Stator, motor, compressor and vehicle

A stator and stator slot technology, which is applied in the field of vehicles, can solve the problems of complex insulation shape, insufficient creepage distance, and phase-to-phase faults.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

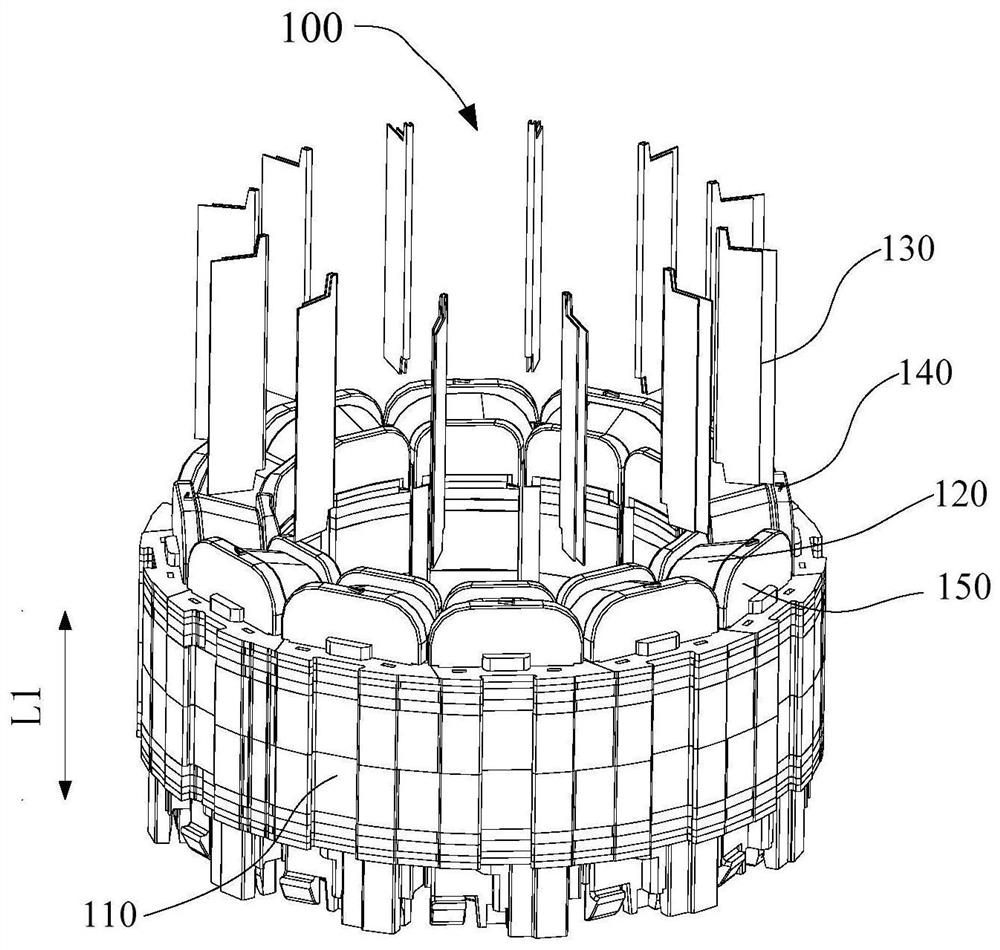

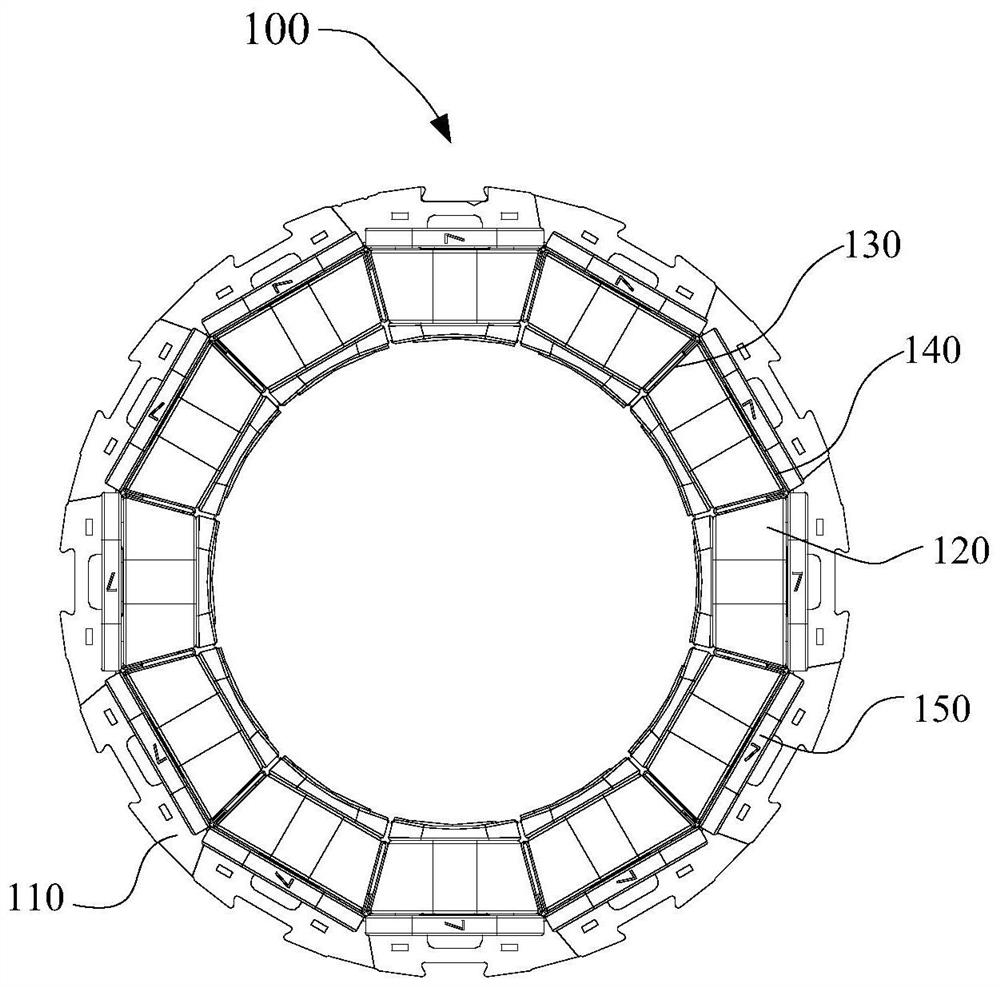

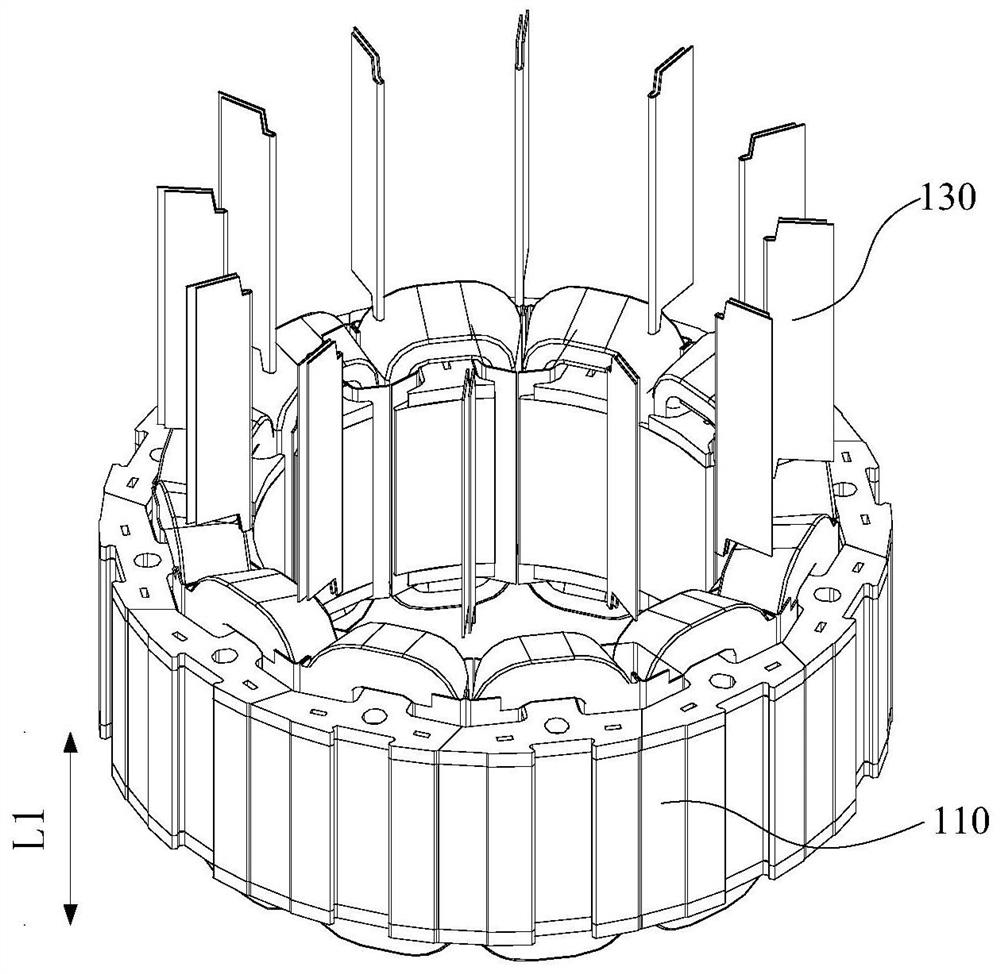

[0143] like Figure 1 to Figure 7 As shown, a specific embodiment of the present invention provides a stator 100 , and the stator 100 includes a stator core 110 , a winding 120 , a first insulating member 130 , a second insulating member 140 and an insulating frame 150 .

[0144] Specifically, such as Figure 1 to Figure 3 As shown, taking the number of stator slots Q=12 of the motor as an example, the first insulator 130 is inserted into the stator slot defined by two adjacent iron cores along the axial direction of the iron core, and the second insulator 130 is arranged along the inner wall of the stator slot. Insulators 140, insulation frames 150 are placed on both sides of the axial end face of the stator core 110, windings 120 wound on the insulation frames 150 are placed in the stator slots, and the first insulators 130 are arranged along the circumferential direction of the motor. The winding 120 is physically isolated, so as to ensure the insulation reliability of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com