Gas current transformer

A current transformer and gas technology, applied in the field of transformers, can solve problems affecting product quality and safety performance, basin insulator insulation breakdown, shielding tube offset, etc., to achieve safe and reliable insulation performance, improved insulation reliability, The effect of ensuring the reliability of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

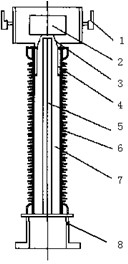

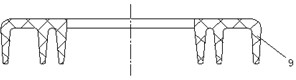

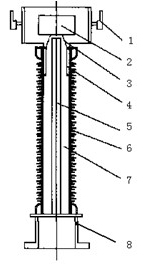

[0012] A gas current transformer, comprising a primary conductor 1, a secondary winding shield 2, a pot insulator 3, a high potential shielding cylinder 4, a secondary winding lead wire shielding tube 5, a hollow composite insulator 6, an SF 6 The gas 7 and the base 8, the primary conductor and the secondary winding shielding cover are set on the top, the bottom is the pot insulator, the high potential shielding cylinder, the secondary winding lead-out line shielding tube, the hollow composite insulator, and the secondary winding lead-out line shielding tube is set on In the hollow composite insulator, the hollow composite insulator is set on the base and filled with SF 6 The special feature is: the upper end of the secondary winding lead-out wire shielding tube is flush with the upper end of the pot insulator, and an insulating sleeve 9 is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com