A kind of lead-free copper alloy for casting and preparation method thereof

A lead-copper alloy and alloy technology, which is applied in the field of lead-free copper alloy for casting and its preparation, can solve the problem that lead-free brass cannot meet the cost of bathroom faucets and valves, cutting performance, casting performance, corrosion resistance, mechanical properties, etc. Performance, casting molding performance, cutting performance, insufficient plasticity, and corrosion resistance decline, etc., to achieve a good market competitive advantage, increase dezincification corrosion resistance, and excellent cutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

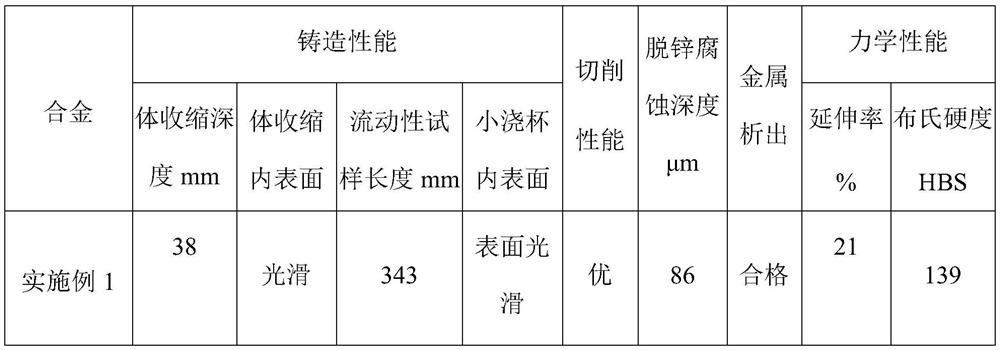

Examples

Embodiment Construction

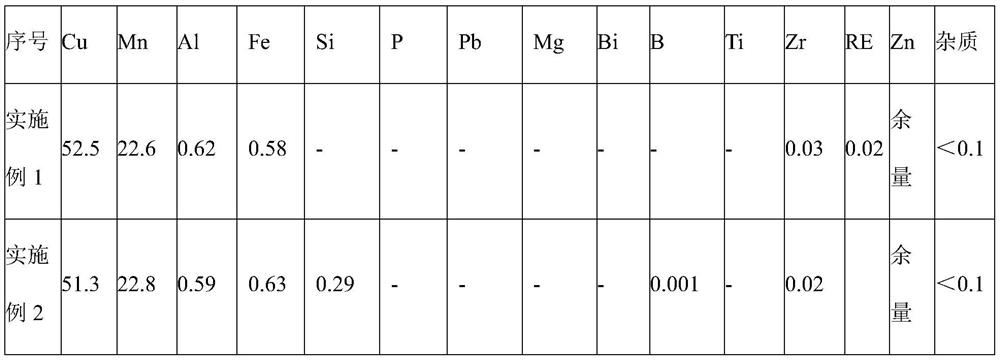

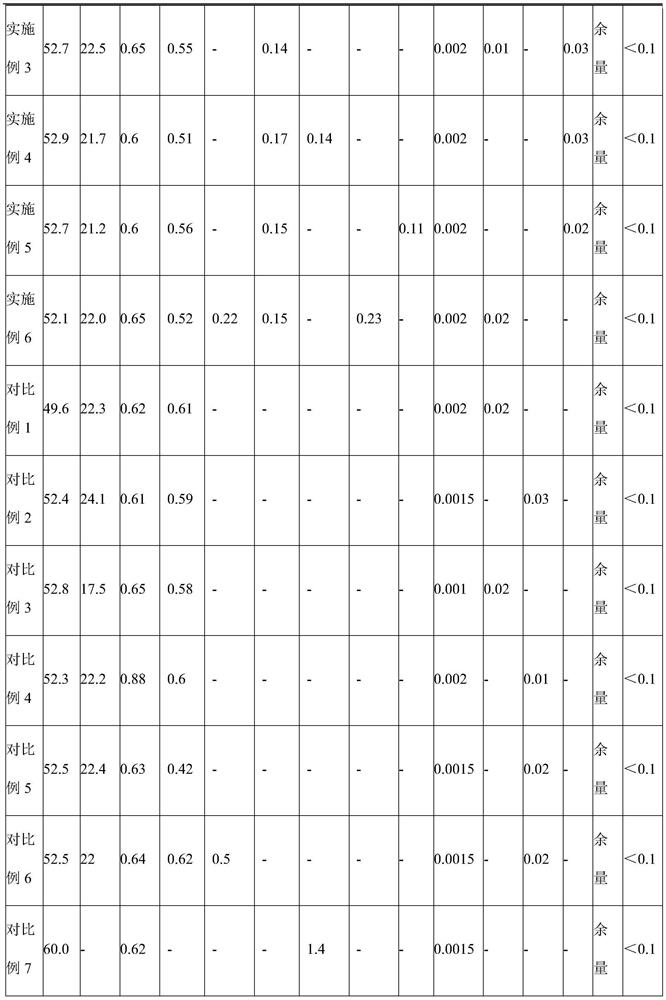

[0038] The following specific examples further explain the present invention.

[0039] A method for preparing lead-free low-cost copper alloy for casting comprises the steps:

[0040] (1) Weigh the raw materials including Cu, Cu-Mn alloy, 0#Zn, Al, Fe, and metamorphic elements according to the composition of lead-free low-cost copper alloy for casting. According to the specific composition, the raw materials also include Si, Cu-P alloy , at least one of Pb, Bi, Mg; the modified element is at least one of B, Ti, Zr and rare earth elements;

[0041](2) Put Cu and Cu-Mn alloy on the bottom of the induction furnace, add slag cleaning agent to refine and cover with charcoal, heat up to 1050-1150°C until all materials are melted, and filter off the surface scum;

[0042] (3) Adjust the temperature to 1030-1080°C, add 0#Zn to the material obtained in step (2) and quickly press it into the bottom of the furnace, and stir fully after melting;

[0043] (4) in the material of step (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com