Epoxy resin composite insulating material and preparation method thereof

A technology of epoxy resin and composite insulation, which is applied in the field of electrical insulation and composite materials, and can solve problems such as difficulty in detection and repair of epoxy resin insulation materials, decline in insulation performance, and power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

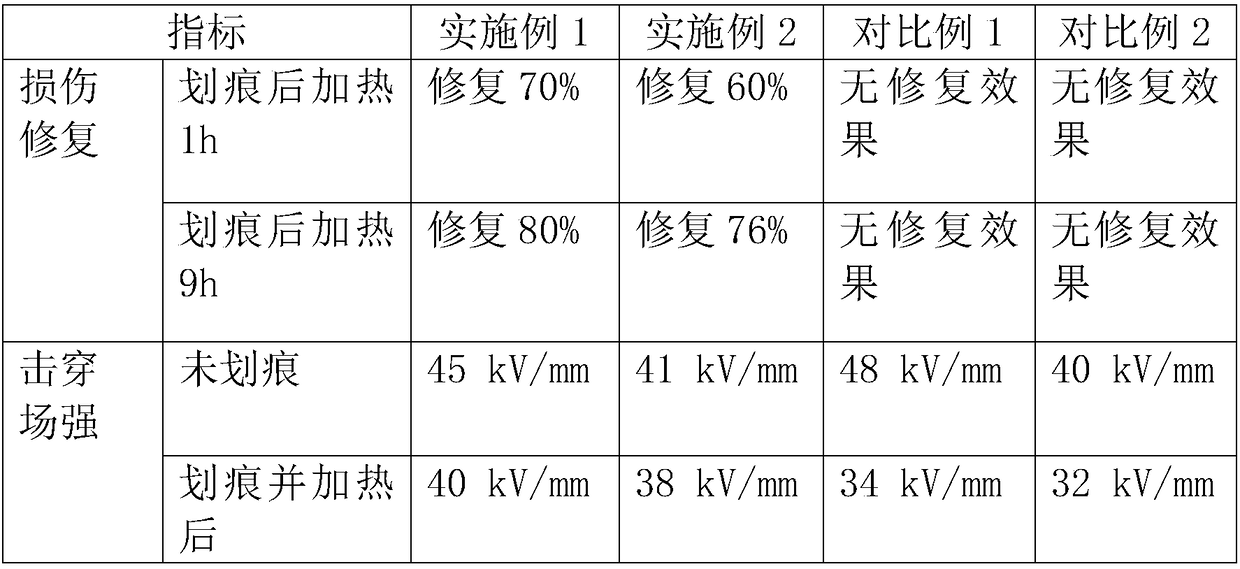

Examples

Embodiment 1

[0034] 1. Preparation of UF / DCPD microcapsules

[0035] After dissolving 1 part of urea with 8 parts of deionized water, add 2.3 parts of 37% formaldehyde solution, adjust the pH to 8.5 with triethanolamine, and keep it under 400rpm magnetic stirring at 70°C for 1h, then cool to room temperature to obtain Aqueous solution A of urea-formaldehyde resin prepolymer with transparent color and certain viscosity.

[0036] Under the conditions of 40°C water bath and 400rpm mechanical stirring, mix 0.5 parts of sodium dodecylbenzenesulfonate emulsifier and 10 parts of molten dicyclopentadiene, add 100 parts of deionized water, and stir for 30 minutes to obtain a stable The core material emulsified solution B.

[0037] Under 380rpm magnetic stirring, 20 parts by weight of solution A was added dropwise to 110.5 parts by weight of emulsion B prepared above, and 3 parts of urea-formaldehyde resin curing agent ammonium chloride and 5 parts of urea-formaldehyde were added After mixing the ...

Embodiment 2

[0043] 1. Preparation of UF / DCPD microcapsules

[0044] Dissolve 1 part of urea with 8 parts of deionized water, add 2 parts of 37% formaldehyde solution, adjust the pH to 9 with triethanolamine, and keep it under 400rpm magnetic stirring at 70°C for 1h, then cool to room temperature to obtain a colorless Transparent and viscous urea-formaldehyde resin prepolymer aqueous solution A.

[0045] Under the conditions of 40°C water bath and 450rpm mechanical stirring, mix 0.5 parts of sodium dodecylbenzenesulfonate emulsifier and 10 parts of molten dicyclopentadiene, add 100 parts of deionized water, and stir for 30 minutes to obtain a stable The core material emulsified solution B.

[0046] Under 400rpm magnetic stirring, 20 parts by weight of solution A was added dropwise to 110.5 parts by weight of emulsion B prepared above, and 3 parts of urea-formaldehyde resin curing agent ammonium chloride and 5 parts of urea-formaldehyde were added After the resin water resistance modifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com