Method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubes

A technology of anti-dezincification and brass tubes, which is applied in the field of copper alloys for bathroom and kitchen industries, can solve the problems of high cost, poor cutting performance, and low processing efficiency of silicon brass, so as to save smelting time, improve strength and hardness, The effect of preventing oxidation burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

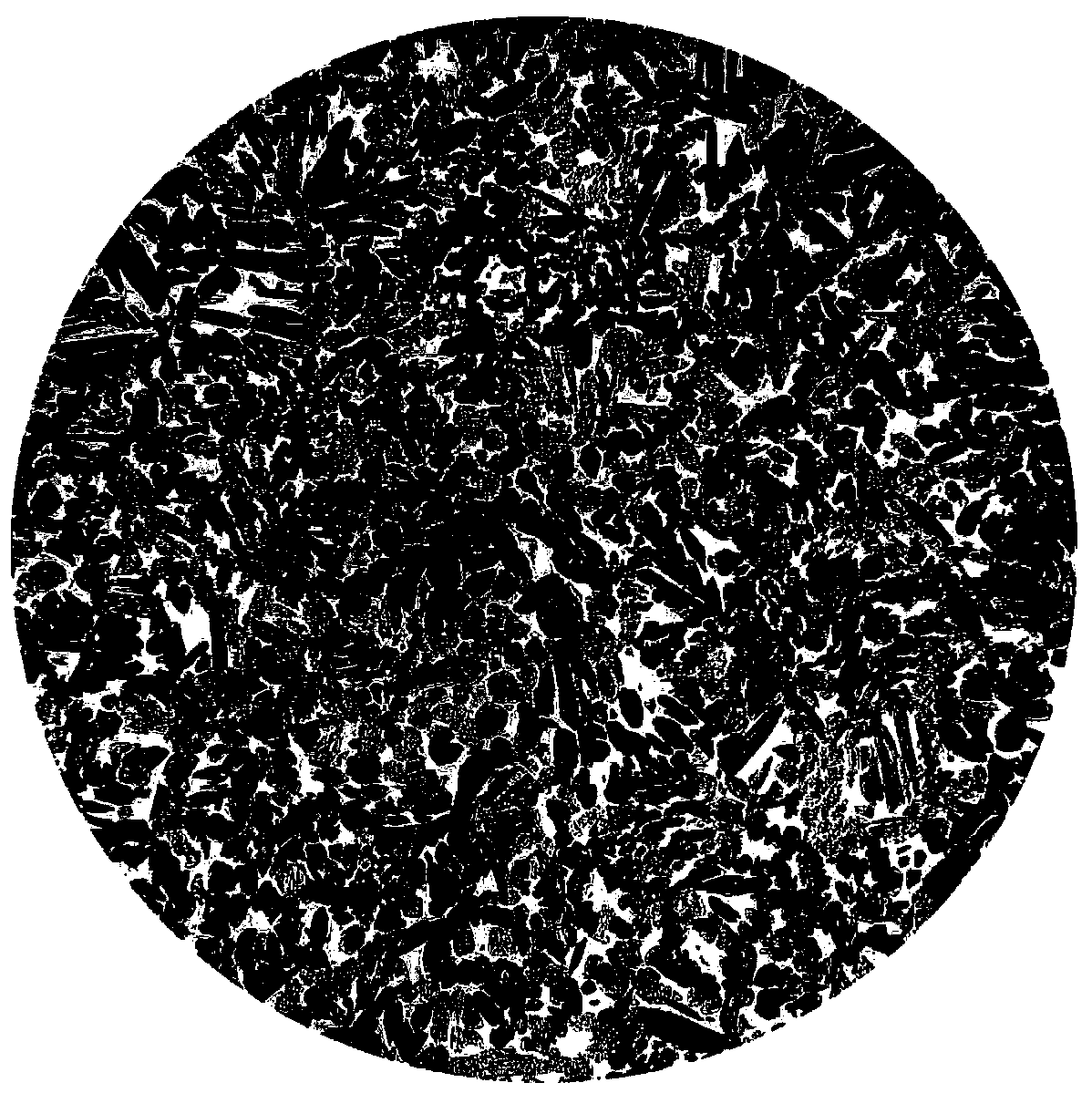

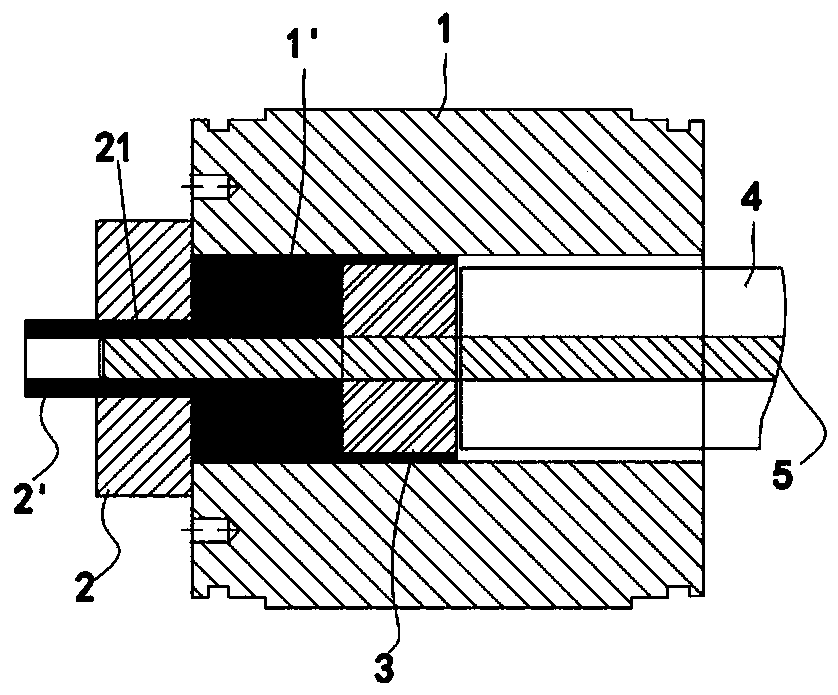

Image

Examples

Embodiment 1

[0025] Embodiment 1: An anti-dezincification lead-free low-silicon-arsenic brass tube is composed of the following raw materials in mass percentage: Cu62%, Si0.6%, As0.07%, Al0.5%, Fe0.03%, Pb0.06%, Zn36.7% and total 0.04% impurities.

[0026] The preparation method of the above-mentioned dezincification-resistant lead-free low-silicon-arsenic brass tube includes melting the above-mentioned raw materials with the mass percentage, casting them into copper ingots → extruding them into copper tube blanks → stretching → annealing → inspection of finished copper tubes → The step of putting the finished copper pipe into storage; wherein, the step of introducing and casting copper ingots includes:

[0027]1) Add 200kg of pure red copper rice into the cored power frequency furnace first, the amount of pure red copper rice added here is 10% of the total raw materials, and when it is in a semi-molten state, the particle size is less than 1cm, accounting for 0.6% of the above total raw m...

Embodiment 2

[0041] A method for preparing an anti-dezincification lead-free low-silicon-arsenic brass tube, which is composed of the following raw materials in mass percentage: Cu65%, Si1.0%, As0.12%, Al0.8%, Fe0.1%, Pb0 .09%, Zn32.79% and total 0.1% impurities.

[0042] The preparation method of the above-mentioned dezincification-resistant lead-free low-silicon-arsenic brass tube includes melting the above-mentioned raw materials with the mass percentage, casting them into copper ingots → extruding them into copper tube blanks → stretching → annealing → inspection of finished copper tubes → The step of putting the finished copper pipe into storage; wherein, the step of introducing and casting copper ingots includes:

[0043] 1) First add 300kg of pure copper rice into the cored industrial frequency furnace. The amount of pure copper rice added here is 15% of the total raw materials. Pure silicon, put it into a copper tube with a suitable diameter, press it into the copper liquid horizo...

Embodiment 3

[0054] A method for preparing an anti-dezincification lead-free low-silicon-arsenic brass tube, which is composed of the following raw materials in mass percentage: Cu63%, Si0.8%, As0.10%, Al0.6%, Fe0.05%, Pb0 .04%, Zn35.3% and total 0.11% impurities.

[0055] The preparation method of the above-mentioned dezincification-resistant lead-free low-silicon-arsenic brass tube includes melting the above-mentioned raw materials with the mass percentage, casting them into copper ingots → extruding them into copper tube blanks → stretching → annealing → inspection of finished copper tubes → The step of putting the finished copper pipe into storage; wherein, the step of introducing and casting copper ingots includes:

[0056]1) First add 300kg of pure copper rice into the cored industrial frequency furnace. The amount of pure copper rice added here is 15% of the total raw materials. Pure silicon, put it into a copper tube with a suitable diameter, press it into the copper liquid horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com