setting, fracture control, and high acid fracturing, which can solve problems such as easy sand plugging, aggravated water flooding, and short fracturing validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] The acid fracturing method of the present invention will be described in detail below through field tests on Tahe Oilfield.

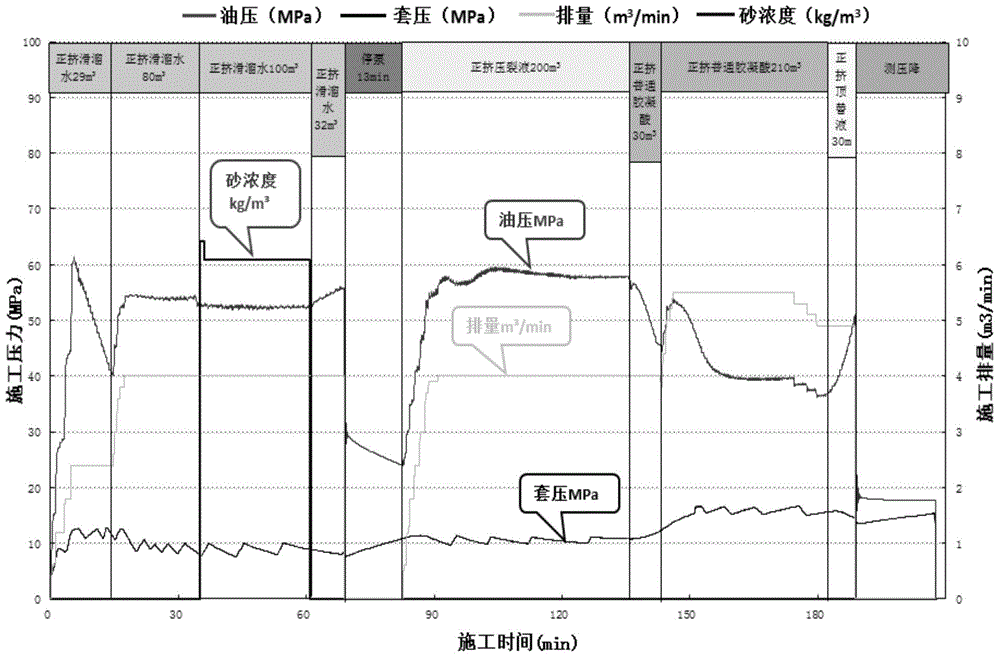

[0090]Acid fracturing construction pump injection process for S72-15 well in Tahe Oilfield

[0091] The liquid composition involved in the acid fracturing pump injection process is as follows, and the following percentages refer to mass % unless otherwise specified.

[0092] Slippery water: 0.3% GRJ-11 guar gum + 0.025% pH regulator + clear water. Wherein, the guar gum is guar gum hydroxypropyltrimethylammonium chloride commonly used in the art.

[0093] Fracturing fluid: use the fracturing fluid product model GRJ-11 sold by Jianghan Fracturing Team JH-YL107, the composition of which is: 20% HCl + 0.4% GRJ-11 guar gum (extra grade) (guar gum hydroxypropyl Trimethylammonium chloride) + 0.02% pH regulator + 1.0% HS-308 demulsifier + 1.0% ZH-5 drainage aid + 0.5% SRD-Y temperature stabilizer + 1.0% SNW-Y clay stabilizer, The rest is water.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com