High-strength corrosion-resistant brass material and preparation and application thereof

A high-corrosion-resistant, high-strength technology, applied in the field of anti-corrosion materials, can solve the problems of arsenic poisoning, human health damage, etc., and achieve the effect of good corrosion resistance and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition weight ratio (wt.%) of the implementation material of the present invention is: 62% Cu, the treatment amount of samarium (Sm) is 0.03%, and the rest is Zn and unavoidable impurities.

[0025] Prepared by following steps:

[0026] (1) Put the electrolytic copper block (plate) into the graphite clay crucible, heat and melt it with an intermediate frequency induction furnace; add broken glass as a covering agent before the copper is melted to prevent the oxidation of metallic copper, and heat up to 1100~1200 °C, Add preheated zinc ingots and stir with a carbon rod to completely melt the zinc;

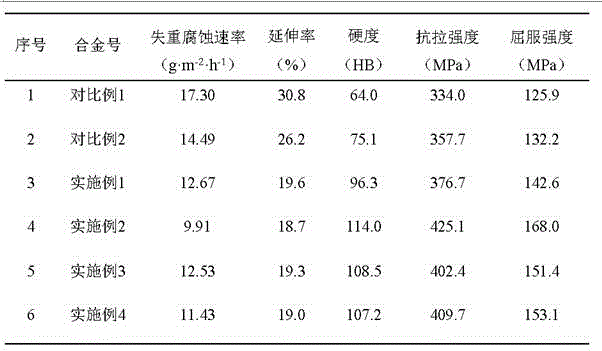

[0027] (2) The alloy continues to heat up to 1300~1400°C, add samarium wrapped in copper foil, stir with a carbon rod, let it stand for 5~10 minutes, lower the temperature, and the alloy liquid is cast at about 1200°C. The properties of the obtained alloy are shown in figure 1 .

Embodiment 2

[0029] The composition weight ratio (wt.%) of the implementation material of the present invention is: 62% Cu, the treatment amount of samarium (Sm) is 0.5%, and the rest is Zn and unavoidable impurities.

[0030] Melting and casting were carried out according to the same preparation process steps and parameters as in Example 1, and the brass material was made through the above process. The properties of the obtained alloy are shown in figure 1 .

Embodiment 3

[0032] The composition weight ratio (wt.%) of the implementation material of the present invention is: 62% Cu, the treatment amount of samarium (Sm) is 2.0%, and the rest is Zn and unavoidable impurities.

[0033] Melting and casting were carried out according to the same preparation process steps and parameters as in Example 1, and the brass material was made through the above process. The properties of the obtained alloy are shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com