Insulating and thermally conductive sheet

A technology of insulation and heat conduction and high heat conduction, which is applied in semiconductor devices, cooling/ventilation/heating transformation, semiconductor/solid-state device components, etc., and can solve problems such as heat conduction resistance, fiber uprightness not required, and high penetration density cannot be obtained. , to achieve the effect of ensuring the reliability of the insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

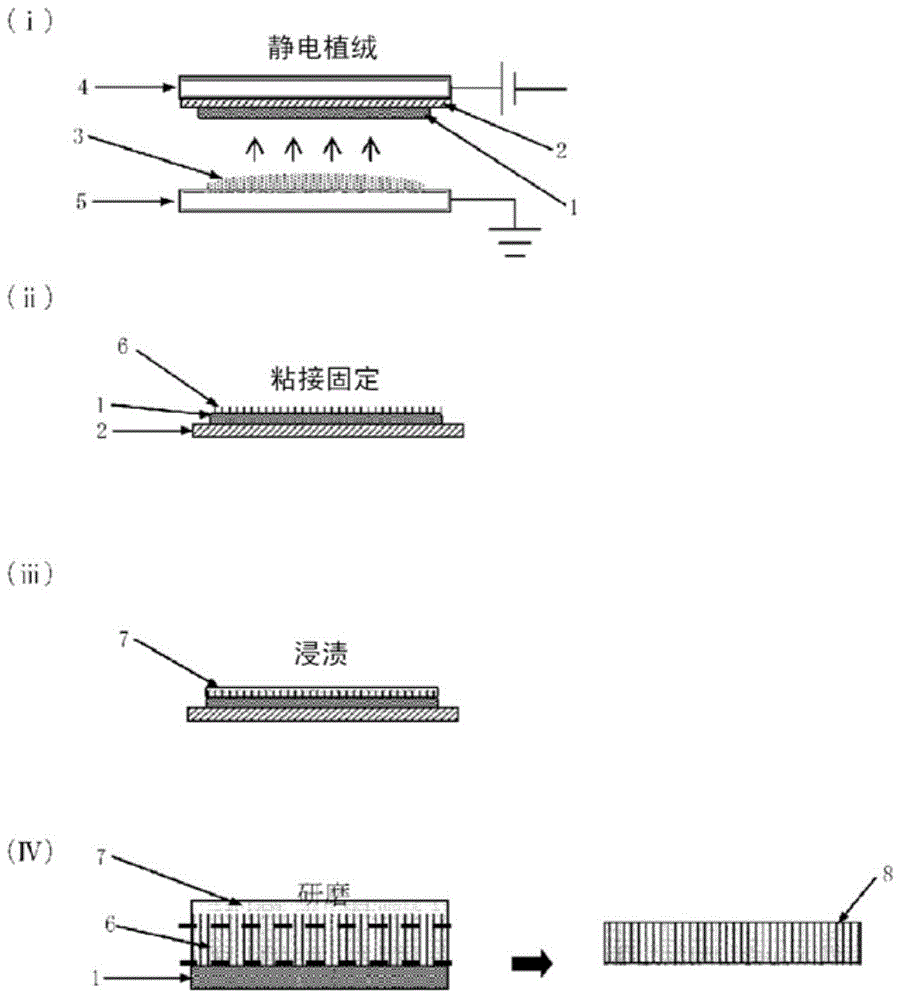

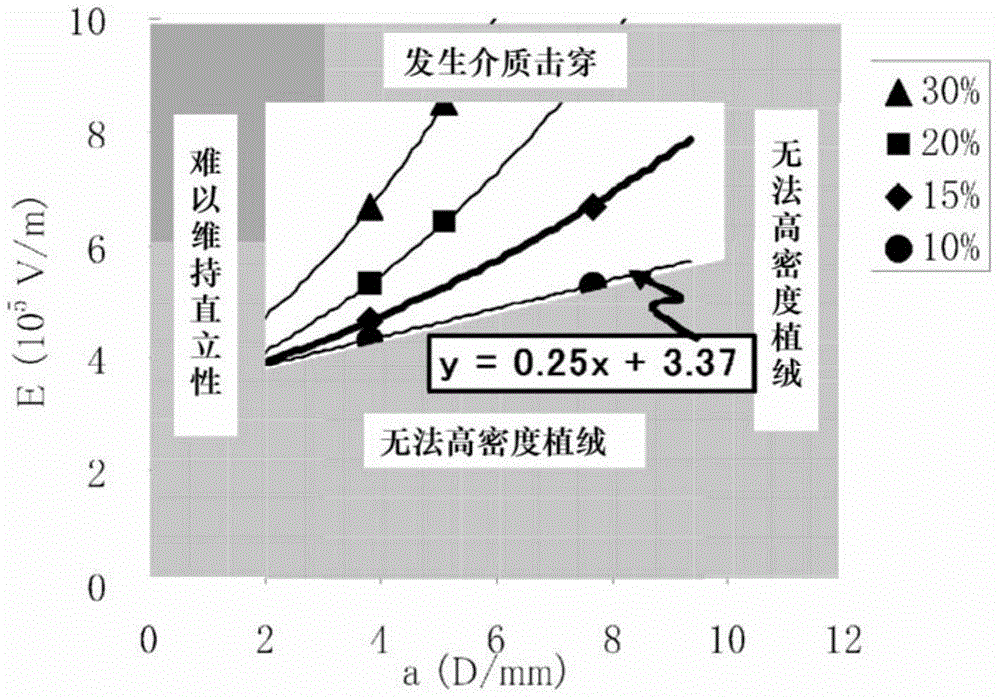

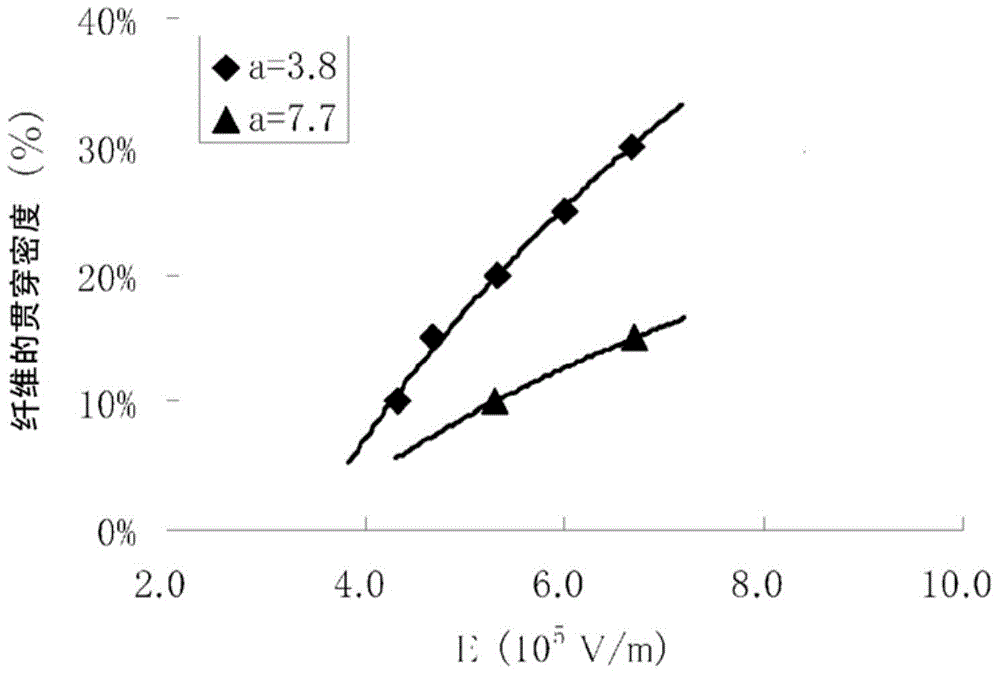

[0118] The thermal conductivity of ZylonHM(R) (manufactured by Toyobo Co., Ltd.) in the fiber axis direction was 40 W / mK. ZylonHM(R) cut to a length of 400 μm was used as insulating high-thermal-conductive fiber, and liquid silicone rubber main agent TSE3431-A / 100 parts by mass manufactured by Momentive Performance Materials Inc., Momentive Performance Materials was used as the binder resin solution. The liquid silicone rubber curing agent TSE3431-C manufactured by Inc. was mixed with 30 parts by mass of the resin solution. As an adhesive, a 10 wt.% aqueous solution of polyvinyl alcohol AH-26 (manufactured by Nippon Synthetic Chemicals) was used. As the base material, an aluminum foil with a thickness of 11 μm was used. A binder resin solution with a thickness of 25 μm was coated on the substrate on the positive electrode plate, and placed on top of the ground electrode plate provided with Zylon short fibers. The electrode spacing was set at 3 cm. Electrostatic flocking was...

Embodiment 2

[0120] As the binder resin solution, Toyobo Co., Ltd. saturated copolyester polyurethane solution UR3600 / 80.9 parts by weight, Toyobo Co., Ltd. saturated copolyester polyurethane solution BX-10SS / 12.0 parts by weight, Toyobo Co., Ltd. A Zylon complex ester urethane resin sheet was produced in the same manner as in Example 1 except that the epoxy resin AH-120 manufactured by the company was mixed with 7.1 parts by weight of the liquid. In addition, the sheet is in a semi-cured state in this state. The penetration density of the fibers was 26%. In actual use, the sheet in the semi-cured state is bonded to the exothermic body and the cooling body, and heated at 140°C for 4 hours to make it completely cured before use, so the volume resistivity is measured in the completely cured state. The volume intrinsic resistance of the fully cured sheet is 10 16 More than Ω·cm (measuring equipment exceeds the range).

Embodiment 3

[0122] As the binder resin liquid, a liquid obtained by mixing saturated copolyester polyurethane solution UR3575 / 100 parts by weight manufactured by Toyobo Co., Ltd. and epoxy resin HY-30 / 2.4 parts by weight manufactured by Toyobo Co., Ltd. was used. In addition, a Zylon complex ester polyurethane resin sheet was produced in the same manner as in Example 1. In addition, the sheet is in a semi-cured state in this state. The penetration density of the fiber is 26%, the volume inherent resistance of the sheet is 10 16 More than Ω·cm (measuring equipment exceeds the range).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com