Conducting particle and preparation method thereof

A technology of conductive particles and particles, which is applied in the field of electricity, can solve the problems of increased contact resistance, decreased insulation reliability, and poor contact between circuit electrodes, achieving good insulation reliability, good insulation reliability, and avoiding short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

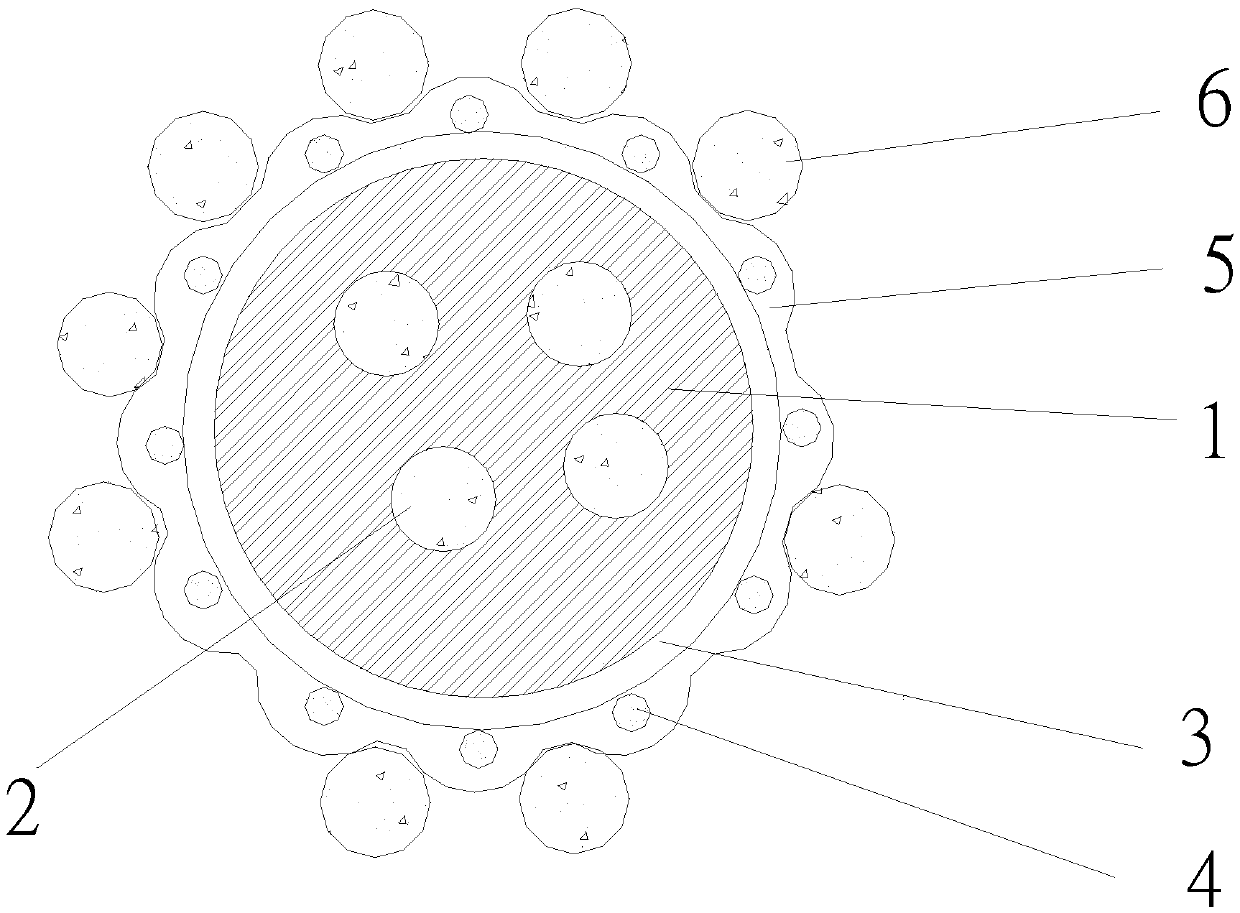

Image

Examples

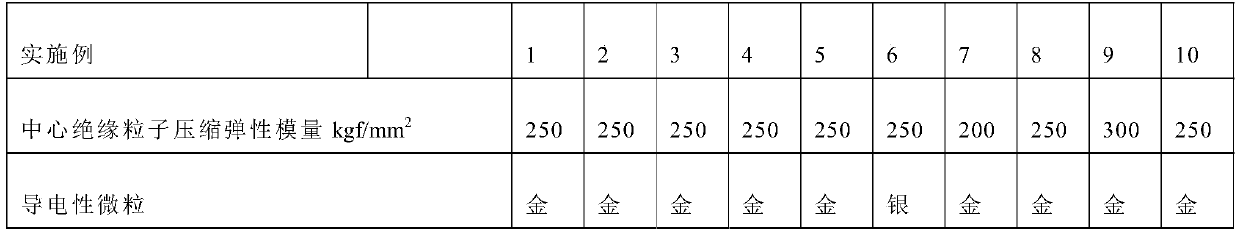

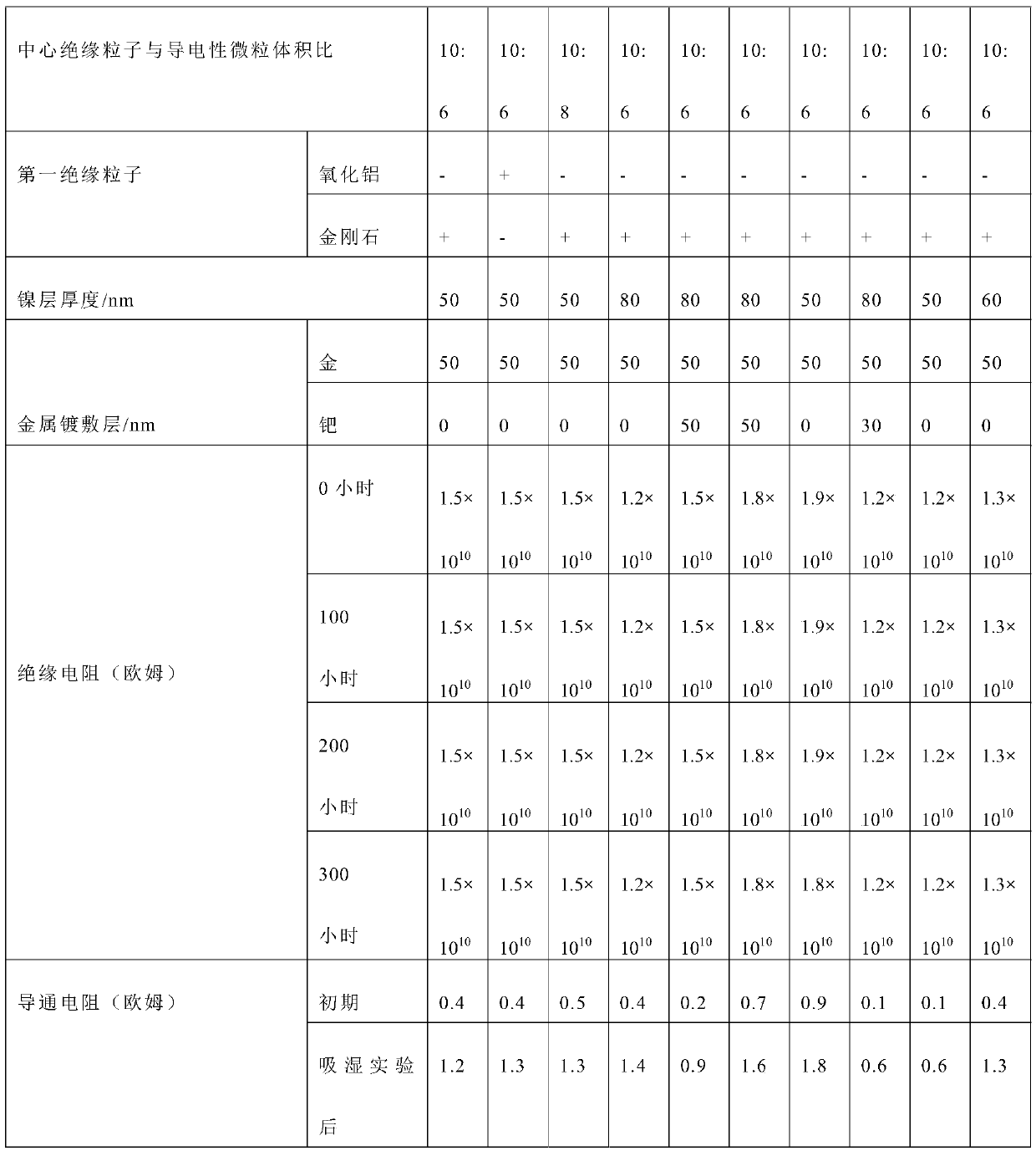

Embodiment 1

[0059] S1: Central insulating particle preparation process: prepare 10 g of central insulating particle 1 composed of a copolymer of divinylbenzene, acrylic acid and acrylonitrile with an adjusted degree of crosslinking, and the surface of the central insulating particle 1 has carboxyl groups. The compressive elastic modulus of the central insulating particle 1 (compressive elastic modulus when the particle diameter is deformed by 20% at 200 degrees Celsius, 20% K value) is 250kgf / mm 2 ;

[0060] S2: Disperse conductive particles 2 in central insulating particles 1: add conductive particles 2 gold to the prepared central insulating particles 1, and put it into a 10% mass concentration polyvinyl alcohol aqueous solution, stir well, and The obtained suspension was polymerized at 100 degrees Celsius for 4 hours to obtain central insulating particles 1 dispersed with conductive particles 2, and the volume ratio of the central insulating particles 1 and conductive particles 2 to go...

Embodiment 2

[0067] In step S5, aluminum oxide is used instead of diamond as the first insulating particles 4, and other steps are the same as in embodiment 1.

Embodiment 3

[0069] In step S2, the volume ratio of the central insulating particles 1 and the conductive particles 2 is adjusted to 10:8, and the rest of the steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive modulus of elasticity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com