EMI filter for image intensifier and assembling method thereof

A technology like an intensifier and an assembly method, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, electrical components, etc. problem, to achieve the effect of improving the electromagnetic compatibility performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

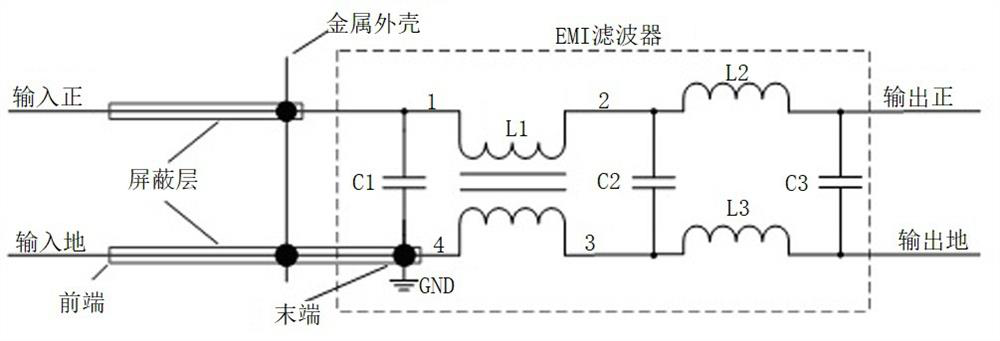

[0038] figure 1 It is a schematic diagram of the circuit principle of the EMI filter, and the parameter design and selection of each component are as follows.

[0039] The low-frequency ceramic capacitor C1 is a chip-type 0603 ceramic dielectric capacitor with a capacity of several uF, which is placed at the front end of the input to reduce the impedance of the input end and avoid abnormal power supply caused by input voltage resonance when connected to a linear stable impedance network (LSIN).

[0040] The high-frequency ceramic capacitor C2 is a chip type 0402 radio-frequency ceramic dielectric capacitor with a capacity of tens of pF and a high quality factor (Q value), especially requiring a low impedance between 100MHz and 1GHz, which is mainly driven by an external RS103 When the electric field common-mode interference coupling is introduced, the differential-mode current caused by the unequal impedance of the positive and negative lines to the ground provides a low-imped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com