Copper alloy material for lead-free brass ball valve assembly and manufacturing method thereof

A technology of lead-free brass and a manufacturing method, applied in the field of alloy materials, can solve problems such as poor dezincification resistance, poor corrosion resistance and other properties, and achieve strong corrosion resistance and improve dezincification resistance. , the effect of high wear resistance and strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

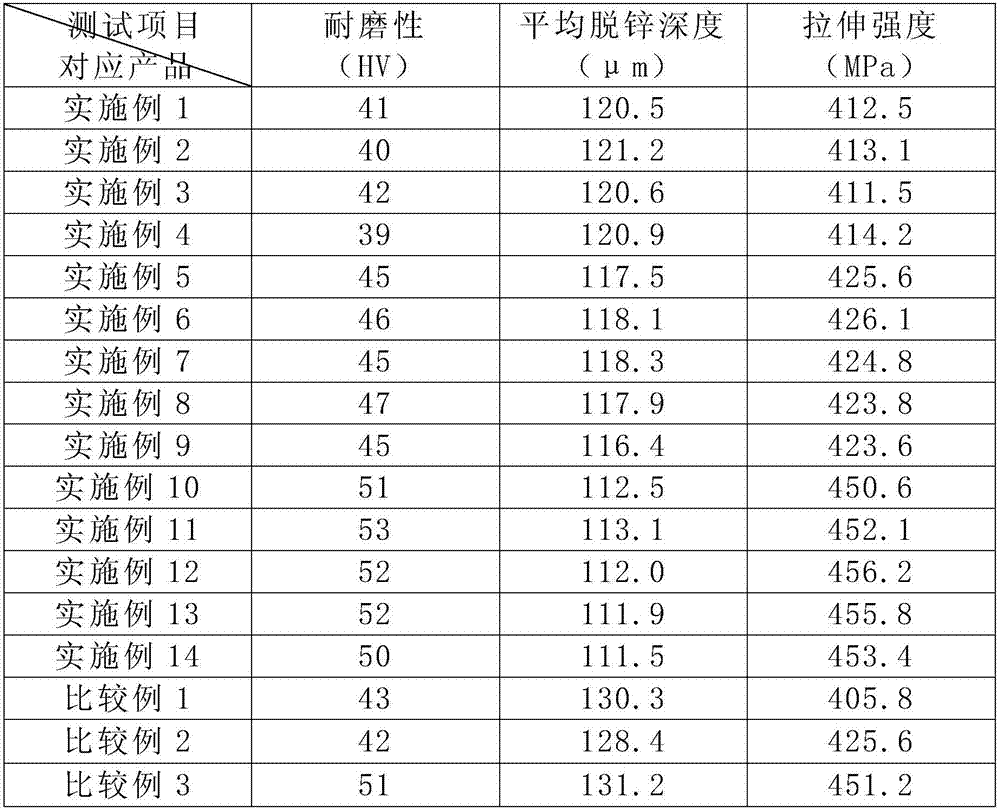

Examples

Embodiment 1

[0022] The copper alloy material used for lead-free brass ball valve components mainly includes the following percentages:

[0023] Copper: 58wt%; tin: 0.5wt%; arsenic: 0.06wt%; The content of iron among the avoided impurities is ≤0.1wt%.

[0024] Among them, the lead-free brass ball valve components can be valve body, valve cover, valve stem, sealing ball (spool) or pressure cap and other related components in the valve can be processed with the above copper alloy materials, more specifically , the corresponding lead-free brass ball valve assembly above is manufactured using the following method:

[0025] According to the shape and size of the lead-free brass ball valve assembly, a copper rod made of copper alloy material is selected for cutting and segmentation, and then heated to 700°C to 750°C for hot forging to obtain the corresponding lead-free brass ball valve The component blank, then, control the temperature at 550°C for the first isothermal annealing treatment for ...

Embodiment 2

[0027] The copper alloy material used for lead-free brass ball valve components mainly includes the following percentages:

[0028] Copper: 63wt%; Tin: 1.0wt%; Arsenic: 0.02wt%; The content of iron in the iron is less than or equal to 0.1wt%.

[0029] Among them, the lead-free brass ball valve components can be the relevant components in the valve such as the valve body, valve cover, valve stem, sealing ball or pressure cap, which can be processed with the above copper alloy materials. More specifically, the above corresponding Lead-free brass ball valve assemblies are manufactured using the following methods:

[0030] According to the shape and size of the lead-free brass ball valve assembly, a copper rod made of copper alloy material is selected for cutting and segmentation, and then heated to 750°C for hot forging to obtain the corresponding lead-free brass ball valve assembly blank, and then , then control the temperature at 580°C for the first isothermal annealing treat...

Embodiment 3

[0032] The copper alloy material used for lead-free brass ball valve components mainly includes the following percentages:

[0033] Copper: 60wt%; tin: 0.8wt%; arsenic: 0.04wt%; The content of iron in the iron is less than or equal to 0.1wt%.

[0034]Among them, the lead-free brass ball valve components can be the relevant components in the valve such as the valve body, valve cover, valve stem, sealing ball or pressure cap, which can be processed with the above copper alloy materials. More specifically, the above corresponding Lead-free brass ball valve assemblies are manufactured using the following methods:

[0035] According to the shape and size of the lead-free brass ball valve assembly, a copper rod made of copper alloy material is selected for cutting and segmentation, and then heated to 800°C for hot forging to obtain the corresponding lead-free brass ball valve assembly blank. Then, control the temperature at 600°C for the first isothermal annealing treatment for 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com