Coil element structure of motor flat enameled wire winding

A technology of enameled wire winding and coil components, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., which can solve the problems of increased probability of damage to insulating coatings and insulation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

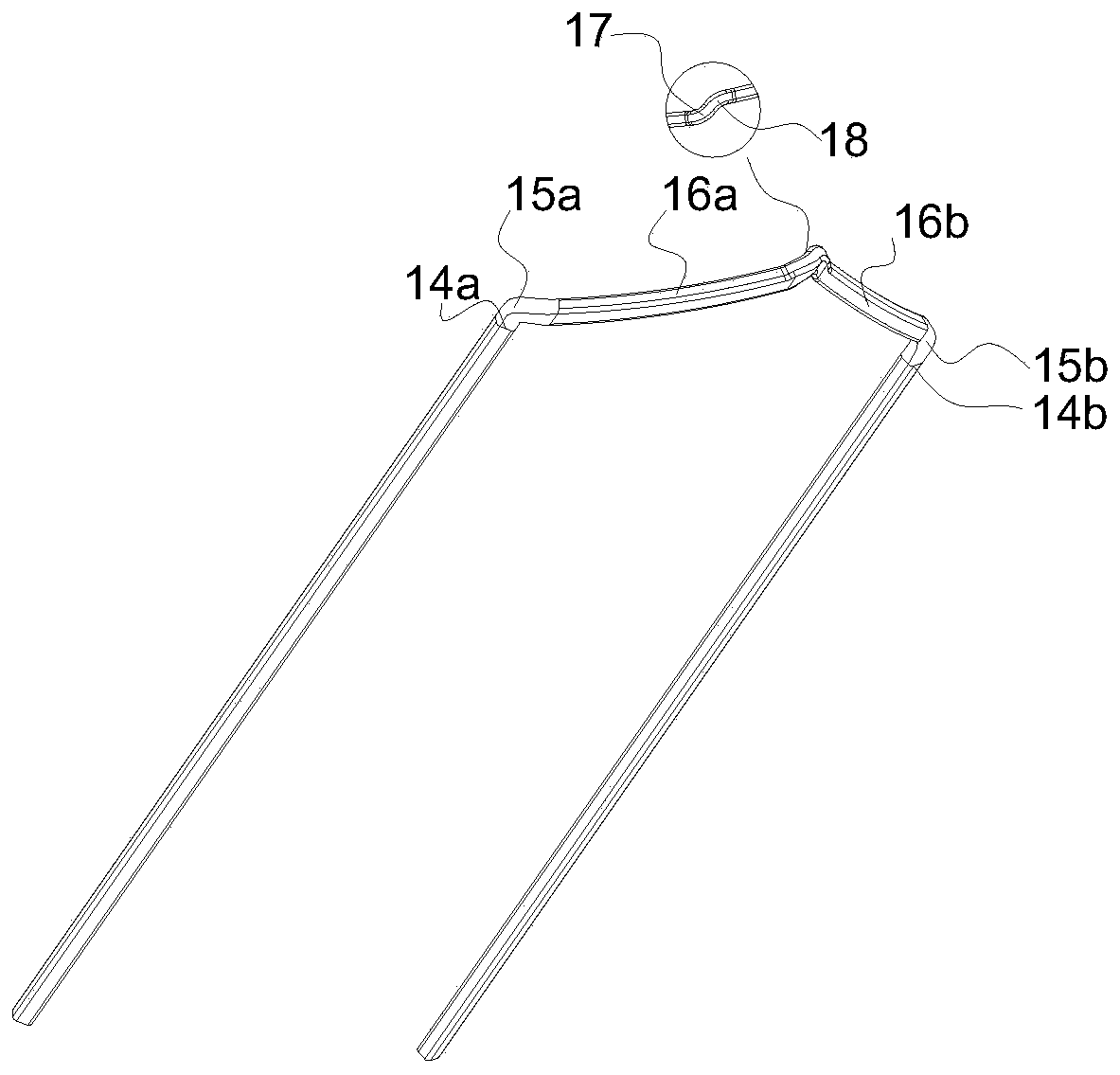

[0021] Such as image 3 and Figure 4 As shown, the coil element structure of the motor flat enameled wire winding of the present invention is composed of ends, bending angles, meander lines, inner bending points and outer bending points connected to each other; 14a and transition 14b are coil element ends, 15a and 15b are bending angles, 16a and 16b are meandering lines, 17 is an inner bending point, and 18 is an outer bending point.

[0022] In this embodiment, a flattened section with a certain length is provided between the end and the bending angle to produce a certain plastic deformation, and the flattened section is flattened on both sides toward the center and toward the center. A flattened section that produces 10%-30% plastic deformation.

[0023] In this embodiment, the crushed length of the crushed section is 10-80 mm.

[0024] Wherein, the section 19 is the section before the deformation of the flattened section, and the section 20 is the section after the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com