A method for installing a maintenance-free wear alarm on a brake

An installation method and alarm technology, applied in the direction of brake types, mechanical equipment, etc., can solve the problems of complex installation, poor installation environment, and many product restrictions, and achieve the effects of improving installation efficiency, simplifying installation, and ensuring assembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

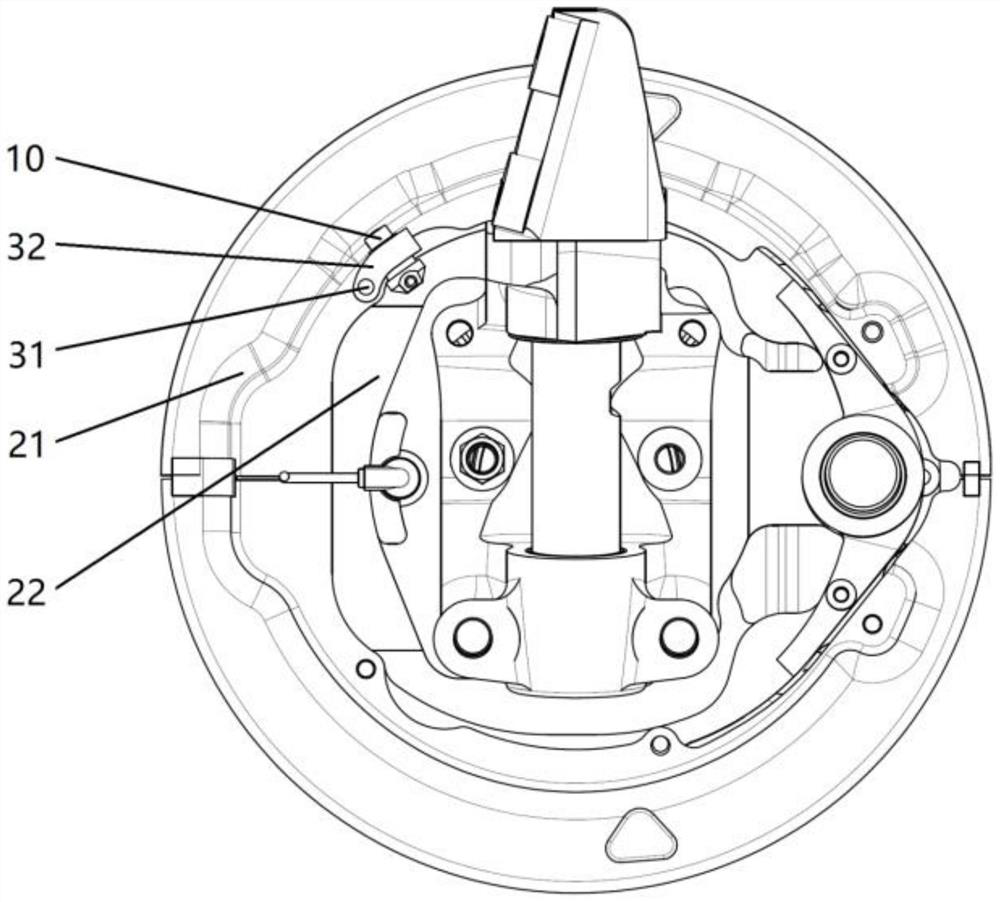

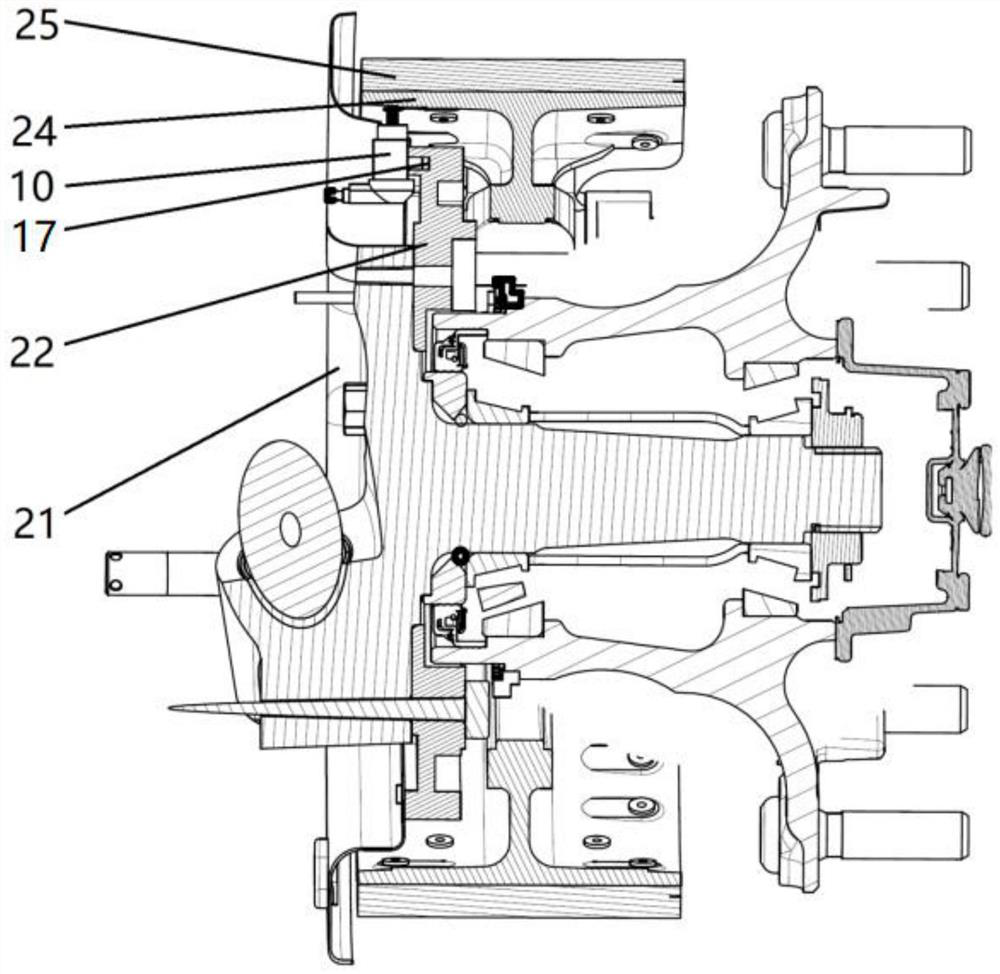

[0028] see Figure 1 to Figure 5 , the embodiment of the present invention provides a brake shoe wear measuring piece, which includes a housing, a telescopic structure that can abut against the brake shoe 25, and an installation assembly that can fix the housing on the brake dust cover 21, There is a detachable connection between the installation assembly and the housing; part of the telescopic structure is installed in the housing, and the end of the telescopic structure abutting against the brake shoe 25 is at the outside the casing. In this embodiment, on the one hand, the use of this measuring piece does not require frequent replacement of the wear alarm after the friction plate is worn out, which reduces user costs. On the other hand, even if it needs to be replaced, the measuring piece is installed on the brake dust-proof The cover 21 simplifies product installation and improves the reliability of product installation. After the measuring piece is installed on the dust...

Embodiment 2

[0036] see Figure 1 to Figure 5 An embodiment of the present invention provides a brake shoe wear alarm mechanism, which includes an alarm and the above-mentioned brake shoe wear measuring piece, and the brake shoe wear measuring piece is connected to the alarm through a signal transmission line. In this embodiment, when the wear condition is measured by the measuring piece, it is connected to the alarm through a signal transmission line, and the alarm will give an alarm. How to monitor and alarm will be described in detail in the following embodiments. The maintenance-free wear alarm 10 is the brake shoe wear measuring piece.

Embodiment 3

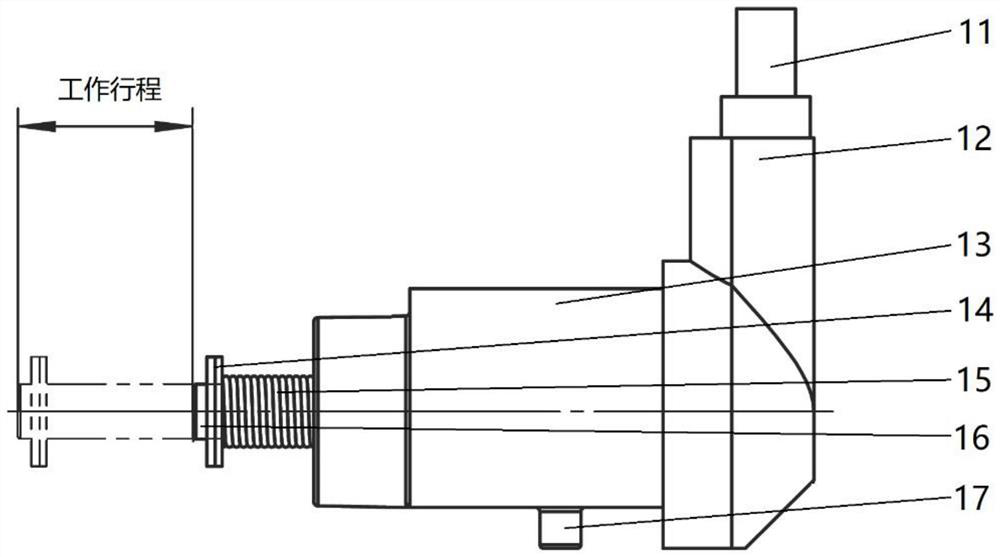

[0038] see figure 1 and Figure 4, the embodiment of the present invention provides a maintenance-free wear alarm, which includes a telescopic push rod 16 that can be supported on the brake shoe 25 at one end, a feedback module that can feed back the degree of wear according to the stretching amount of the push rod 16, and the The signal fed back by the feedback module is output to an external output component, and the output component is electrically connected to the feedback module through a PIN pin 1, and the PIN pin 1 is provided with a conductive member, and the conductive member is pressed on the When the feedback module is on, it is a shrapnel electrically connected to the feedback module. In this embodiment, the effect of the maintenance-free wear alarm 10 can be achieved through the cooperation of the telescopic ejector rod 16, the feedback module and the output assembly. In addition, the shrapnel that can be electrically connected to the feedback module during crimp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com