Patents

Literature

38results about How to "Guaranteed assembly reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

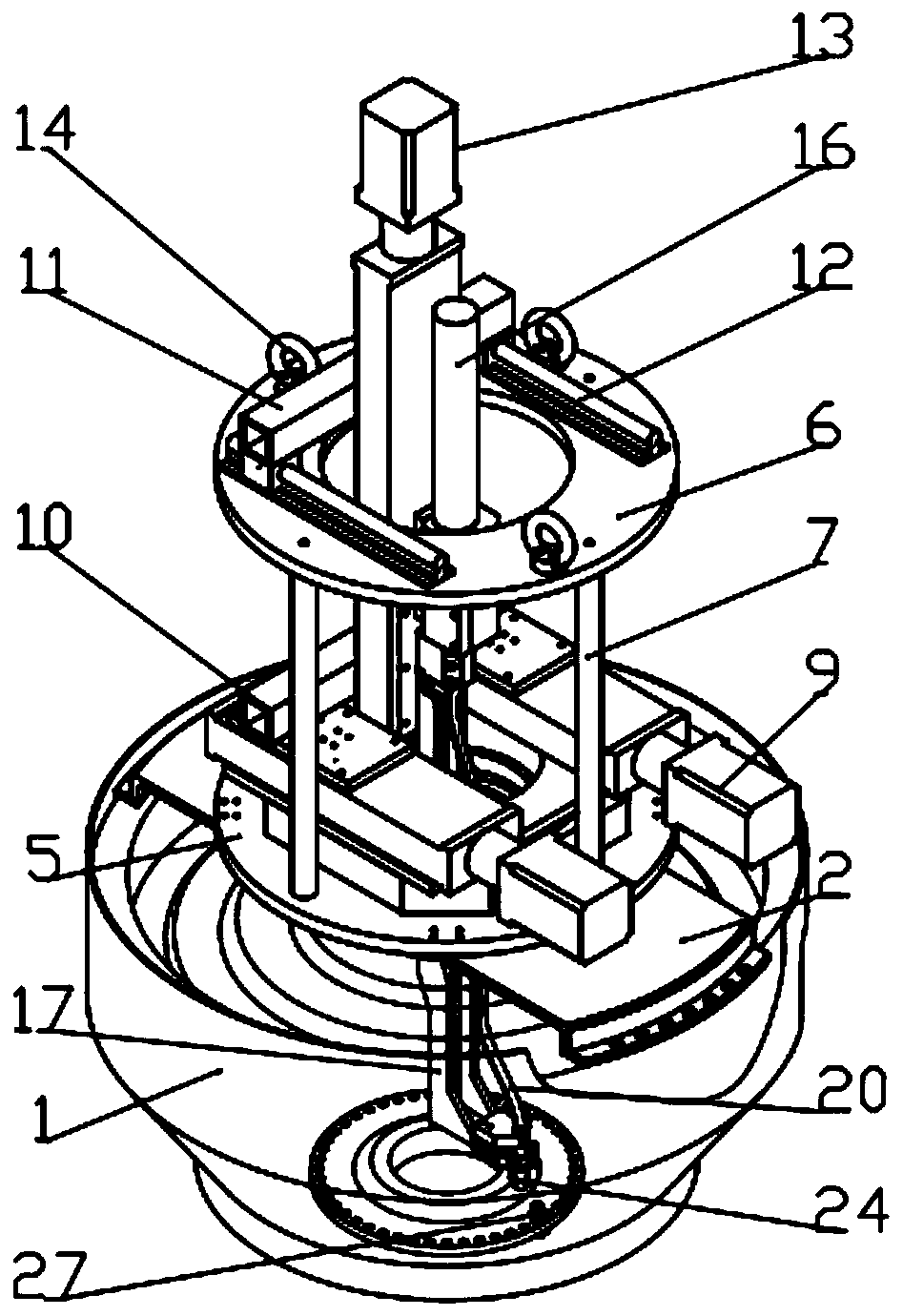

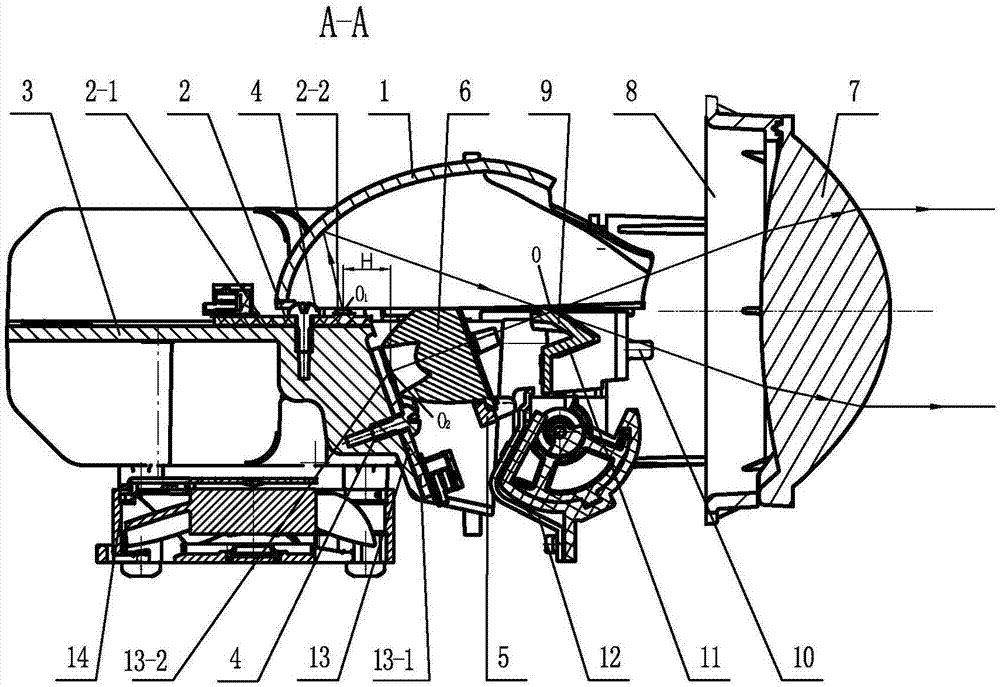

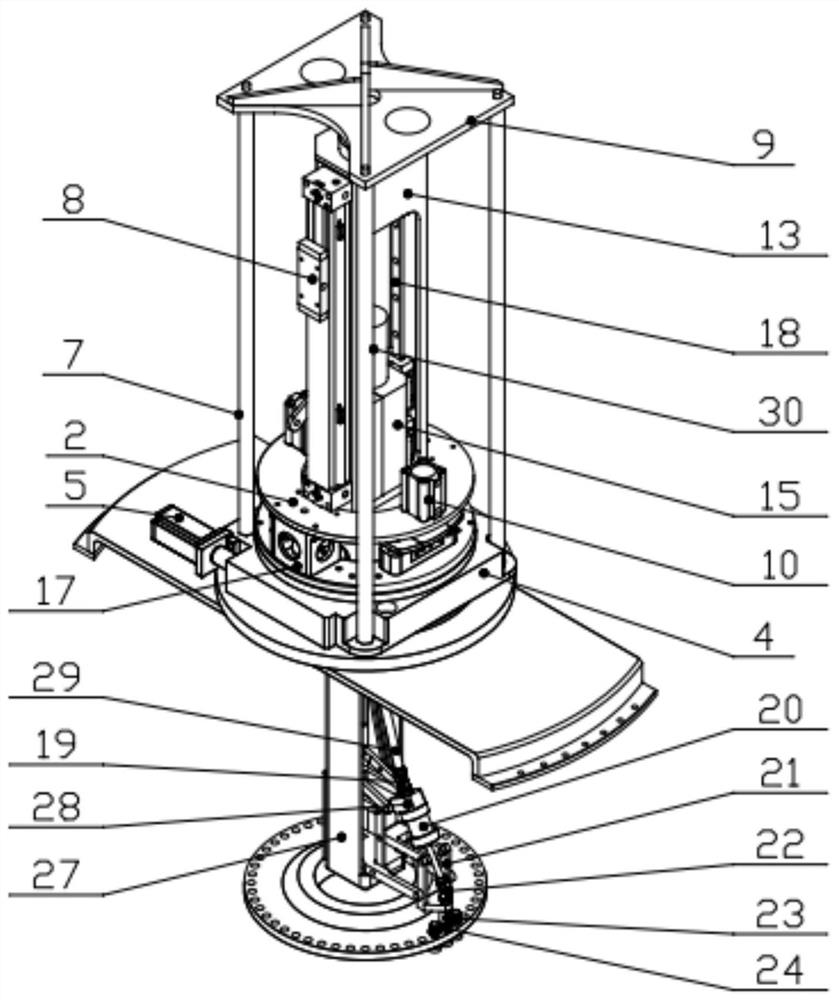

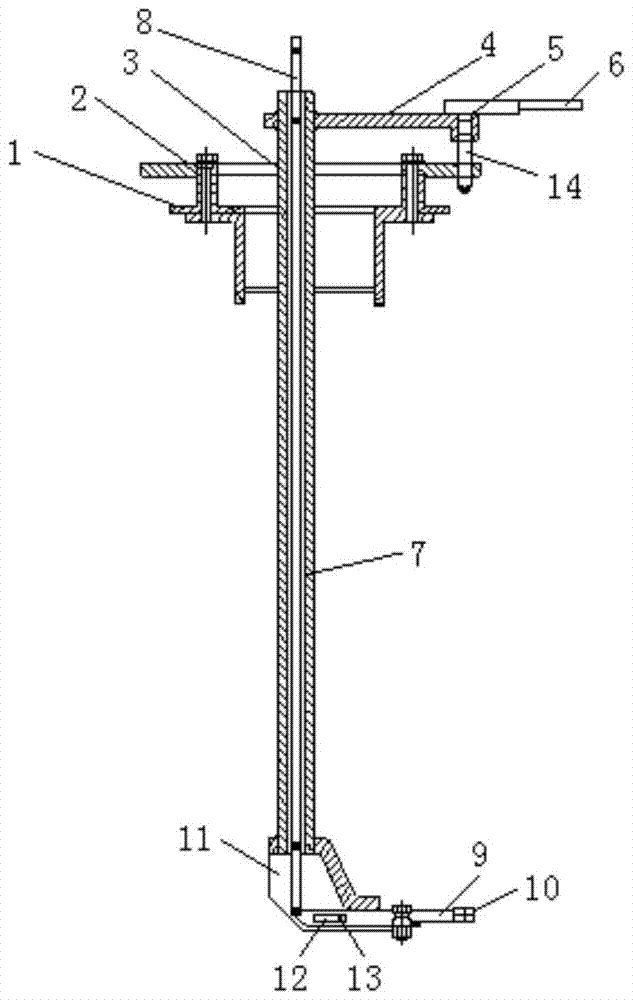

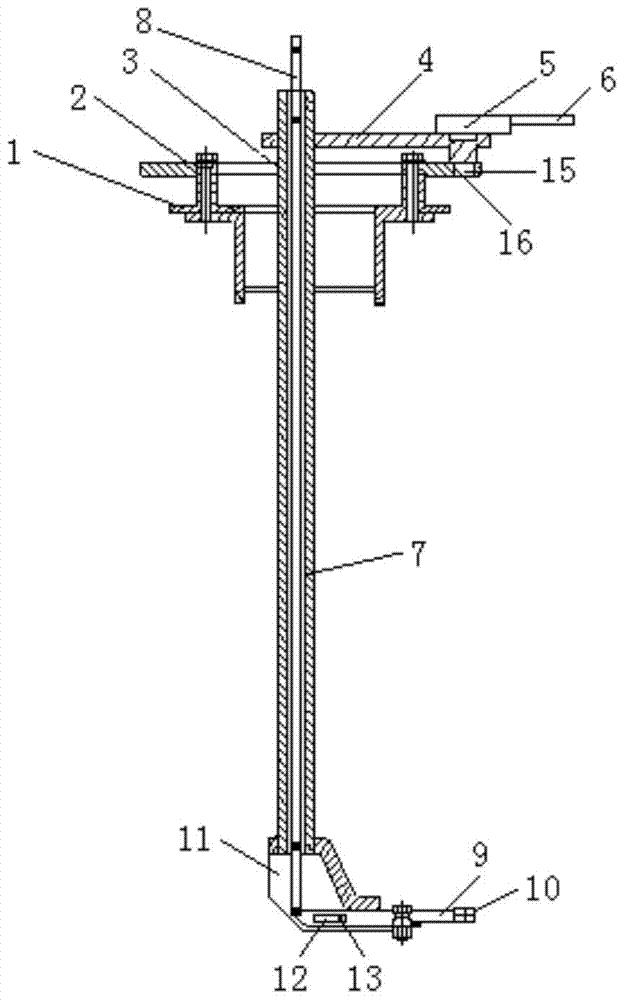

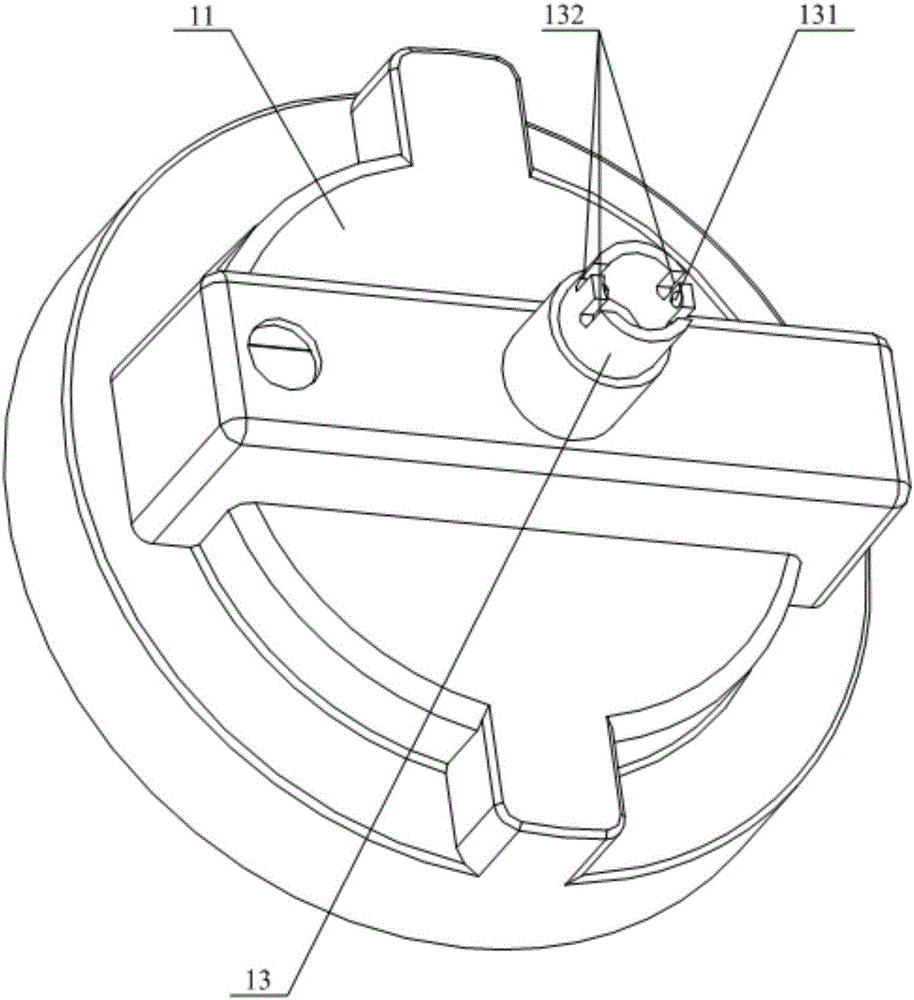

Aero-engine internal nut universal joint driven tightening device and method

InactiveCN110497190AHigh degree of automationHigh movement precisionMetal working apparatusEngineeringAviation

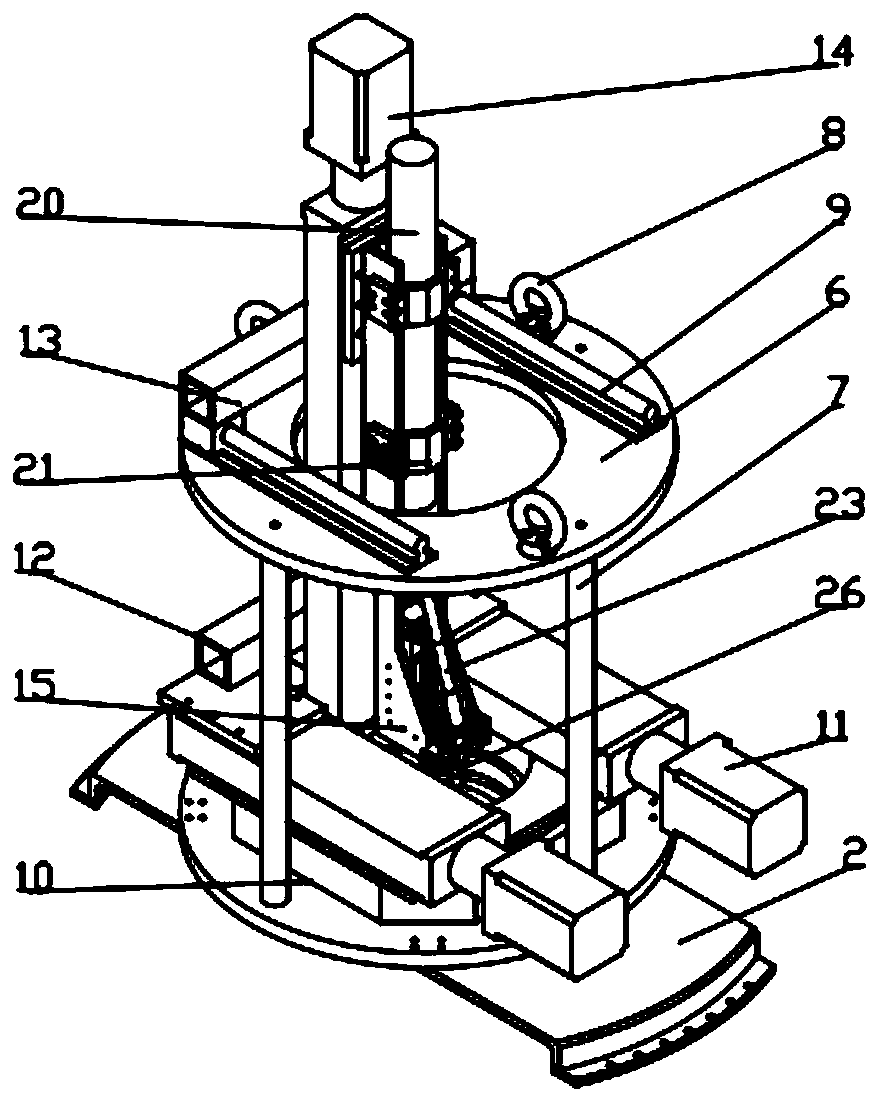

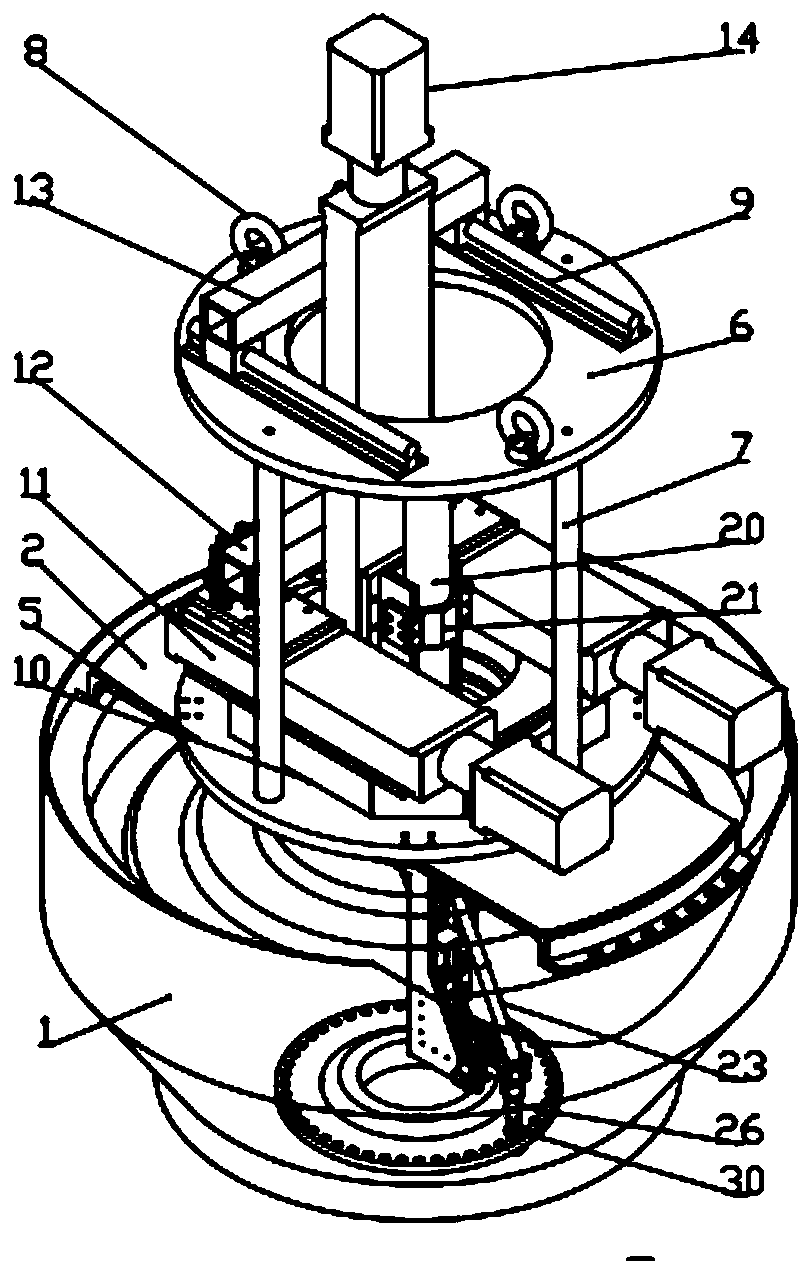

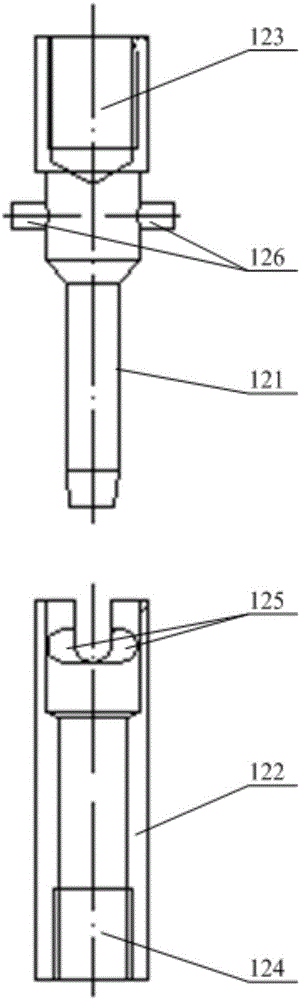

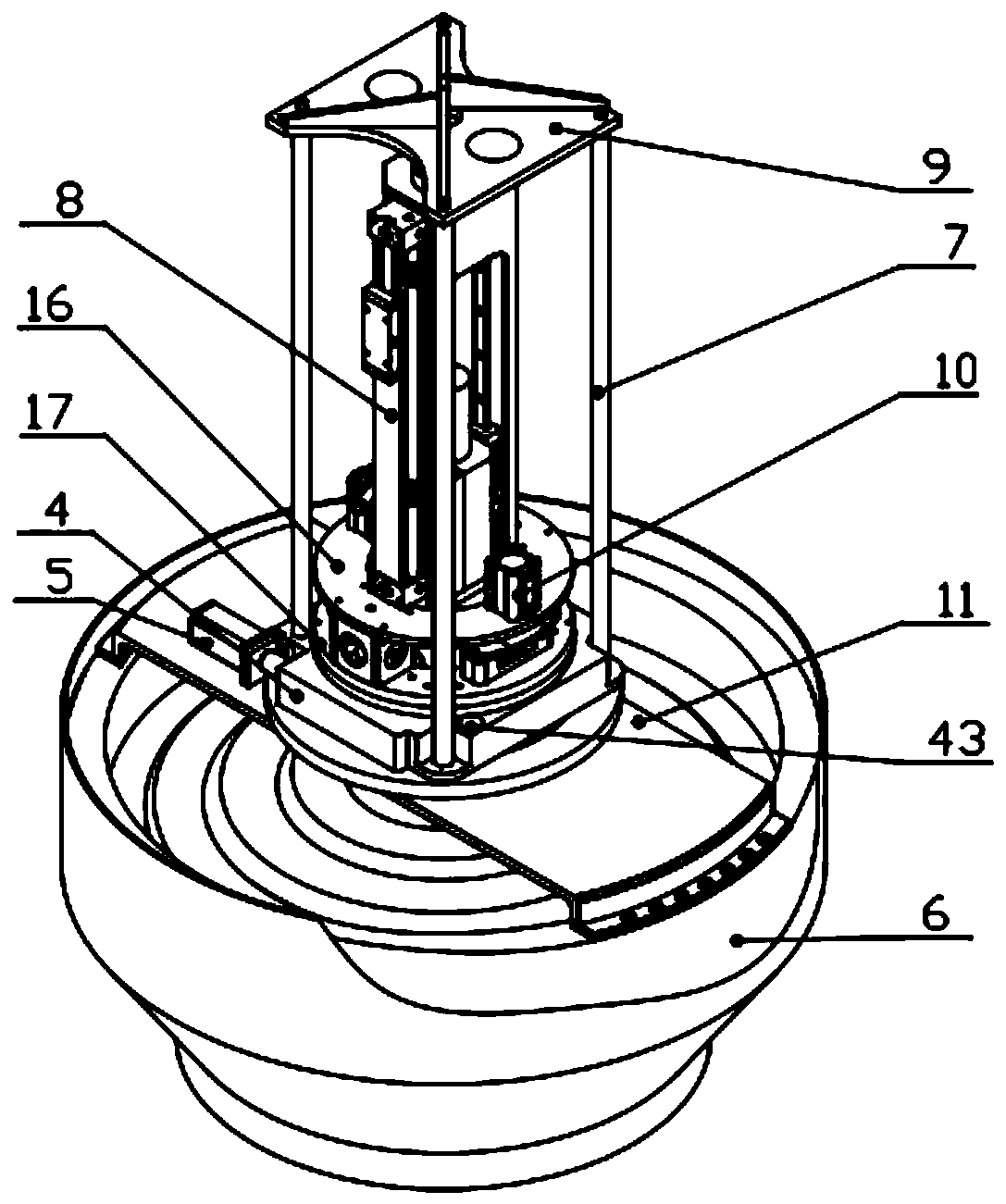

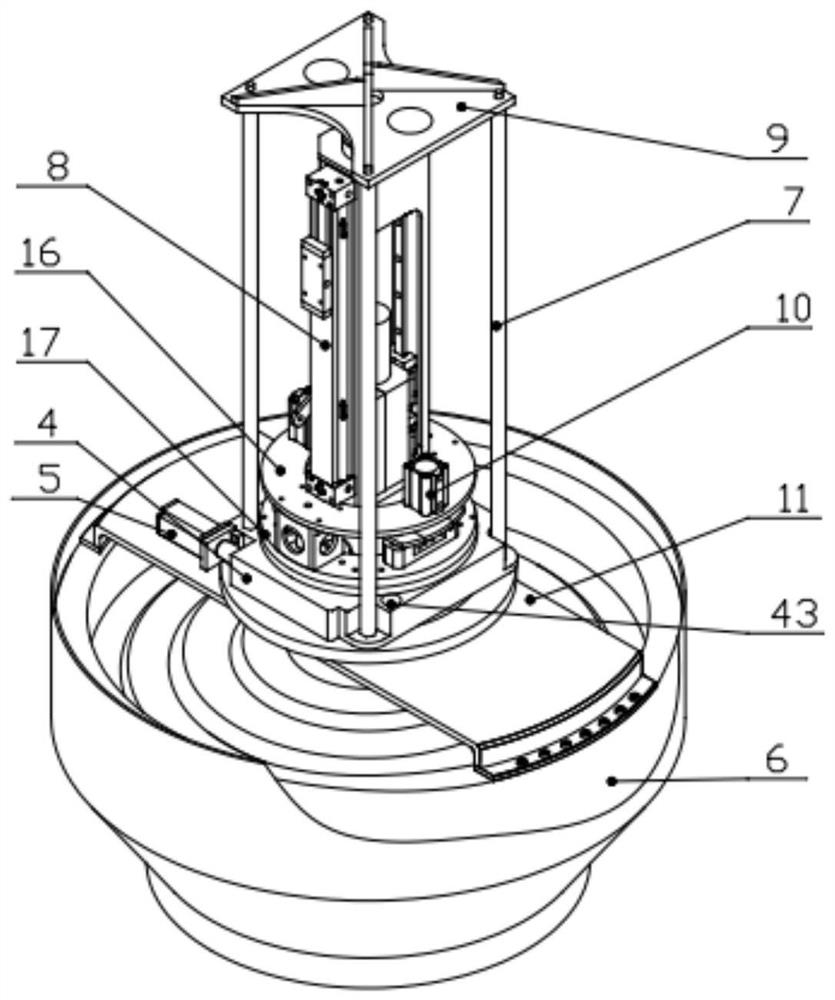

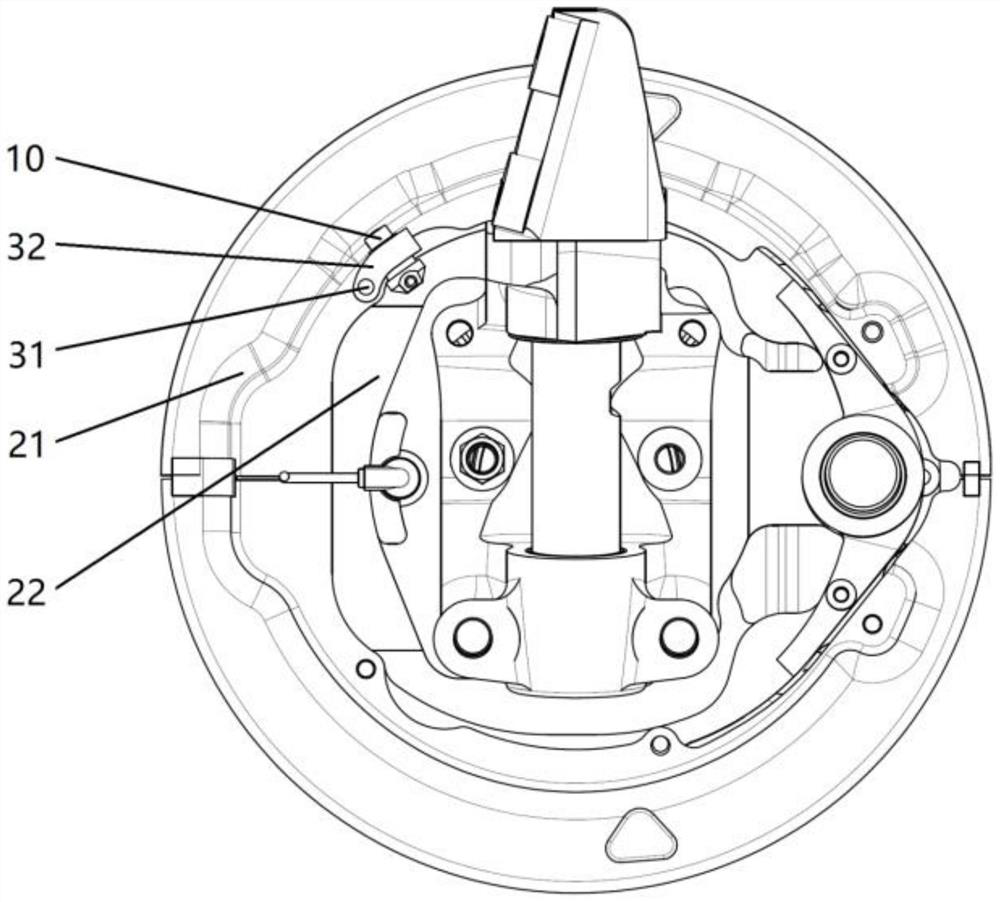

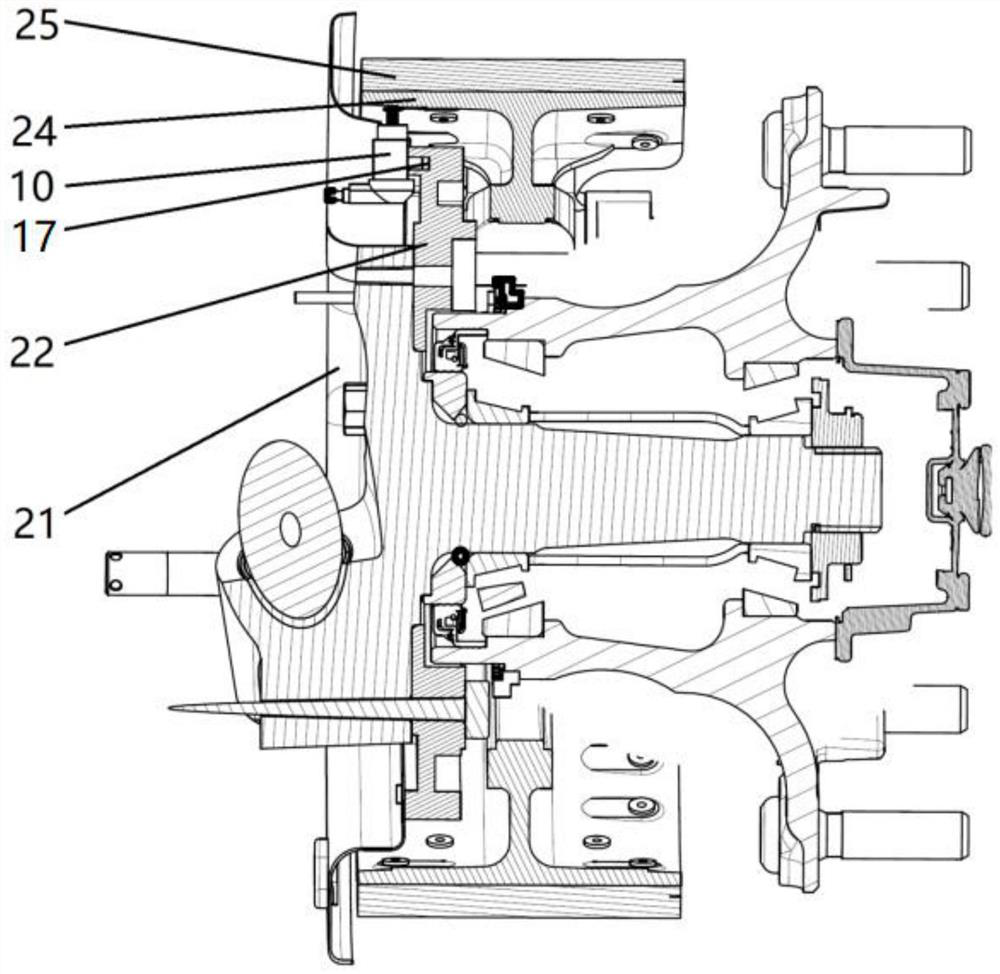

The invention discloses an aero-engine internal nut universal joint driven tightening device and method and belongs to the technical field of automatic assembly. The aero-engine internal nut universaljoint driven tightening device comprises a tool pre-locating system, a nut alignment locating system and a universal joint tightening system. A nut to be tightened is sleeved with a tightening sleevethrough the nut alignment locating system. A tightening motor drives the tightening sleeve to complete tightening operation. The aero-engine internal nut universal joint driven tightening device adopts the automatic operation mode to implement the steps of coaxially locating the tightening device and a rotor shell, rotating the tightening sleeve to the nut to be tightened, tightening the nut andthe like, has the characteristics of being high in automation degree, motion precision and tightening precision, reduces manual operation tasks, greatly simplifies the operation process, avoids errorscaused by manual operation and ensures the tightening consistency of the internal nut, and the working efficiency of whole machine assembling is improved.

Owner:DALIAN UNIV OF TECH

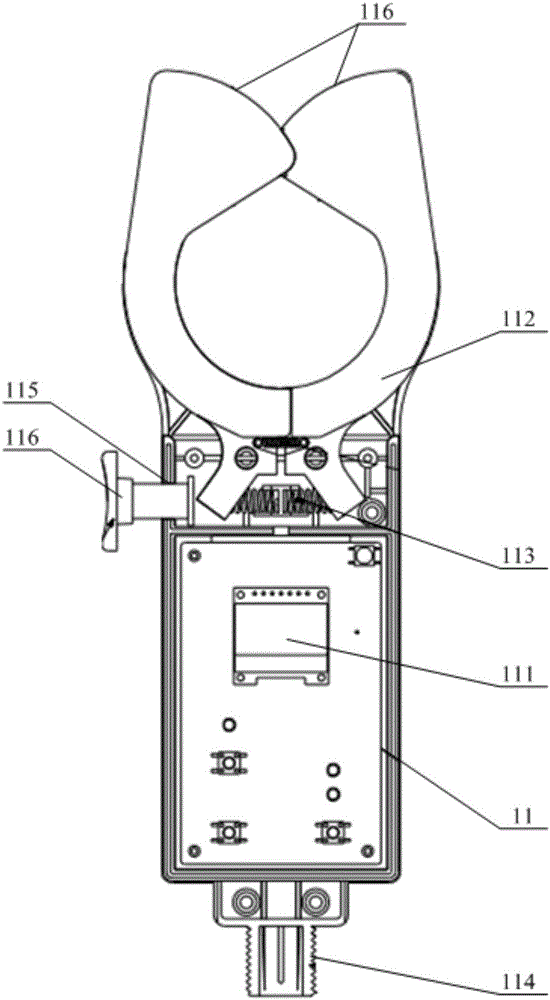

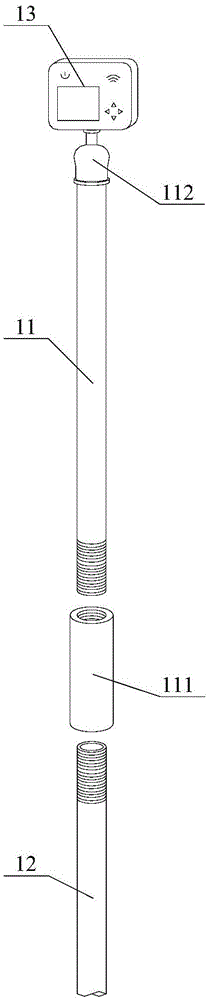

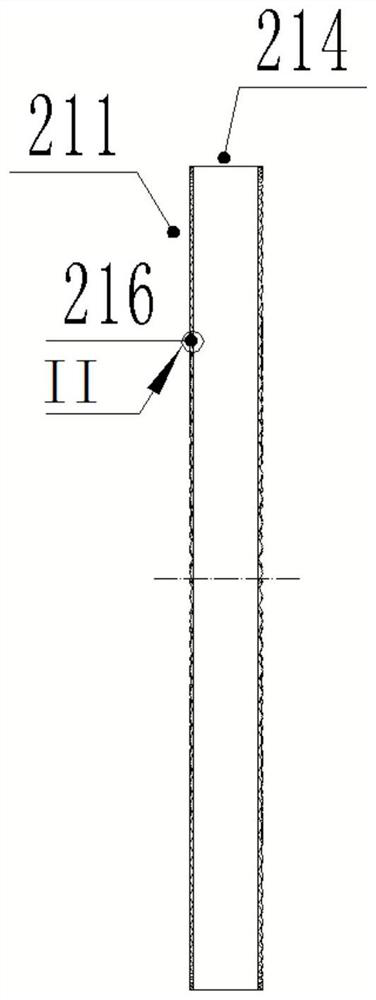

Electric leakage detection device

InactiveCN106370971AAvoid working at heightsAvoid operabilityElectrical testingMeasurement instrument housingEngineeringElectrical and Electronics engineering

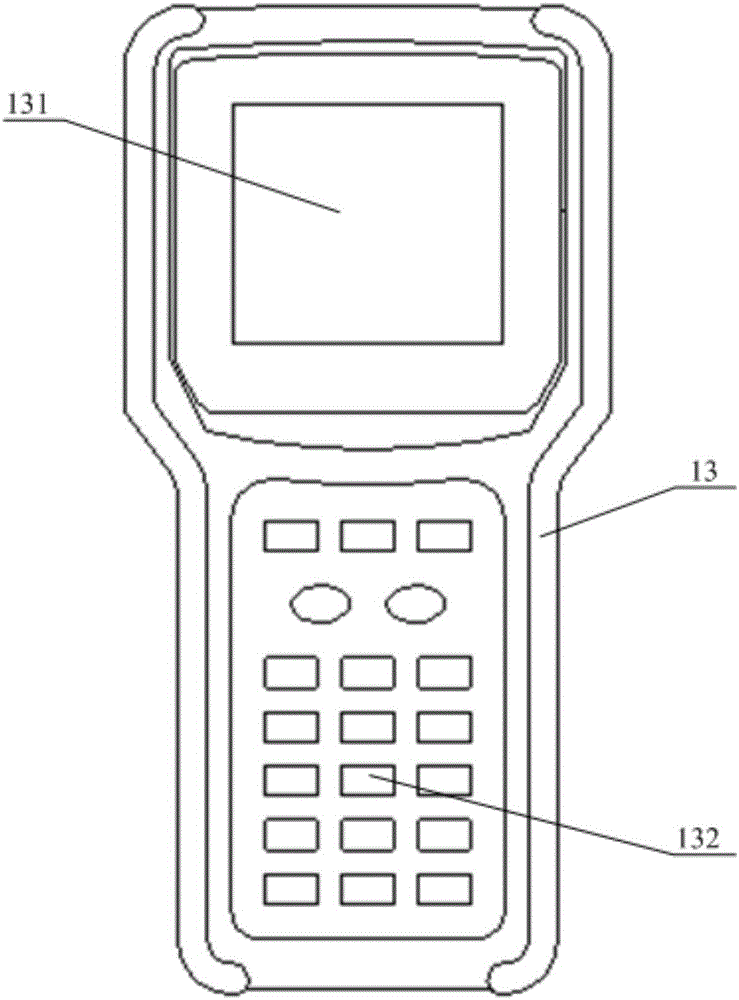

The invention discloses an electric leakage detection device. The electric leakage detection device comprises a detection terminal, an insulated extension rod and a control terminal in wireless communication with the detection terminal, wherein an installation connector is connected between the detection terminal and the insulated extension rod; the detection terminal comprises a machine body; a detection module is arranged at the middle part of the machine body; a clamp is retractably arranged at the front end part of the machine body; a reset piece is clamped and connected between the inner end parts of two clamp bodies of the clamp; the control terminal comprises a handheld machine; the handheld machine is provided with a display screen and a keyboard. The electric leakage detection device disclosed by the invention is capable of safely and efficiently implementing electric leakage detection under different working conditions.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +1

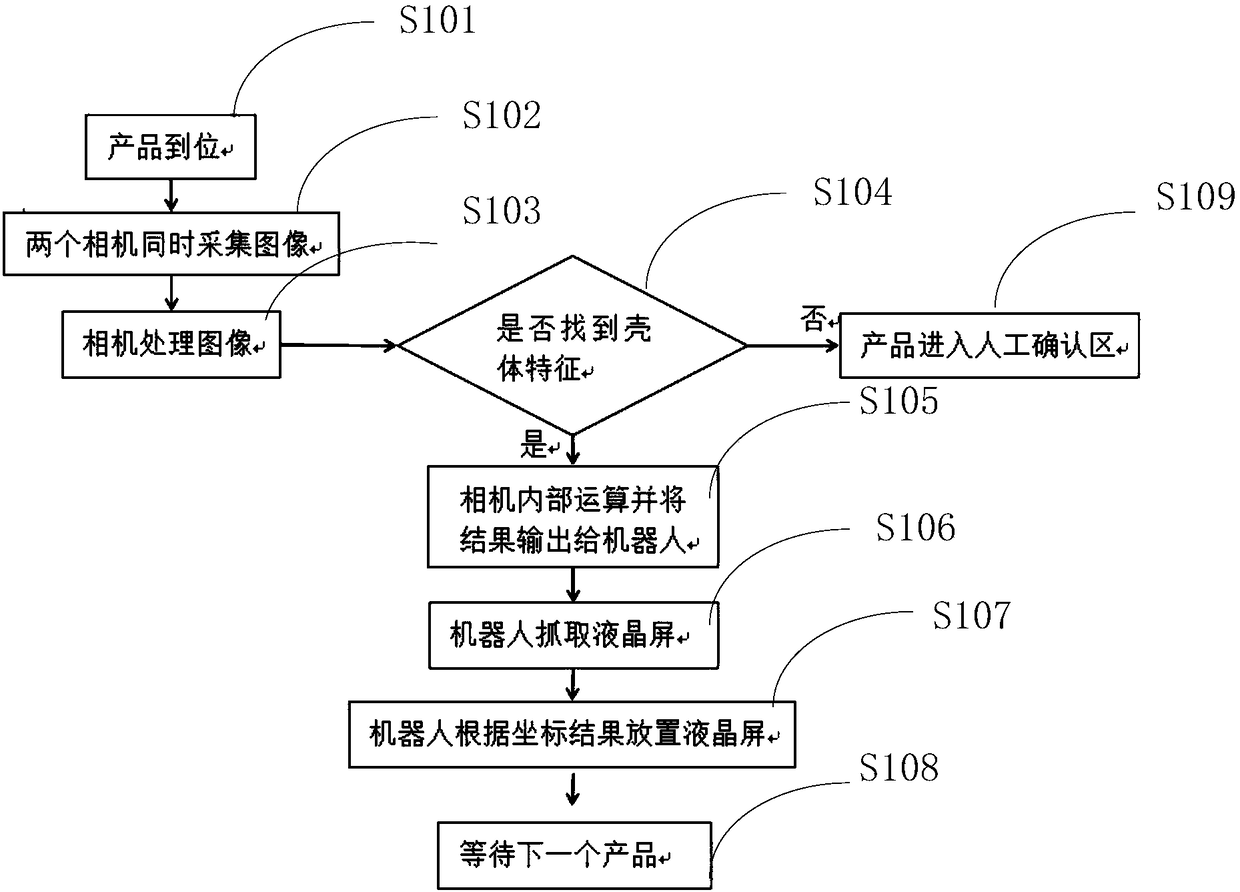

Method for positioning and grabbing electronic liquid crystal display screens with different sizes

ActiveCN105856241AReduce occasional errorsReduce labor costsProgramme controlProgramme-controlled manipulatorLiquid-crystal displayComputer science

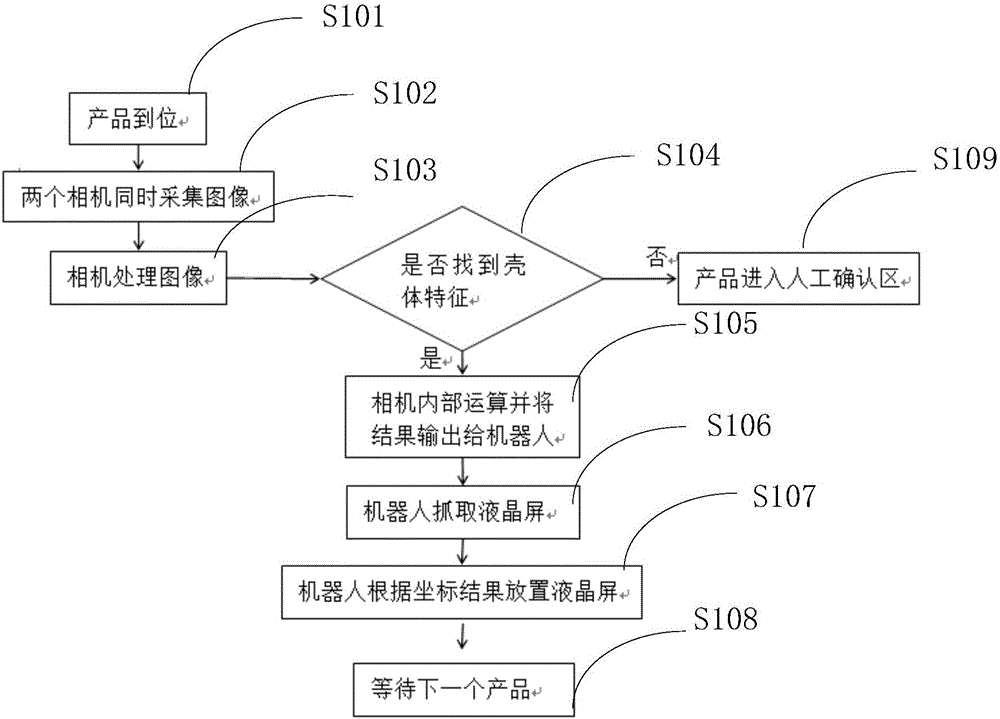

The invention discloses a method for positioning and grabbing electronic liquid crystal display screens with different sizes. The method includes simultaneously acquiring images by the aid of two cameras; processing the images; searching for characteristics of shells; carrying out interior operation by the aid of the cameras and outputting operation results to robots; grabbing the liquid crystal display screens by the aid of the robots; arranging the liquid crystal display screens by the aid of the robots according to the operation results. The method has the advantages that an integral assembling procedures for grabbing and positioning each liquid crystal display screen and accurately arranging the liquid crystal display screen in the corresponding shell can be completed within the time no longer than 5 seconds, and accordingly the efficiency can be improved by more than 20 times as compared with the labor efficiency; work can be continuously carried out throughout the day all year round; only initial investment is required, and the cost can be correspondingly reduced by the cost for five workers; personnel operation can be omitted, accordingly, occasional errors due to personnel assembly and detection can be greatly reduced, and the assembly reliability can be guaranteed; the method is compatible to the liquid crystal display screens with different dimensions, only additional programs are required, and additional mechanical structures can be omitted; personnel do not need to be in contact with the liquid crystal display screens, and accordingly risks of product damage and product contamination can be prevented.

Owner:SHANGHAI BETTERWAY AUTOMATION CO LTD

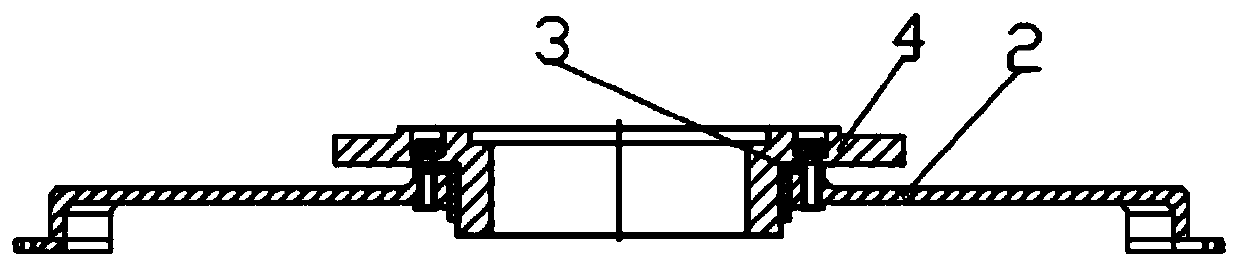

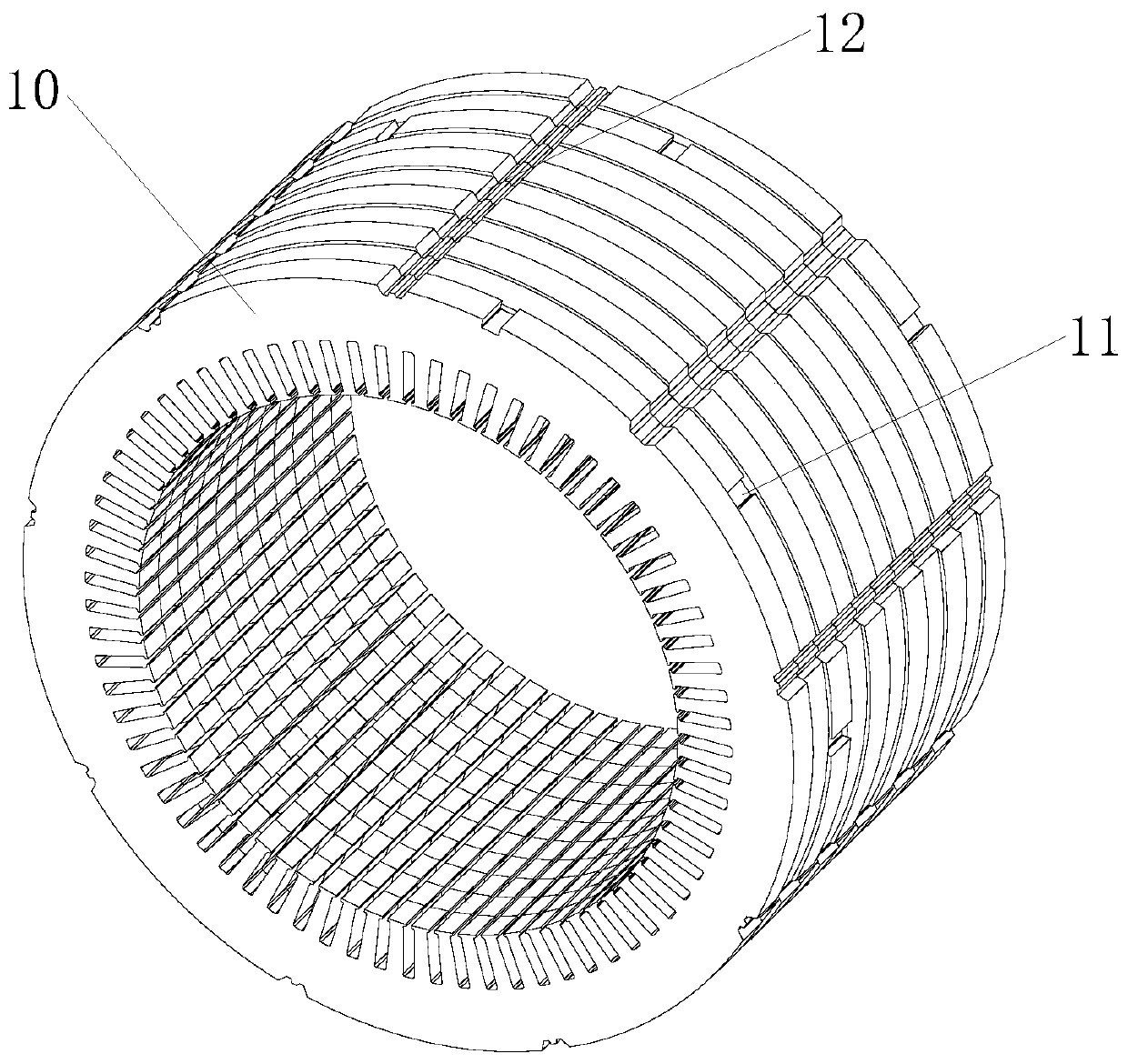

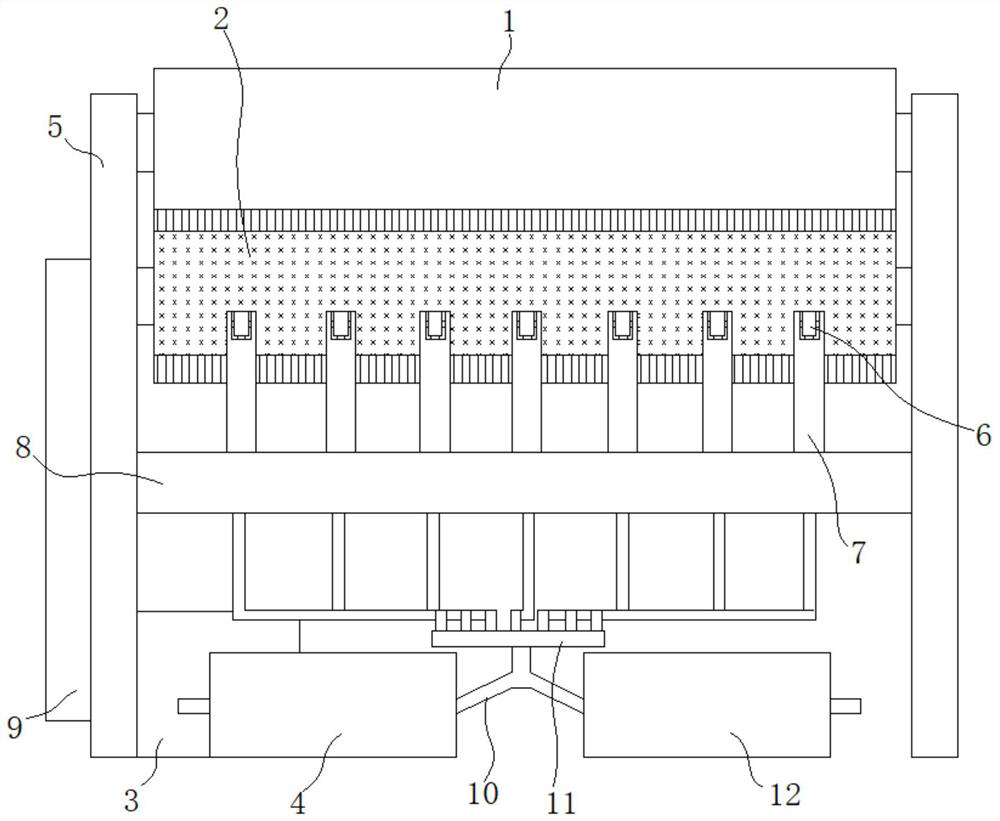

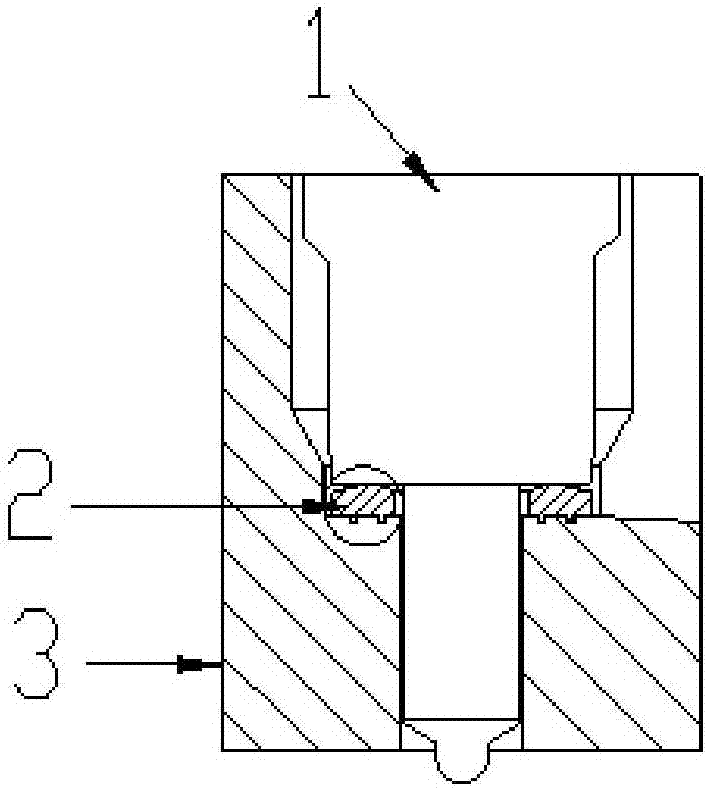

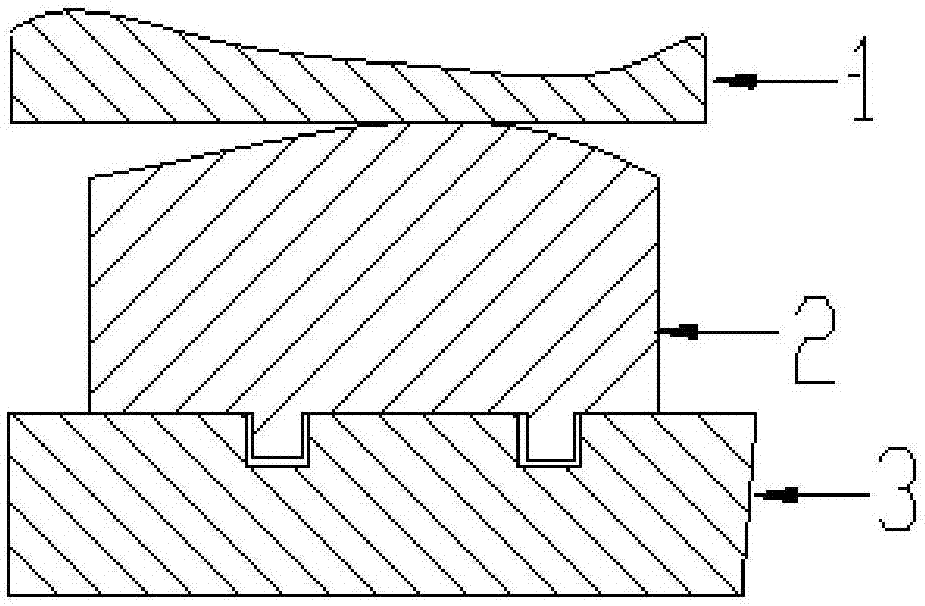

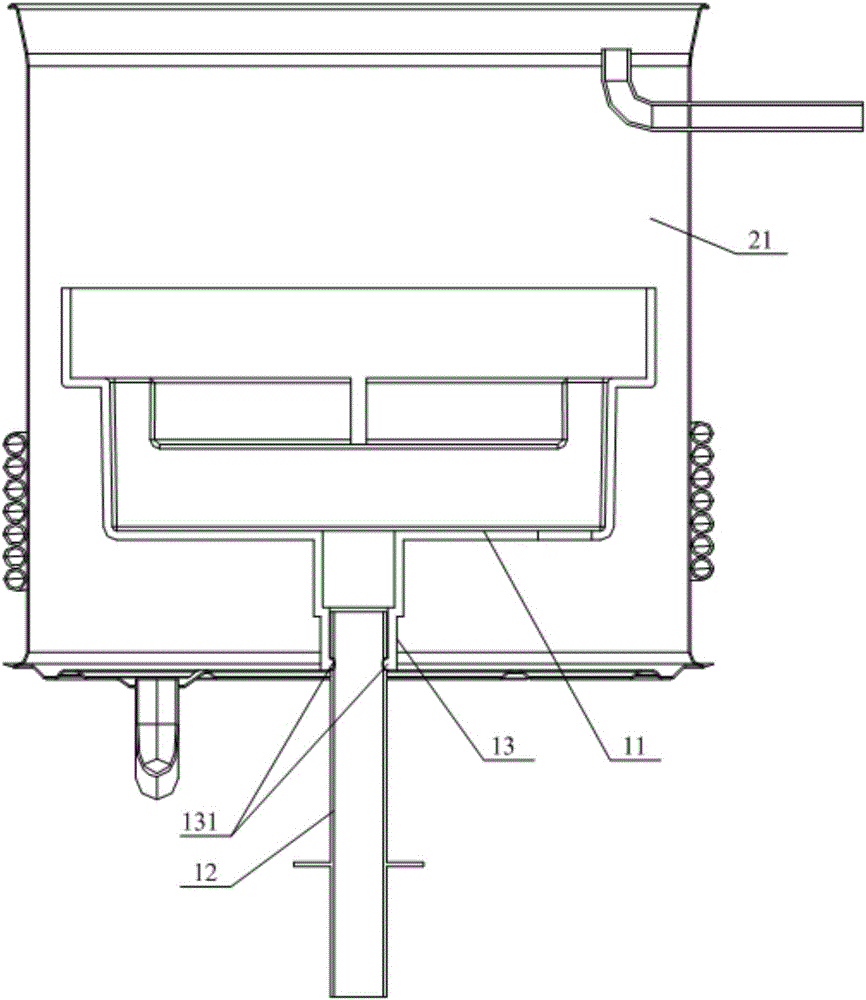

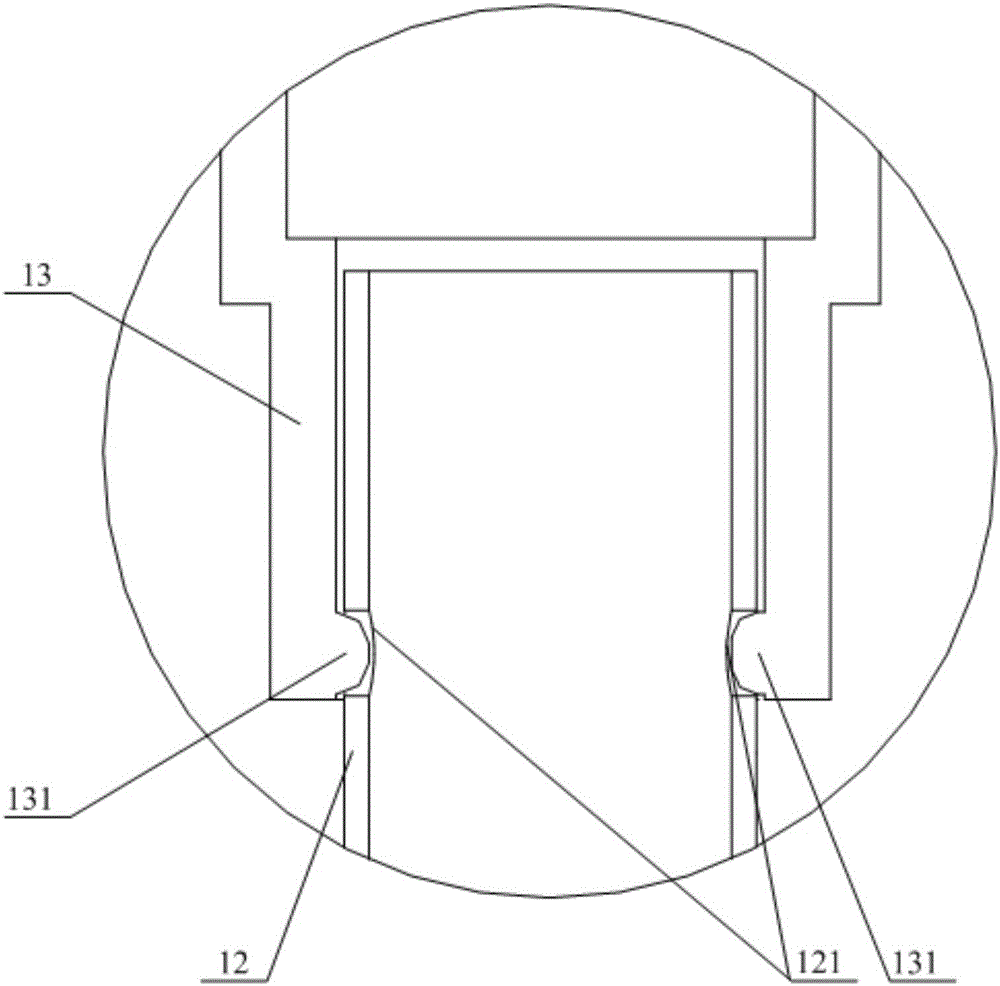

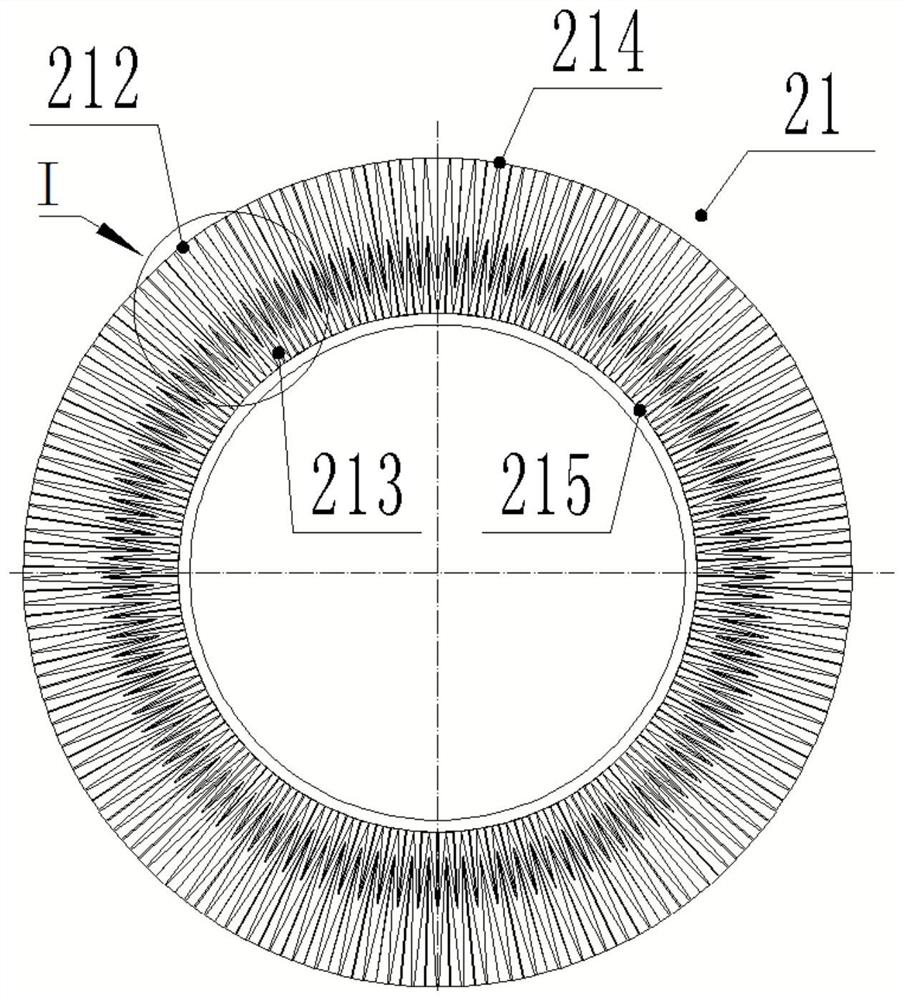

Oil circuit structure of oil-cooled motor

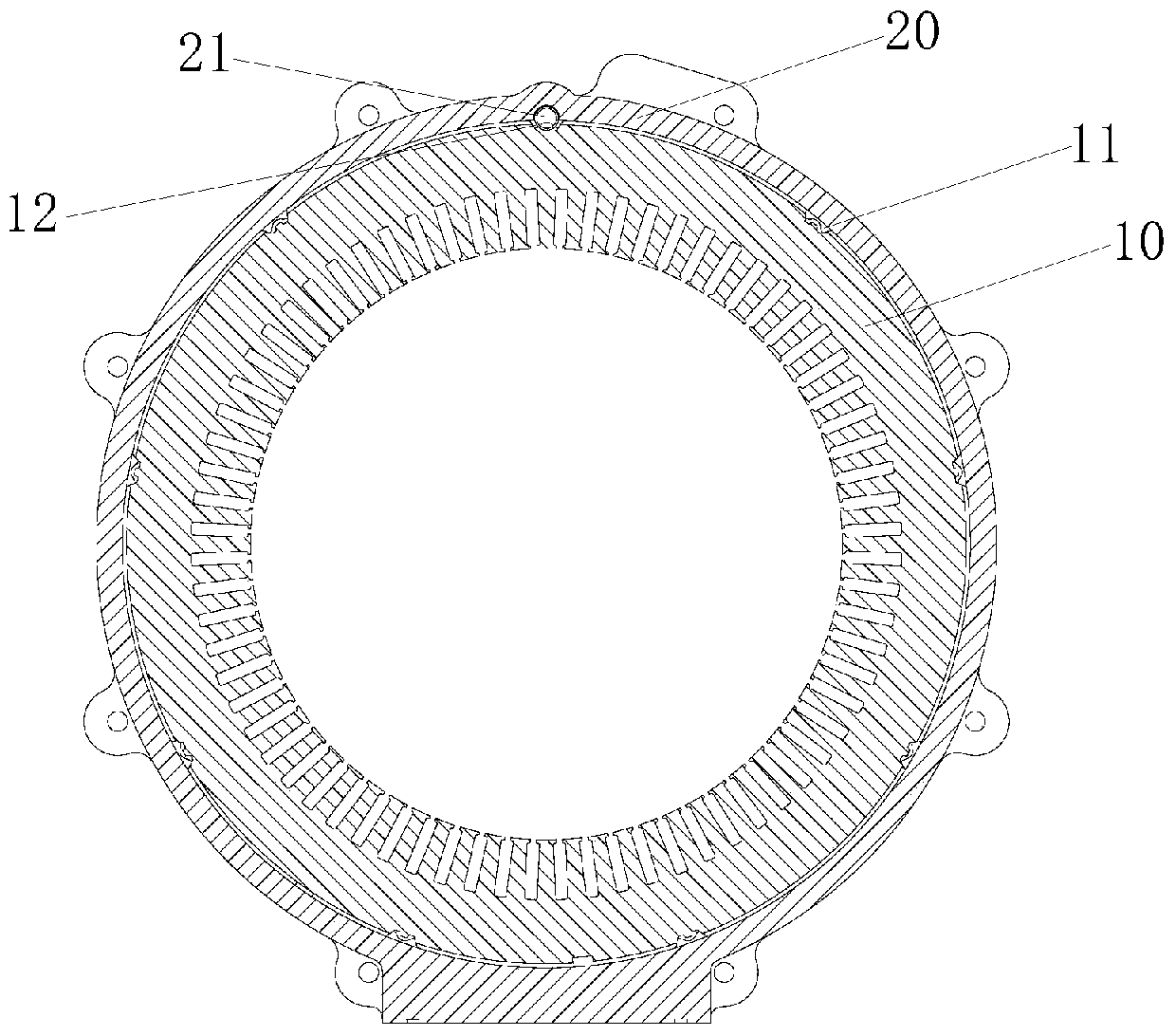

PendingCN110855083AGuaranteed assembly reliabilityCooling/ventillation arrangementSupports/enclosures/casingsElectric machineEngineering

An object of the present invention is to disclose an oil circuit structure of an oil-cooled motor. At least one groove is disposed in the circumferential direction of an outer circle of the stator core, and at least one groove is disposed in the axial direction of the outer circle of the stator core. Each groove has a certain depth. An oil passage is arranged between the inner wall of a motor casing and the stator core. The groove in the axial direction of the outer circle of the stator core introduces cooling oil through the oil passage. Compared with the prior art, the outer circle of the stator core has grooves in the circumferential direction and the axial direction, and is in interference, transition or clearance fit with the inner wall of the motor casing. The oil passage is arrangedbetween the inner wall of the motor casing and the outer circle of the stator core and can be filled with the cooling oil through an oil pipe, a through hole in the motor casing or other things. On the premise of ensuring the assembly reliability of the motor, the cooling oil is in contact with heat-generating components to dissipate heat, thereby achieving the object of the present invention.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

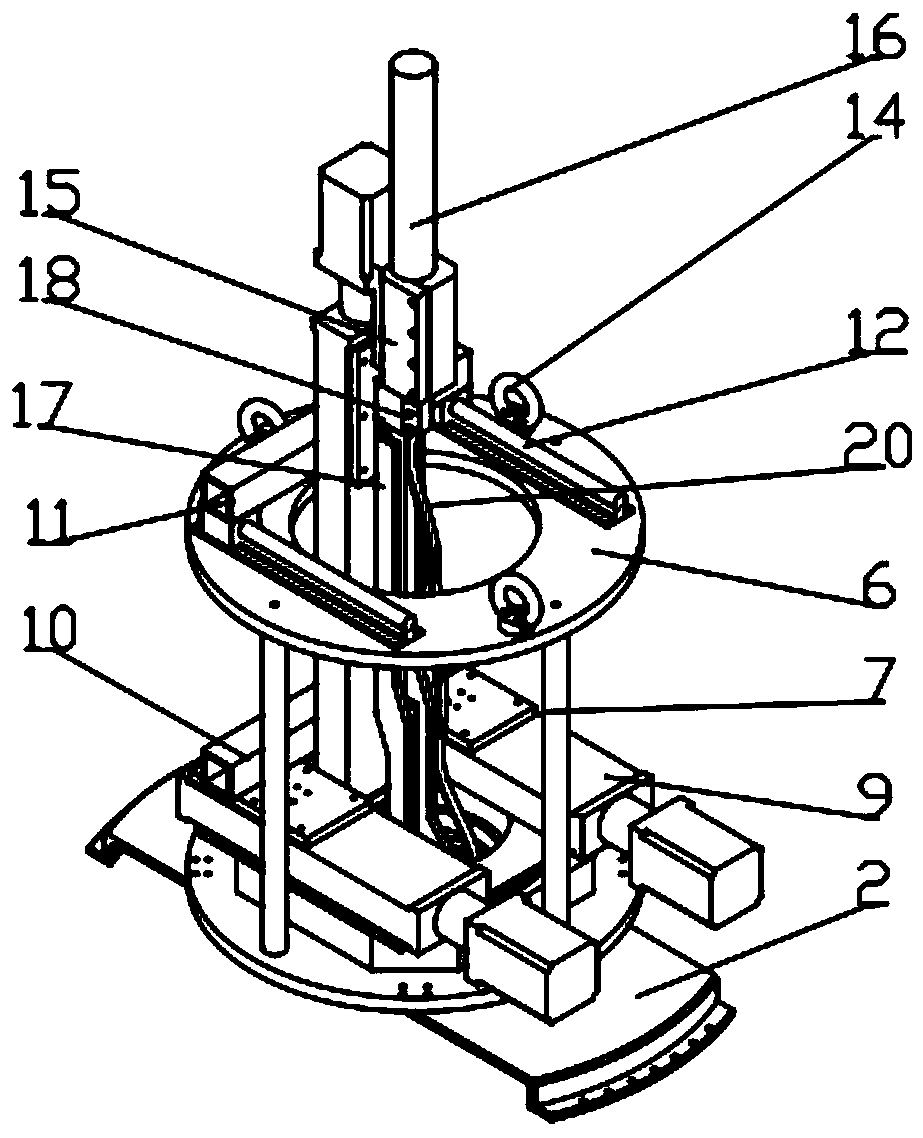

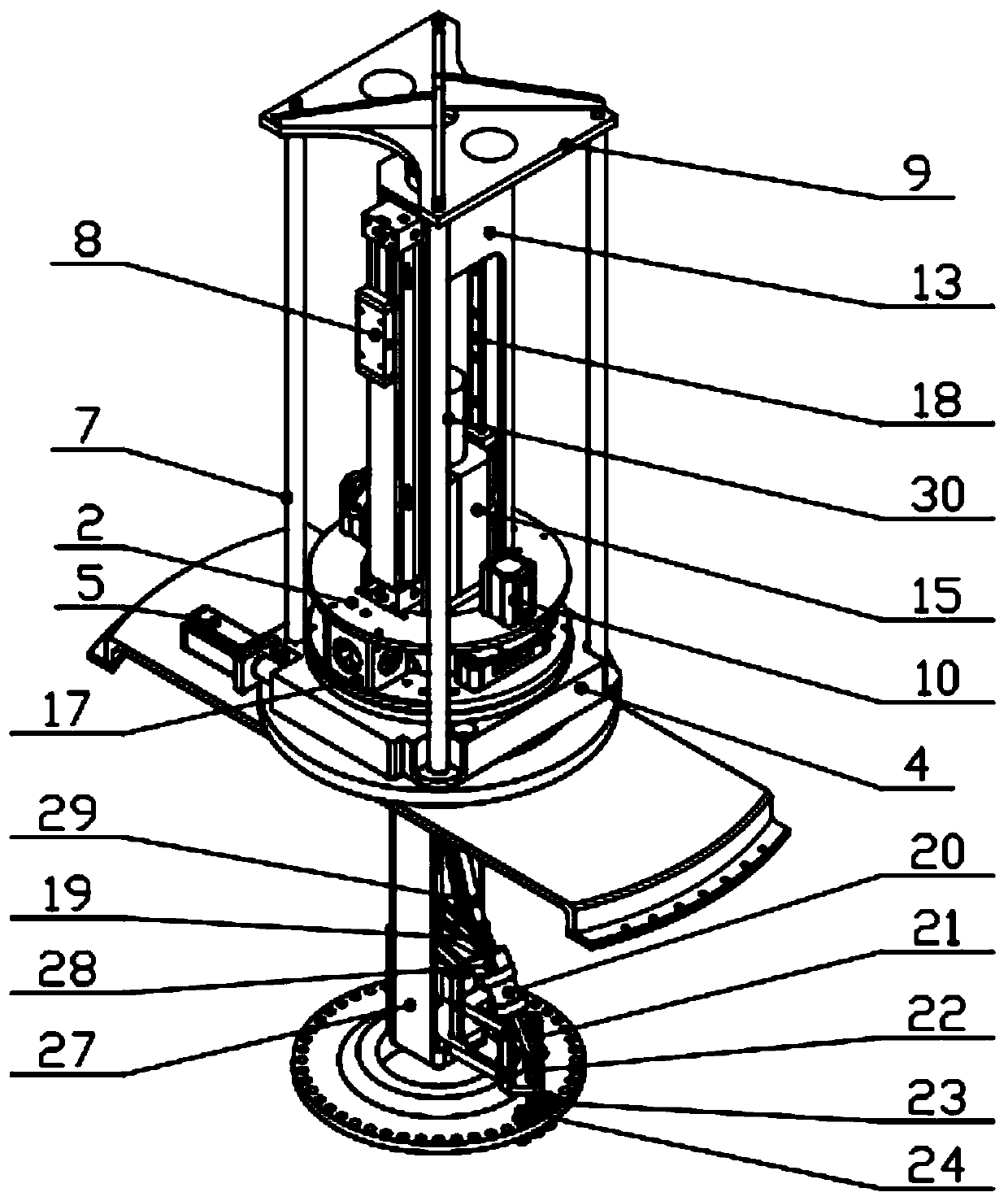

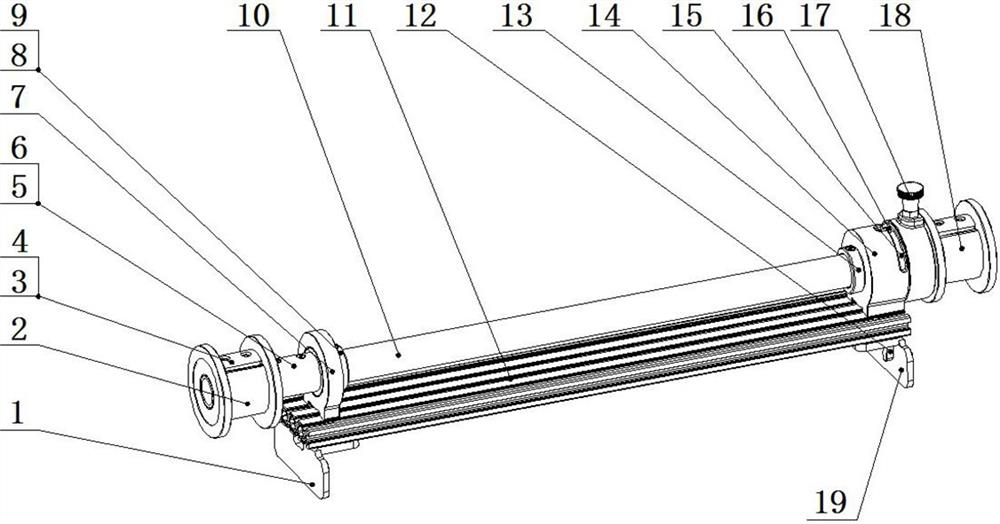

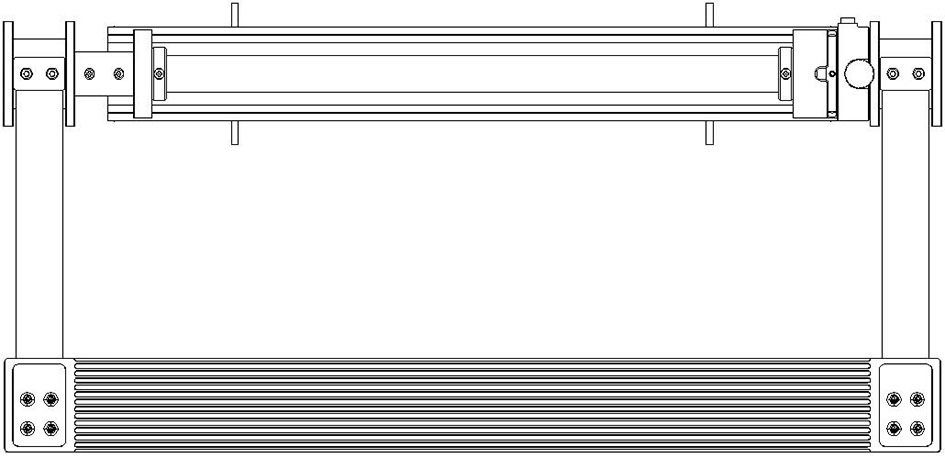

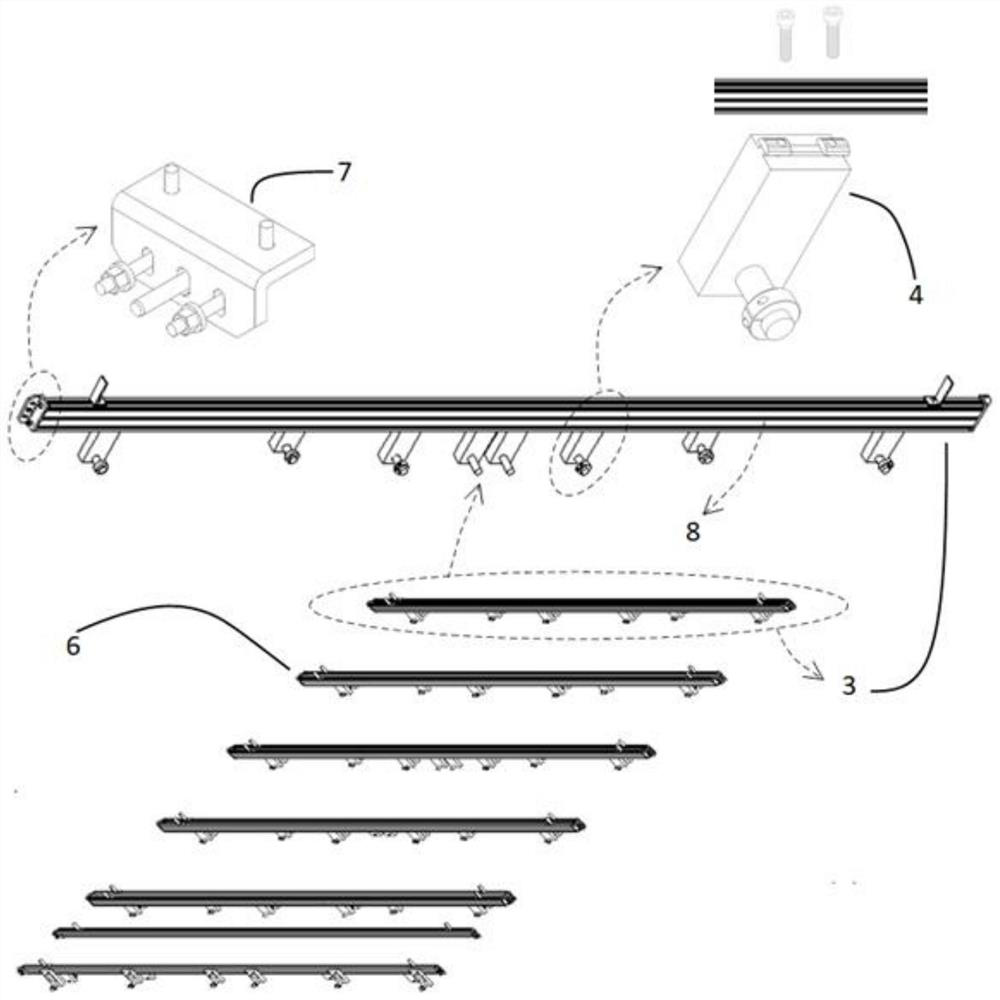

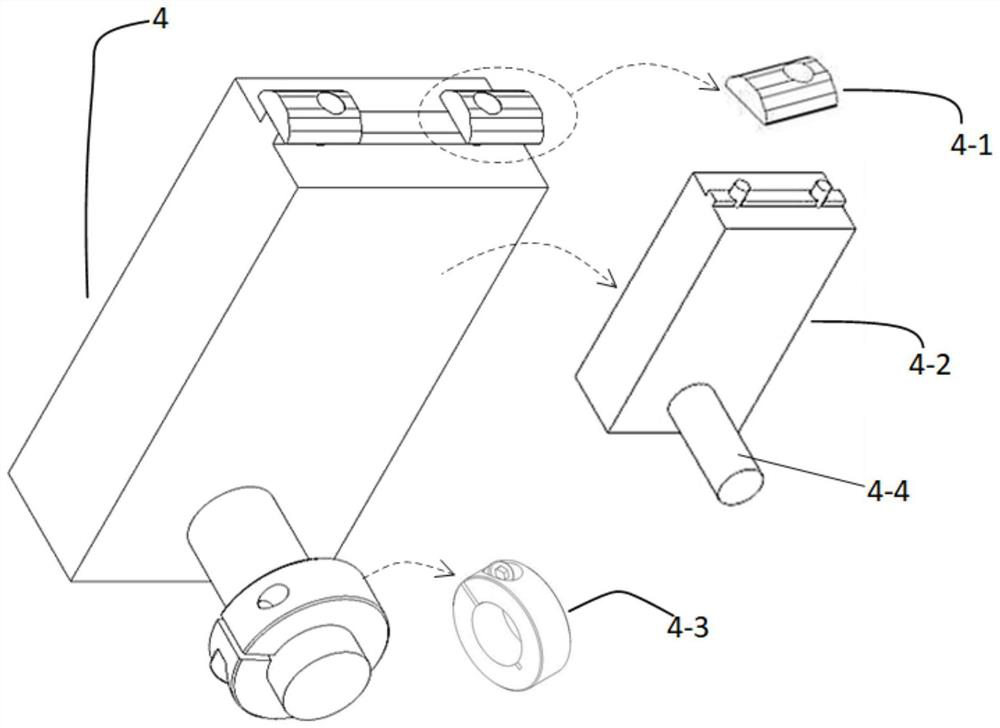

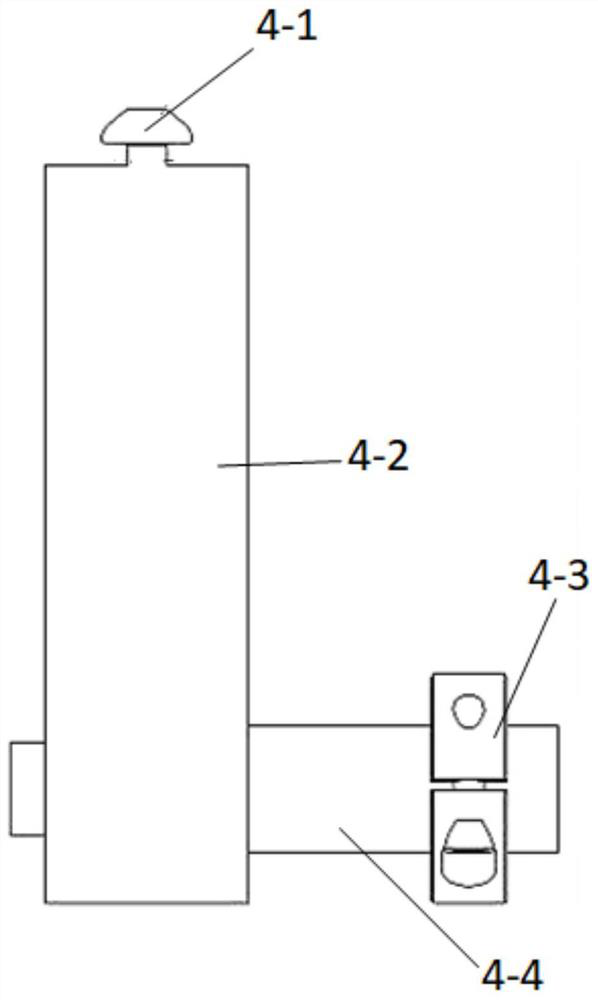

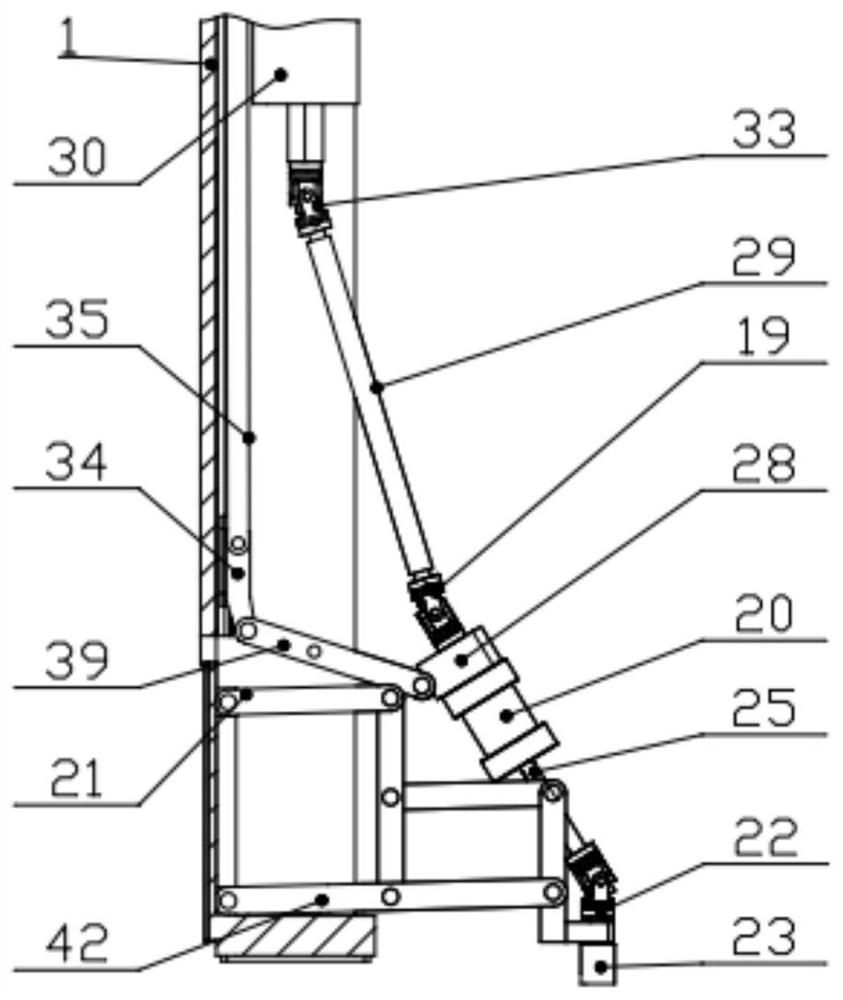

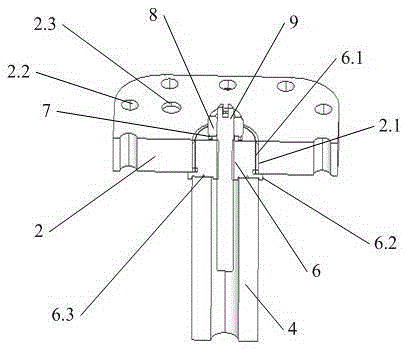

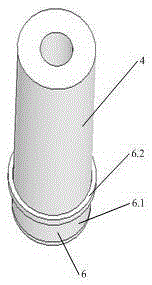

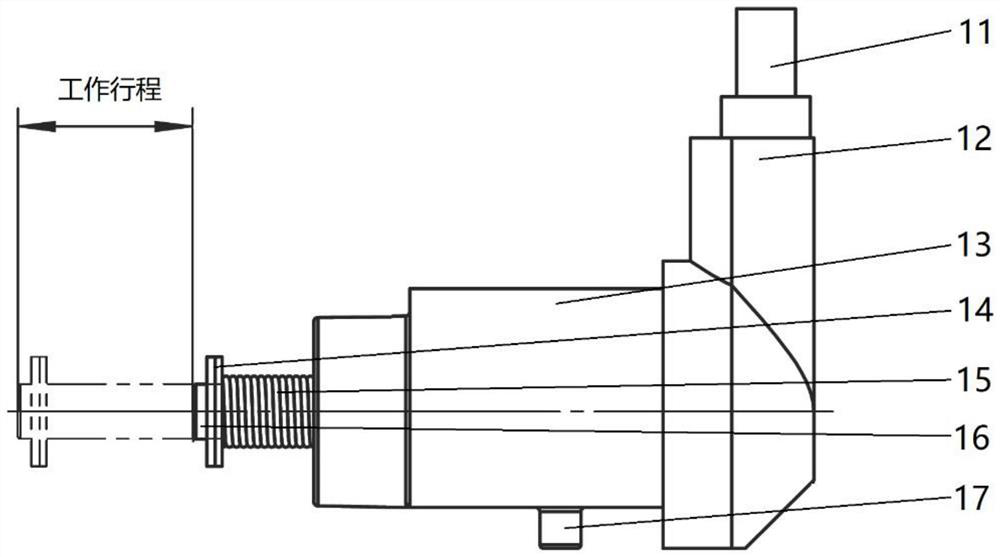

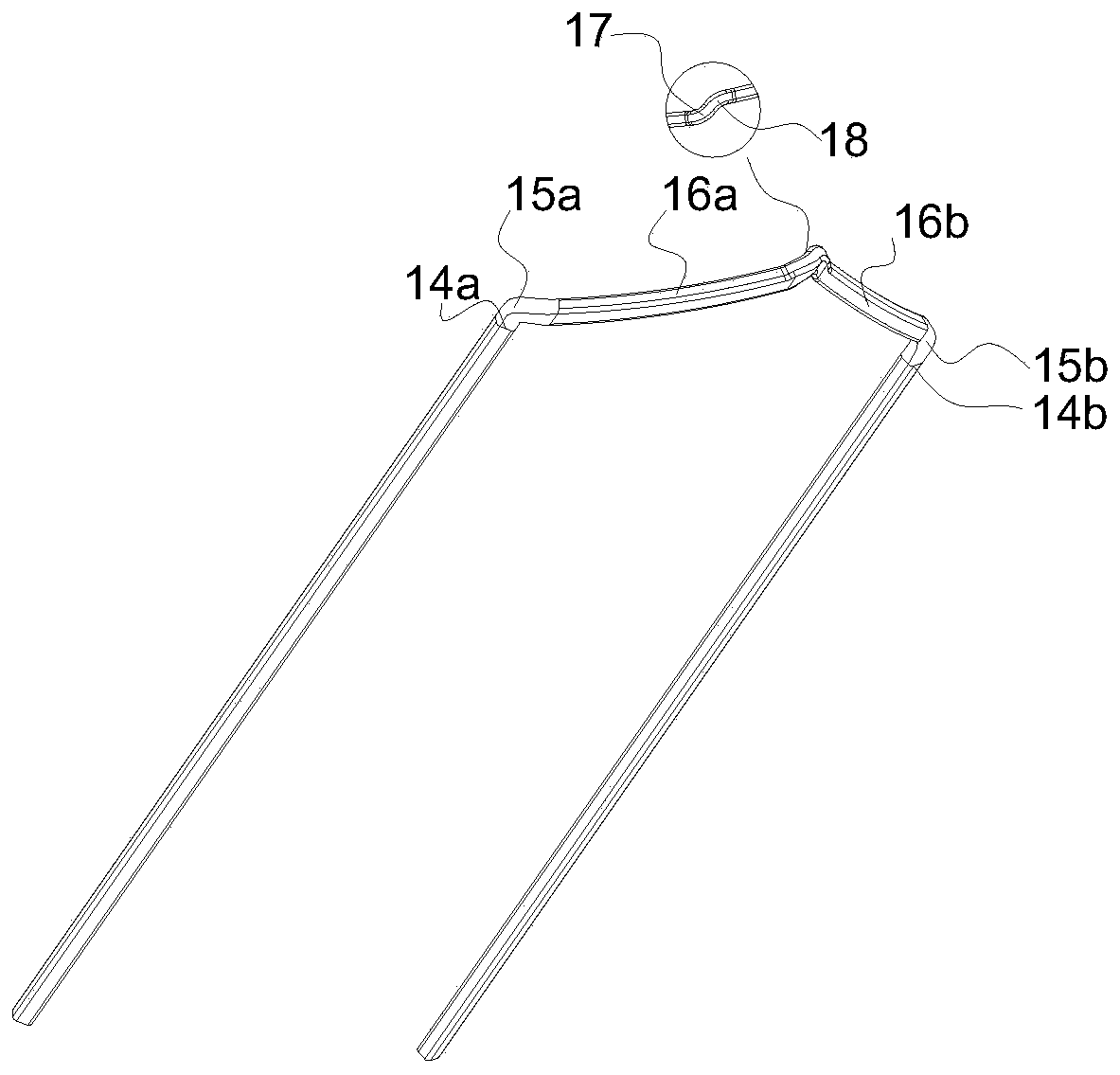

Flexible-shaft transmission-type tightening device and method for internal nuts of aero-engine

InactiveCN110561098AGuaranteed accuracySmall space impactMetal working apparatusOperation modePositioning system

The invention discloses a flexible-shaft transmission-type tightening device and method for internal nuts of an aero-engine, and belongs to the technical field of automated assembly. The flexible-shaft transmission-type tightening device for the internal nuts of the aero-engine comprises a tooling pre-positioning system, a nut aligning and positioning system and a flexible-shaft transmission-typetightening execution system. Through the nut aligning and positioning system, a tightening sleeve is mounted on a to-be-tightened nut in a sleeving manner and driven by a tightening motor to completethe tightening work; by the adoption of the automated operation mode, the flexible-shaft transmission-type tightening device disclosed by the invention has the characteristics of being high in degreeof automation, high in motion precision and high in tightening precision; the manual operation task is relieved; the operation process is greatly simplified; errors introduced by the manual operationare avoided; the tightening consistency of the internal nuts is guaranteed; and the whole machine assembly work efficiency is improved.

Owner:DALIAN UNIV OF TECH

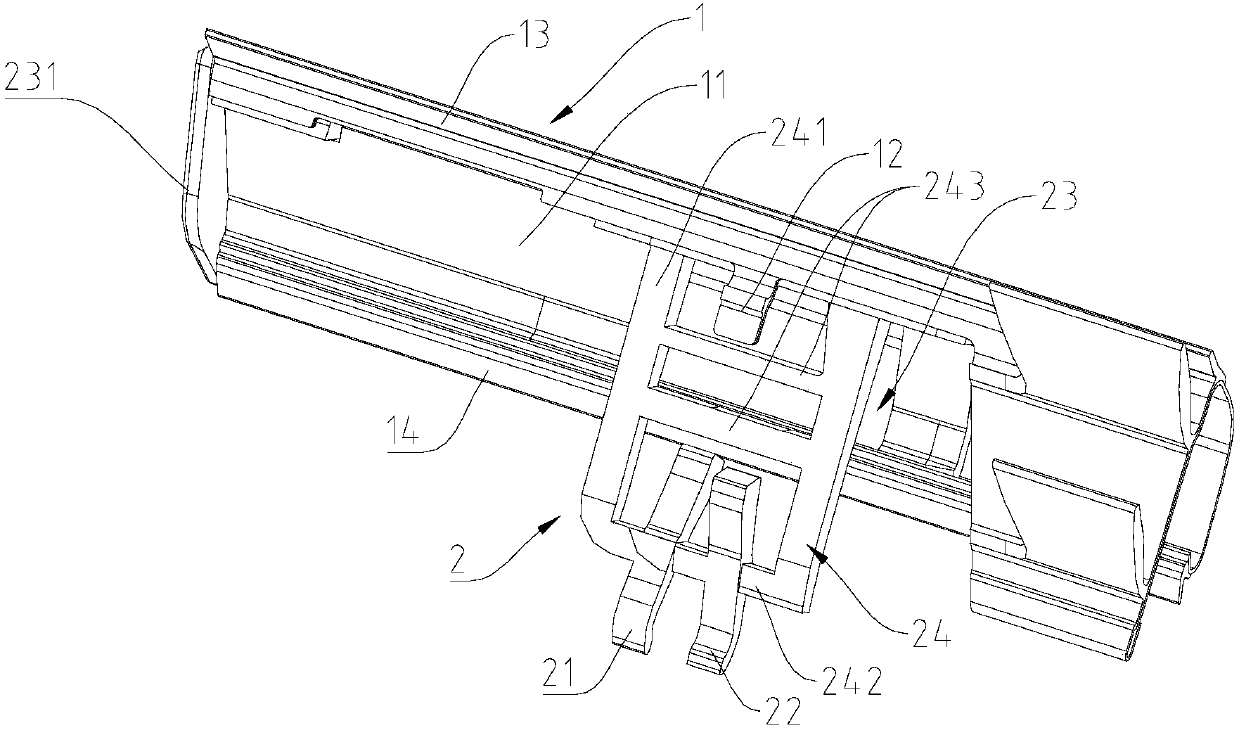

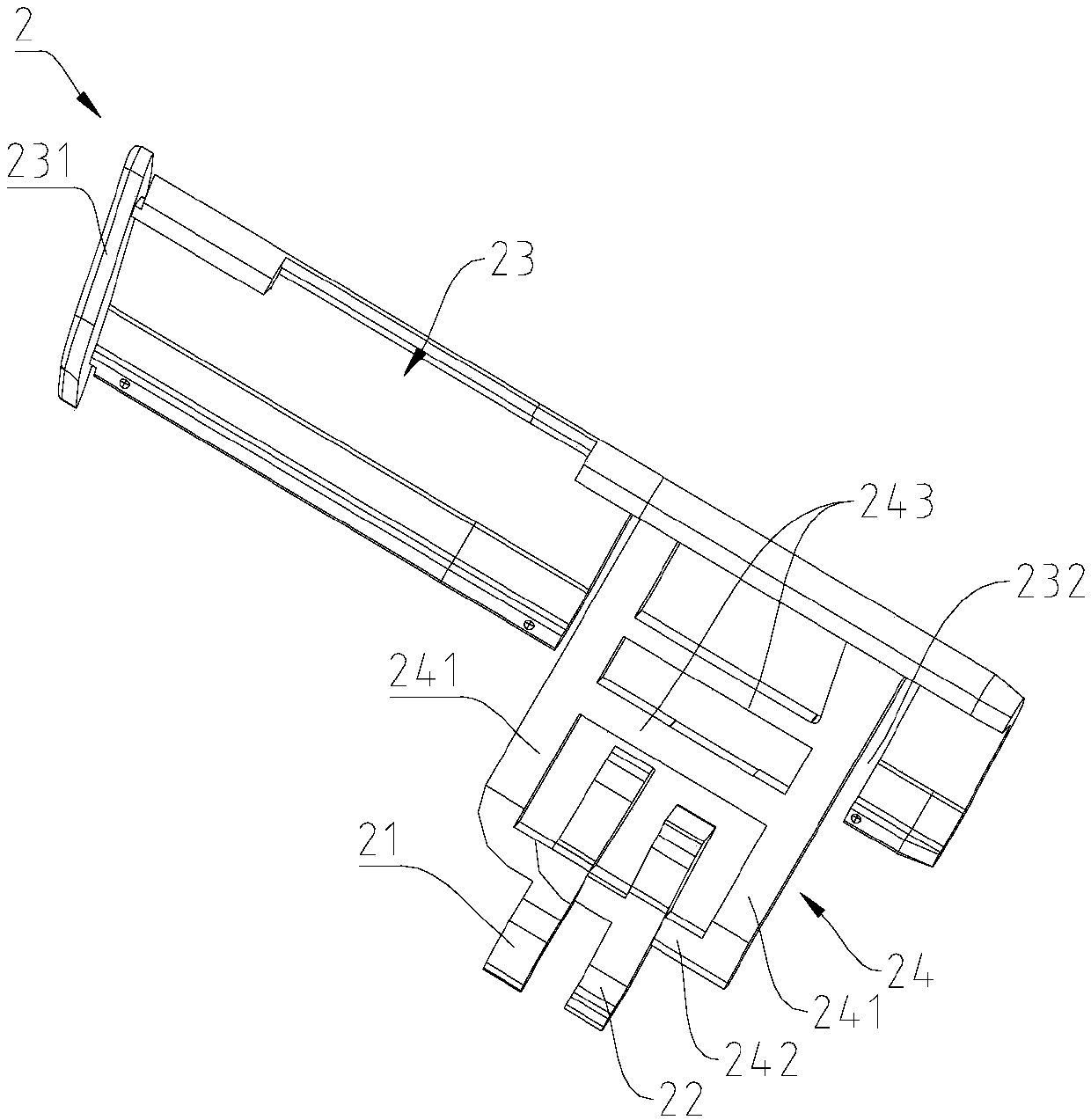

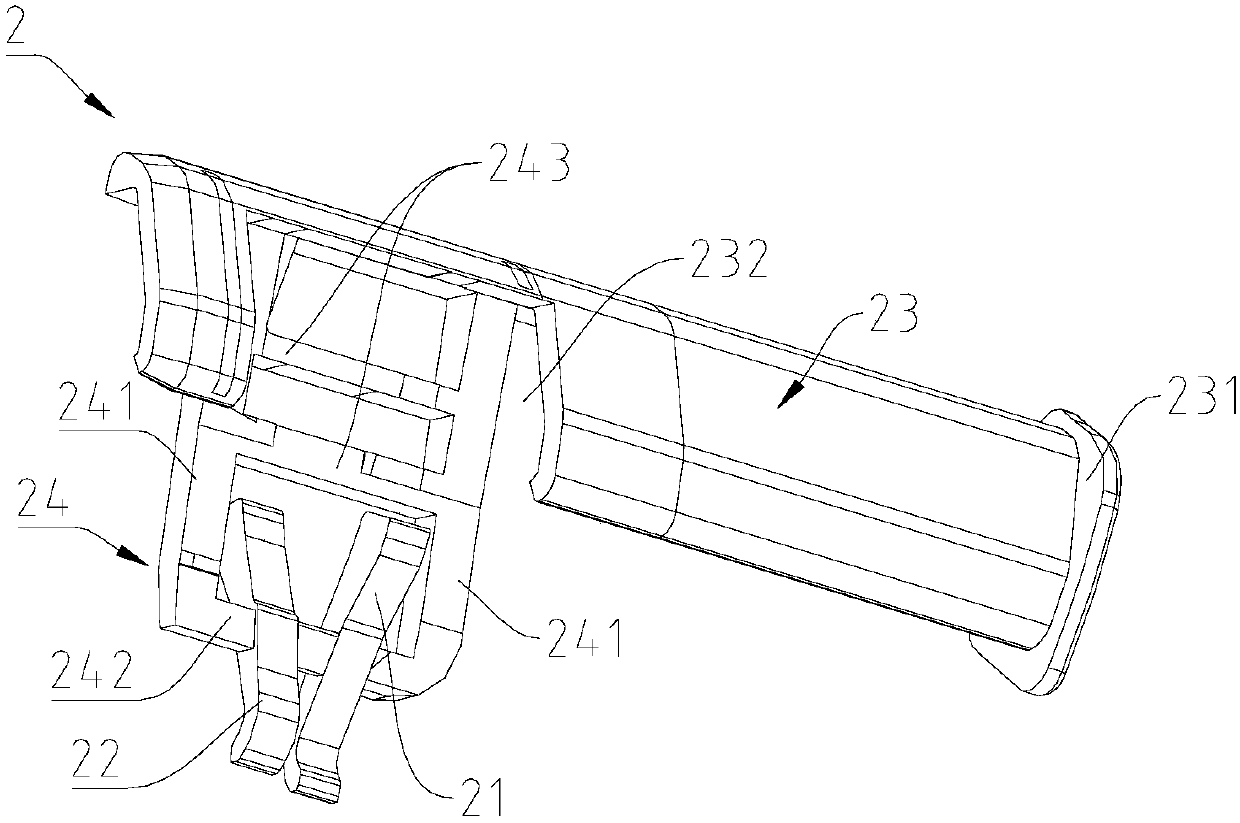

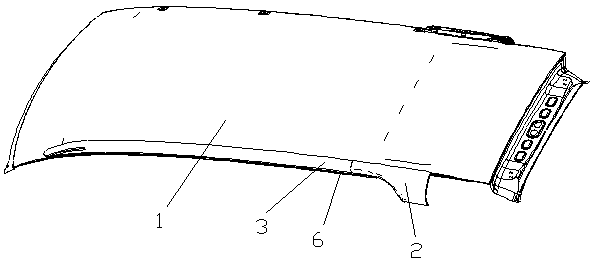

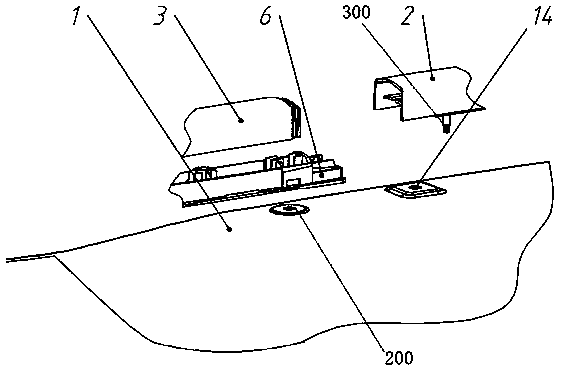

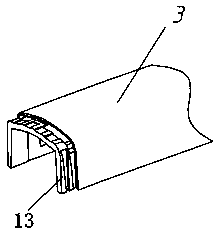

A water cutting end mounting structure and a vehicle

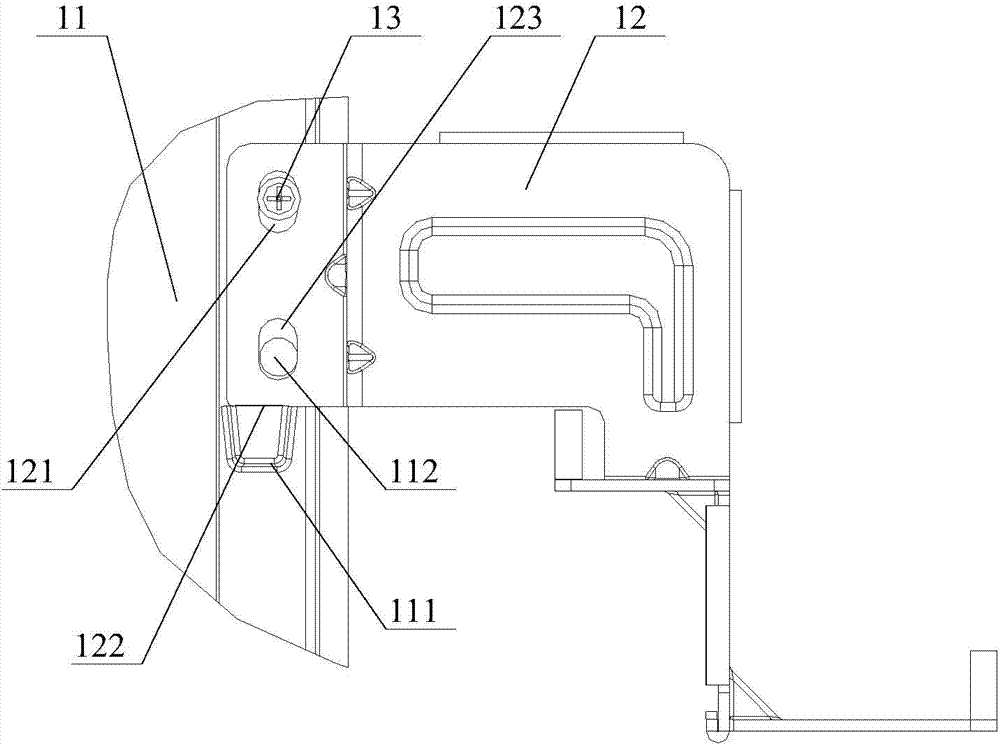

ActiveCN109849634AAvoid flippingPrecise positioningEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

The invention provides a water cutting end mounting structure and a vehicle. The water cutting end mounting structure comprises a water cutting end body and a clamping structure arranged on the watercutting end body. The clamping structure comprises a first clamping part used for being clamped and matched with the inner surface of an automobile door outer plate and a second clamping part used forbeing clamped and matched with an automobile door window frame, so that the water cutting end body is positioned through cooperation of the first clamping part and the second clamping part. The watercutting end mounting structure can effectively prevent the water cutting end body from overturning relative to the automobile door window frame and the automobile door outer plate and displacing andchanging in the Z direction through clamping fit of the first clamping part and the inner surface of the automobile door outer plate in the assembling state; therefore, the water cutting end body canbe reliably positioned, the assembly reliability is effectively ensured, and the overall outer sightseeing smoothness of the water cutting end mounting structure is ensured.

Owner:GREAT WALL MOTOR CO LTD

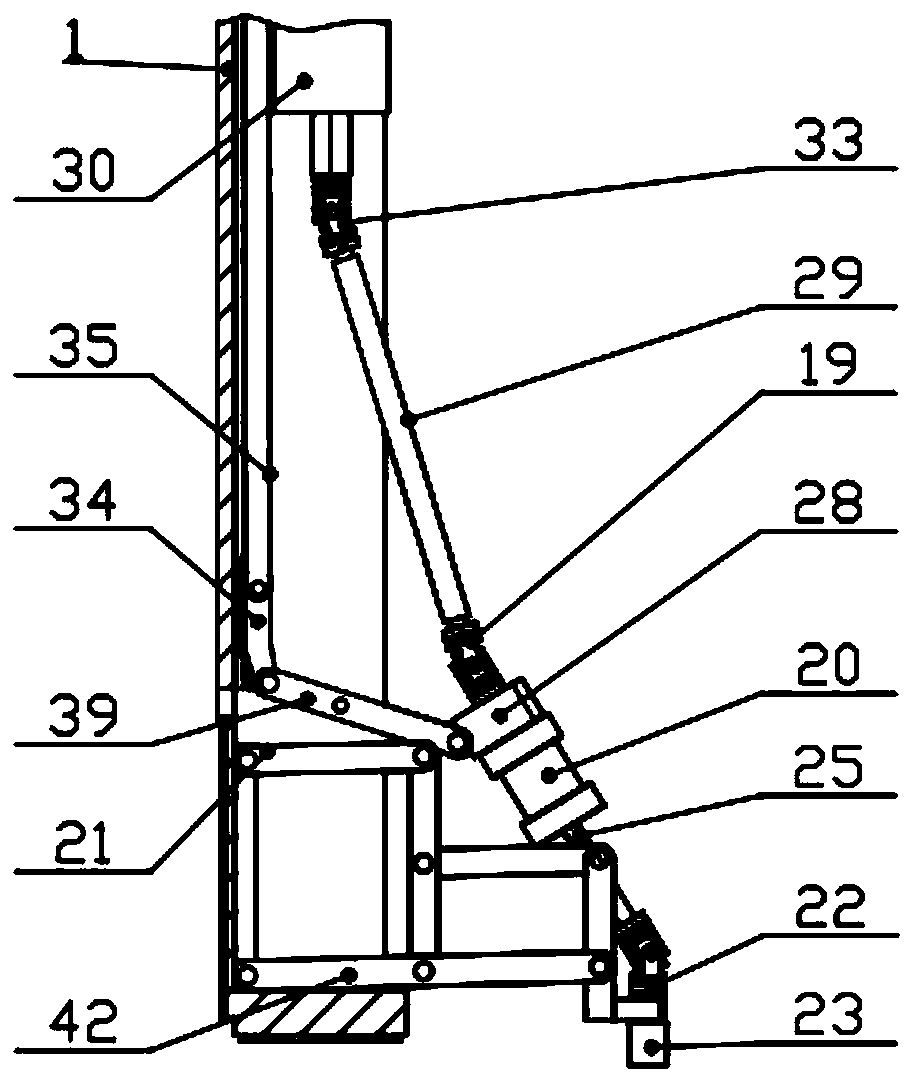

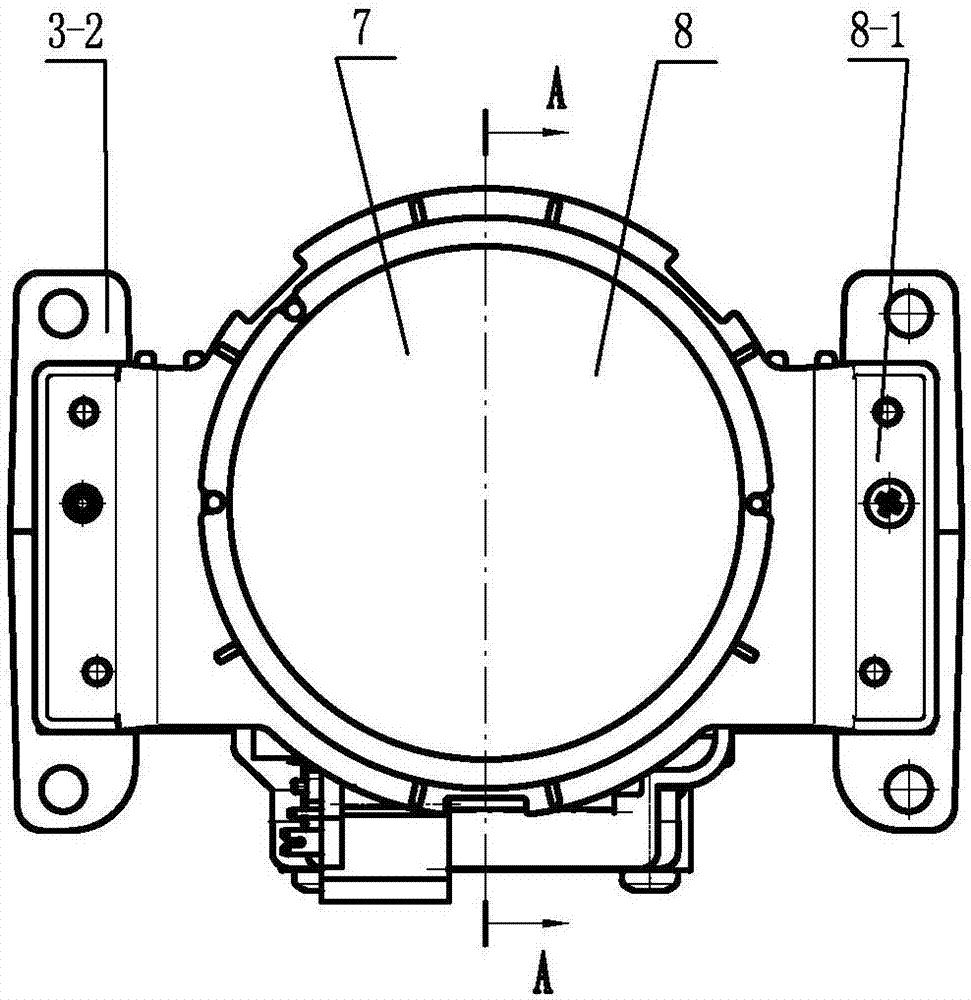

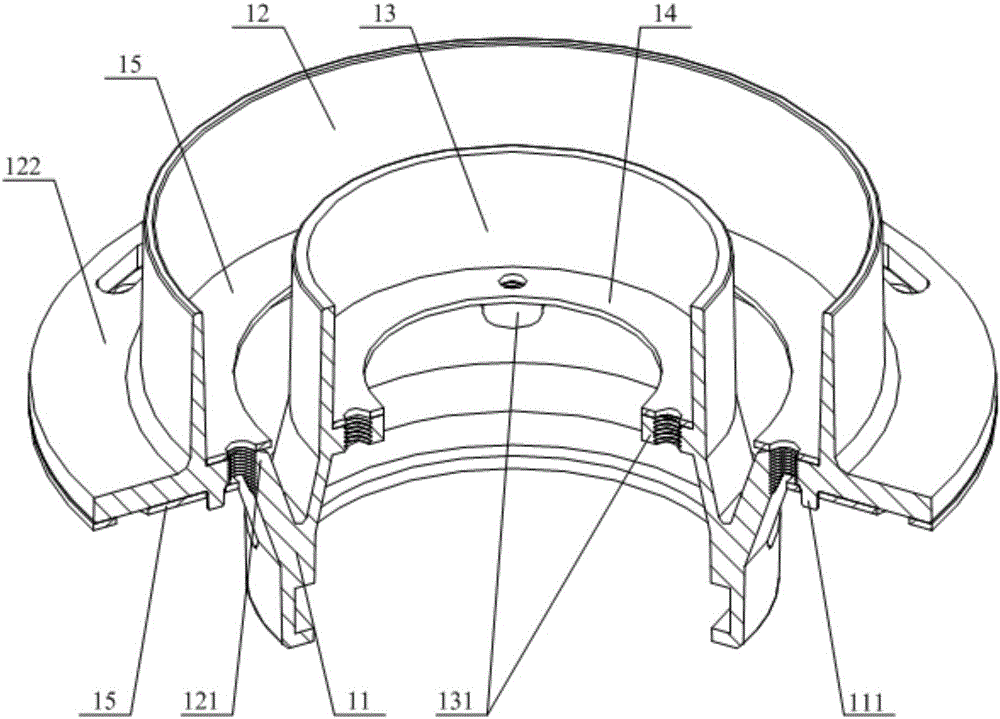

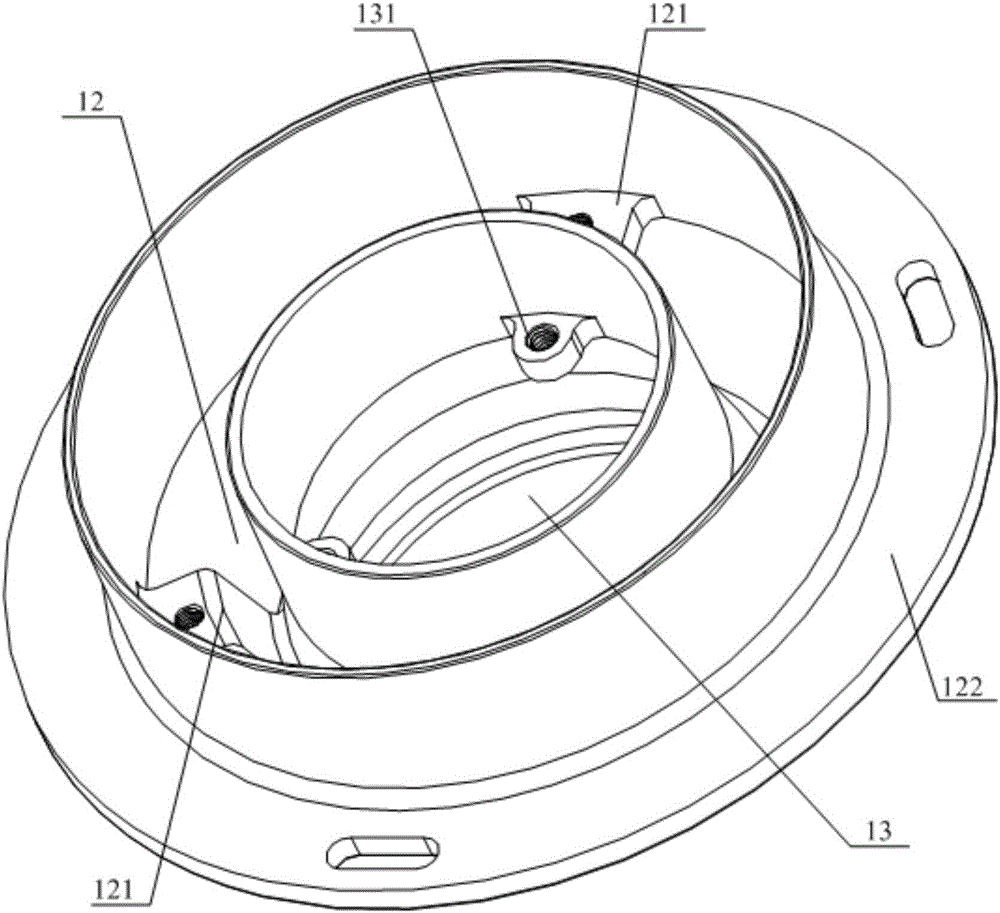

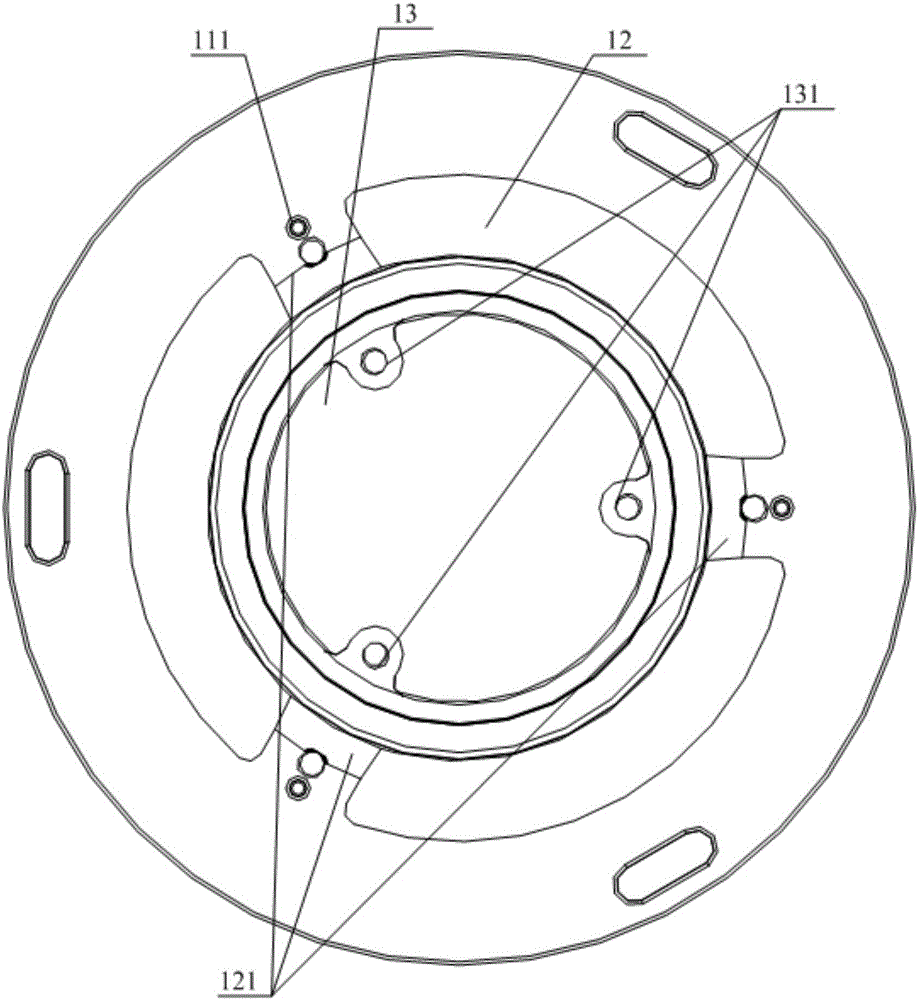

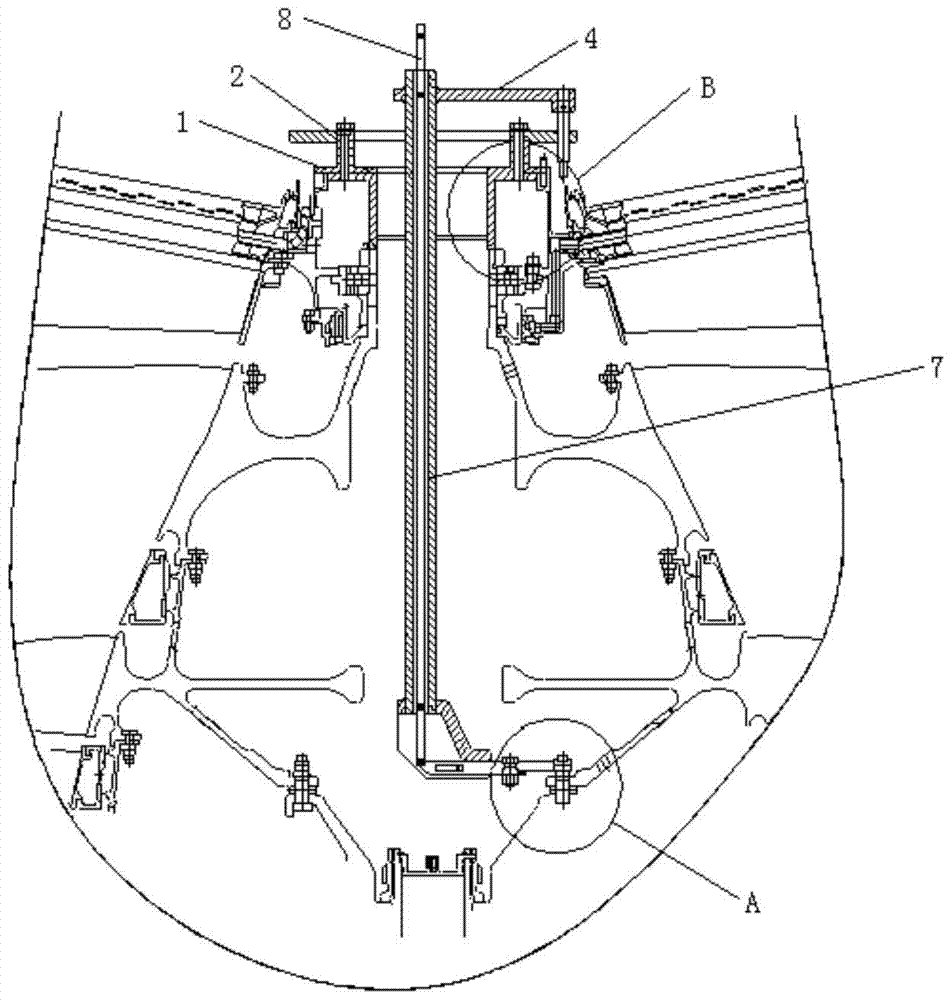

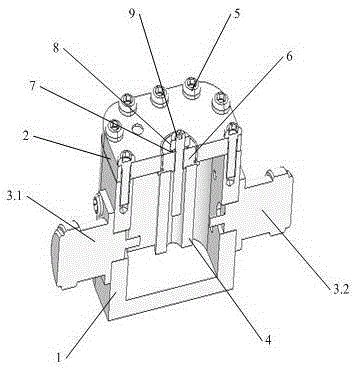

Aircraft engine link mechanism nut alignment and tightening device and method

ActiveCN110561097AGuaranteed tightening angle accuracyHigh static rigidity of the structureMetal working apparatusAviationOperation mode

The invention discloses an aircraft engine link mechanism nut alignment and tightening device and an aircraft engine link mechanism nut alignment and tightening method, and belongs to the aircraft engine internal assembly technology field. The aircraft engine link mechanism nut alignment and tightening device comprises a universal joint driving type tightening system, a nut alignment and positioning system and a device tool prepositioning system, wherein the device tool prepositioning system is installed on a housing of a rotor of an aircraft engine, the nut alignment and positioning system isinstalled on the upper portion of the device tool prepositioning system, and the universal joint driving type tightening system is installed in the nut alignment and positioning system. Positioning of a tightening sleeve is completed through the nut alignment and positioning system, and tightening work for nuts is completed by driving the tightening sleeve through a tightening motor. The aircraftengine link mechanism nut alignment and tightening device adopts a numerical control operation mode, simplifies the operation process, reduces manual operation task intensity, has the characteristicsof being high in automatic degree, high in motion precision and good in tightening state, and improves internal nut tightening efficiency of the aircraft engine.

Owner:DALIAN UNIV OF TECH

Two-stage inspection auxiliary device

InactiveCN105119201ASimple and fast operationOperational securityApparatus for overhead lines/cablesSwitchgearHigh intensityEngineering

The invention discloses a two-stage inspection auxiliary device, comprising a front rod body and a rear rod body which are detachably and coaxially connected in sequence, wherein the front end of the front rod body is provided with a detection terminal. In a assembly and use process, the detection terminal can be stretched into a relatively narrow workspace or a higher workspace by holding the front rod body and the rear rod body by a worker, meanwhile rod body lengths which can be operated by the worker can be flexibly adjusted according to the different demands of actual working conditions by disassembling or assembling the rear rod body and the front rod body, so that demands of use for inspection operations of multiple working conditions under high strength can be met; the two-stage inspection auxiliary device is simple in operation, safe and reliable in operation process, and high in work efficiency.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +2

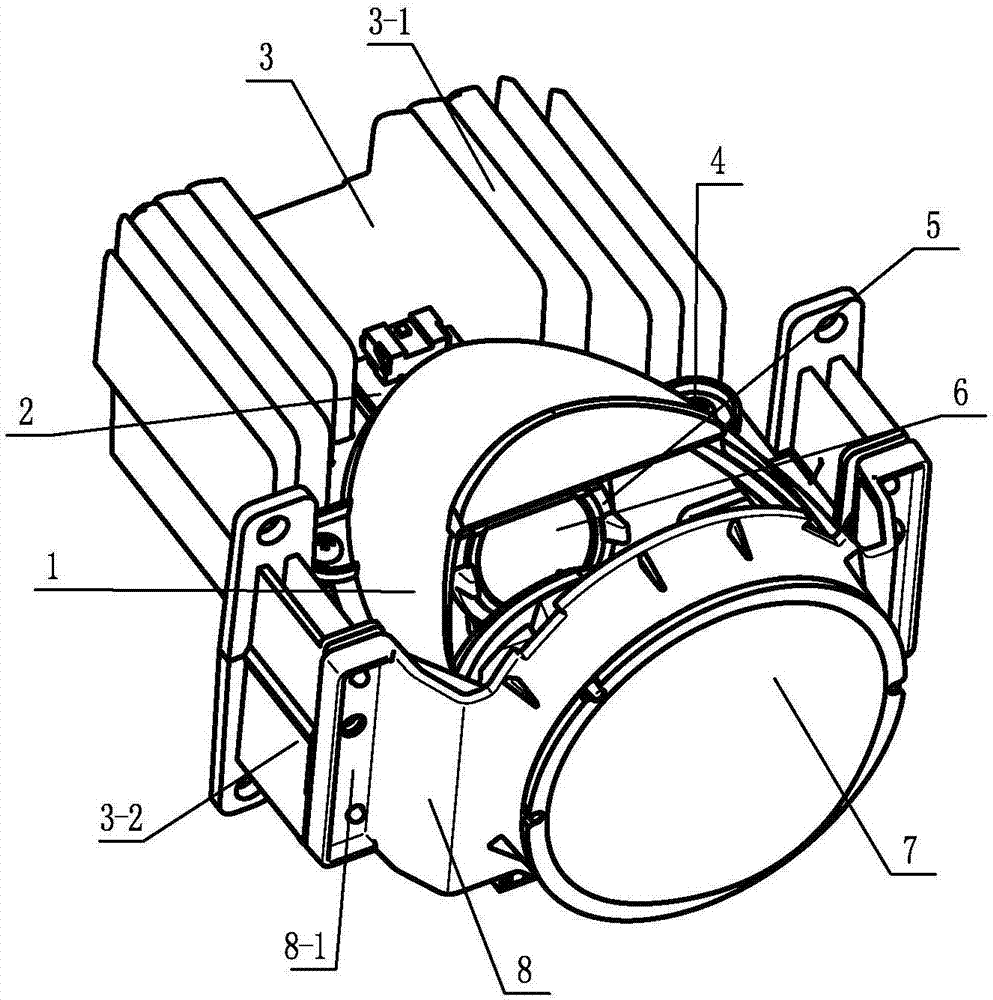

Concentrating led bifocal lens module

ActiveCN106051585BEffective temperature controlImprove luminous flux stabilityVehicle headlampsLighting heating/cooling arrangementsFree formOptoelectronics

The invention relates to a light-concentrating type LED dual-light lens die set. The light-concentrating type LED dual-light lens die set comprises a radiator, a light source assembly mounted on the radiator, a light barrier assembly and a lens assembly, wherein the light barrier assembly and the lens assembly are mounted at the front part of the radiator; a first circuit board of a near LED die set of the light source assembly is mounted on a first mounting surface of the radiator, and a reflecting mirror with a free-form surface is mounted at the upper part of the radiator; rays emitted by a neat LED light source are reflected to a focal spot O in the lens by the reflecting mirror to be collected, and then ejected to the lens through a light barrier so as to form a near dead line light type; a second circuit board of a distance LED die set is mounted on a second mounting surface of the radiator, and a light condenser is mounted at the front part of the radiator through a light condenser bracket; and rays emitted by the distance LED light source are totally reflected to the focal spot O in the lens through the light condenser to be collected, and then ejected to the lens so as to form a distance light type. The light-concentrating type LED dual-light lens die set disclosed by the invention is compact in structure, can improve the precision of the distance light type and the near light type, and well solves the problems that dead lines spray color light, the distance light and the near light are out of alignment in focusing, and the distance light is uneven.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

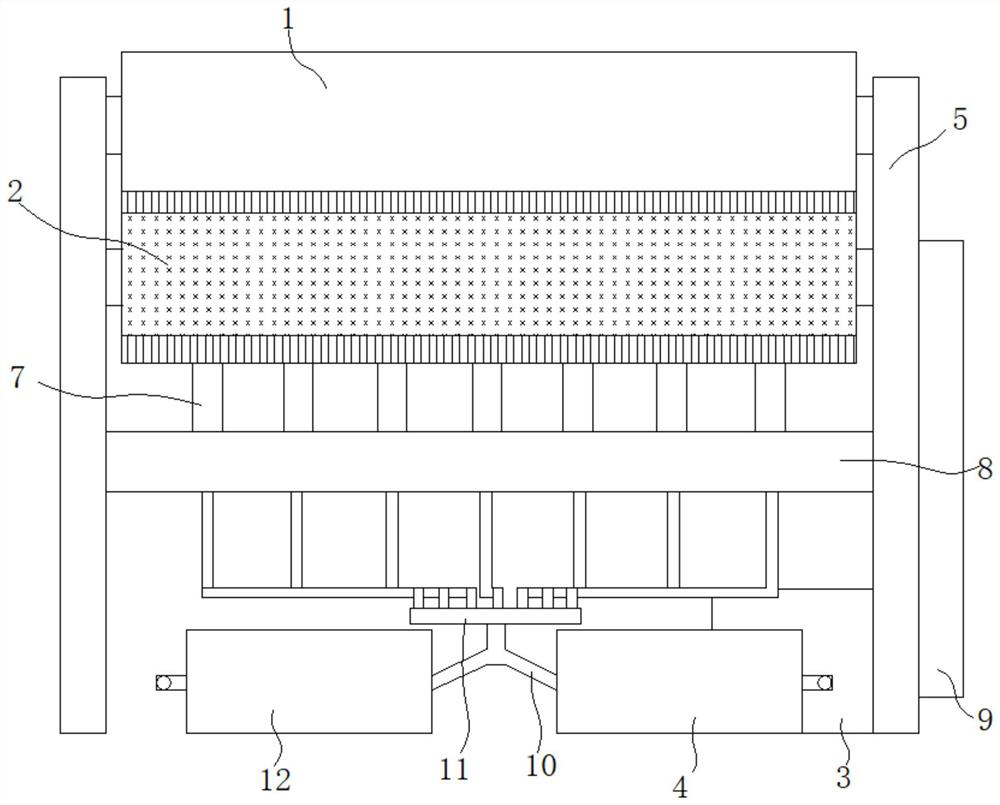

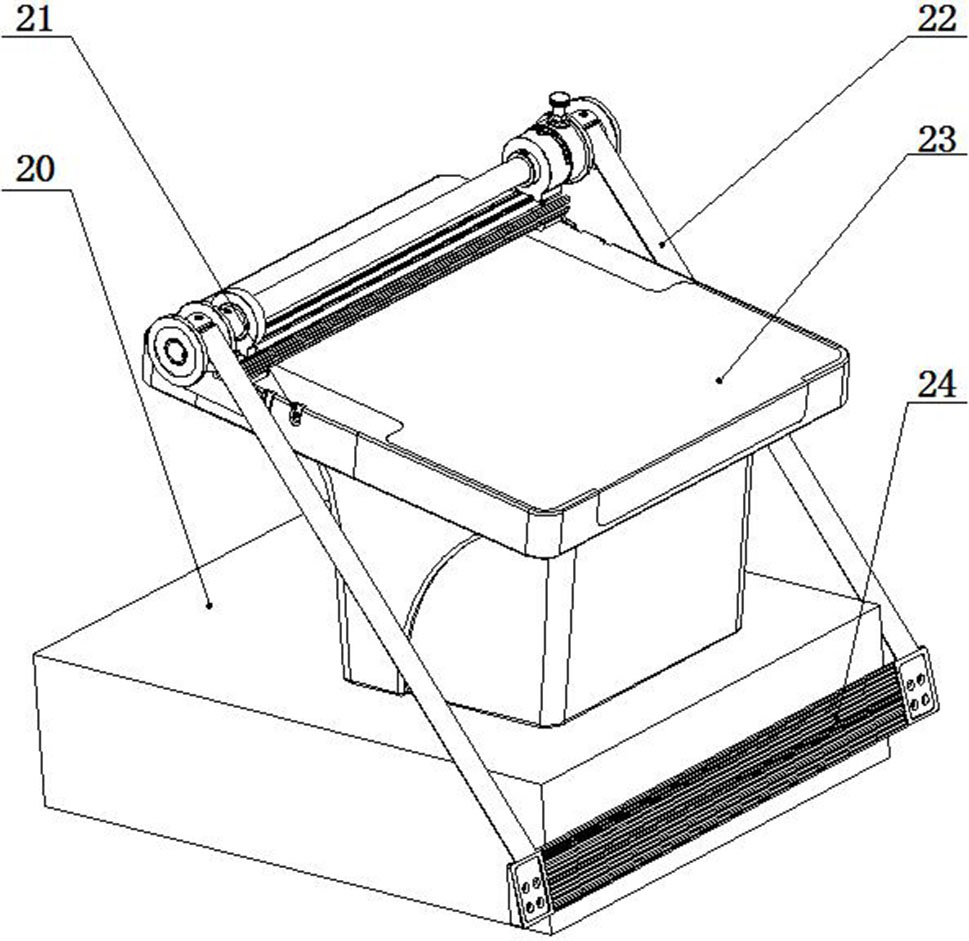

Automatic deslagging conveying belt of earth pressure balance shield machine

InactiveCN111874569AImprove slag carrying capacityImprove delivery efficiencyCleaningPhysicsEarth pressure balance

The invention discloses an automatic deslagging conveying belt of an earth pressure balance shield machine. The automatic deslagging conveying belt comprises a conveying belt body. A plurality of herringbone protrusions are arranged on the outer surface of a belt of the conveying belt body in the extending direction of the belt. A brush roller is arranged at the position, close to the output end of the conveying belt body, below the rear portion of the conveying belt body in a crossing manner, the brush roller is driven by a motor located below the rear portion of the conveying belt body to rotate in the direction of the output end of the conveying belt body, and bristles of the brush roller abut against the outer surface of the belt of the conveying belt body. An automatic steam flushingdevice used for automatically flushing the brush roller is further included. According to the conveying belt, the slag carrying capacity is improved, much is removed quickly and smoothly, and the maintenance and use cost of the conveying belt body is effectively reduced.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

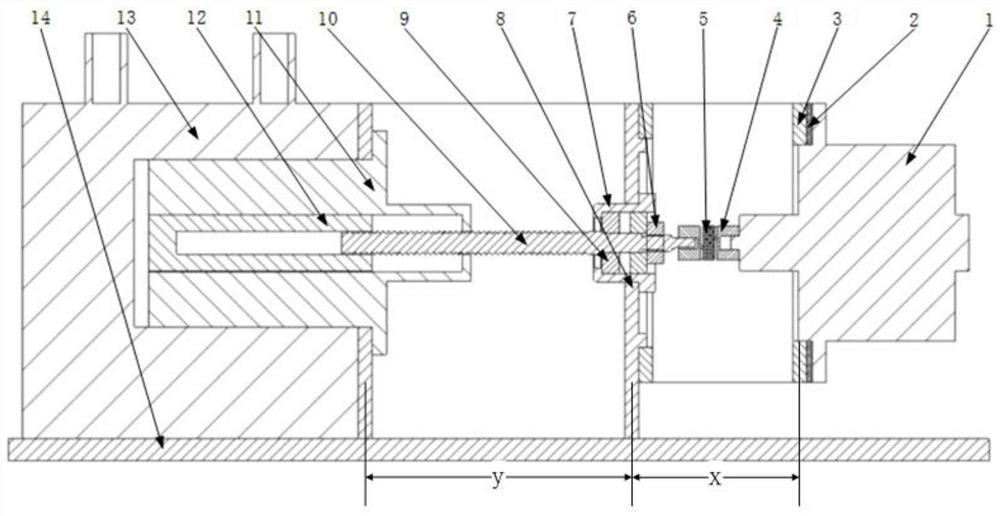

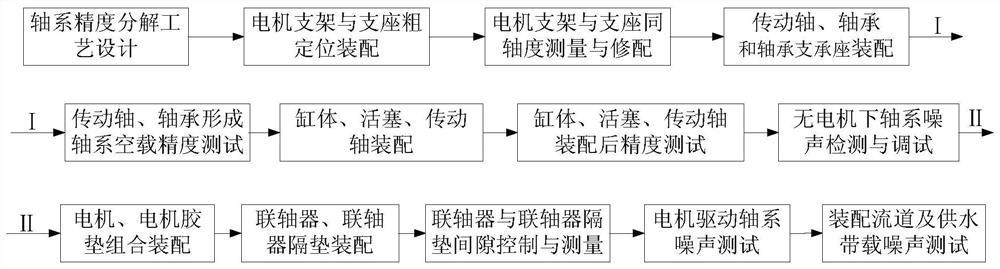

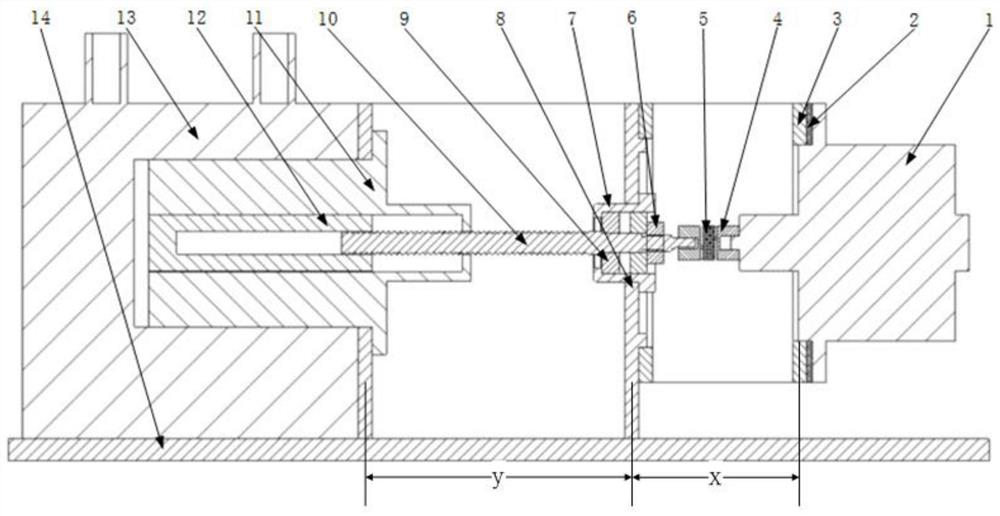

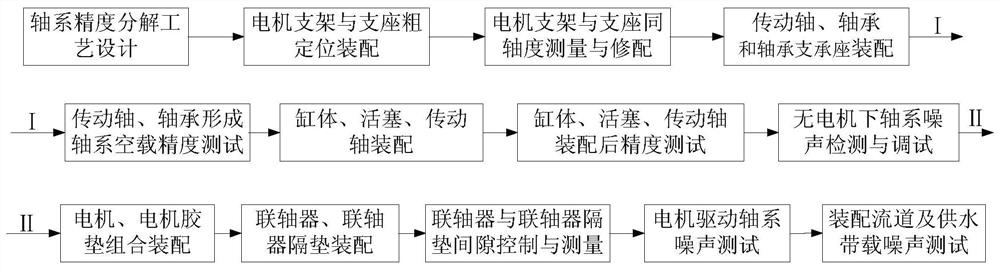

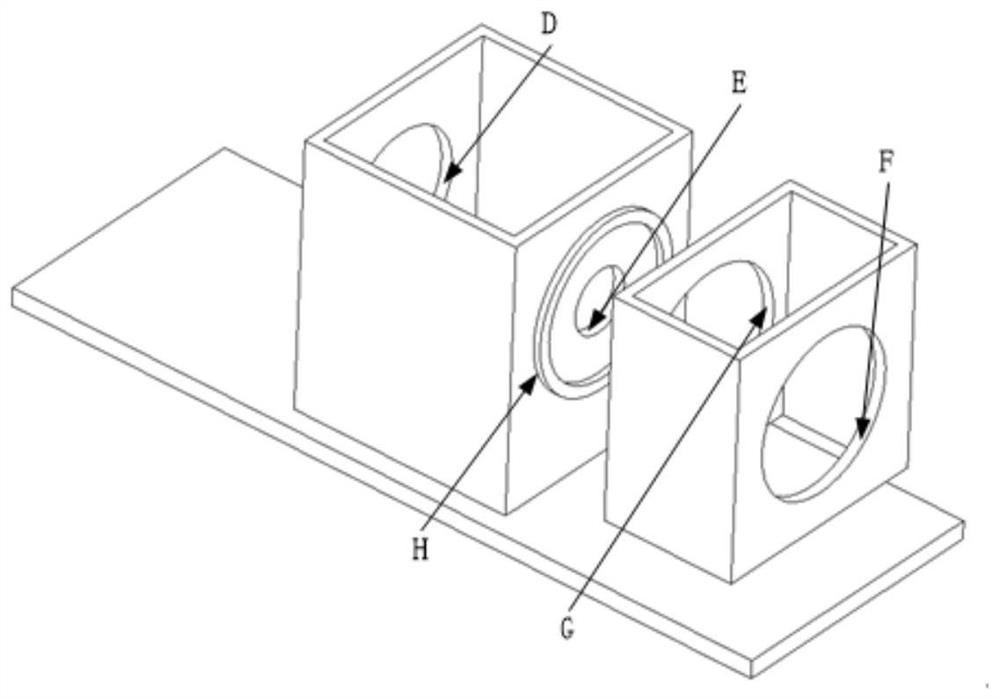

Assembly method of low-noise water supply pump

ActiveCN113084488ARealize precision detectionSolve development problemsMeasurement/indication equipmentsHydro energy generationLow noiseDrive shaft

The invention provides an assembly method of a low-noise water supply pump. The assembly method comprises the following steps of designing a shaft system precision decomposition process, roughly positioning and assembling a motor bracket and a support, measuring the coaxiality of the hole positions of the motor bracket and the support, repairing and matching the coaxiality of the hole positions of the motor bracket and the support, assembling a transmission shaft, a bearing and a bearing supporting seat, forming a shafting no-load precision test by the transmission shaft and the bearing, assembling a cylinder body, a piston and the transmission shaft, testing the precision after assembling, detecting and debugging the noise of a motor-free lower shaft system, combining and assembling a motor and a motor rubber mat, and combining and assembling a coupler and a coupler shock insulator. According to the assembly method, the problems that resonance is prone to being generated due to the fact that motor vibration reduction assembling control of the space low-noise water supply pump is not quantified, shaft system rotating friction noise is prone to being caused due to the fact that precision such as coaxiality is not high during shaft system assembling, the noise is out of tolerance due to the fact that noise and performance measuring process control is not refined and the like are solved, the performance and the service life of the water supply pump are improved, and long-term operation safety is ensured.

Owner:BEIJING SATELLITE MFG FACTORY

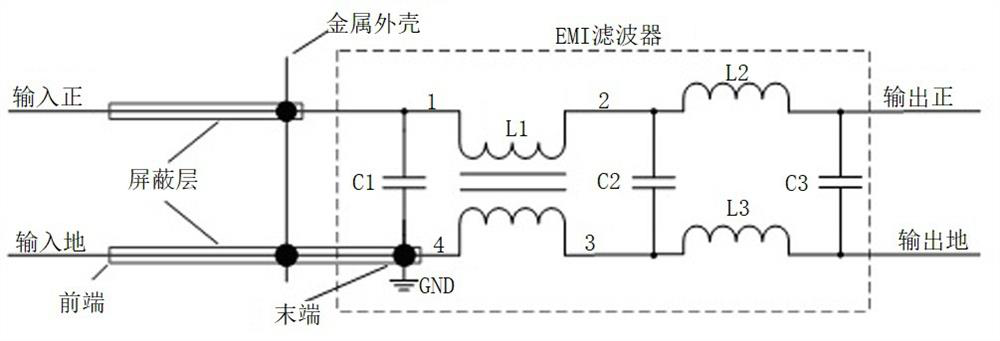

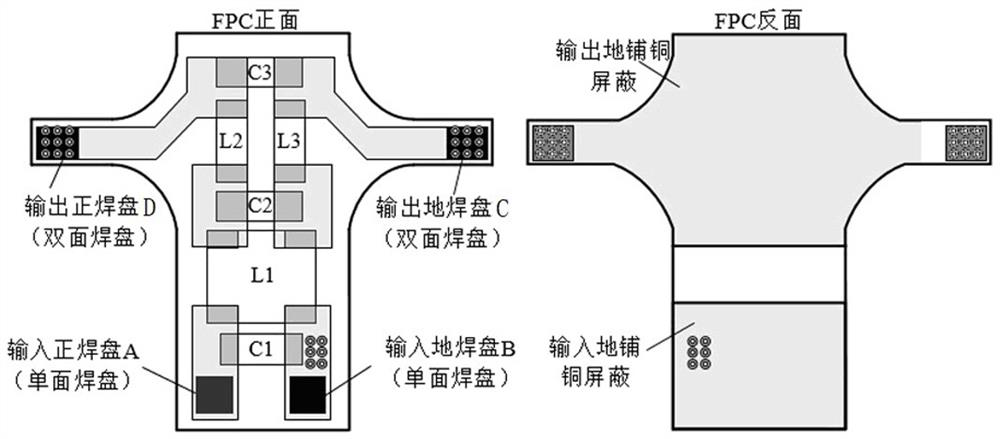

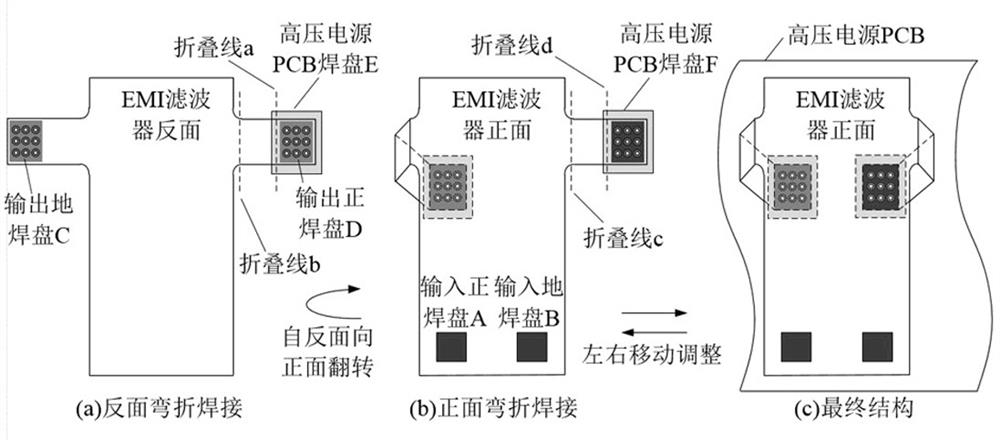

EMI filter for image intensifier and assembling method thereof

PendingCN112117983AThe solution cannot be placed reasonablyImprove electromagnetic compatibilityPrinted circuit assemblingMultiple-port networksCapacitanceMetallic enclosure

The invention belongs to the technical field of image intensifiers, and particularly provides an EMI filter for an image intensifier and an assembling method thereof, the EMI filter is of a two-stagecombined filtering structure, integrates a capacitor, an inductor and a magnetic bead component, adopts a flexible printed board to independently design a layout, and then welds the designed flexibleprinted board on a high-voltage power supply PCB in a laminated mode. The bonding pad on the front side is reinforced, the bonding pad on the back side is insulated, the bonding pad and the high-voltage power supply PCB are bent together, the bonding pad and the high-voltage power supply PCB are put into the metal shell, encapsulating by using silicone rubber to finish integral shaping, and finally welding the shielding wire and the metal shell by 360 degrees. Reasonable placement of the EMI filter is achieved, the problems that a small image intensifier cannot directly use the EMI filter or the placement position and layout design are not ideal are solved, meanwhile, the small image intensifier can be reliably assembled on the image intensifier, the electromagnetic compatibility of the image intensifier is effectively improved, and it is ensured that the image intensifier can meet the requirement of an electromagnetic compatibility test.

Owner:NORTH NIGHT VISION TECH

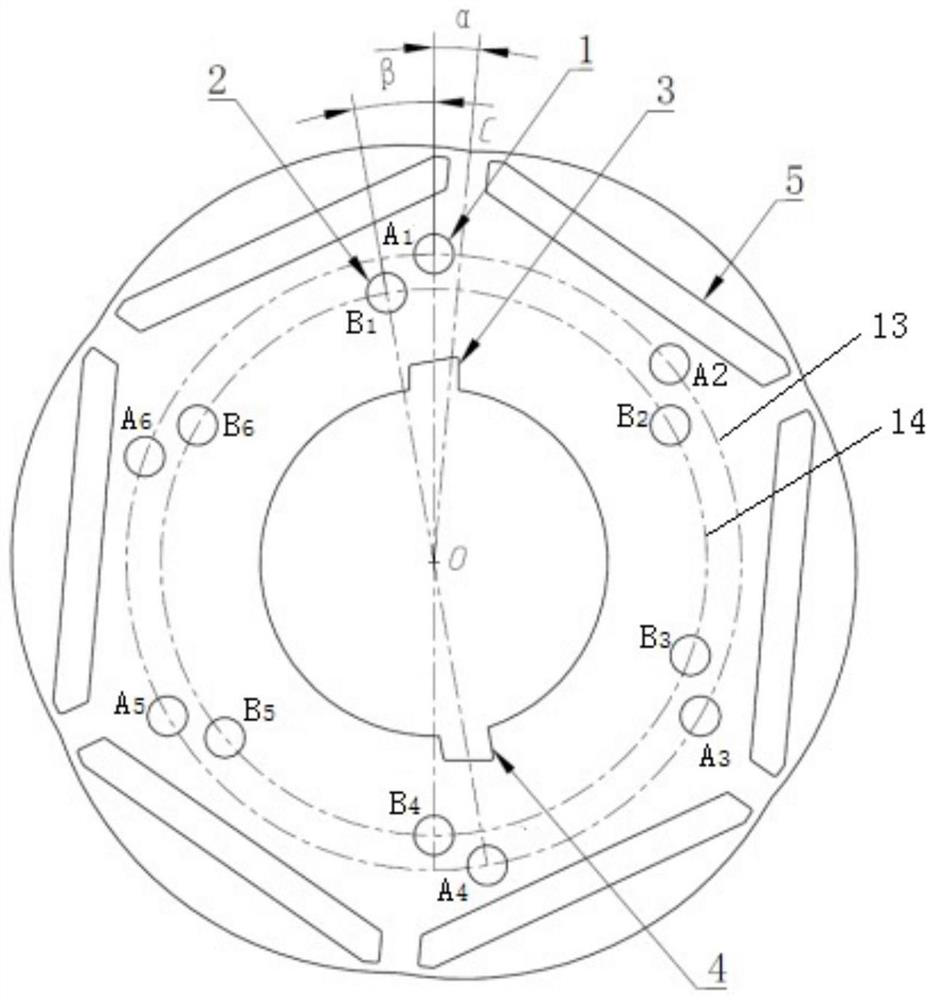

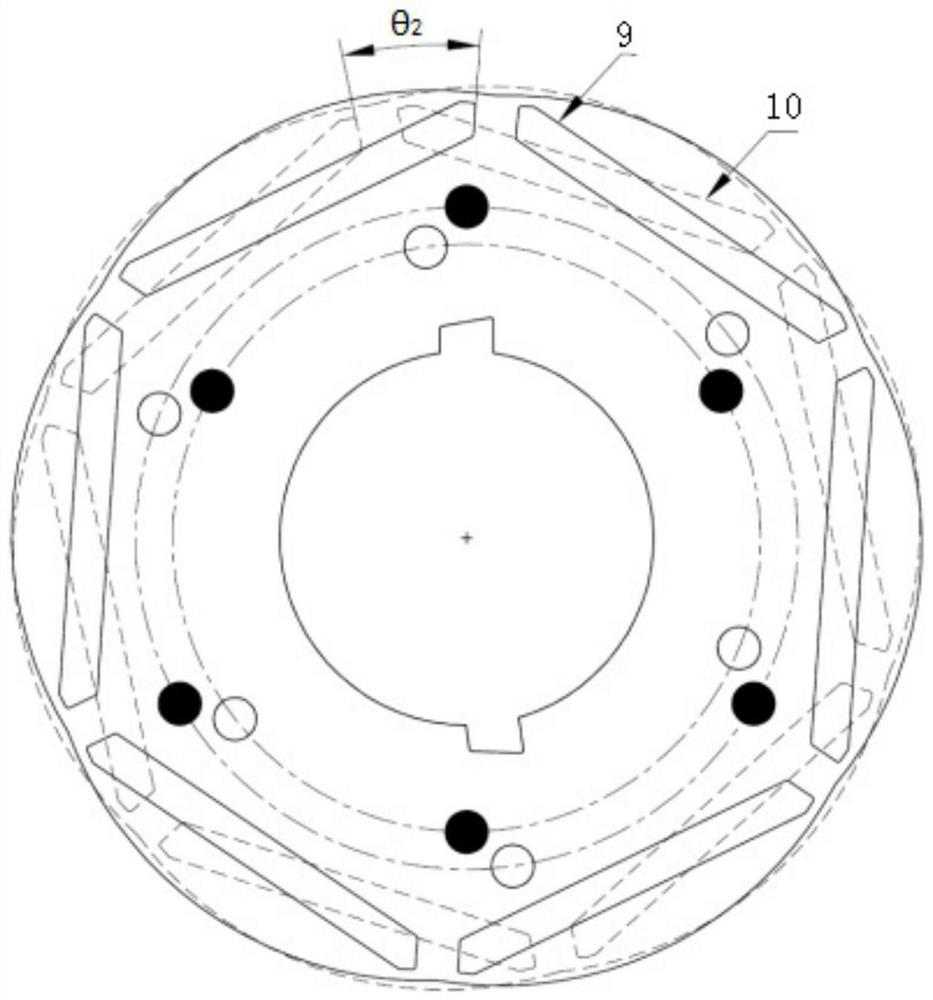

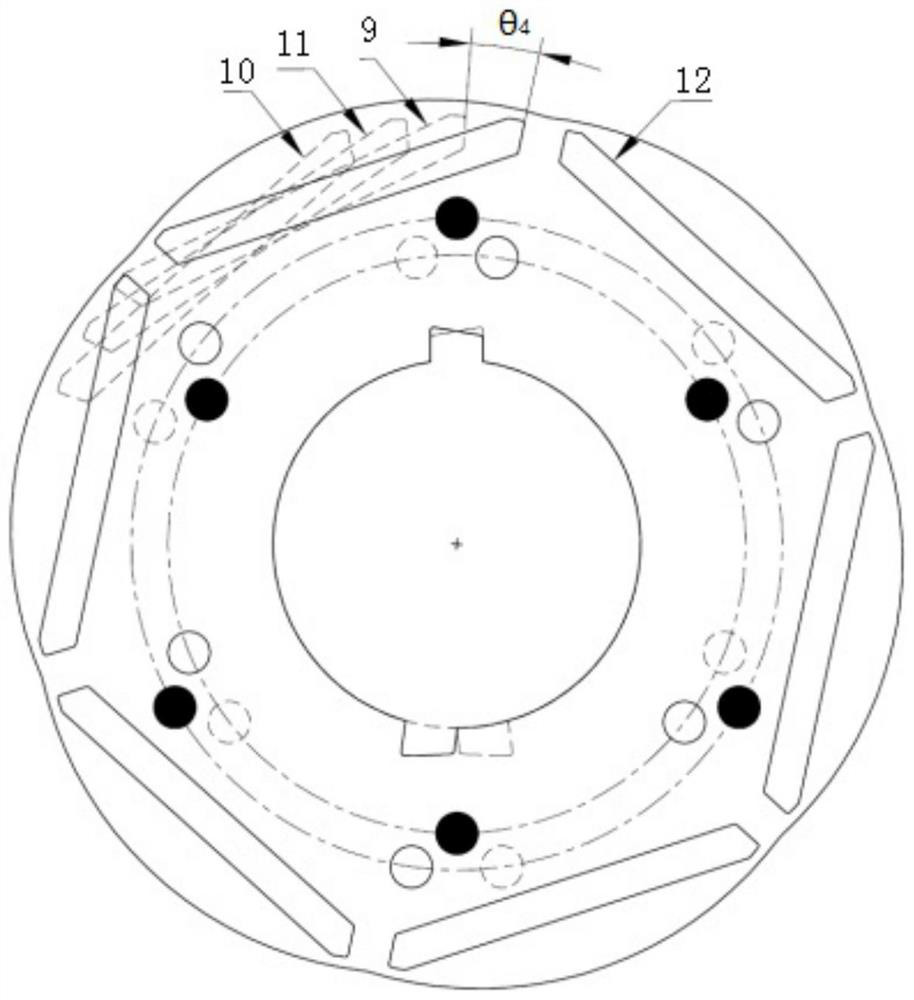

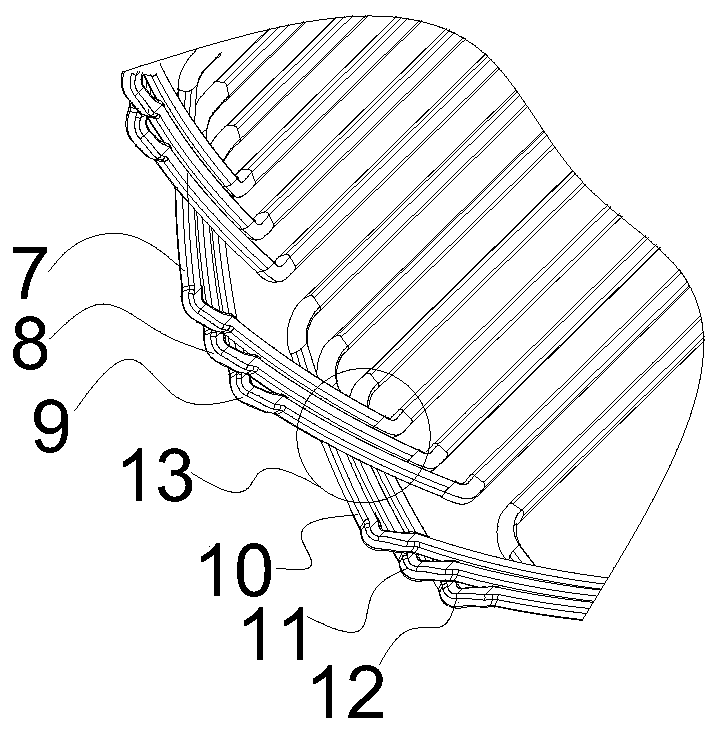

Manufacturing method and structure of segmented skewed pole permanent magnet motor rotor

PendingCN114552825ASimplify the assembly processReduce manufacturing costMagnetic circuit rotating partsElectric machinesPunchingElectric machinery

The invention relates to the field of motors, and discloses a method for manufacturing a segmented skewed pole permanent magnet motor rotor, which comprises the following steps of: S1, manufacturing a punching sheet unit: digging a magnetic steel assembling groove matched with a magnetic steel arrangement mode, a rotating shaft hole, inner and outer layers of riveting holes designed in a staggered manner and a sheet arranging groove used for replacing positioning of a positioning tool in the punching sheet unit; and S2, assembling the punching sheet units, overlapping the punching sheet units by adopting a specific stacking mode, and fixing the punching sheet units into a whole by using rivets. The invention further discloses a segmented skewed pole permanent magnet motor rotor structure which is manufactured by the method. According to the invention, the punching sheet units with preset riveting holes and sheet arranging grooves are adopted, and riveting can be directly carried out after the punching sheet units adopt a specific stacking mode, so that the deflection angle precision of each section and the simplicity and convenience of the process are ensured, and the yield and the production efficiency are also improved.

Owner:JSCC AUTOMATION XIAMEN

Gasket for fuel injector of internal combustion engine

ActiveCN104863747BGood positioning functionImprove sealing functionSealing arrangements for enginesFuel injection apparatusGas cylinderEngineering

The invention discloses an oil injector sealing gasket of an internal combustion engine. One to three ring-shaped bulges are formed on the lower surface of the oil injector sealing gasket; the lower surface of the oil injector sealing gasket is in contact with a gas cylinder cover; one to three ring-shaped grooves are formed in the plane of the gas cylinder cover, and mutually matched with the ring-shaped bulges on the oil injector sealing gasket; the upper surface of the oil injector sealing gasket is arch-shaped and in contact with an oil injector. The oil injector sealing gasket has the advantages of being simple in structure and convenient to machine; the sealing effect and the reliability are excellent; the oil injector has a positioning function, so that the assembly and work reliability can be guaranteed.

Owner:CHINA NORTH ENGINE INST TIANJIN

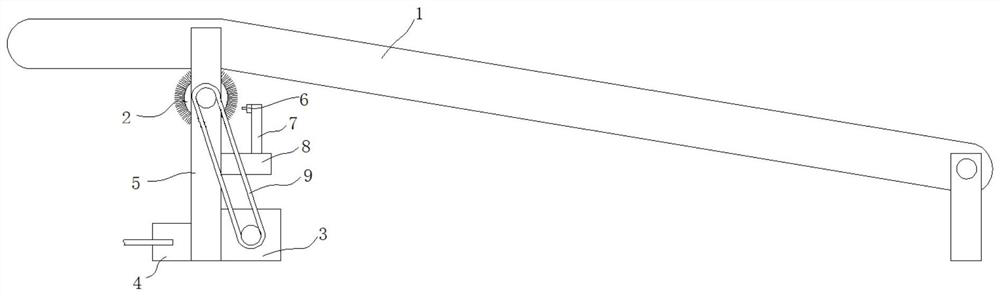

Backstroke starting device and assembly

PendingCN111803888AGuaranteed assembly reliabilityQuick disassemblySwimming aidsStructural engineeringMechanical engineering

The invention discloses a backstroke starting device and an assembly. The backstroke starting device comprises: a base provided with a plug so as to adapt to a jack or a groove disposed on a startingplatform; a bearing seat mounted or constructed on the base; a shaft supported on the bearing seat through a bearing; rope belt wheels, wherein one rope belt wheel is arranged at each of the two endsof the shaft, and a rope belt is wound on the rope belt wheel; and a pedal, wherein the two ends of the pedal are correspondingly connected to the rope heads of the rope belts, and the pedal is parallel to the shaft. The backstroke starting device based on the embodiment of the invention is convenient to disassemble and assemble.

Owner:山东悦实信息科技有限责任公司

Luggage box assembly device and assembly method in aircraft cabin

ActiveCN111591449BEasy to adjustQuick assemblyStowage devicesTrunk compartmentStructural engineering

The present invention proposes a suitcase assembly device for assembling the suitcase on the fuselage frame, comprising a fuselage connecting unit, a suitcase connecting unit and a suitcase positioning unit, the fuselage connecting unit and the suitcase connecting unit adopt a certain The connection unit with axial freedom, the trunk positioning unit has a locking mechanism, which allows the connection unit to adjust the positioning position in the unlocked state, and fixes the connection unit in the locked state, so that the trunk assembly device can realize the rapid assembly of the trunk. Positioning and assembly solves the problems of cumbersome luggage installation process, difficult positioning adjustment and inconvenient maintenance in the later period.

Owner:COMAC +1

A device and method for aligning and tightening nuts of an aero-engine connecting rod mechanism

ActiveCN110561097BAvoid space constraintsGuaranteed accuracyMetal working apparatusAviationNumerical control

The invention discloses an aircraft engine link mechanism nut alignment and tightening device and an aircraft engine link mechanism nut alignment and tightening method, and belongs to the aircraft engine internal assembly technology field. The aircraft engine link mechanism nut alignment and tightening device comprises a universal joint driving type tightening system, a nut alignment and positioning system and a device tool prepositioning system, wherein the device tool prepositioning system is installed on a housing of a rotor of an aircraft engine, the nut alignment and positioning system isinstalled on the upper portion of the device tool prepositioning system, and the universal joint driving type tightening system is installed in the nut alignment and positioning system. Positioning of a tightening sleeve is completed through the nut alignment and positioning system, and tightening work for nuts is completed by driving the tightening sleeve through a tightening motor. The aircraftengine link mechanism nut alignment and tightening device adopts a numerical control operation mode, simplifies the operation process, reduces manual operation task intensity, has the characteristicsof being high in automatic degree, high in motion precision and good in tightening state, and improves internal nut tightening efficiency of the aircraft engine.

Owner:DALIAN UNIV OF TECH

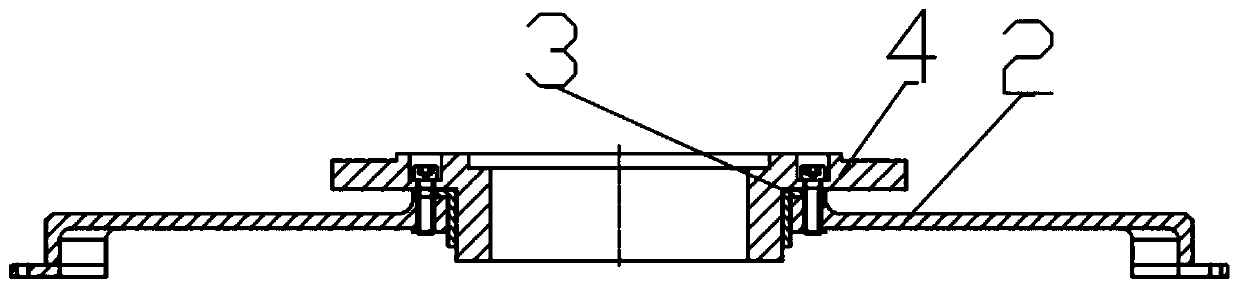

Combined butt-joint connecting device for vehicle-mounted baggage carrier

ActiveCN110861589ACompact assemblyGuaranteed assembly reliabilityInternal combustion piston enginesSupplementary fittingsIn vehicleStructural engineering

Owner:SAIC MAXUS AUTOMOTIVE CO LTD

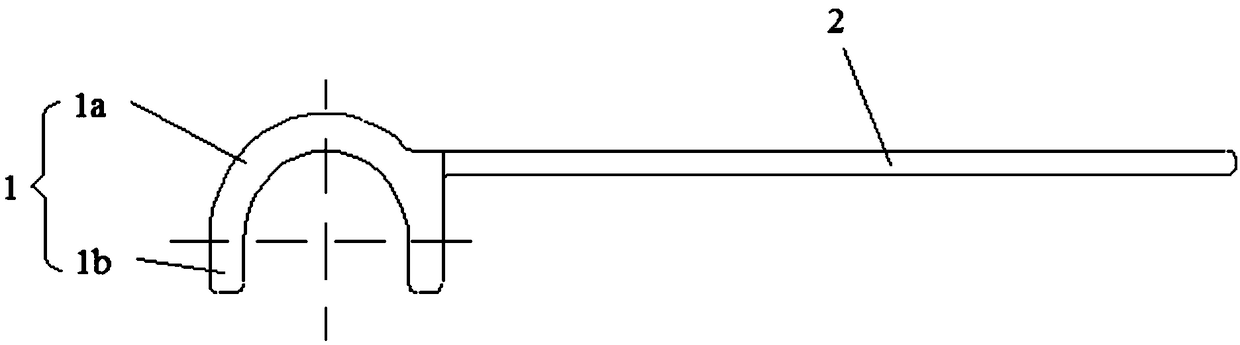

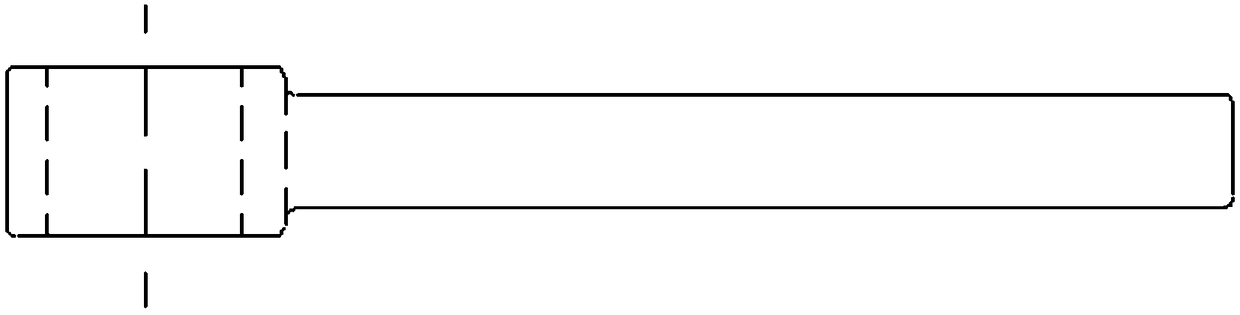

Untwisting wrench used for assembling guide pipe with three-way joint, and assembly method

InactiveCN109352569AEnsure assembly reliability and qualitySolve the tightening problemSpannersWrenchesWrenchEngineering

The invention discloses an untwisting wrench used for assembling a guide pipe with a three-way joint. The guide pipe with the three-way joint comprises the three-way joint, wherein two ports of the three-way joint are tubular ports, the other port is a thread port, and untwisting end flanges are connected to the two tubular ports of the three-way joint through pipelines. The untwisting wrench usedfor assembling the guide pipe with the three-way joint comprises an untwisting wrench head and an untwisting rod, wherein the untwisting wrench head and the untwisting rod are integrally formed; theuntwisting wrench head comprises a semicircular part and extension parts arranged at the two ends of the semicircular part, and the extension parts are parallel to the tangential direction of the endpart of the semicircular part; and the untwisting rod is a straight rod, and the untwisting rod is arranged on one side surface of the semicircular part and vertical to the extension parts. The untwisting wrench used for assembling the guide pipe with the three-way joint achieves the purpose of twisting for the guide pipe with the three-way joint, of an engine with a similar structure, and ensuresthe assembly reliability and quality for the guide pipe of the engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

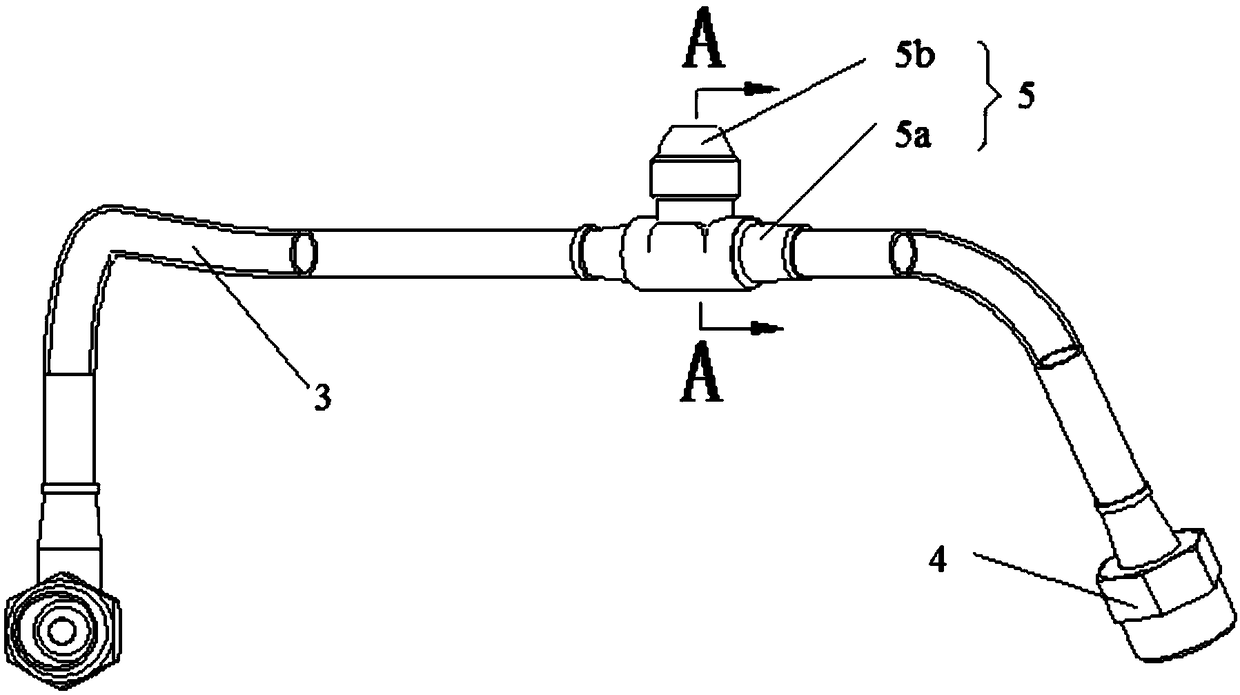

Wall-mounted furnace and coaxial smoke pipe connector assembly thereof

ActiveCN105972627ALarge adjustment rangeImprove working condition adaptabilityChimneysInlet channelWork performance

The invention discloses a coaxial smoke pipe connector assembly comprising a connector body. The connector body is provided with an air inlet channel; a smoke exhausting channel is coaxially arranged on the middle portion of the air inlet channel; and the connector body is provided with an exhausting flow limiting ring matched with the smoke exhausting channel and an air inlet flow limiting ring matched with the air inlet channel. In the assembling and using process, by means of cooperation of the exhausting flow limiting ring and the air inlet flow limiting ring, the channel area of the air inlet channel and the channel area of the smoke exhausting channel are adjusted at the same time, and therefore the adjustable range of the area specific value of channel ports of the coaxial smoke pipe connector assembly is effectively widened, and the overall work condition adaptive capacity and work performance of a wall-mounted furnace are remarkably improved. The invention further discloses the wall-mounted furnace applying the coaxial smoke pipe connector assembly.

Owner:GREE ELECTRIC APPLIANCES INC

A tightening and force limiting device and its application method

ActiveCN105291024BSimple and reasonable structureSolve assembly problemsSpannersWrenchesEngineeringTorque wrench

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Water dispenser and diversion cover assembly thereof

The invention discloses a diversion cover assembly which comprises a diversion cover body and a cold tank water outlet tube, wherein a connecting tube which is coaxially connected with the port of the cold tank water outlet tube in a sleeving manner is arranged on the diversion cover body; a plurality of buckles clamped and matched with the port of the cold tank water outlet tube are arranged on the connecting tube. When the diversion cover assembly is assembled and used, only the connecting tube of the diversion cover body needs to be coaxially connected outside the port of the cold tank water outlet tube in the sleeving manner, and the buckles are clamped and fixed at the port of the cold tank water outlet tube, so that reliable assembling of the diversion cover body and the cold tank water outlet tube can be achieved; when the diversion cover assembly needs to be disassembled, the clamping assembling mode achieved by the buckles is relatively small in structural resistance, only the connecting tube needs to be pulled down from the port of the cold tank water outlet tube in the axial direction, and thus the operation is simple, convenient and feasible. The invention further discloses a water dispenser using the diversion cover assembly.

Owner:GREE ELECTRIC APPLIANCES INC

A positioning and grasping method for electronic liquid crystal screens of different sizes

ActiveCN105856241BReduce occasional errorsReduce labor costsProgramme controlProgramme-controlled manipulatorLiquid-crystal displayComputer science

The invention discloses a method for positioning and grabbing electronic liquid crystal display screens with different sizes. The method includes simultaneously acquiring images by the aid of two cameras; processing the images; searching for characteristics of shells; carrying out interior operation by the aid of the cameras and outputting operation results to robots; grabbing the liquid crystal display screens by the aid of the robots; arranging the liquid crystal display screens by the aid of the robots according to the operation results. The method has the advantages that an integral assembling procedures for grabbing and positioning each liquid crystal display screen and accurately arranging the liquid crystal display screen in the corresponding shell can be completed within the time no longer than 5 seconds, and accordingly the efficiency can be improved by more than 20 times as compared with the labor efficiency; work can be continuously carried out throughout the day all year round; only initial investment is required, and the cost can be correspondingly reduced by the cost for five workers; personnel operation can be omitted, accordingly, occasional errors due to personnel assembly and detection can be greatly reduced, and the assembly reliability can be guaranteed; the method is compatible to the liquid crystal display screens with different dimensions, only additional programs are required, and additional mechanical structures can be omitted; personnel do not need to be in contact with the liquid crystal display screens, and accordingly risks of product damage and product contamination can be prevented.

Owner:SHANGHAI BETTERWAY AUTOMATION CO LTD

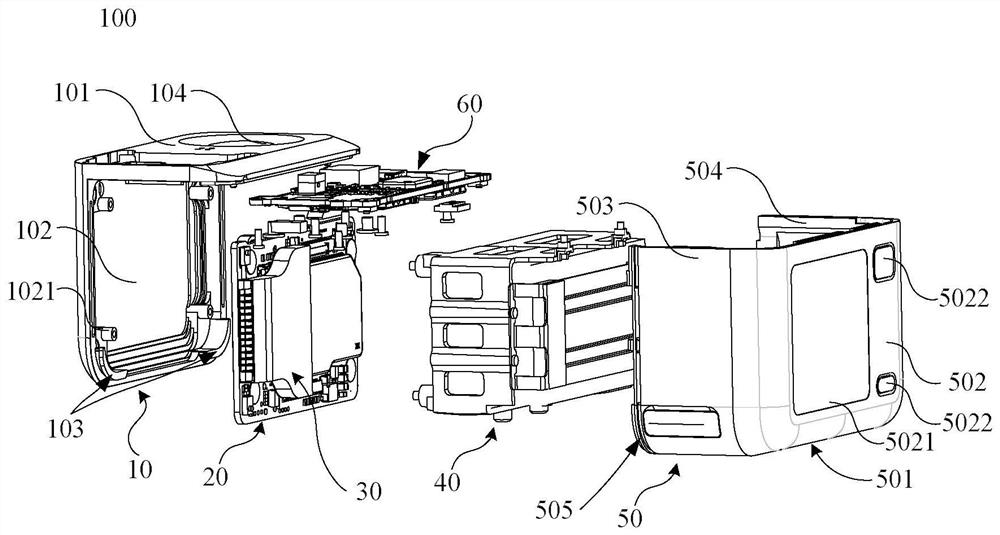

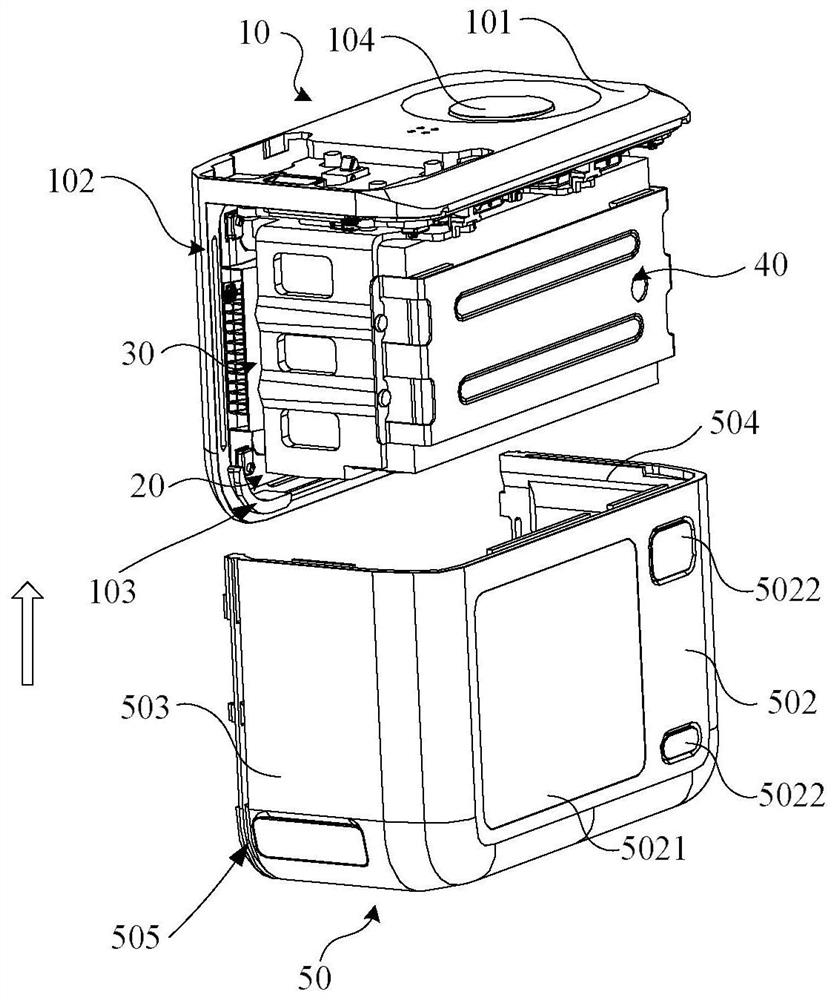

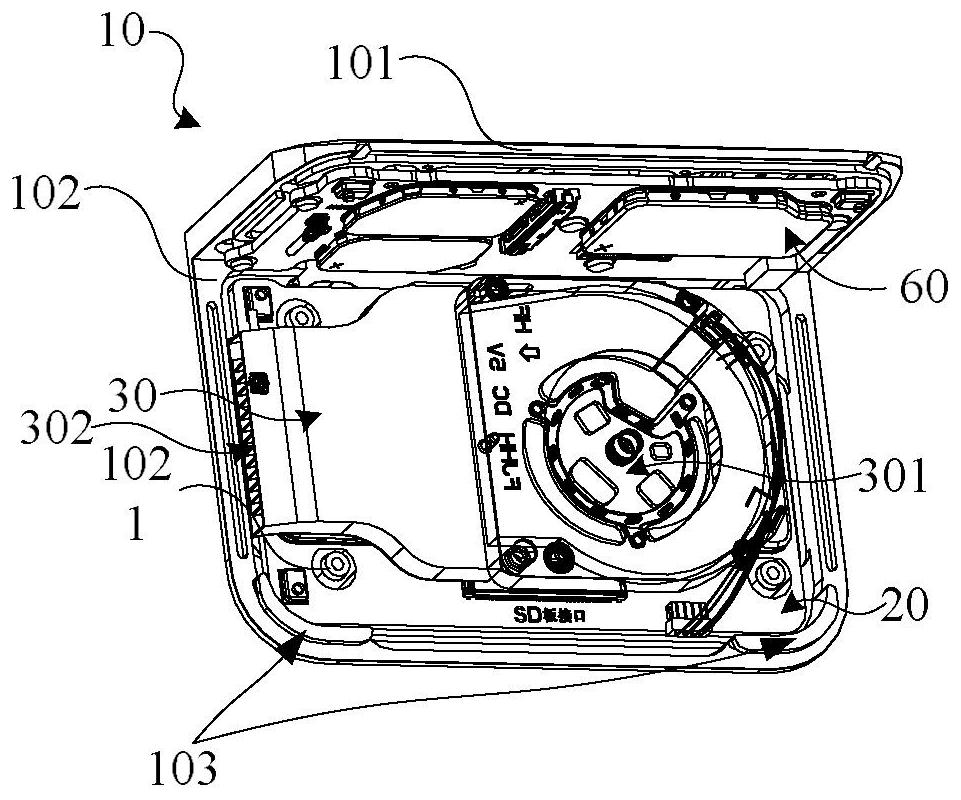

Camera body and camera structure

ActiveCN109983400BGuaranteed assembly reliabilitySimplify the assembly processCamera body detailsCooling/ventilation/heating modificationsPhysicsHeat sink

The embodiment of the invention discloses a camera body and a camera structure. The camera body (100) includes a front cover assembly (10), a first circuit board (20), a heat dissipation assembly (30), a power supply assembly (40) and a rear cover assembly (50); the front cover assembly (10) and the rear cover The components are enclosed to form a cavity; the first circuit board (20), the heat dissipation component (30) and the power supply component (40) are all arranged in the cavity, and extend from the front cover assembly (10) to the rear cover assembly ( 50), the heat dissipation assembly (30) is disposed between the first circuit board (20) and the power source assembly (40); wherein, the power source assembly (40) is close to the first circuit board (20) and the heat dissipation assembly One side of the (30) is fixed to the front cover assembly (10), and is pressed and held on the first circuit board (20) and the heat dissipation assembly (30). Through the above structure, the first circuit board and the heat dissipation assembly are relatively fixed by the power supply assembly, and the assembly method of the camera body can be simplified while maintaining the assembly reliability of the camera body.

Owner:SZ DJI OSMO TECH CO LTD

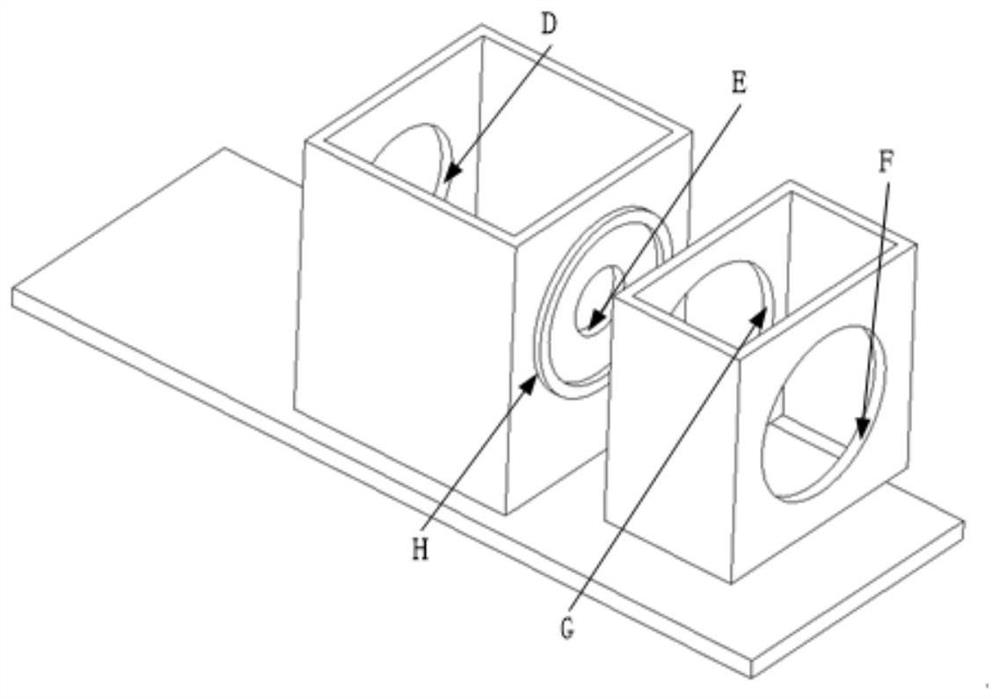

A tm01 dielectric resonator assembly device

ActiveCN102969555BGuaranteed assembly reliabilityResonatorsDielectric resonator antennaFirst pass yield

The invention relates to a TM01 medium resonator assembling device. A transitional metal band is introduced, so that the reliability of assembly of a TM01 medium resonator and a metal cavity is guaranteed. The TM01 medium resonator assembling device is characterized in that the TM01 medium resonator is welded on the transitional metal band in a single-end manner; the transitional metal band on which the TM01 medium resonator welded in a single-end manner is arranged on a cavity cover board by a thread on the transitional metal band; and therefore, a TM01 medium filter can be stably and reliably assembled. The TM01 medium resonator assembling device is suitable for any TM01 medium resonator and is particularly suitable for products which have relatively high requirement on the first pass yield of the TM01 medium filter, are relatively complicated in design and need massive overhaul and maintenance in the later stage.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

A low-noise water supply pump assembly method

ActiveCN113084488BRealize precision detectionSolve development problemsMeasurement/indication equipmentsHydro energy generationLow noiseDrive shaft

The invention provides an assembly method of a low-noise water supply pump, including the precision decomposition process design of the shaft system; the rough positioning assembly of the motor bracket and the support; the coaxiality measurement of the motor bracket and the support hole; Hole coaxiality repair; transmission shaft, bearing and bearing support seat assembly; transmission shaft, bearing forming shaft no-load accuracy test; cylinder, piston, transmission shaft assembly and accuracy test after assembly; shaft noise detection without motor and debugging; combined assembly of motor and motor pad; combined assembly of coupling and coupling spacer. The assembly method provided by the present invention solves the problem that the motor vibration reduction assembly control of the low-noise water supply pump in the space is not quantified, and resonance is easily generated, and the coaxiality of the shaft assembly is not high, which may easily lead to shaft rotation friction noise, noise and performance measurement process. Unrefined control leads to problems such as excessive noise, which improves the performance and life of the water supply pump and ensures long-term operation safety.

Owner:BEIJING SATELLITE MFG FACTORY

A method for installing a maintenance-free wear alarm on a brake

The invention relates to the technical field of braking, and provides a method for installing a maintenance-free wear alarm on a brake, comprising the following steps: opening a first hole and a second hole on the brake; inserting the maintenance-free wear alarm into the In the first hole, until the first hole clamps the maintenance-free wear alarm and prevents the maintenance-free wear alarm from continuing to enter the first hole; swing the maintenance-free wear alarm so that the mounting protrusion on the housing The table is snapped into the second hole to prevent the maintenance-free wear alarm from withdrawing from the first hole; wherein, the distance between the first hole and the second hole on the same horizontal plane is the same as that of the housing The distance from the position of the opening of the first hole to the position of the installation boss is equal. The invention provides two holes on the brake, and only needs two steps to install the maintenance-free wear alarm on the brake, which simplifies installation, improves installation efficiency, and ensures assembly reliability.

Owner:派德森(京山)汽车零部件有限公司

Partition and supporting frame assembly

InactiveCN104729037AGuaranteed assembly accuracyGuaranteed assembly reliabilityLighting and heating apparatusSpace heating and ventilation detailsUltimate tensile strengthAssembly structure

The invention discloses a partition and supporting frame assembly. The partition and supporting frame assembly comprises a partition and a supporting frame which are matched with each other, wherein the partition is provided with a threaded hole; the supporting frame is provided with a positioning hole which is aligned with the threaded hole in a matched manner; the partition is connected with the supporting frame through a threaded fastener which sequentially penetrates in the positioning hole and the threaded hole; the partition is provided with a clamping hole; and the supporting frame is provided with a fastener which is matched with the clamping hole in a fastened manner. In a working process, by a double-fastening assembling structure comprising a threaded matching structure and a fastening matching structure, the overall assembly difficulty and the operation amount of the partition and supporting frame assembly can be reduced effectively on the basis that the strength of assembling of the supporting frame and the partition is guaranteed, an assembling process is simple and convenient, and the labor intensity of workers is reduced correspondingly.

Owner:GREE ELECTRIC APPLIANCES INC

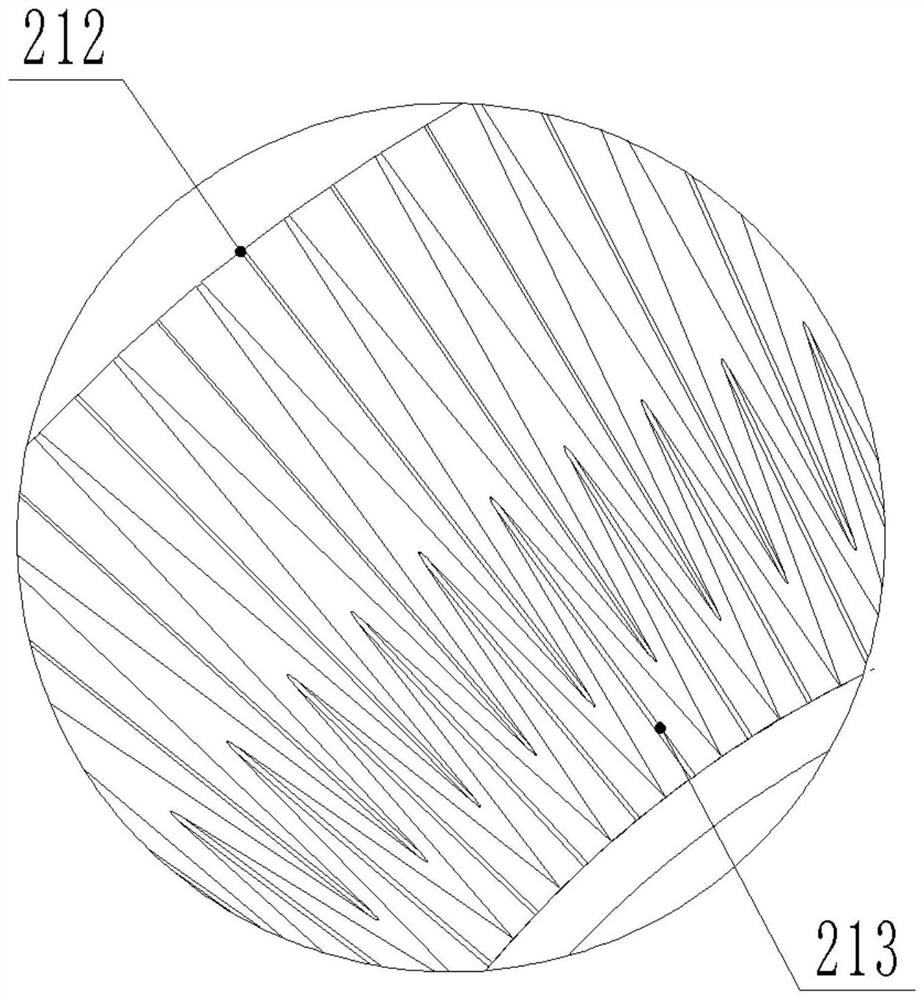

Tooth-shaped gasket for preventing following rotation of bolt and high-strength bolt connecting pair

The invention discloses a tooth-shaped gasket for preventing bolt following rotation and a high-strength bolt connecting pair. The tooth-shaped gasket comprises a gasket body, and radial teeth in the radial direction are arranged on the two end faces of the gasket body correspondingly; the radial tooth profiles comprise a plurality of outer tooth profiles extending inwards from the outer circle face of the gasket along the end face and a plurality of inner tooth profiles extending outwards from the inner hole of the gasket along the end face, the outer tooth profiles and the inner tooth profiles are arranged in a staggered and spaced mode, and the interval between every two adjacent outer tooth profiles and inner tooth profiles is small. The outer tooth profiles and the inner tooth profiles are arranged densely, and the number is large. By the adoption of the gasket, in the tightening process of applying torque to a bolt and a nut in a matched mode, the situation that the bolt and the gasket rotate along with the bolt is avoided, the nut can be reliably tightened, the assembling reliability and the equipment installation quality are guaranteed, and therefore the equipment safety is guaranteed. The device is particularly suitable for outdoor environments with severe use environments and places with severe working conditions on working sites and high working difficulty.

Owner:济南中船设备有限公司

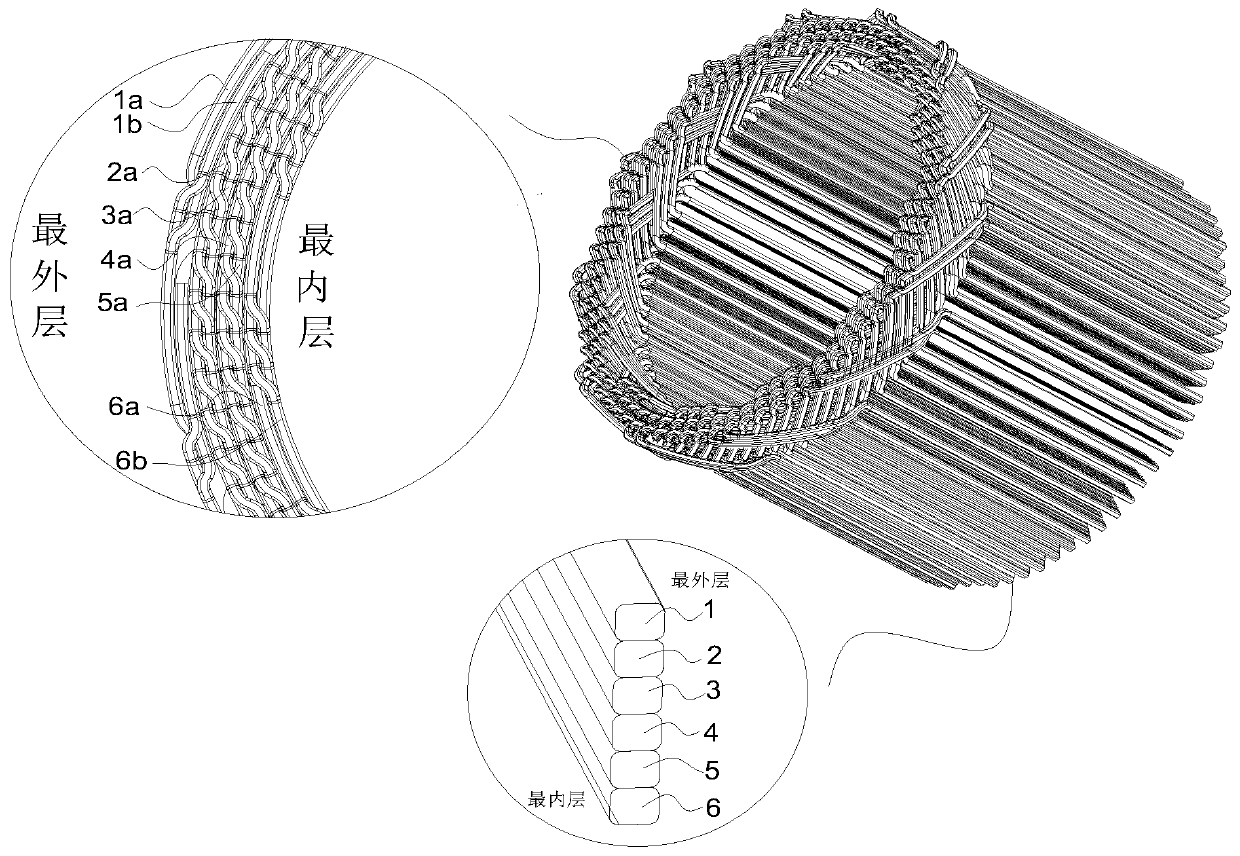

Coil element structure of motor flat enameled wire winding

PendingCN110957834AGuaranteed assembly reliabilityReduce or eliminate interference problemsWindings conductor shape/form/constructionElectric machineStructural engineering

The invention aims at disclosing a coil element structure of a motor flat enameled wire winding. The coil element structure is formed by communicating an end part, a bending angle, a zigzag line, an inner bending point and an outer bending point, and a flattening section which generates certain plastic deformation and has a certain length is arranged between the end part and the bending angle; compared with the prior art, a flattening measure is adopted from the end part of the coil element structure to the zigzag line of the coil element structure, so that the interference problem when the inner layer and the outer layer of the winding are directly stacked is reduced or eliminated on the premise of ensuring the assembly reliability of the motor, and the purpose of the invention is achieved.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com