High-insulation moisture-resistant back panel for crystal silicon photovoltaic module packaging

A technology for encapsulation and high insulation of photovoltaic modules, applied in photovoltaic power generation, electrical components, lamination devices, etc., can solve the problems of inability to take into account the comprehensive performance of high insulation and moisture resistance, poor insulation performance, and complicated preparation processes, so as to ensure long-term Reliability, interface delamination reduction, and comprehensive performance optimization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

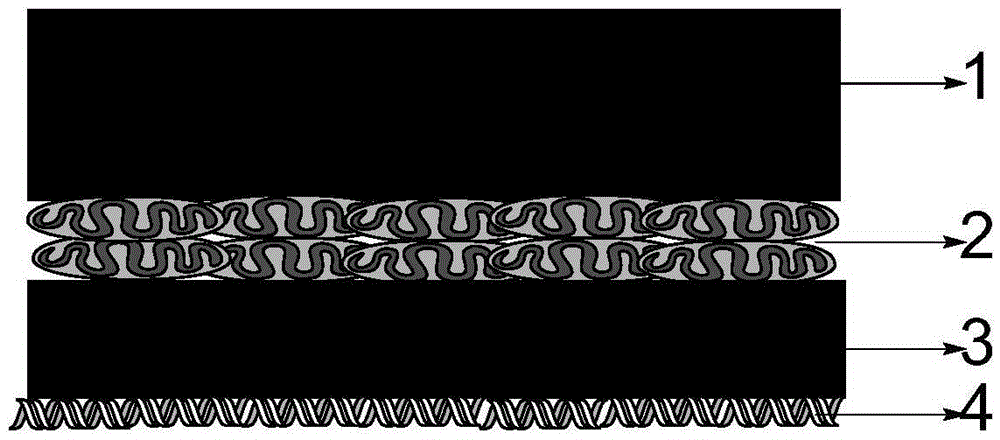

Image

Examples

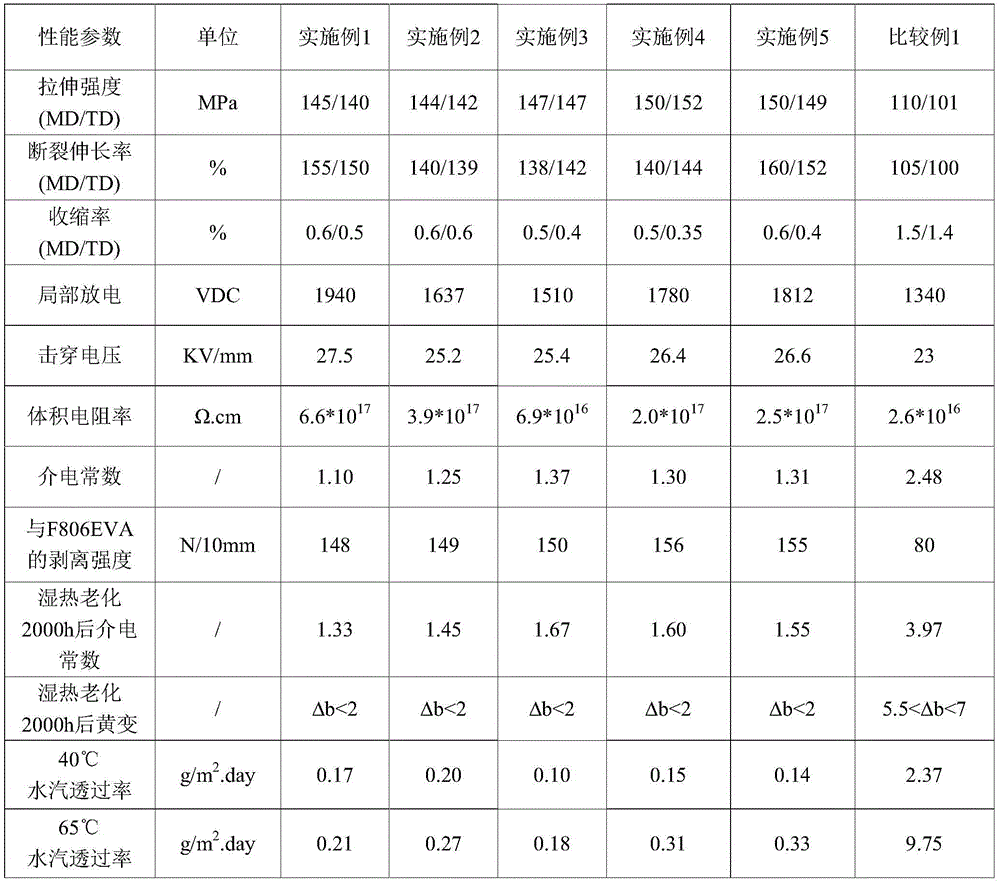

Embodiment 1

[0055] The backplane manufacturing process is as follows:

[0056] First, 85 wt% of polyethylene terephthalate (DuPont, USA), 10 wt% of iron chrome black (Sheeter, USA), 4 wt% of hydrolysis stabilizer P400 (Germany Rheinland Chemical Company), anti-thermal oxidation aging agent 2,6-Di-tert-butyl-4-methylphenol (Shenghe Chemical Co., Ltd.) 1wt%, mixed uniformly and melted at 250-300℃, then cast into a film, and biaxially stretched to obtain a thickness of 50 microns the support layer film.

[0057] In the second step, a 30-micron thick weather-resistant topcoat was rolled on one side of the support layer. The ingredients of the outer layer coating are 90wt% of fluororesin GK570 (Japan Daikin Co., Ltd.), 5wt% of carbon black MA-11 (Japan Mitsubishi Co., Ltd.), and 4.5wt% of cross-linking agent hexamethylene diisocyanate trimer (Germany Bayer Co., Ltd.) , the catalyst bis-dimethylaminoethyl ether (Jiubang Chemical Co., Ltd.) 0.5wt%. The raw materials are uniformly dispersed in...

Embodiment 2

[0061] The backplane manufacturing process is as follows:

[0062] First, polybutylene terephthalate (DSM, Netherlands) 80wt%, talc (Changxing Longfeng Powder Materials Co., Ltd.) 15wt%, hydrolysis stabilizer phenyl glycidyl ether (Hongyu Chemical Co., Ltd.) 4.9 wt%, anti-thermal oxygen aging agent 3,9-dioctadecyloxy-2,4,8,10-tetraoxo-3,9-diphosphospiro[5.5]undecane (Taiwan Yongguang Chemical Co., Ltd.) 0.1 wt %, mixed uniformly and melted at 250-300 DEG C, then cast to form a film, and biaxially stretched to obtain a 200-micron-thick support layer film.

[0063] Then, a 10-micron thick weather-resistant topcoat was roll-coated on one side of the support layer. The outer coating ingredients are 80wt% of fluororesin LF200 (Asahi Glass Co., Japan), 10wt% of titanium dioxide TR81 (Huntsman Co., USA), 5wt% of cross-linking agent isophorone diisocyanate prepolymer (Bayer, Germany) and methyl alcohol. Etherified polymethylol melamine resin (Huate Chemical Co., Ltd.) 4 wt %, cataly...

Embodiment 3

[0067] The backplane manufacturing process is as follows:

[0068] First, 80wt% of polyethylene terephthalate (DSM, Netherlands), 11.9wt% of filler mica powder (Fengshuo Chemical Co., Ltd.), 8wt% of hydrolysis stabilizer P400 (Germany Rheinland Chemical Co., Ltd.), 2 '-Methylenebis-(4-methyl-6-tert-butylphenol) (BASF, Germany) 0.1 wt%, mixed uniformly and melted at 250-300 °C, then cast into a film, biaxially stretched A 150 micron thick support layer film was produced.

[0069]Then, a 20-micron thick weather-resistant topcoat was roll-coated on one side of the support layer. The outer coating ingredients are fluororesin 41088 (Changxing Chemical) 68.2wt%, titanium dioxide CR-60-2 (Japan Ishihara Co.) 20wt% and anti-scratch powder (Botong Chemical Co., Ltd.) 10wt%, cross-linking agent hexamethylene Base diisocyanate trimer (Bayer, Germany) 1 wt%, catalyst dibutyltin dilaurate (Sinopharm Reagent Co.) 0.8 wt%. The raw materials are uniformly dispersed in solvents such as keto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com