Patents

Literature

33results about How to "Reliable tightening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

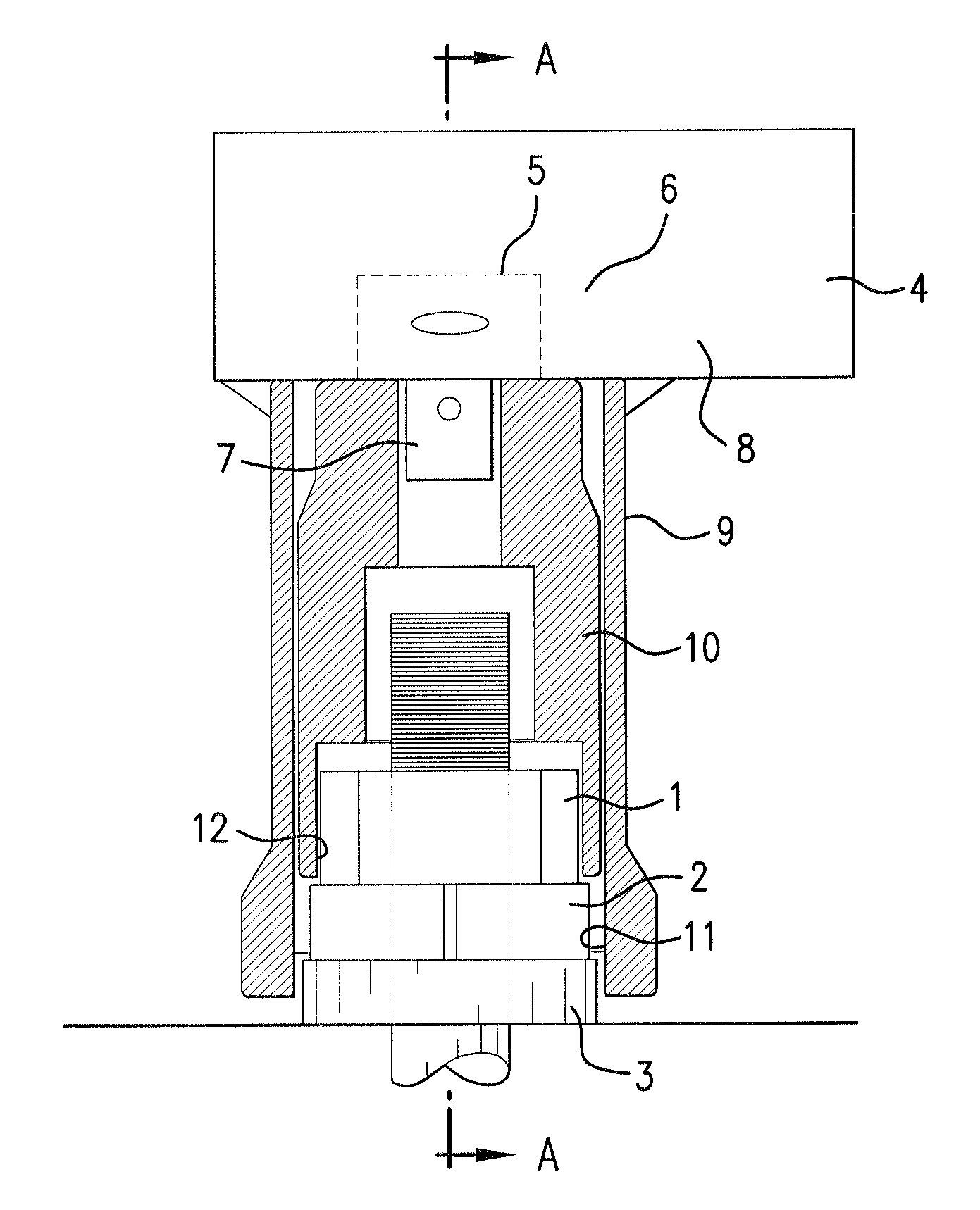

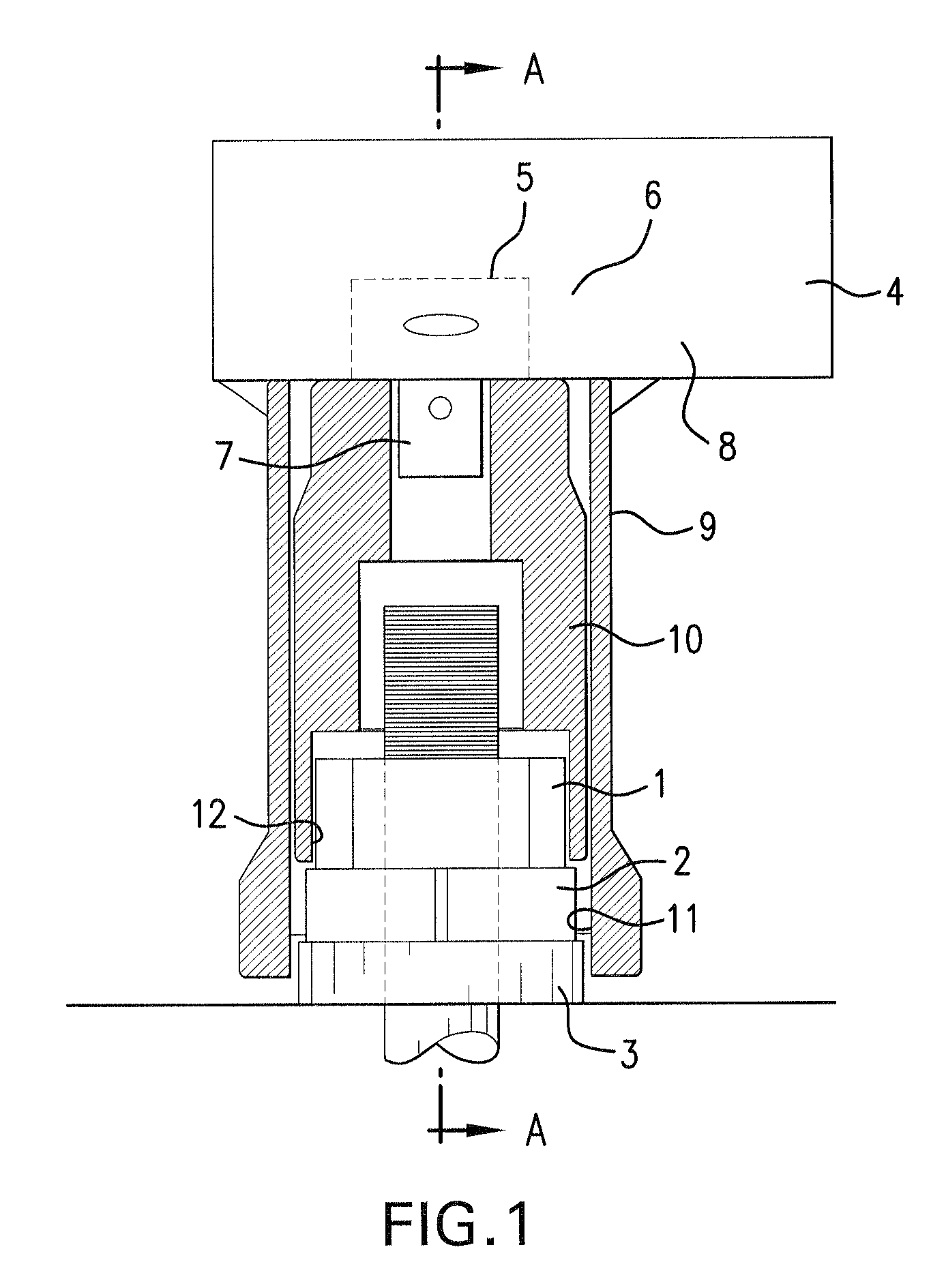

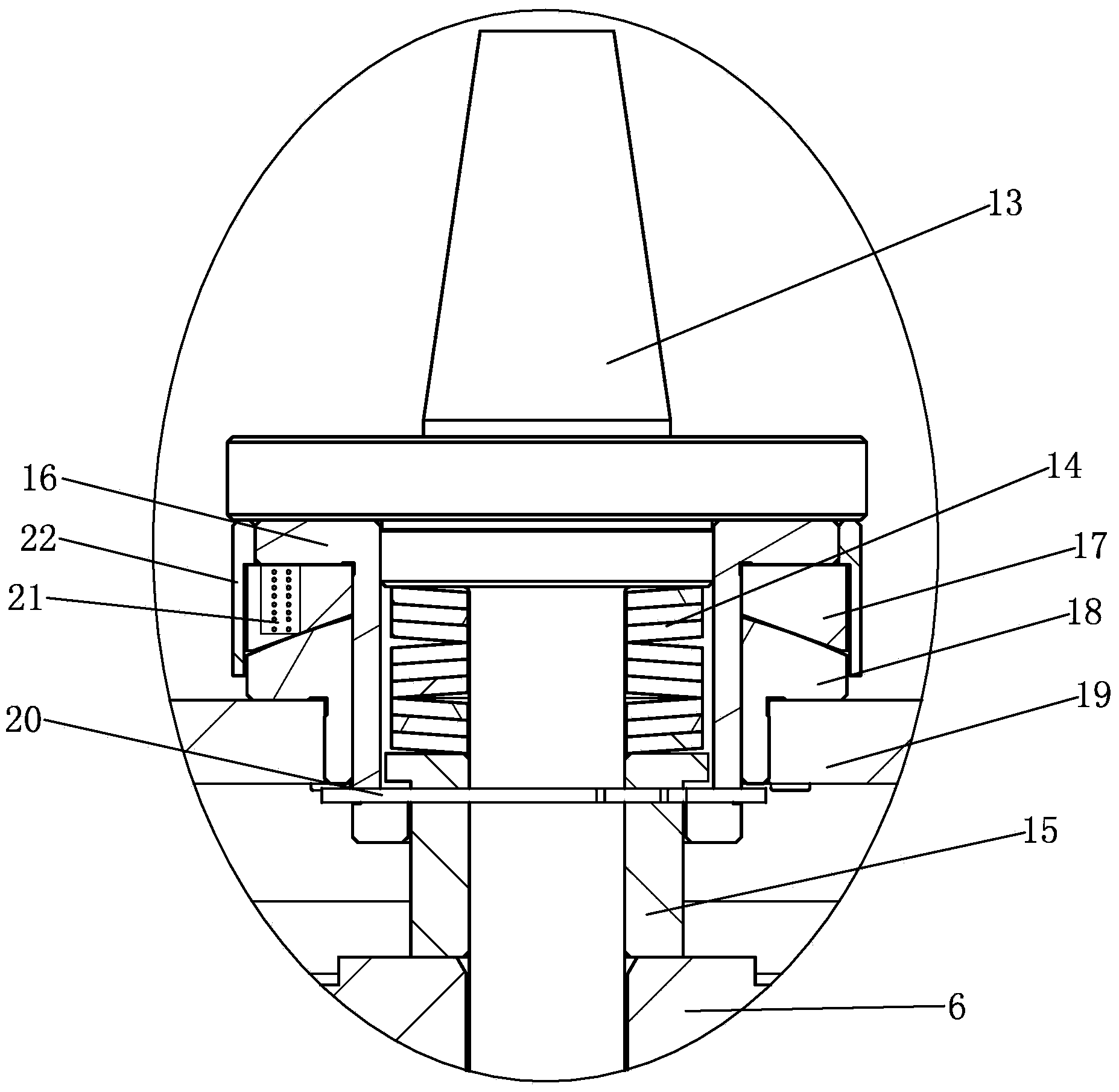

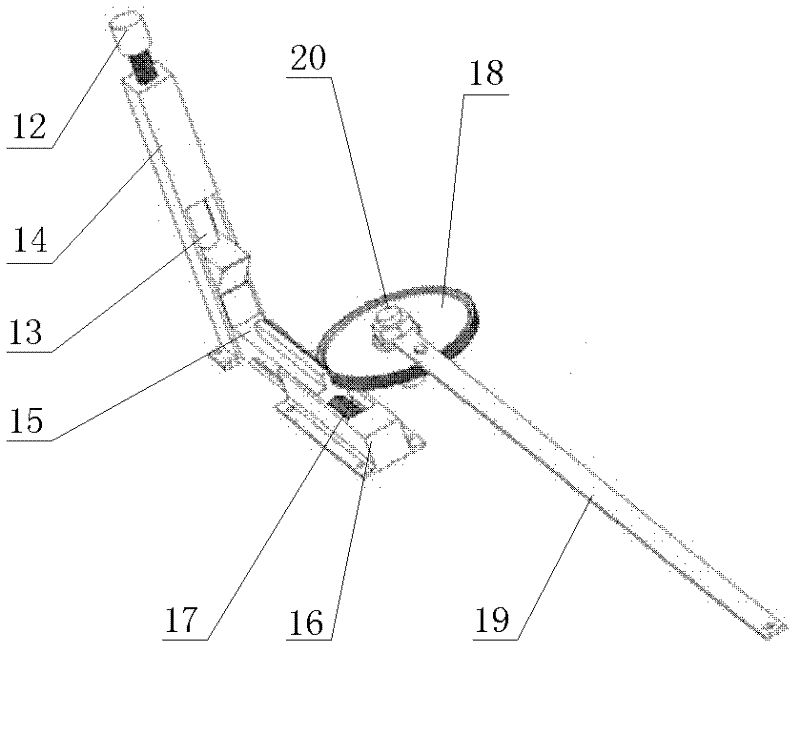

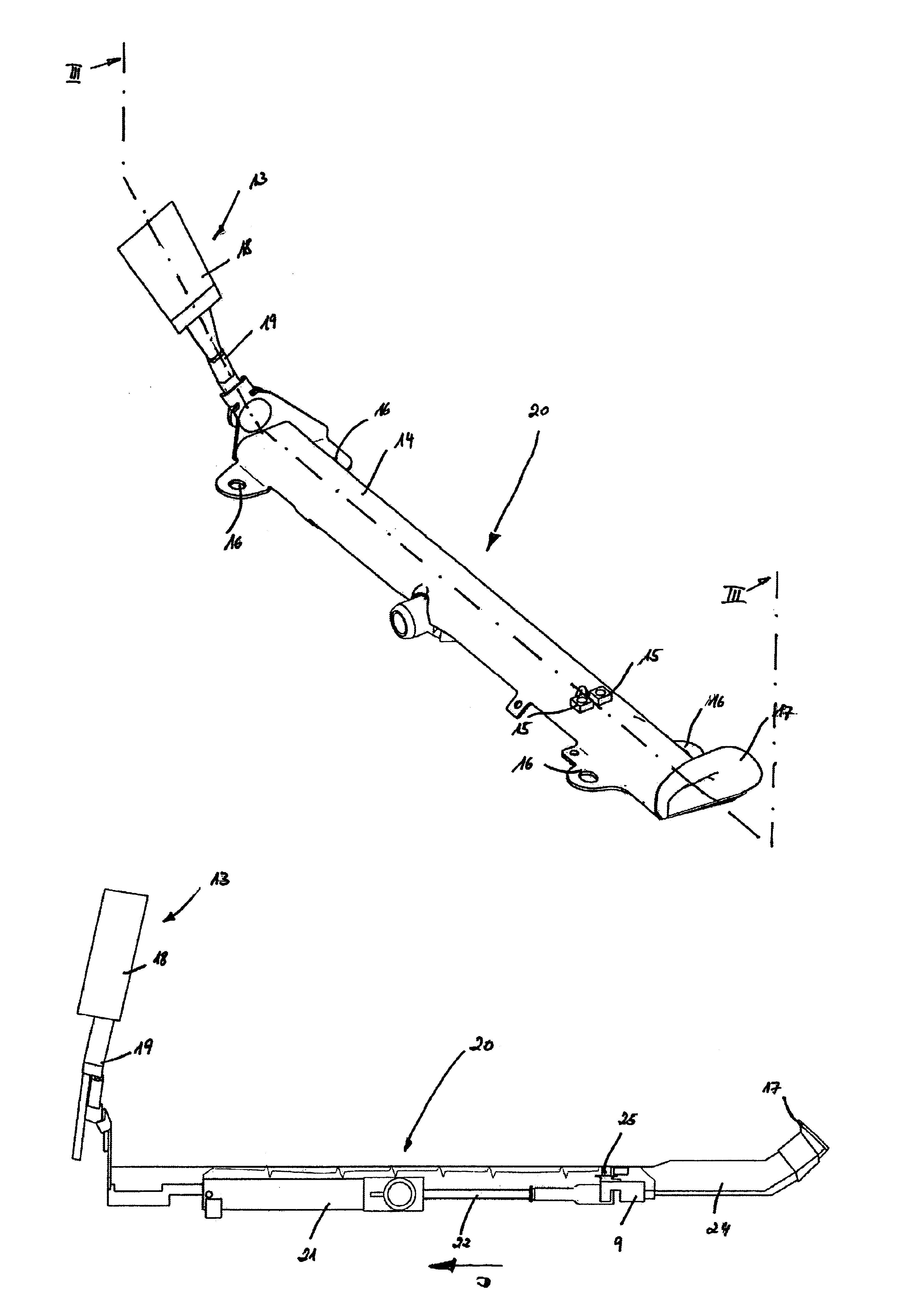

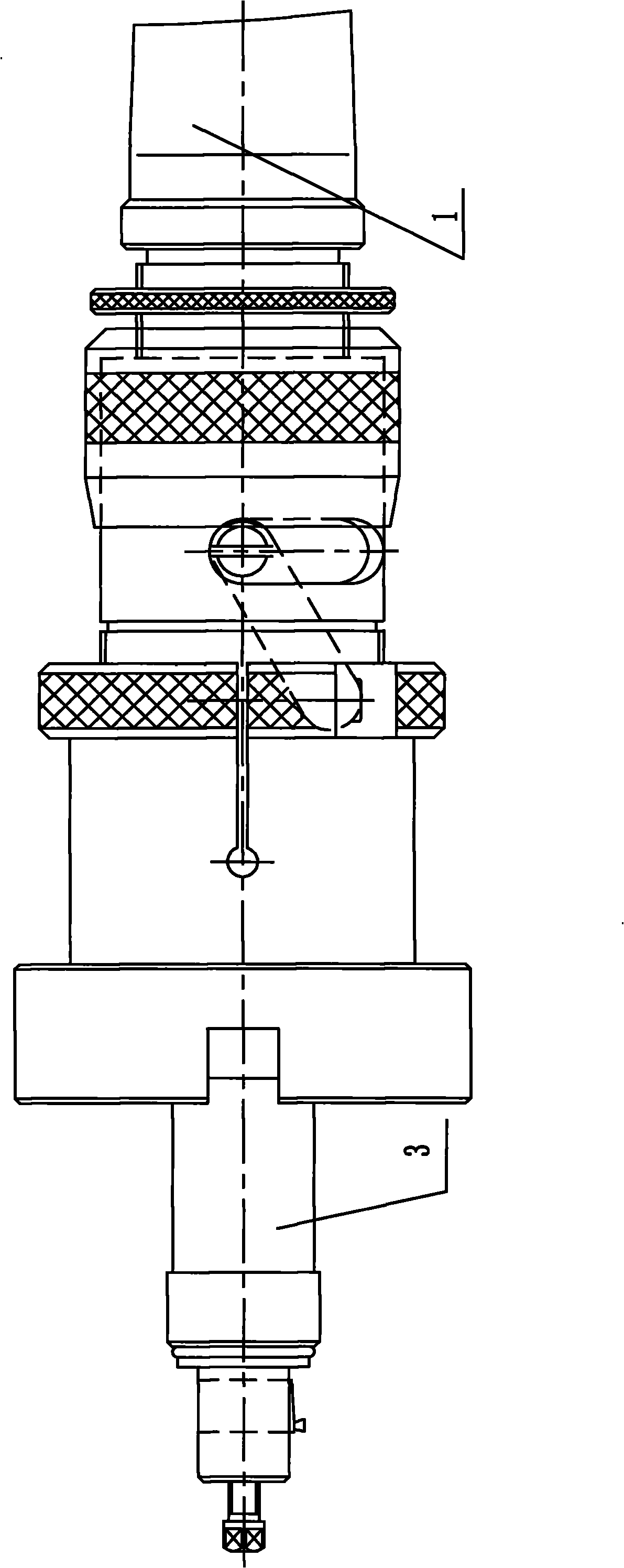

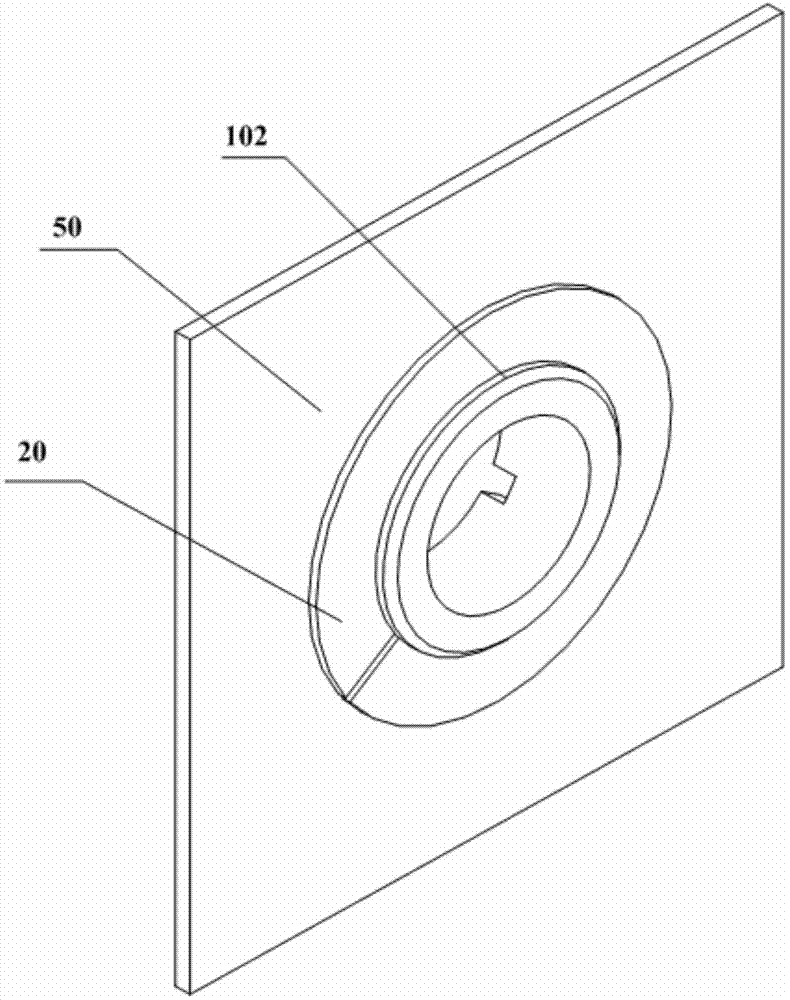

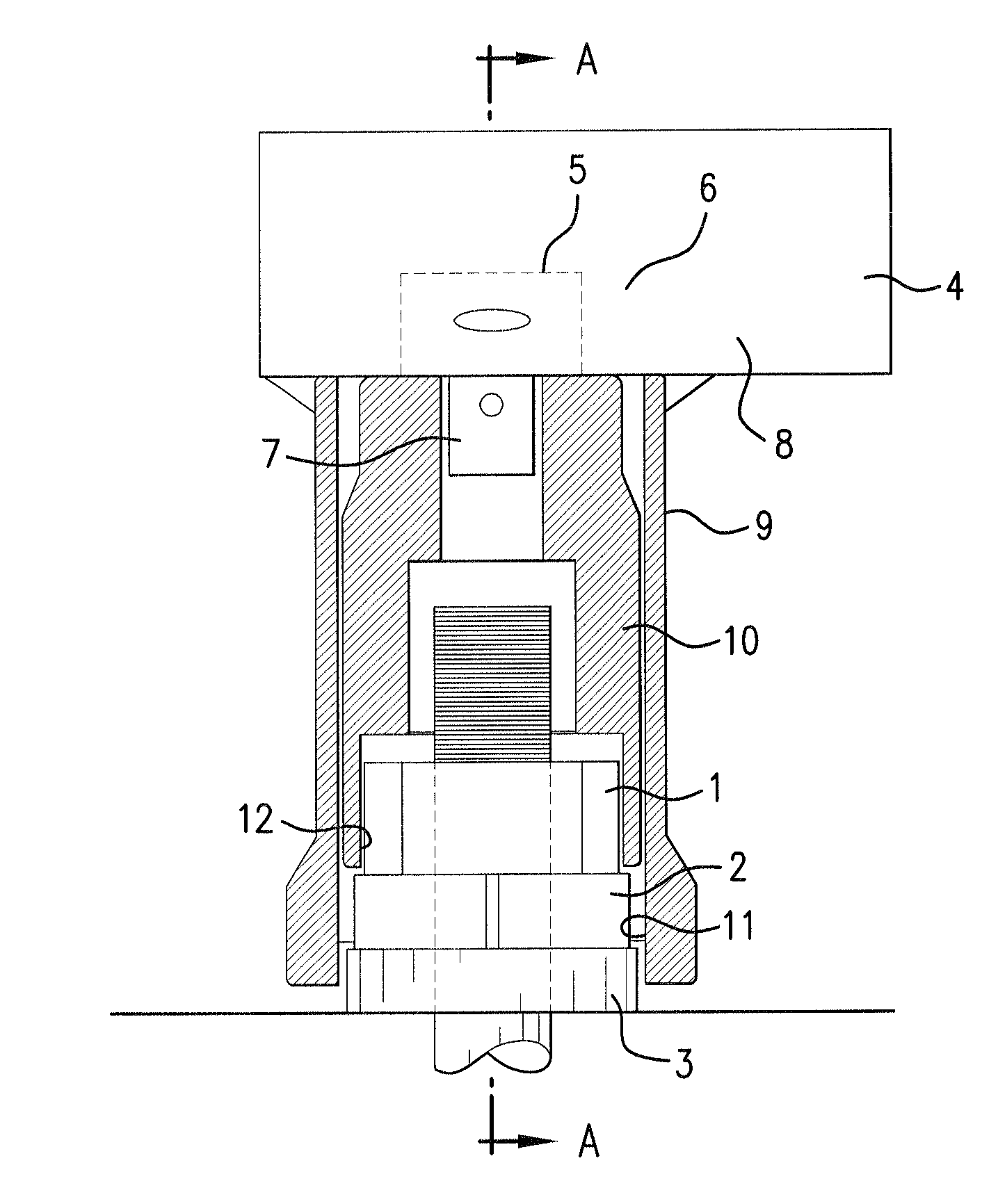

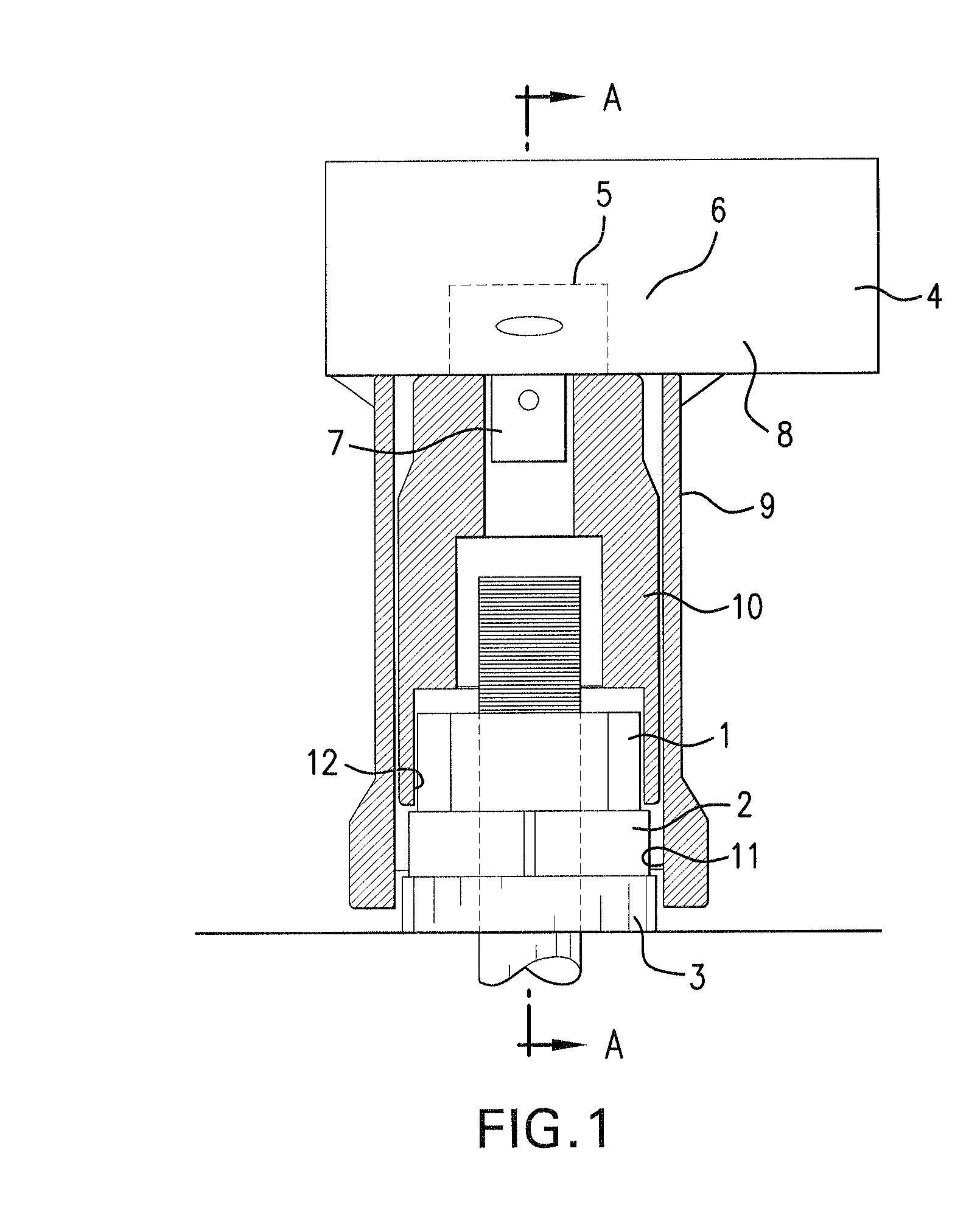

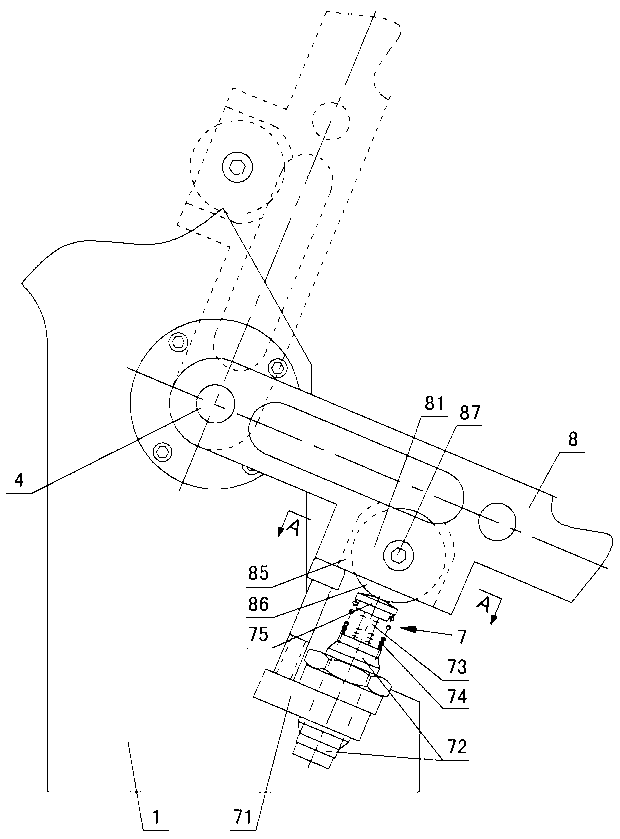

Fluid operated torque tool for and a method of tightening a nut on a plate on railroad crossings

A fluid operated torque tool tightens a nut through a spring washer on a plate on a railroad crossing, and has a housing, two coaxial drives applying equal turning forces in opposite directions around an axis, with one of the two coaxial drives located around the other of the two coaxial drives, a first socket attached to the one coaxial drive and configured to fit on the rectangular plate, and a second socket attached to the other coaxial drive inside the first socket and configured to fit on the nut, with the washer being not engaged by the sockets, so as to tighten the nut and to tighten up the spring washer onto the plate while the first socket and the housing stand still.

Owner:HYTORC DIV UNEX CORP

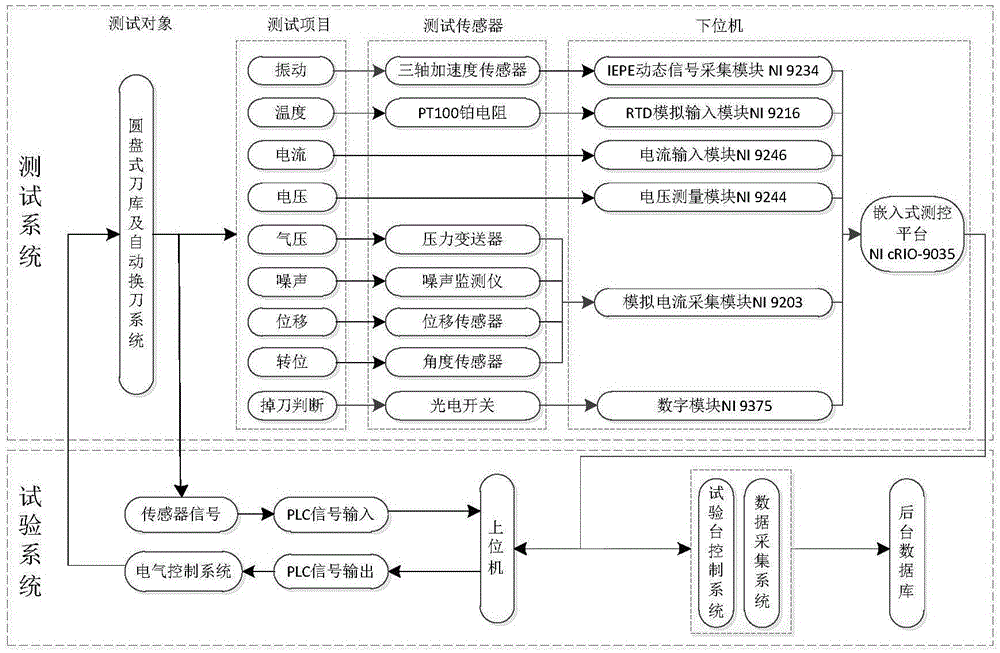

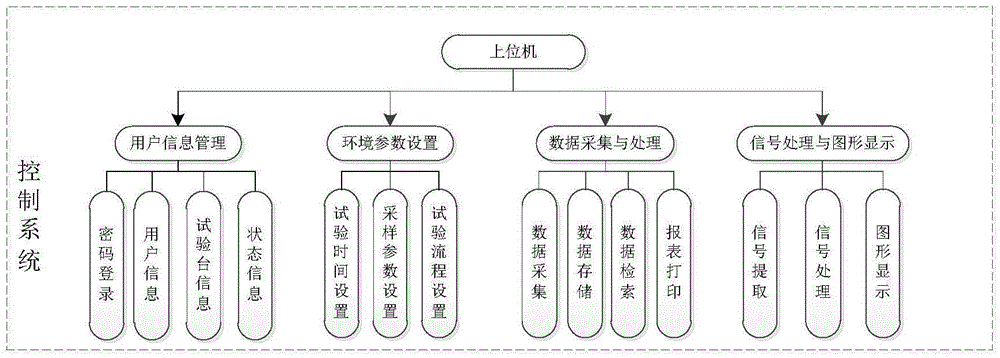

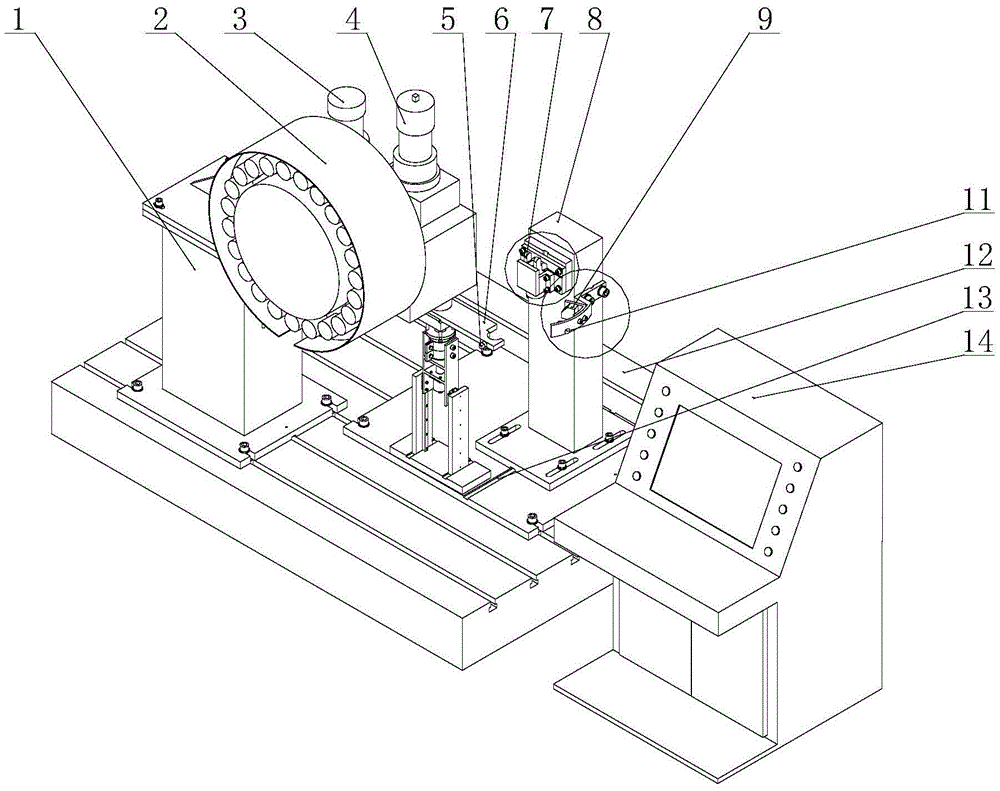

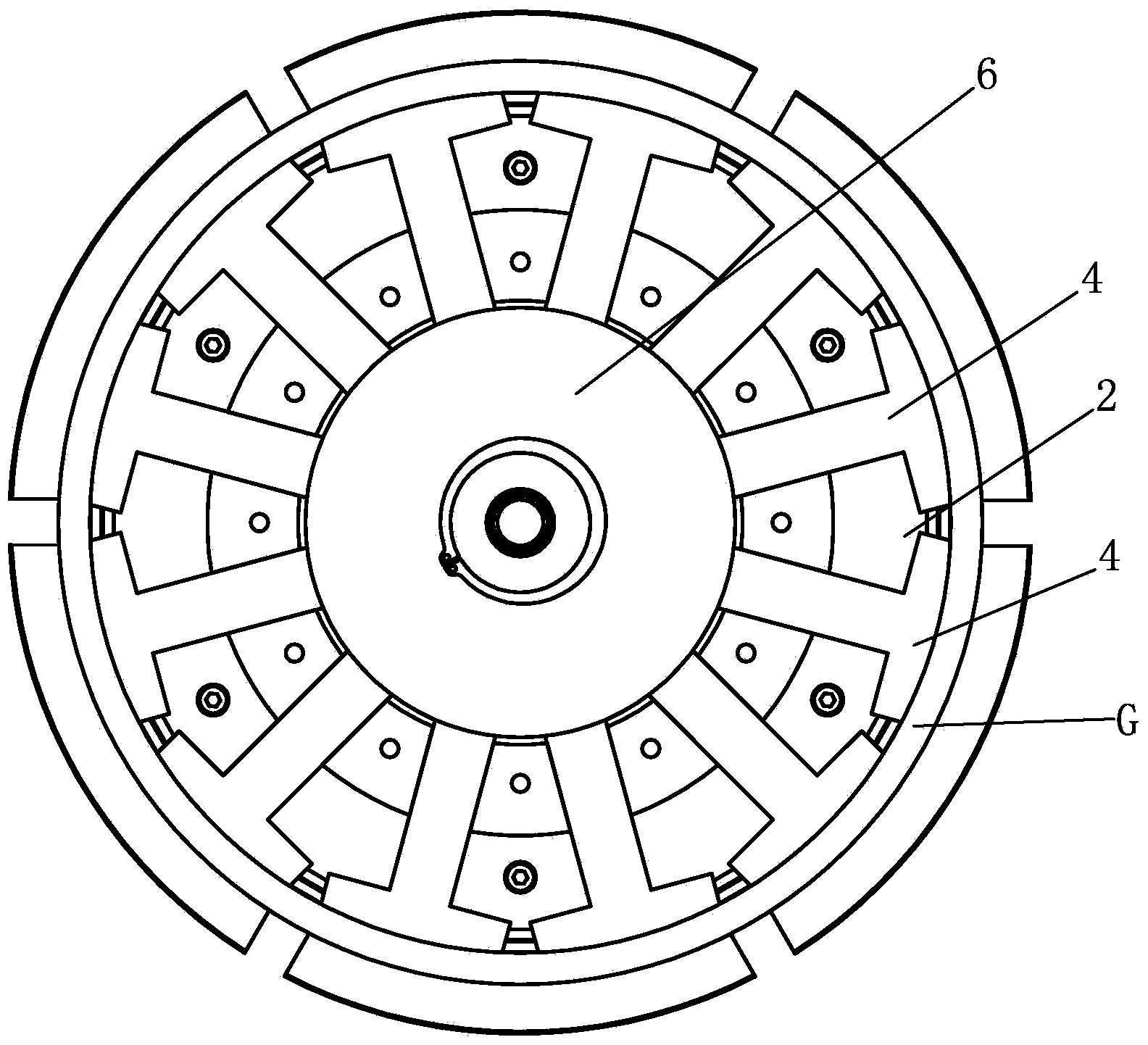

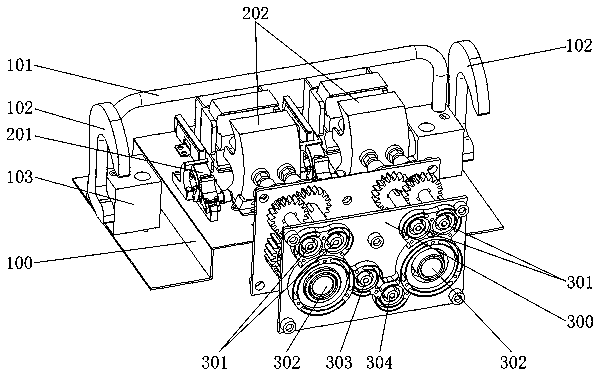

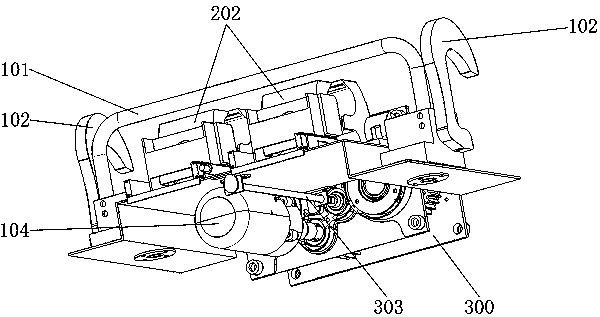

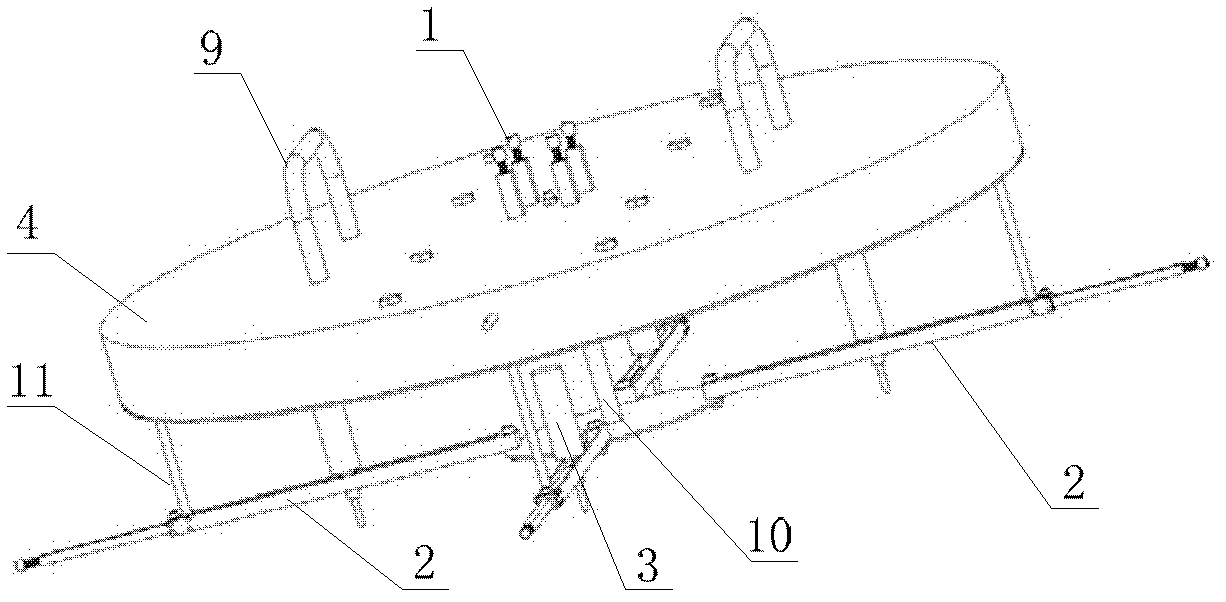

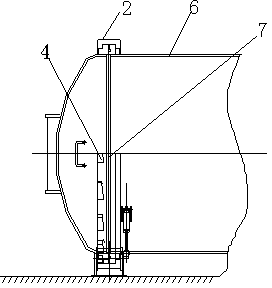

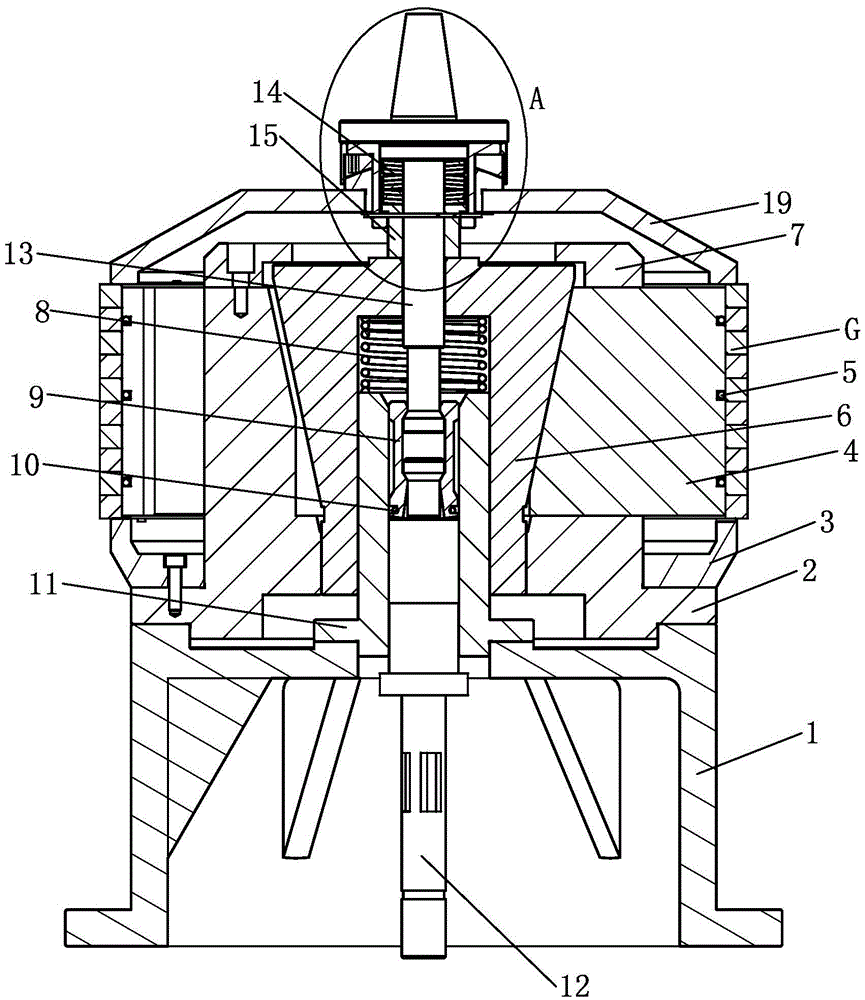

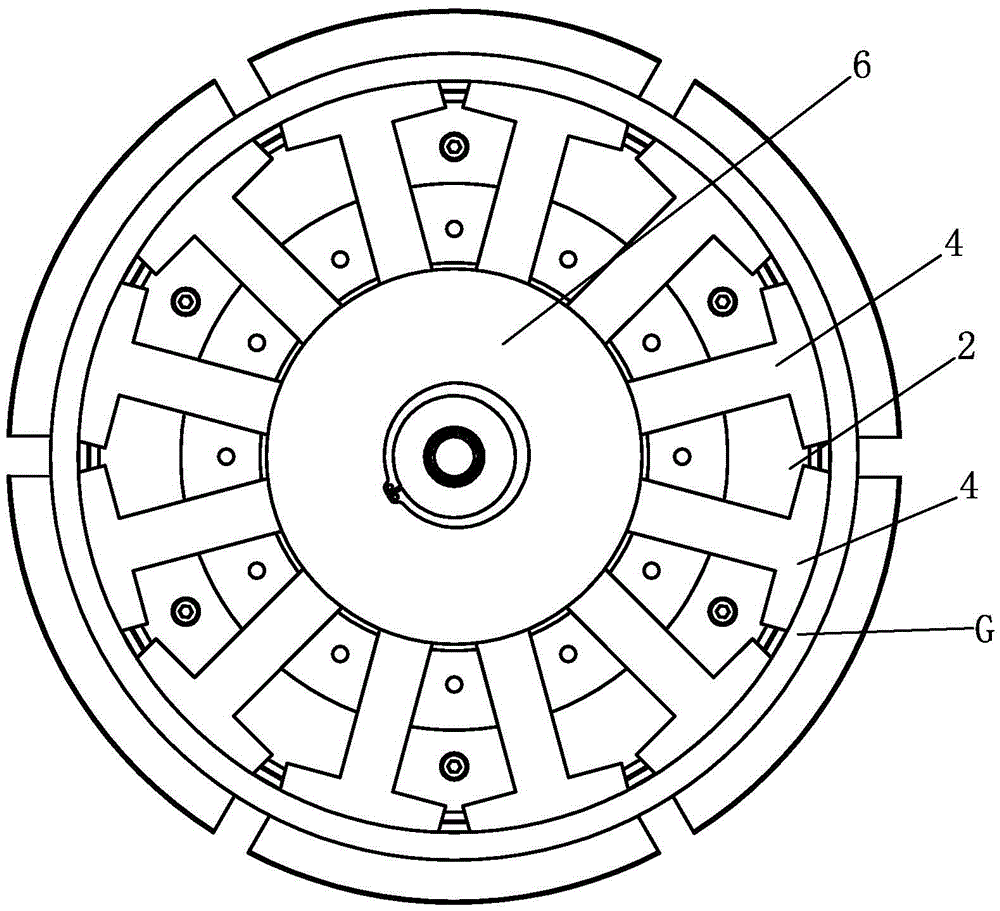

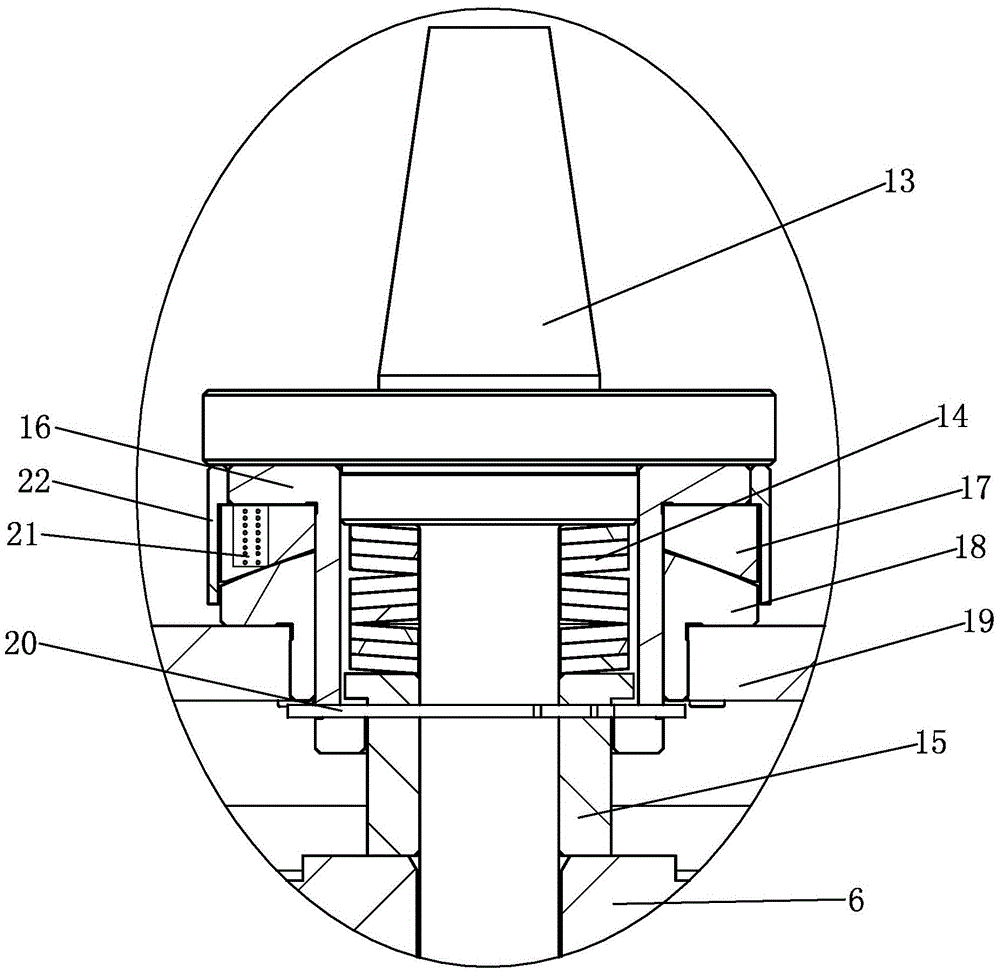

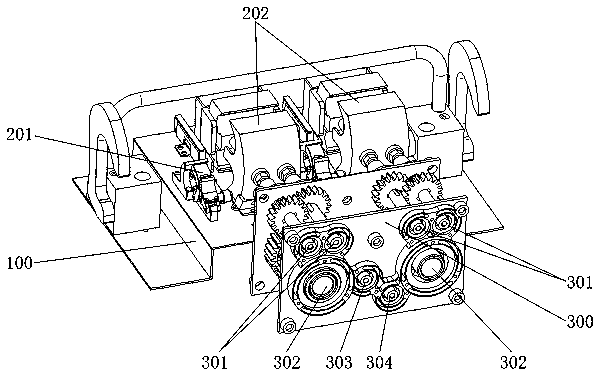

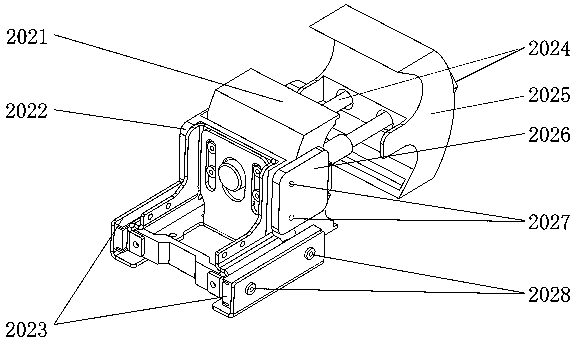

Disc-type tool magazine and automatic tool-changing system comprehensive performance detection platform

ActiveCN105573251AImprove performanceMany testing itemsProgramme controlComputer controlPilot systemControl system

The invention relates to the technical field of reliability test of a disc-type tool magazine and automatic tool-changing system for a machining center and specifically relates to a disc-type tool magazine and automatic tool-changing system comprehensive performance detection platform. The detection platform comprises a detection system, a test system and a control system. The detection system is used for finishing detection and collection of various parameters of the disc-type tool magazine and automatic tool-changing system; the test system is used for testing the reliability of the same-kind multi-dimension disc-type tool magazine and automatic tool-changing systems; and the control system is used for finishing setting of related test parameters in the test process and carrying out processing and analysis on the collected parameters, graphical display and test result display, and realizing comprehensive control of the detection system and the test system. The comprehensive performance detection platform is a test platform capable of loading the same-kind multi-dimension disc-type tool magazine and automatic tool-changing systems; and especially, the platform can carry out detection on the state and performance of the disc-type tool magazine and automatic tool-changing system and give corresponding analysis results.

Owner:JILIN UNIV

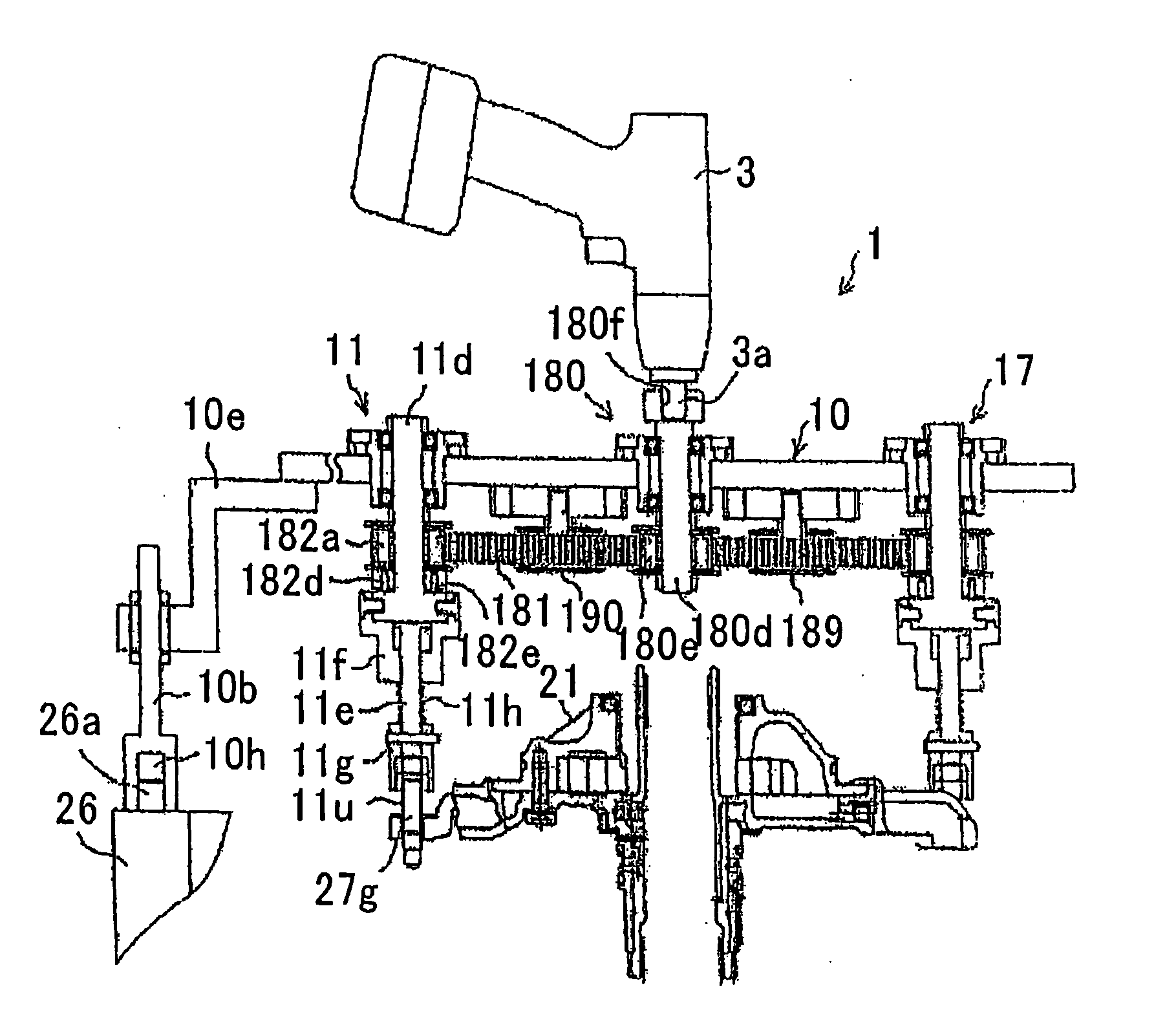

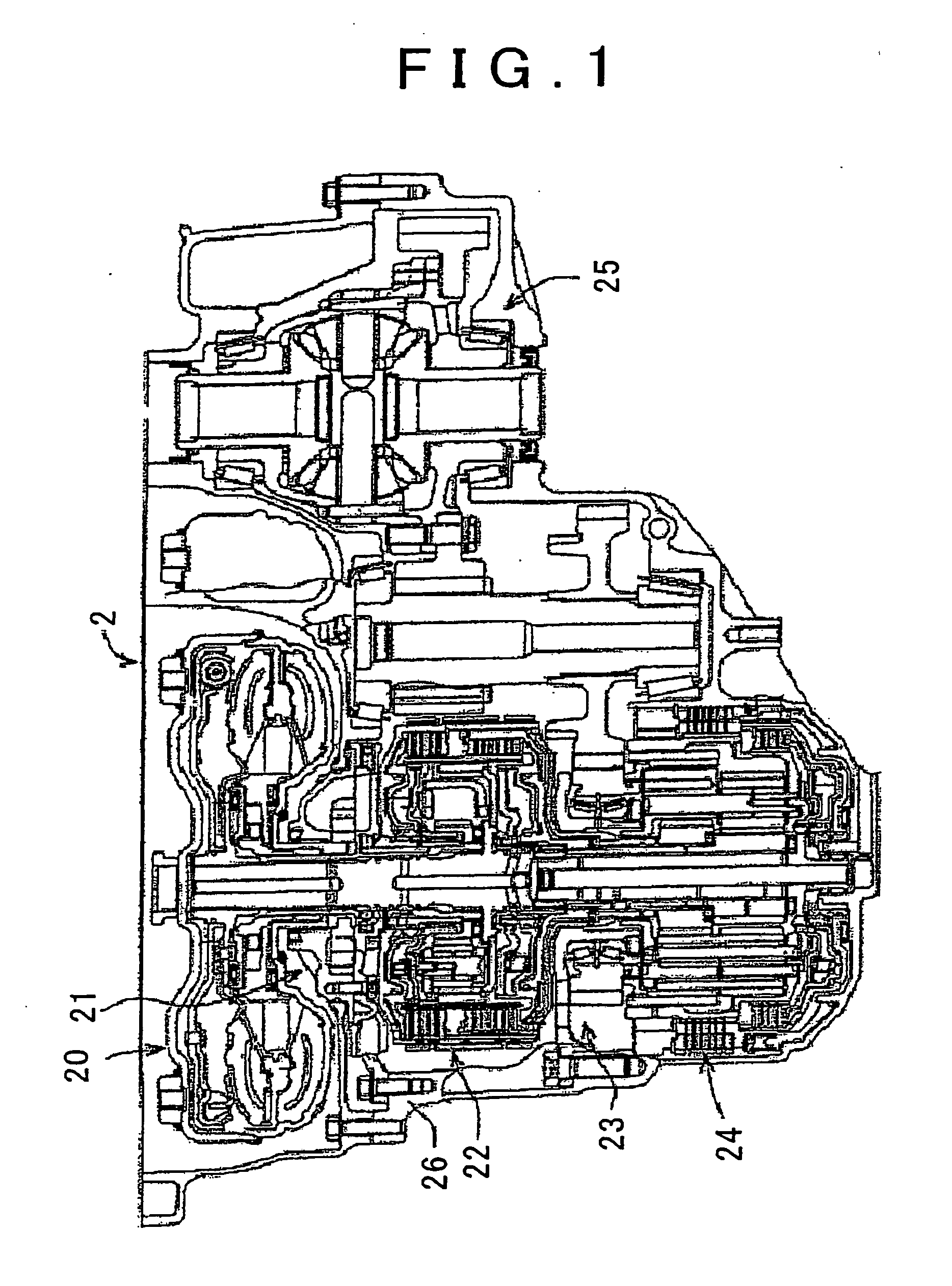

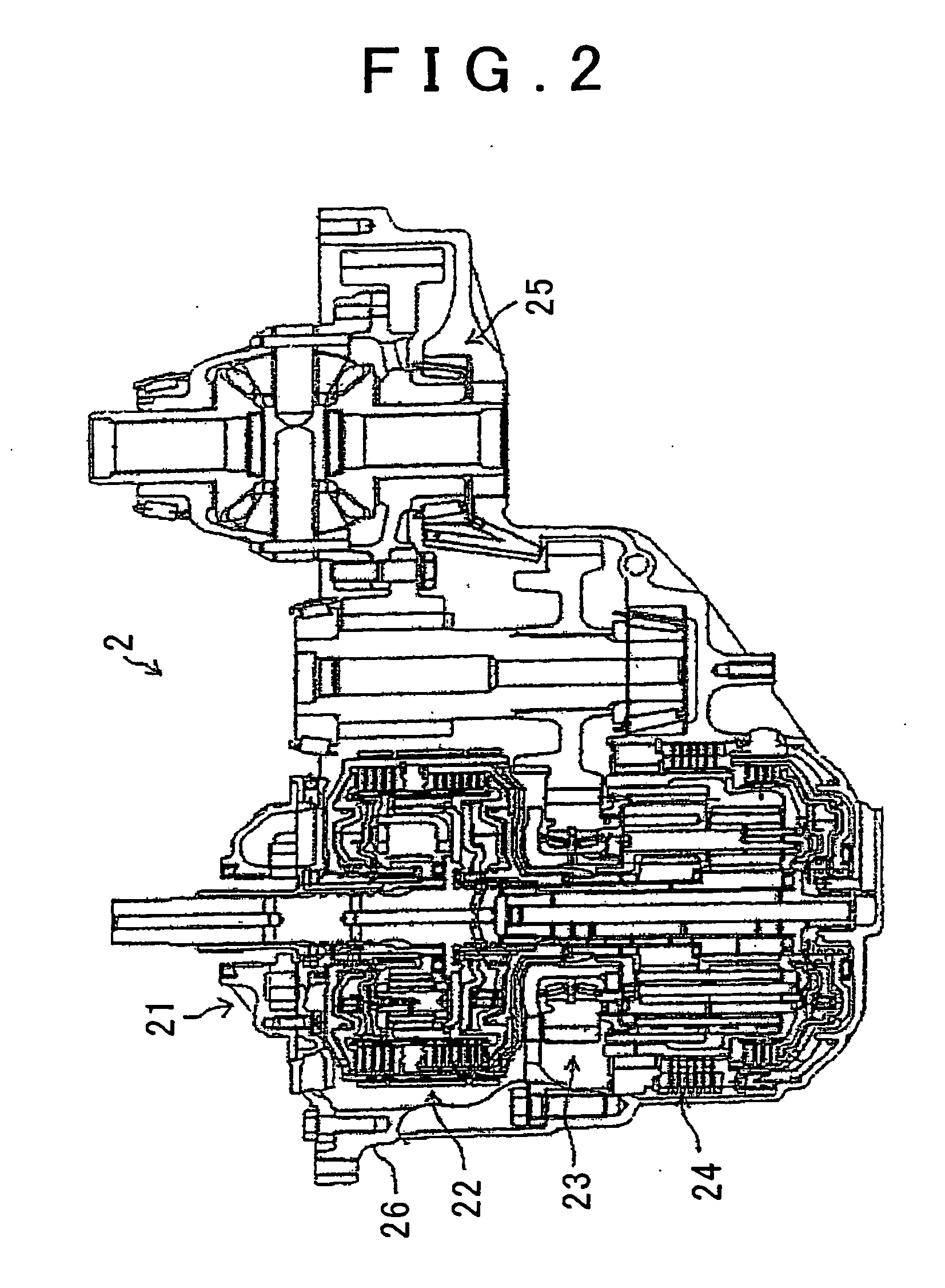

Fastener tightening device

A bolt tightening device includes bolt tightening mechanisms, a torque input unit, a toothed belt and torque transmission units. The torque transmission units are provided with toothed pulleys and are integrated with the bolt tightening mechanisms. A toothed pulley is fixed to the torque input unit, and drivably connected to all the toothed pulleys of the plural torque input units by the single toothed belt. Torque input to the torque input unit is transmitted to the bolt tightening mechanisms by the toothed belt, and used to simultaneously tighten, for example, seven bolts. Because, torque can be simultaneously transmitted to plural bolt tightening mechanisms using a single belt, the number of components is reduced and the size, weight and cost are reduced and ease of use is improved.

Owner:AISIN AW CO LTD

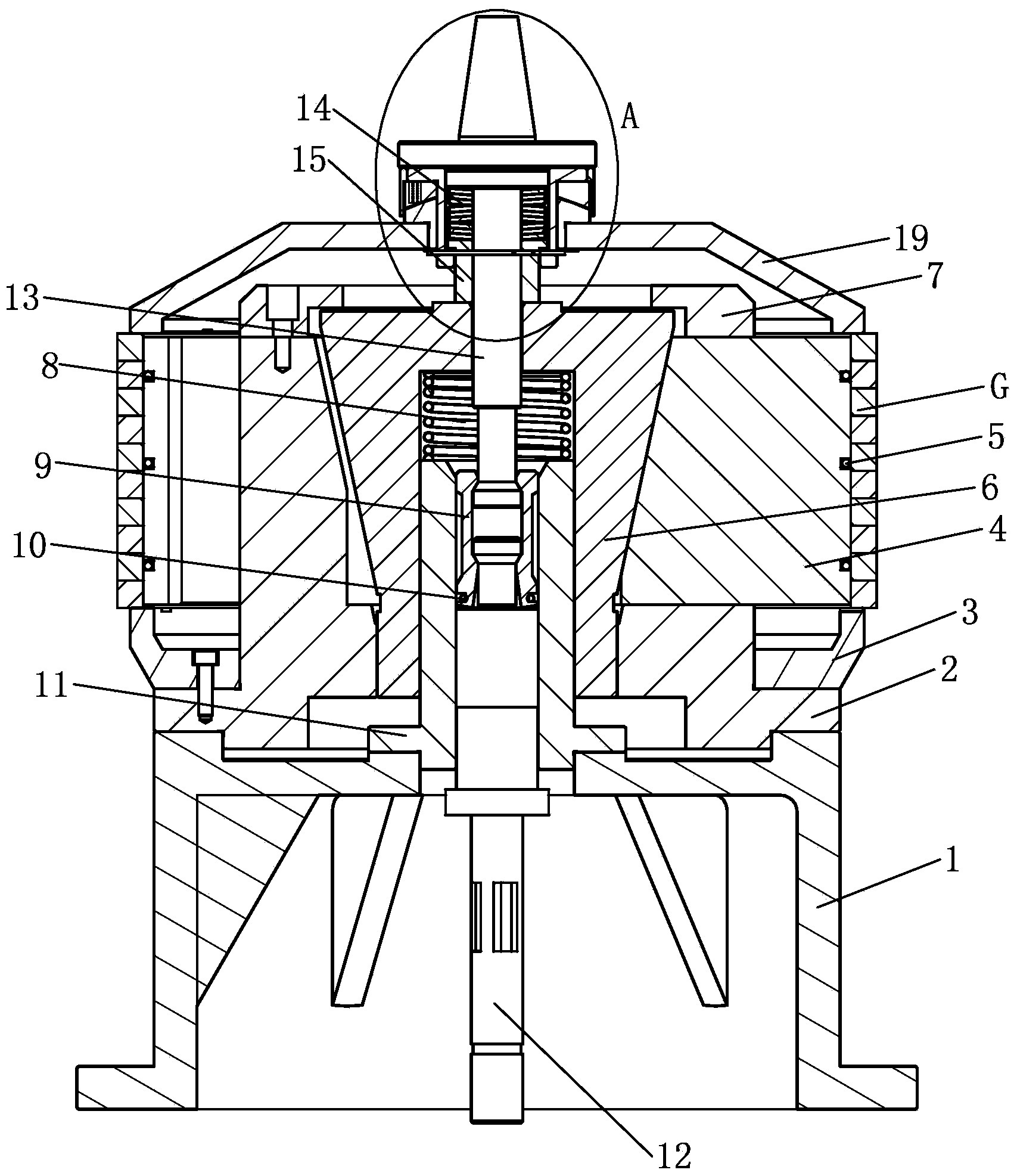

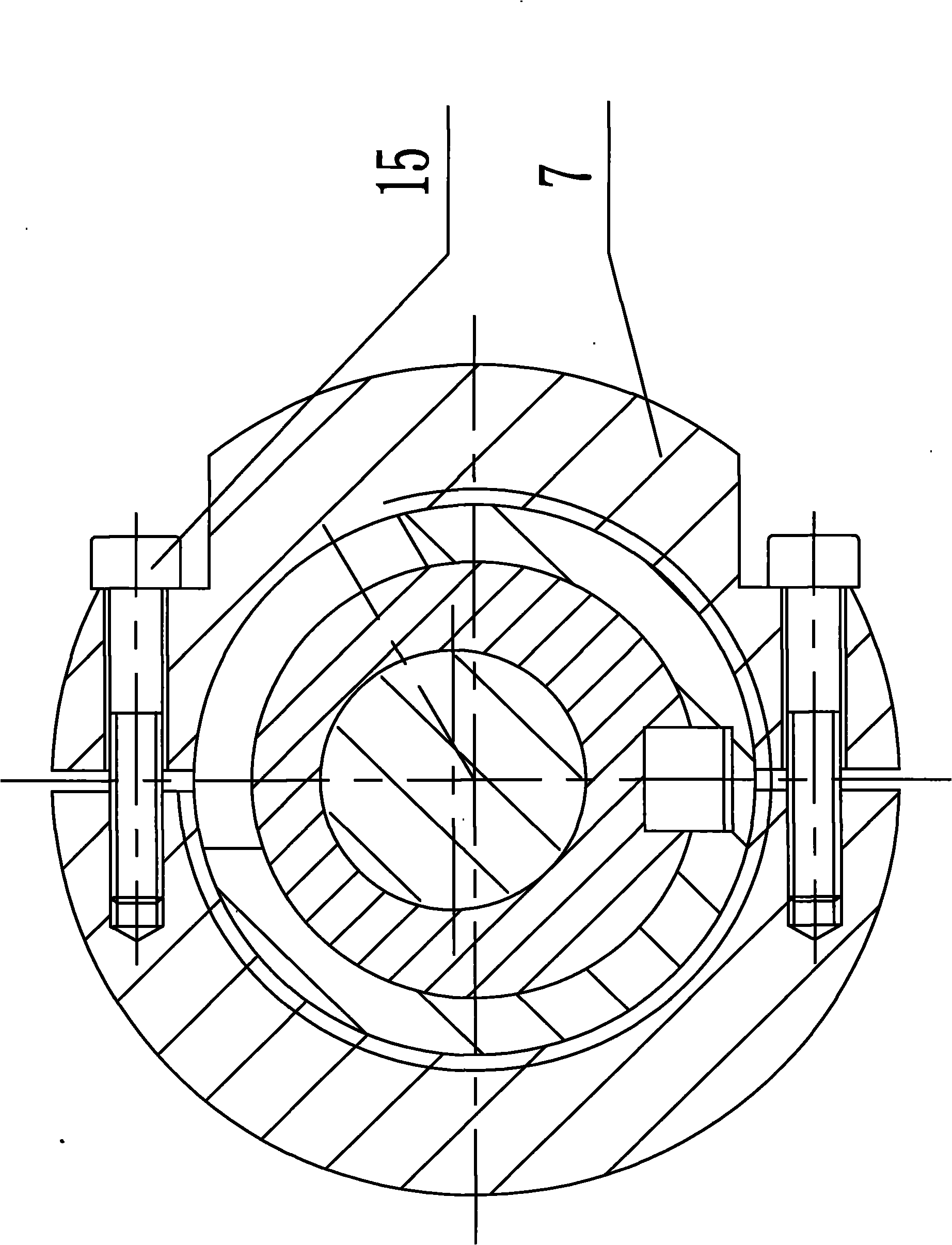

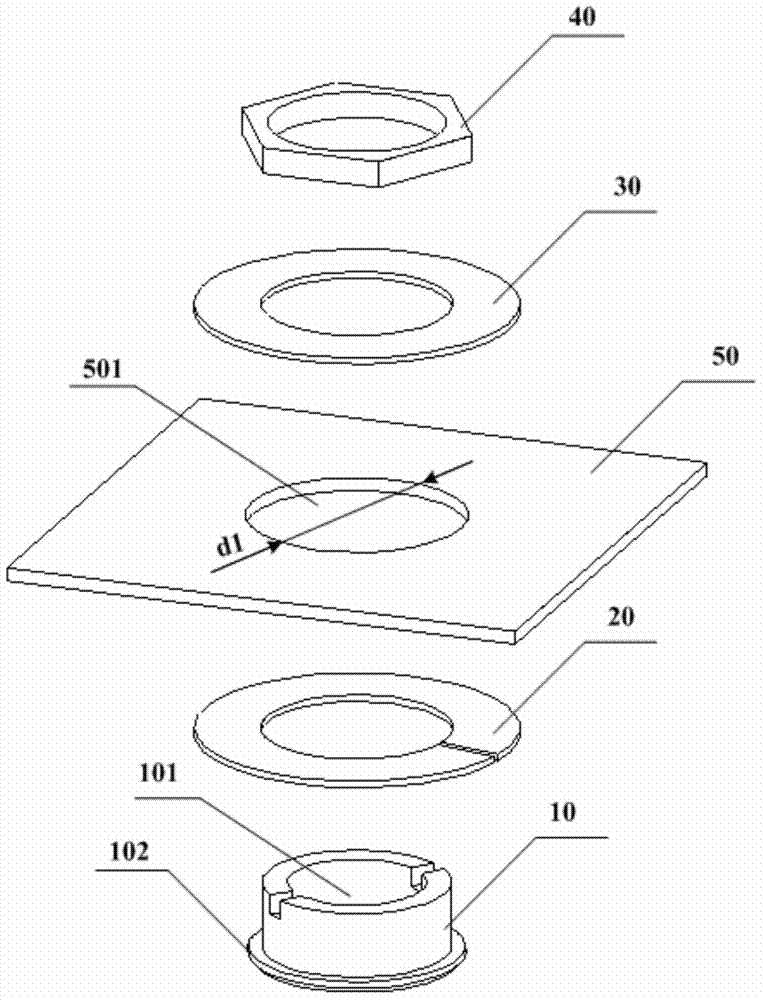

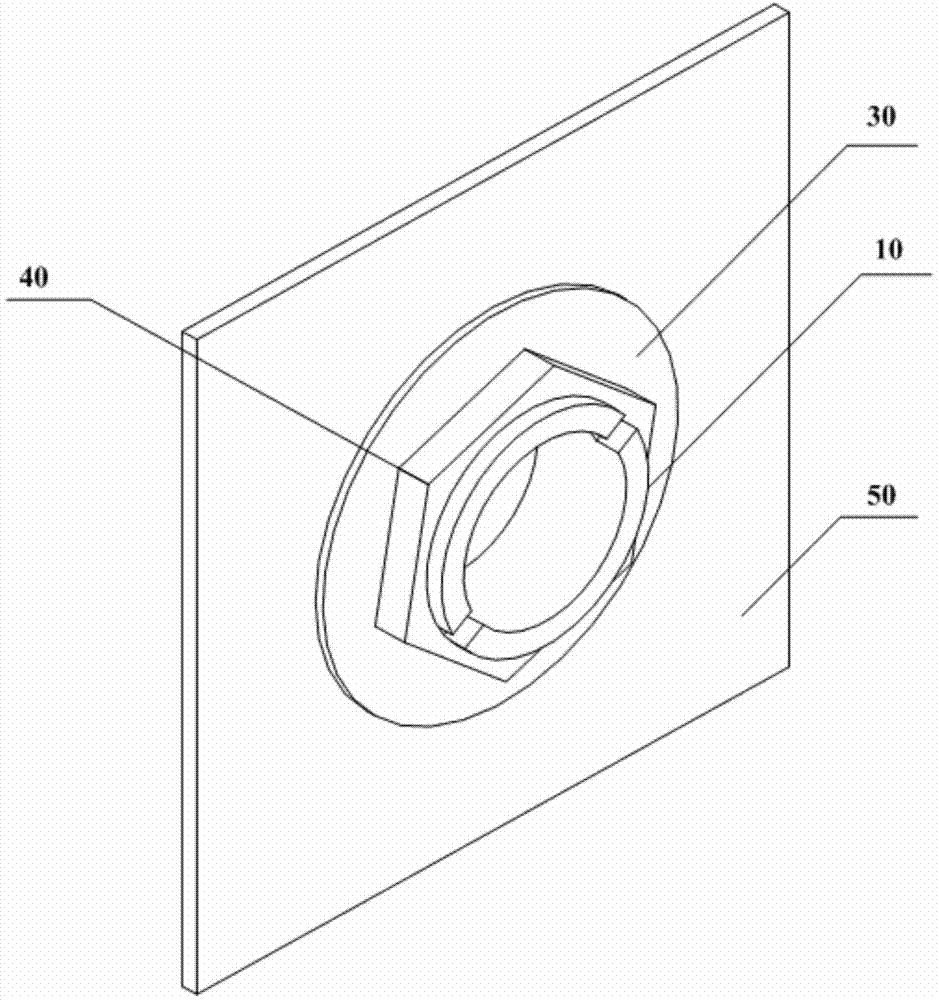

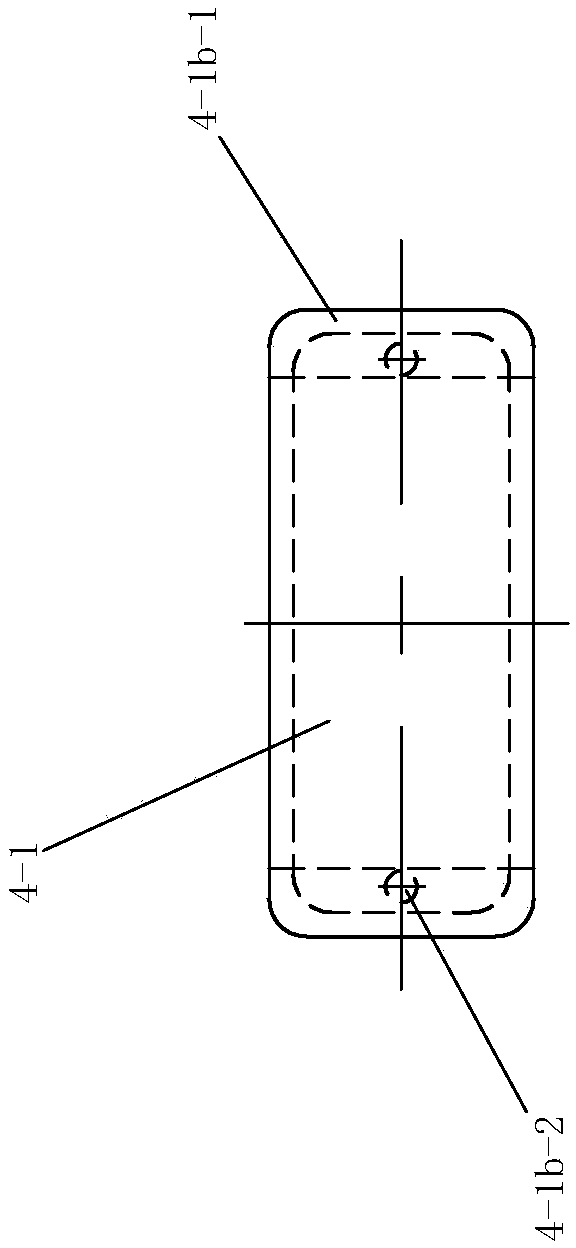

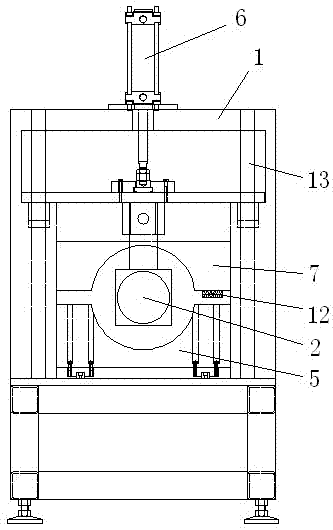

Hobbing clamp for clamping a plurality of parts with big gear rings

The invention discloses a hobbing clamp for clamping a plurality of parts with big gear rings. The hobbing clamp for clamping the parts with the big gear rings comprises a pressing portion and a centering portion, wherein the centering portion comprises a base, a first spring, a locating sleeve, force transmission blocks, a lower pull rod and the like, a support is arranged on the top surface of the base, the support is sleeved with a supporting disk, the pressing portion comprises an upper pull rod and a press plate, the upper pull rod is sleeve with a disk spring and a pressing sleeve in sequence from top to bottom, the disk spring and the pressing sleeve are sleeved with a bushing in a spaced mode, a supporting plate is arranged at the bottom of the press plate, the top surface of the supporting plate is a big-end-down conical surface, the conical surface is attached to the bottom surface of the press plate, the lower end of the supporting plate is fixedly sleeved with a gland, the lower end of the upper pull rod is provided with a T-shaped portion, and the T-shaped portion penetrates through a small-diameter section of a center hole of a taper sleeve and a center hole of a reset spring, and then is clamped into a large-diameter section of a cylindrical hole formed by inner surfaces of all the force transmission blocks. According to the hobbing clamp for clamping the parts with the big gear rings, centering of workpieces with big gear rings can be well carried out through expansion blocks, the workpieces can be tightly pressed at the same time, and centering accuracy can be ensured.

Owner:CHONGQING MACHINE TOOL GROUP

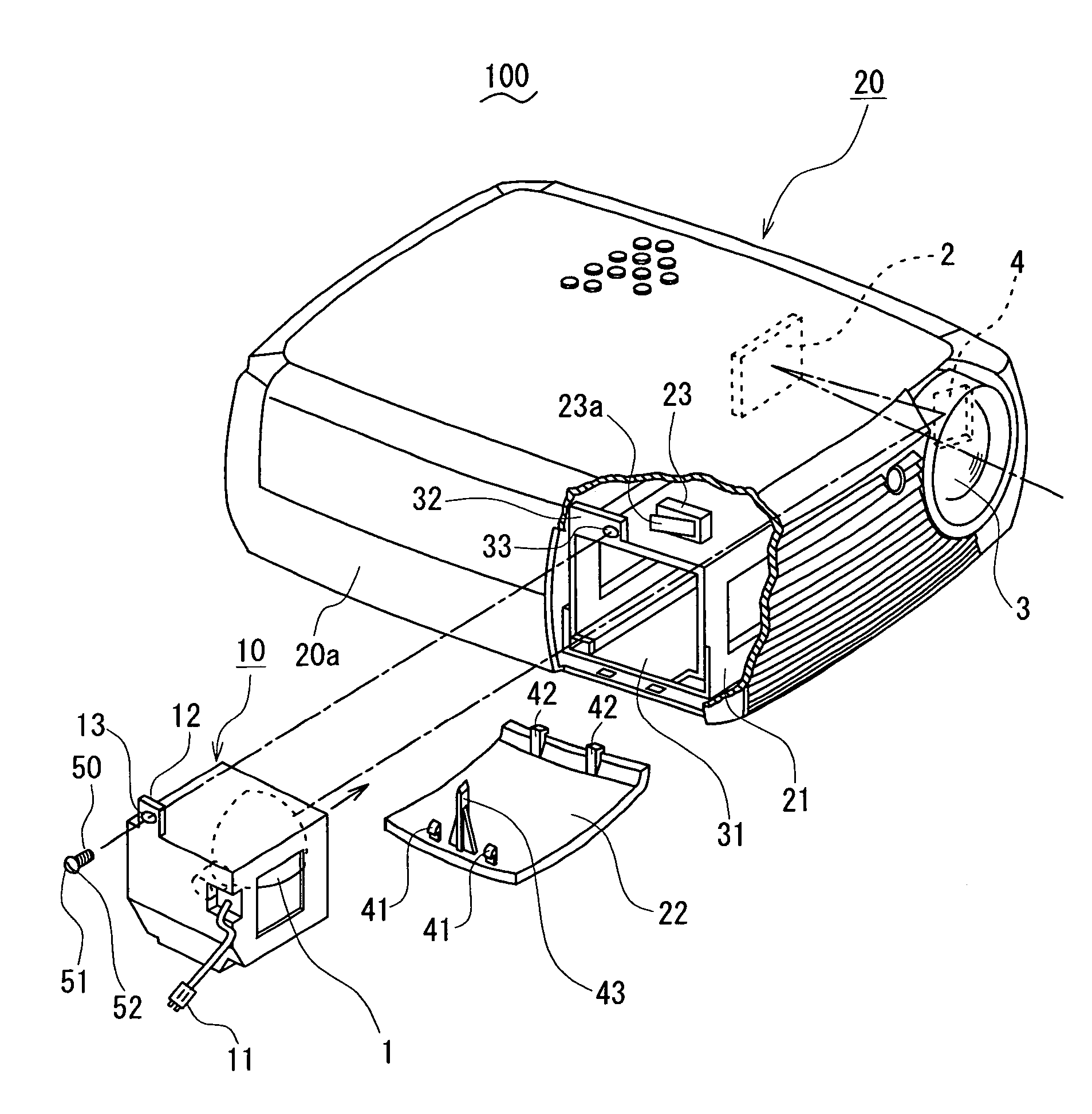

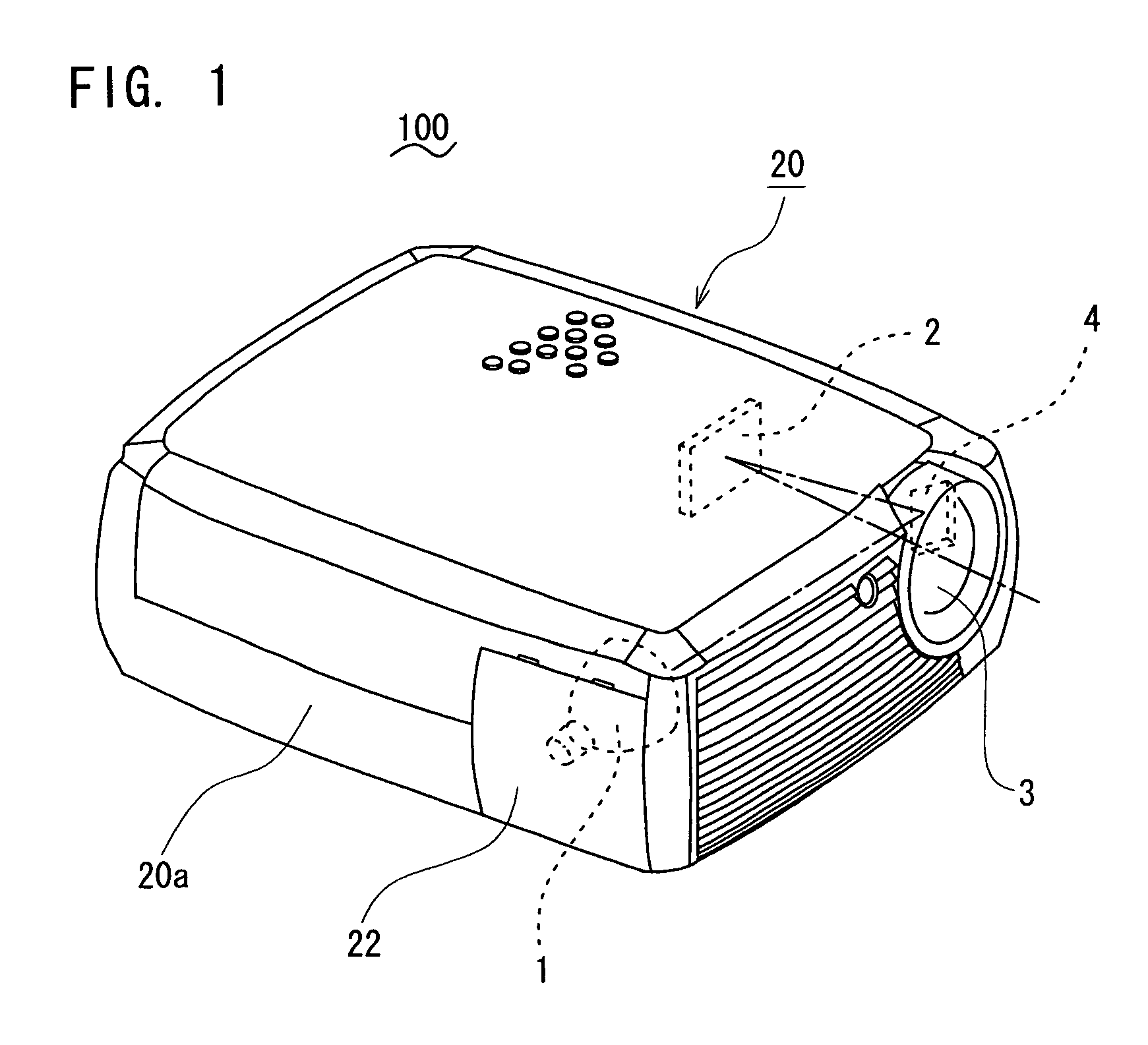

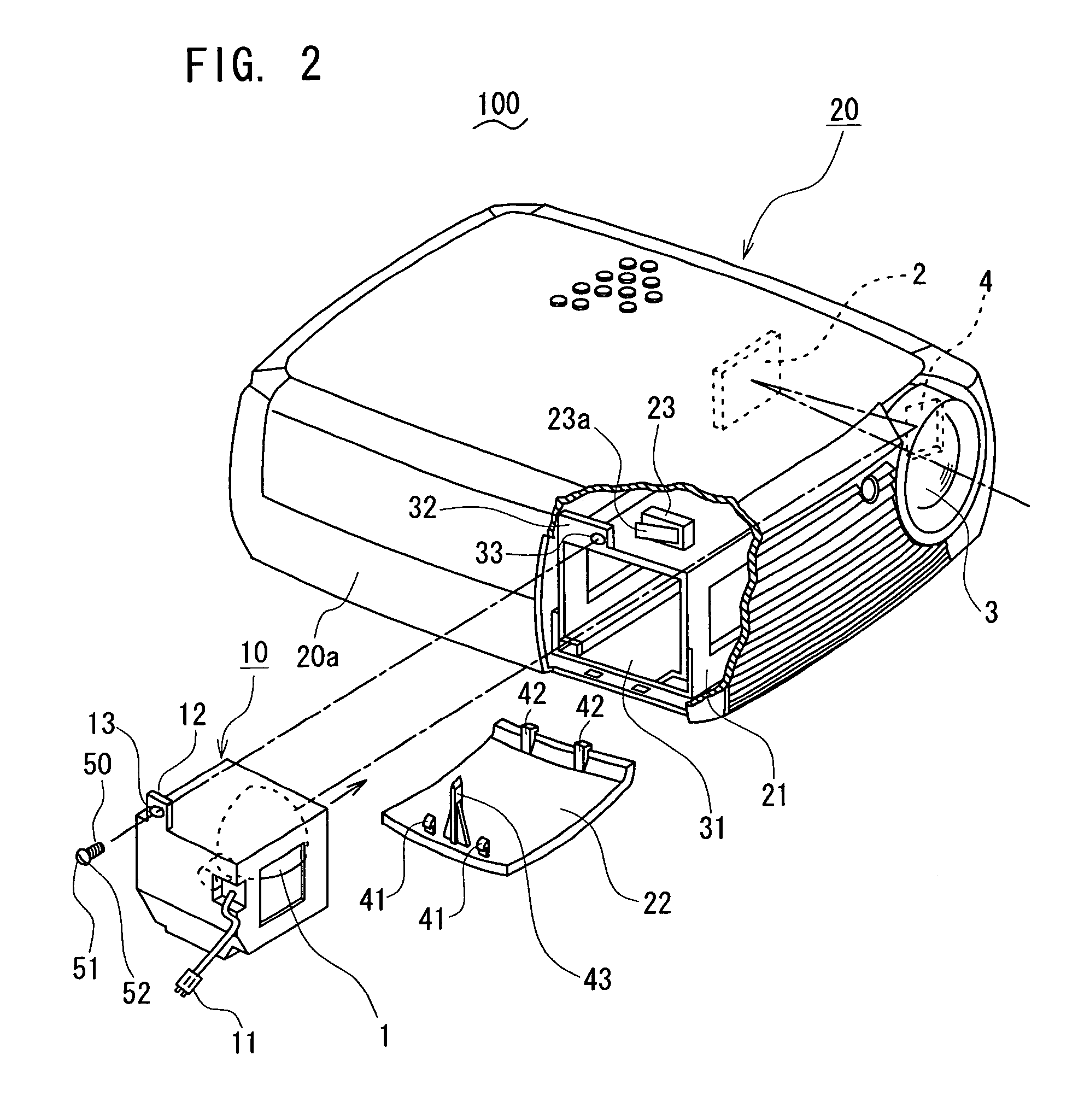

Image projector lamp door with screw tuning component

InactiveUS7011417B2Easy to lockReliably loosenedProjectorsCamera body detailsEngineeringMechanical engineering

An image projector includes a lamp box containing a lamp, a case for forming a housing for the projector and having an opening for inserting the lamp box into the housing, a lamp housing provided inside the case and used for fixing the lamp box, and a lamp door removably attached to the case and used for opening and closing the opening. The lamp door has a screw-turning component capable of engaging with a groove on the head of the fixing screw when removed from the case, and threadable tightening / loosening can be performed by rotating the lamp door with the screw-turning component engaged with the groove in the fixing screw. This allows the lamp box to be replaced without the need for a screw-turning tool.

Owner:FUNAI ELECTRIC CO LTD

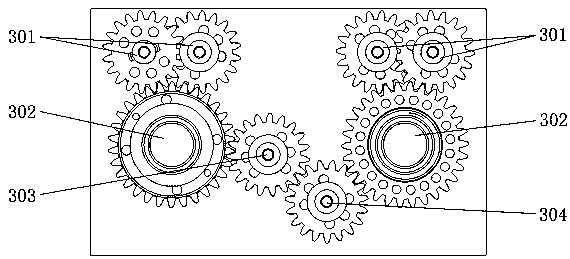

Adjustable multishaft screwing mechanism

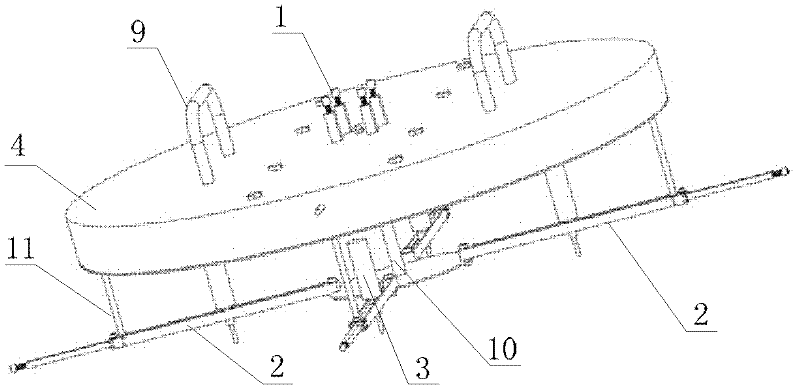

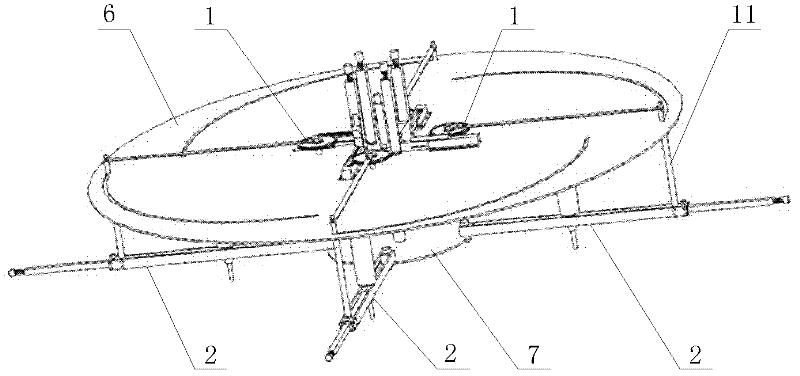

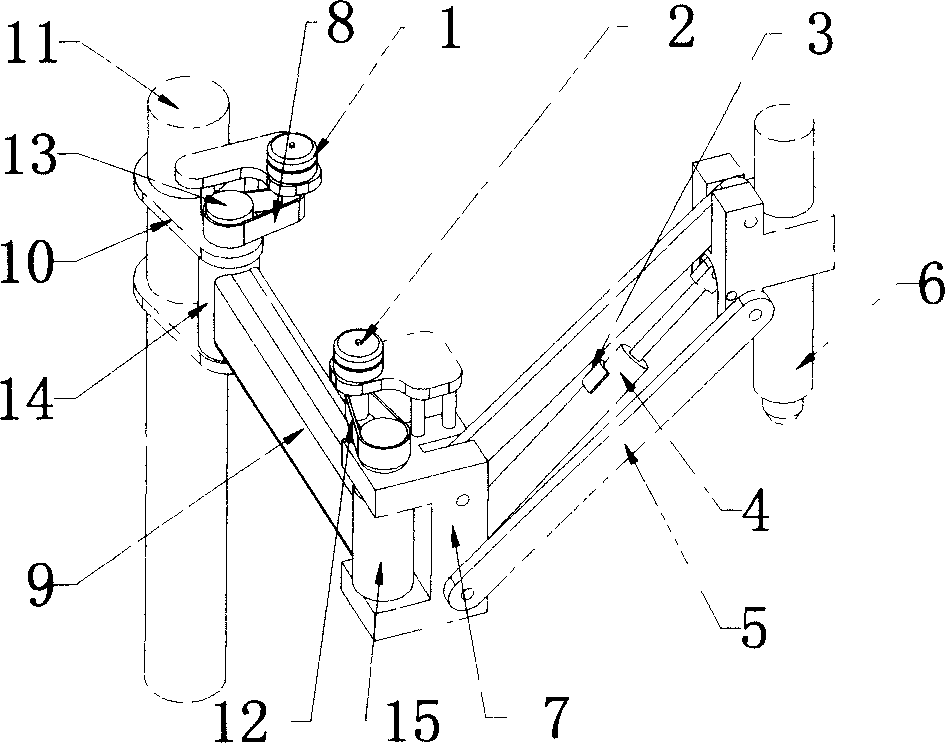

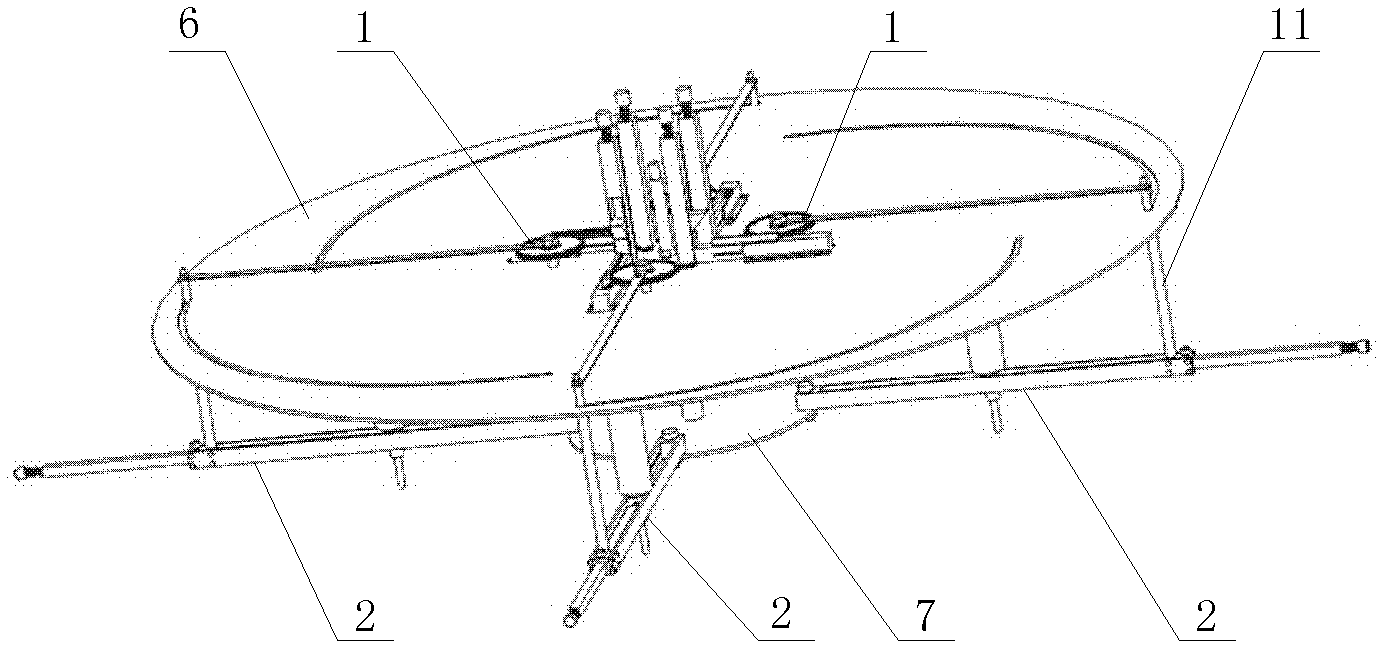

The invention discloses an adjustable multishaft screwing mechanism, which comprises angle adjusting mechanisms, radial adjusting mechanisms, single-shaft screwing machines, a frame and a driving control unit, wherein the angle adjusting mechanisms are fixed on the upper disc of the frame, the radial adjusting mechanisms are installed on a lower disc, adjusting link rods are used for connecting the angle adjusting mechanisms with the corresponding radial adjusting mechanisms, the single-shaft screwing machines are installed on the radial adjusting mechanisms, and the driving control unit is installed on the top cover of the frame. By adopting the invention, the screwing speeds, moments and directions of different single-shaft screwing machines are controlled; and the adjustable multishaft screwing mechanism disclosed by the invention has the advantages of high regulation precision, simple structure, convenience for adjusting and the like, and can realize rapid screwing of bolts at different positions.

Owner:AIR FORCE UNIV PLA

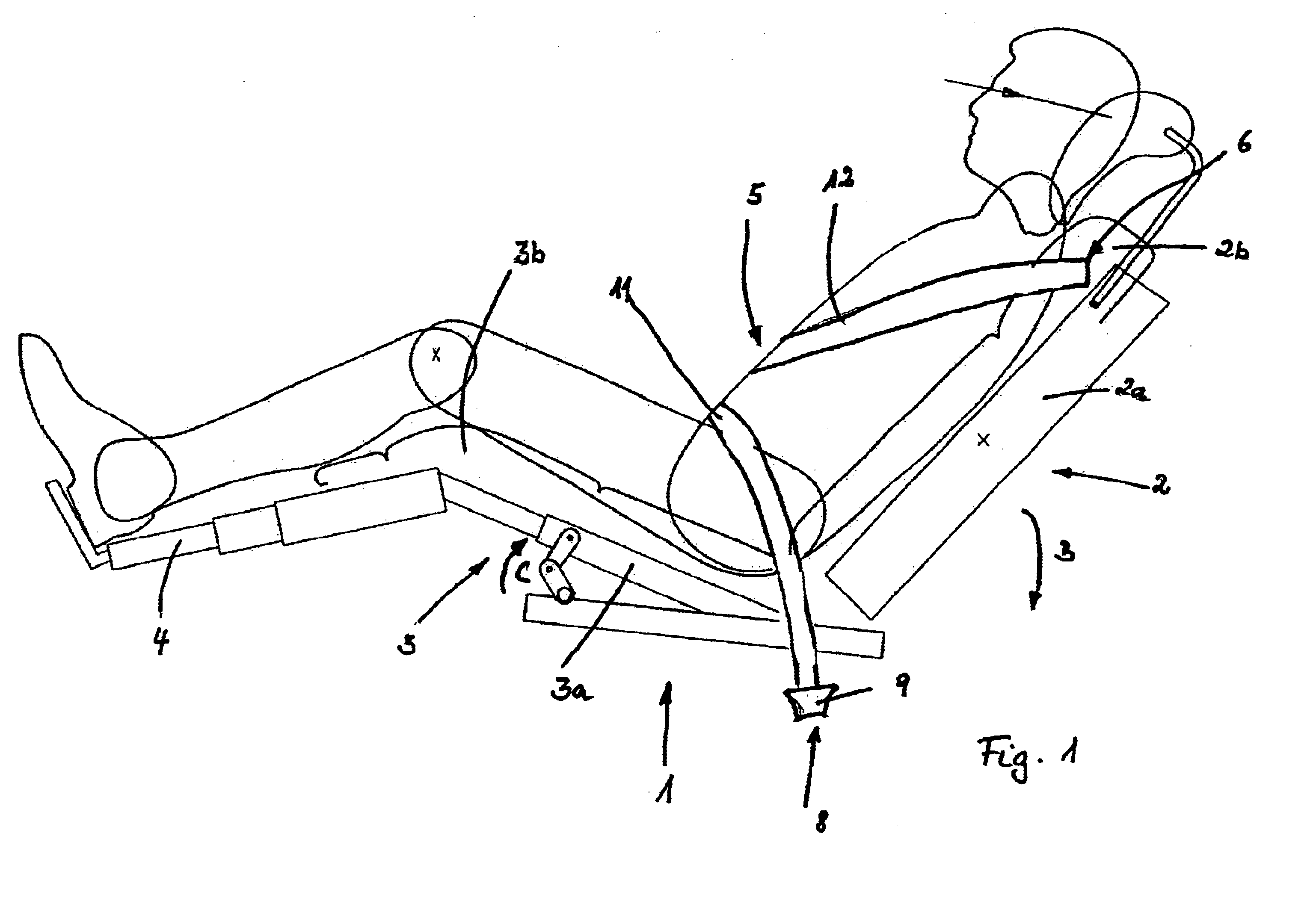

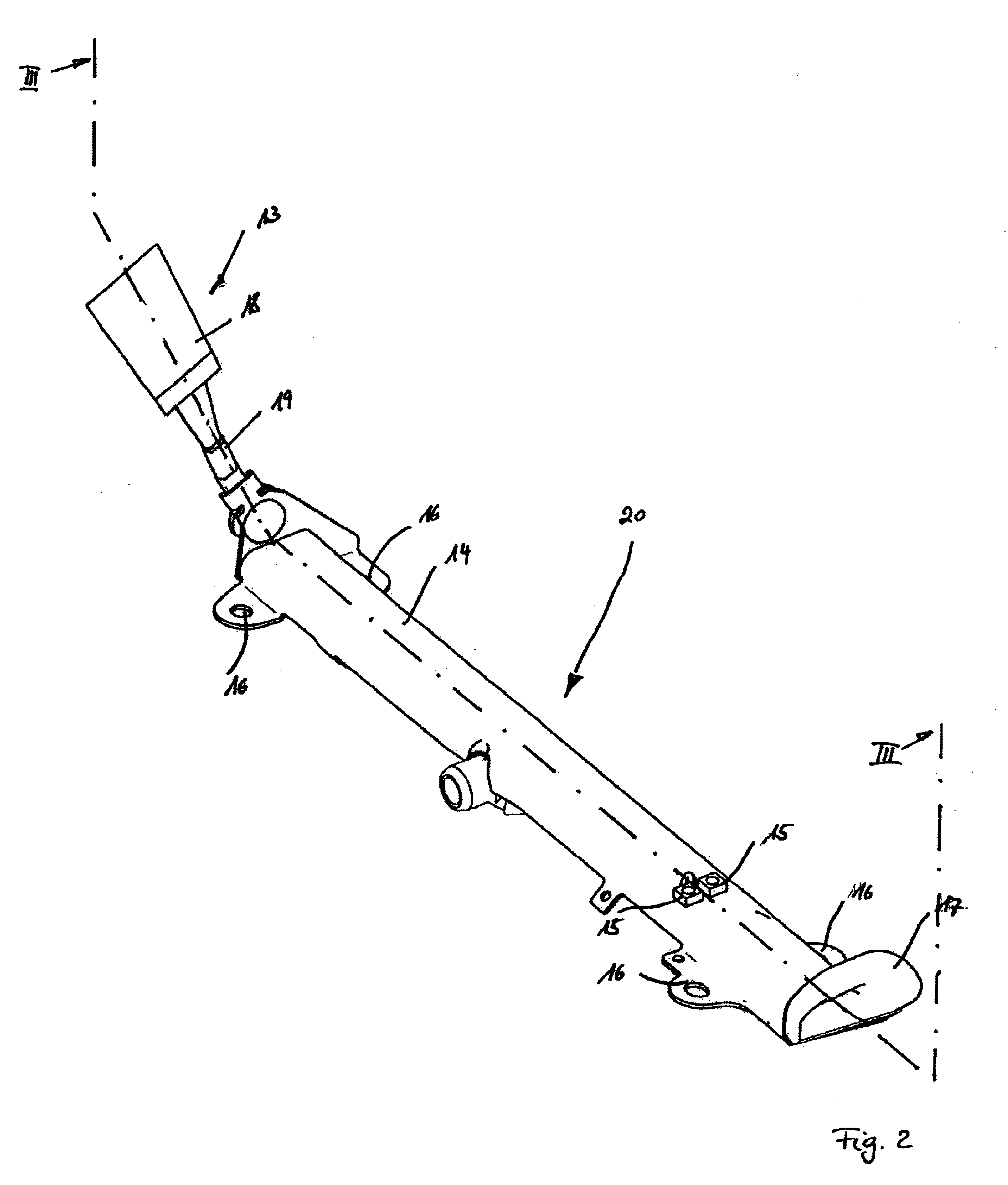

Safety device for a comfortable seat

InactiveUS6938926B2Ensure reliable functionImprove securityBelt retractorsSafety beltsRest positionSeat belt

In order to provide a safety device for a comfortable seat having a seat surface and a backrest which may be transferred from a sitting position into a resting position and vice versa, the safety device being used to increase the safety of vehicle occupants on the comfortable seat, the comfortable seat includes with a seat belt system which includes a belt strap which is fixed in the region of the seat surface via a belt end fitting and is stored on a belt-retracting mechanism arranged in the upper region of the backrest, a belt buckle being provided on that side of the seat surface which is opposite the belt end fitting so as to couple up the belt strap via a belt tongue in accordance with a three-point belt system, and, in the event of an accident, the belt strap being tightened via the belt-retracting mechanism and a pretensioning system engaging on the belt end fitting.

Owner:DAIMLER AG

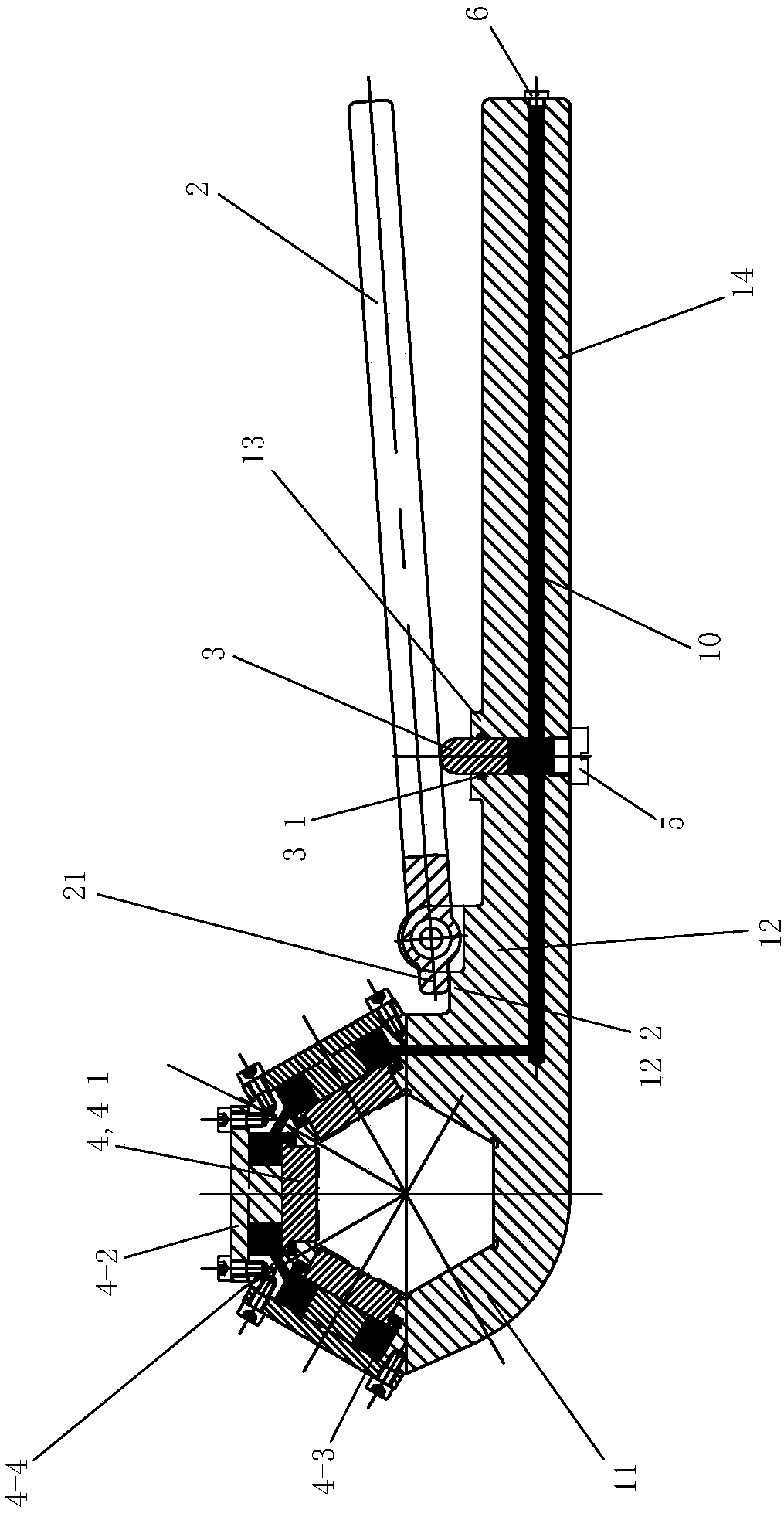

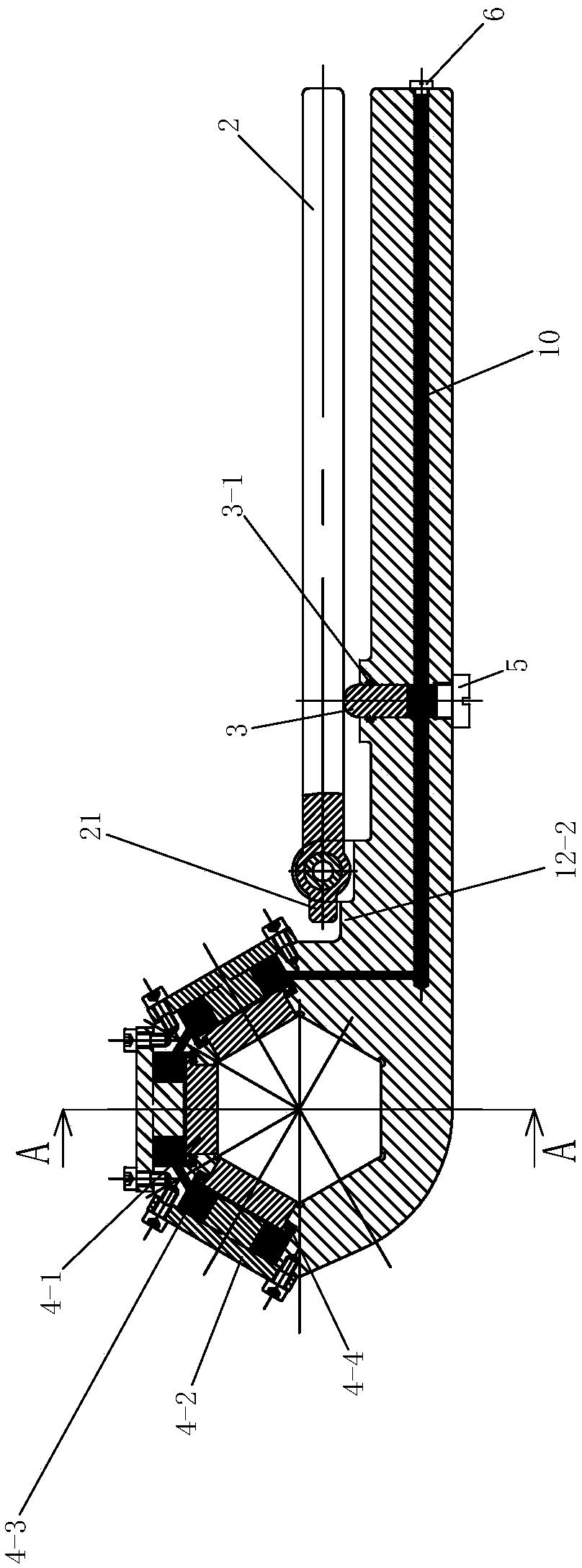

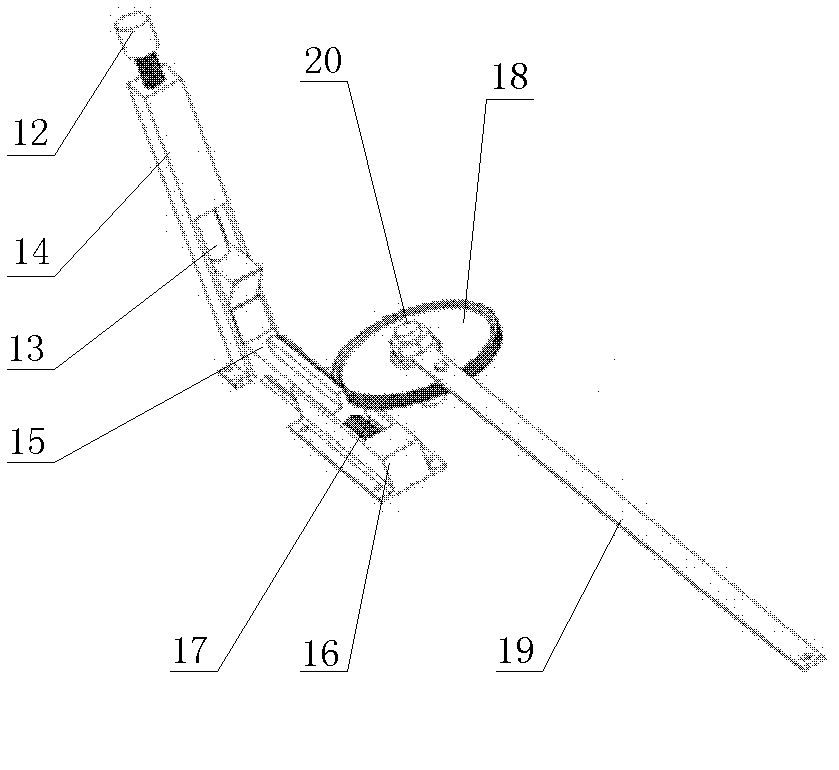

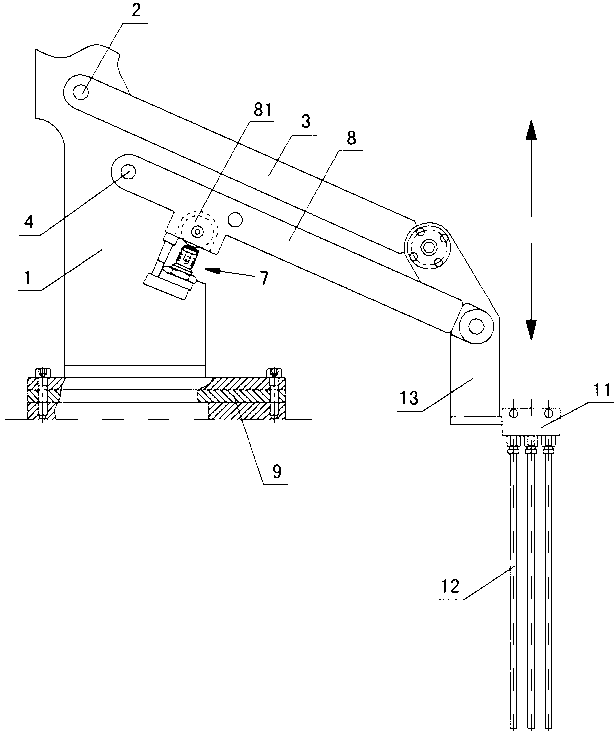

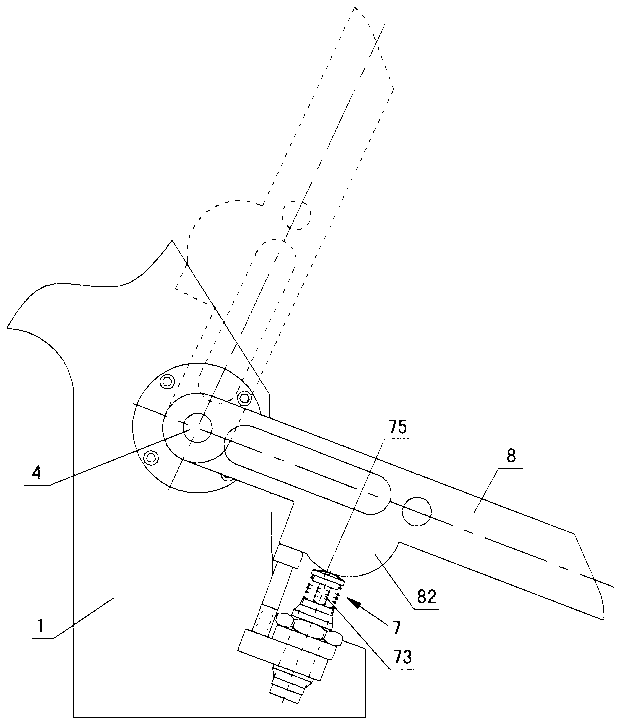

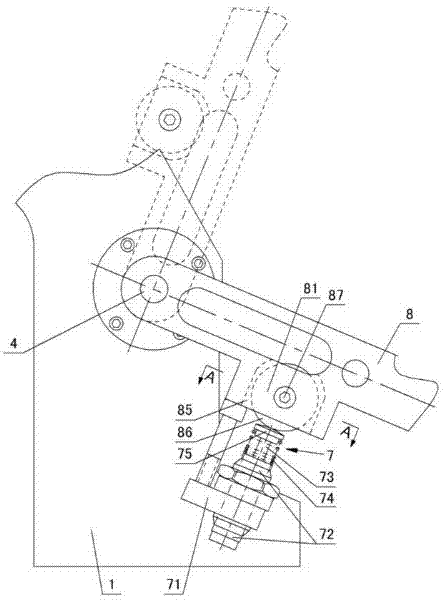

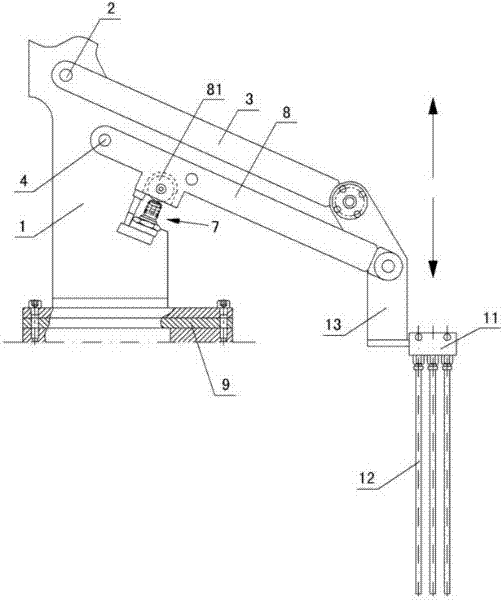

High-efficiency distribution network branch wiring live-line robot

ActiveCN111446601AReliable tighteningImprove reliabilityUnstripped conductor connection apparatusClip conductor connectionRemote controlControl engineering

The invention relates to the technical field of robots, and in particular relates to a high-efficiency distribution network branch wiring live-line robot. The robot comprises a chassis, a suspension arm, wire clamp seats, a wire clamp tightening device, a camera and a remote controller. The suspension arm and the wire clamp seats are both installed on the chassis. The number of the wire clamp seats is two. The two wire clamp seats are arranged side by side along the extension direction of a target wire. Puncture wire clamps are installed on the two wire clamp seats. The target wire penetratesthrough the puncture wire clamps. The wire clamp tightening device is fixedly connected with the chassis, and the wire clamp tightening device is connected with the puncture wire clamp. The camera isinstalled on the chassis and is aligned with the puncture wire clamp. The camera shoots a video image of the puncture wire clamp. The camera and the wire clamp tightening device are both connected with the remote controller, and the remote controller is provided with a display screen. The robot has the substantial effects that wiring of two branches can be completed at a time, and the working efficiency is high; control is carried out through remote control, and deployment is simple and flexible; and the robot can adapt to a complex distribution network environment.

Owner:STATE GRID ZHEJIANG HANGZHOU XIAOSHAN POWER SUPPLY CO +1

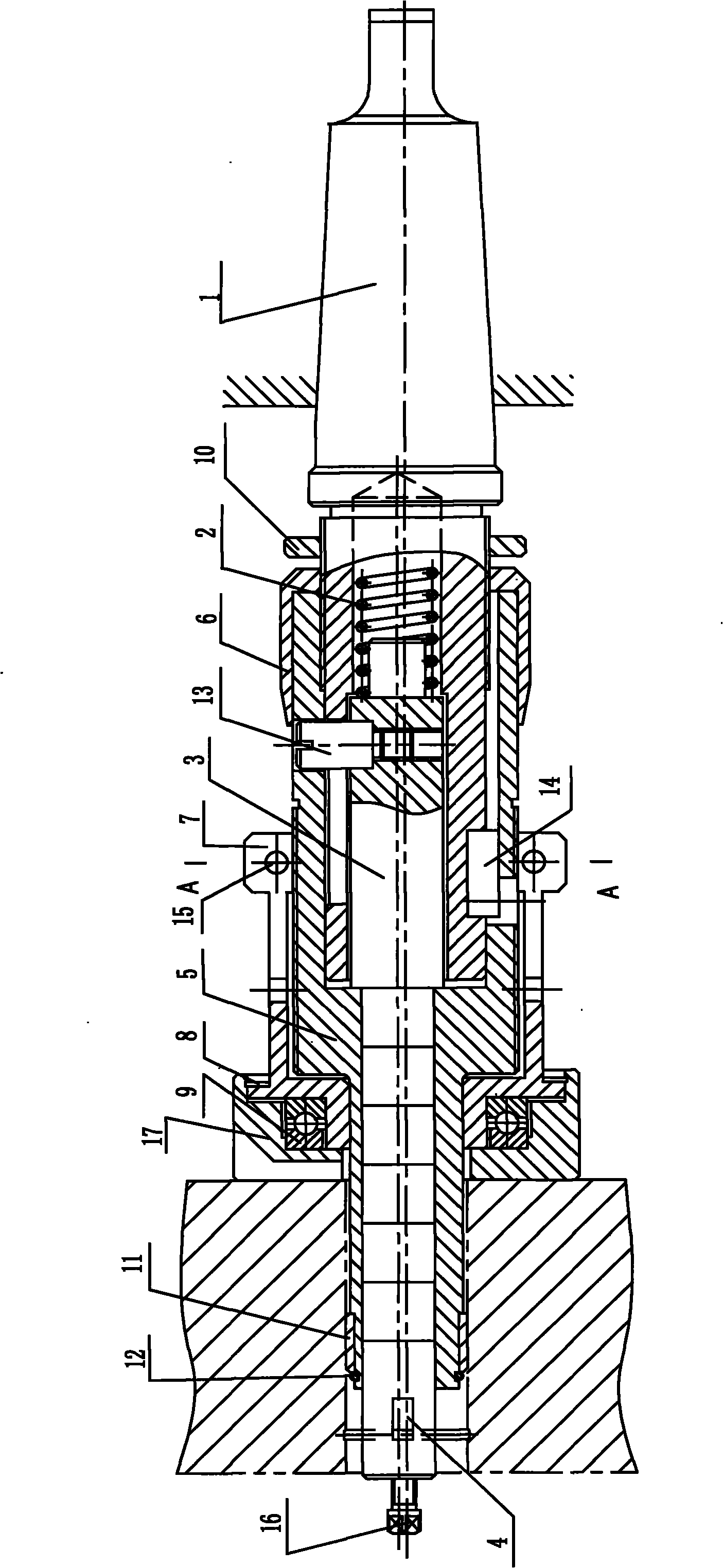

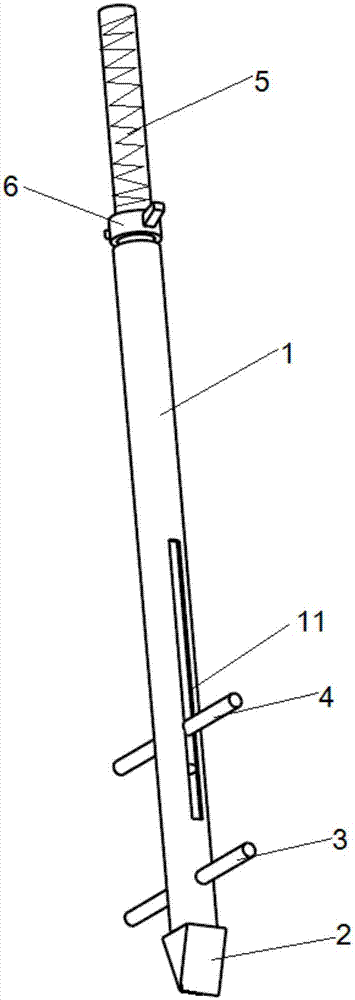

Adjustable groove scraping tool

The invention discloses an adjustable groove scraping tool. Because researched boilers and chemical container product expansion joint structures are increasingly commonly used and the requirements are increasingly strict, groove scrapers are frequently repaired for a variety of reasons, and the production period is delayed. The adjustable groove scraping tool comprises a taper shank (1); the taper shank is connected with a tool bar (3) with a spring (2); one end of the tool bar is provided with a slotting tool (4); a sleeve (5) is sleeved outside the taper shank and the tool bar; one end of the sleeve is connected with an adjusting nut (6); the sleeve is connected with a bush retainer (7); the bush retainer is connected with a stop collar (8) and a bearing (9); the taper shank is connected with a locking nut (10); and the other end of the sleeve is connected with a copper sleeve (11) and a retainer ring (12). The invention is used for the groove scraping tool.

Owner:HARBIN BOILER

Bolt assemble sequence control equipment

InactiveCN1632703AAvoid causing assembly quality problemsSimple mechanical structureSpannersWrenchesProduction lineOrder control

It is a bolt alignment order control device in the mechanical aligning technique field, which comprises two angle displacement sensors, linear sensor, piston cylinder, raising bar, bolt screwing tool, hinged head, turning arm, turning joint and turning rack. And the turning rack and turning joint and turning arm and the first angle displacement sensor form the turning structure; the second angle displacement sensor, hinged head form hinged turning structure; the raising bar, piston cylinder, linear displacement sensor and bolt screwing tool form vertical moving mechanical structure.

Owner:SHANGHAI JIAO TONG UNIV +2

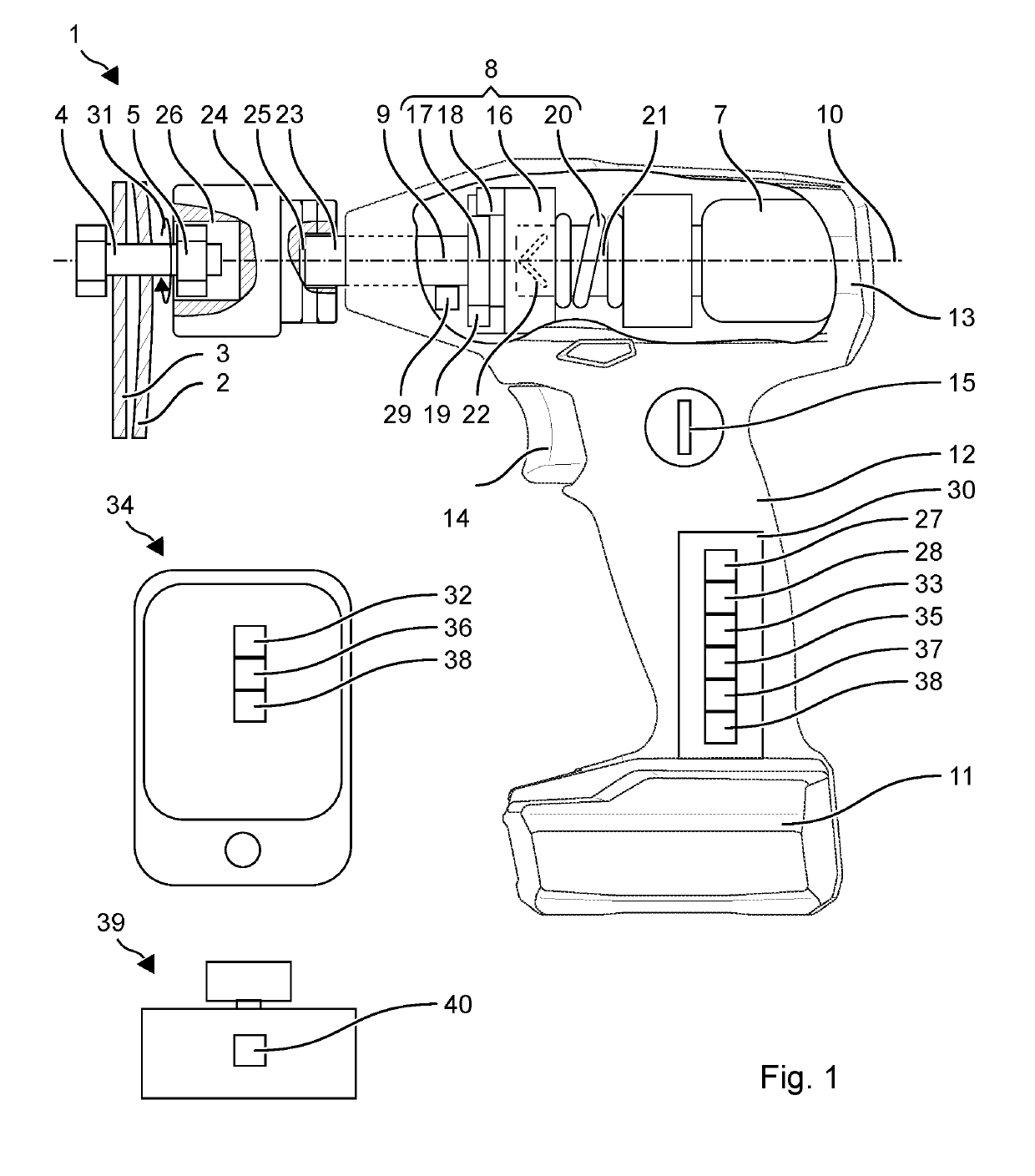

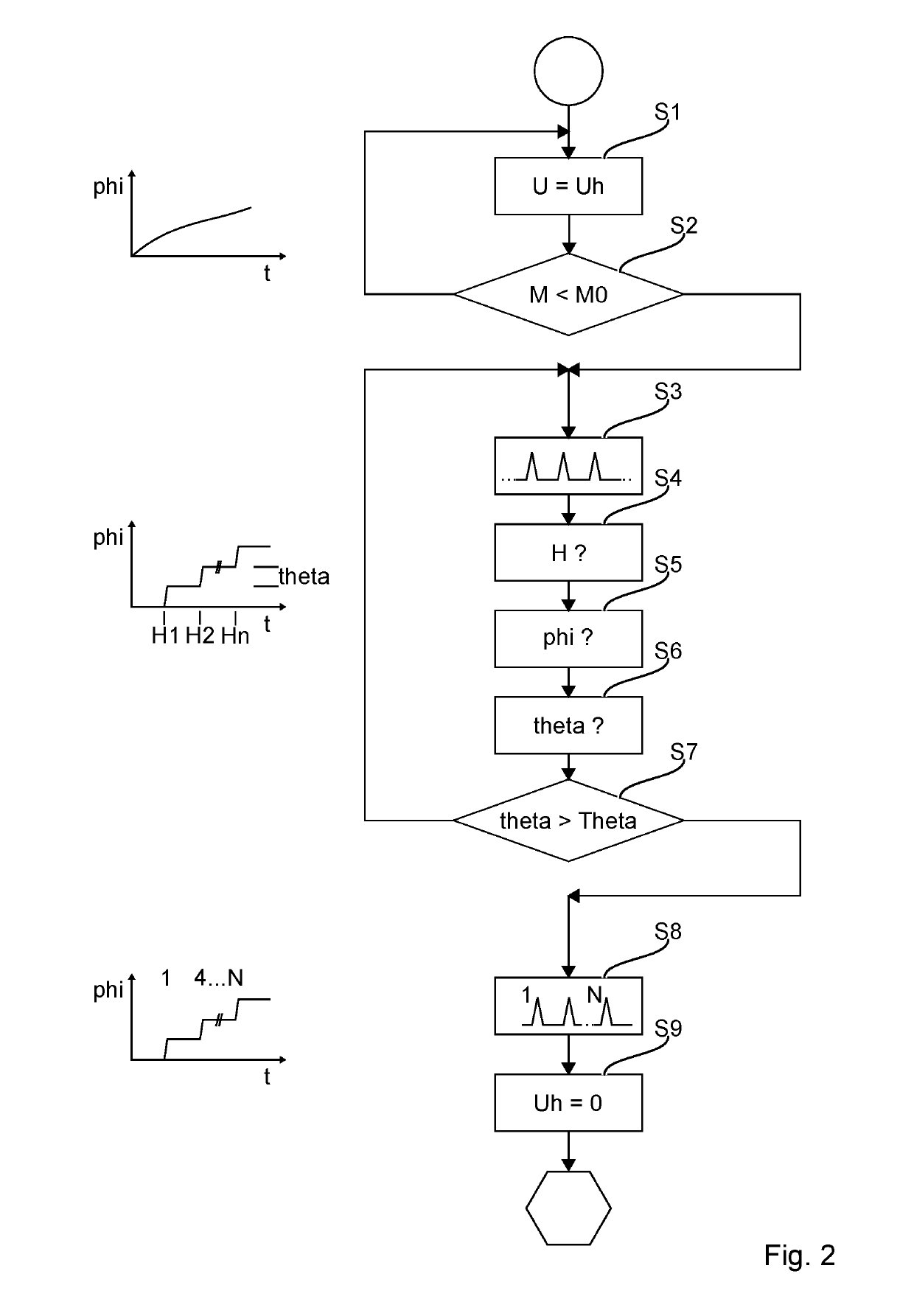

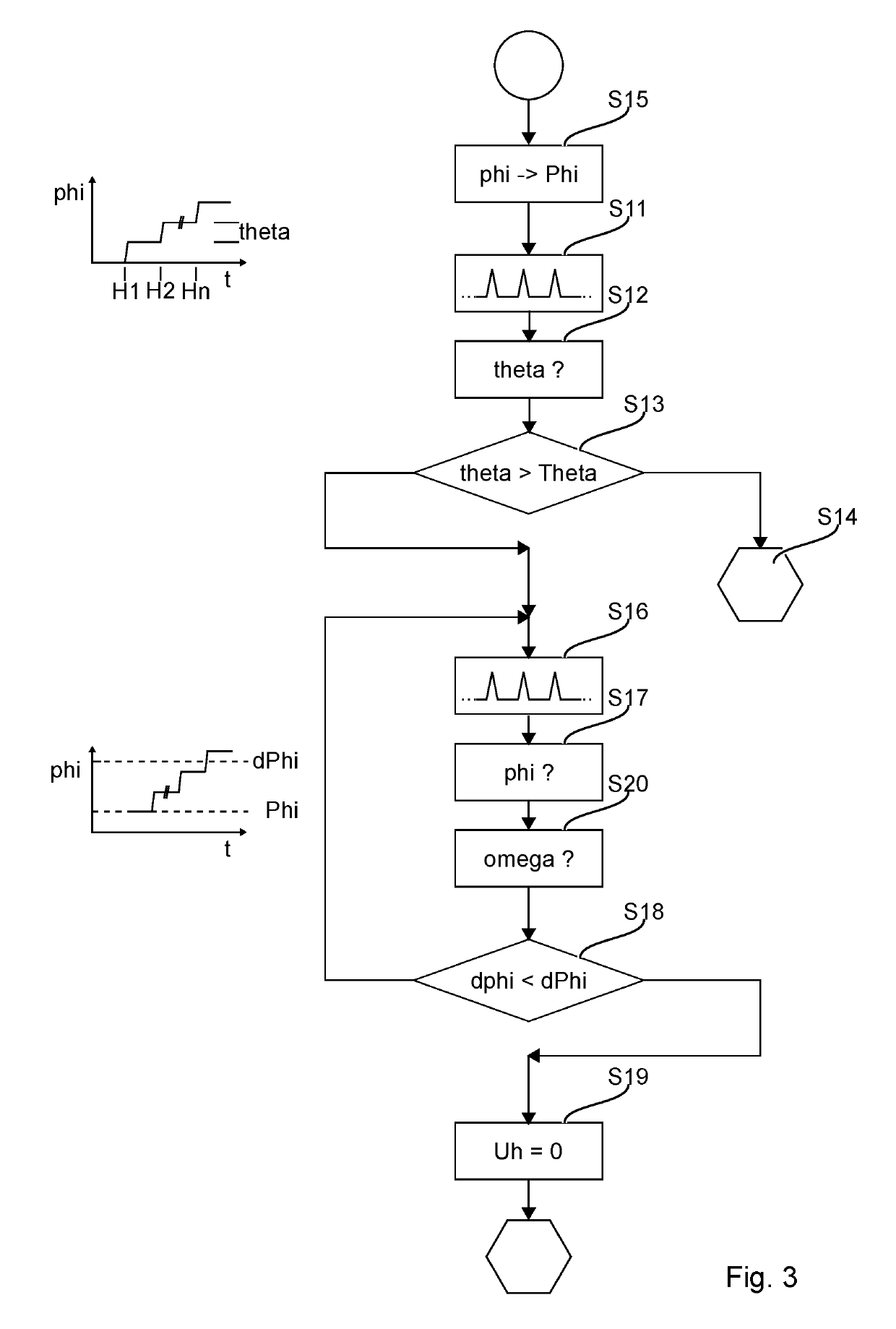

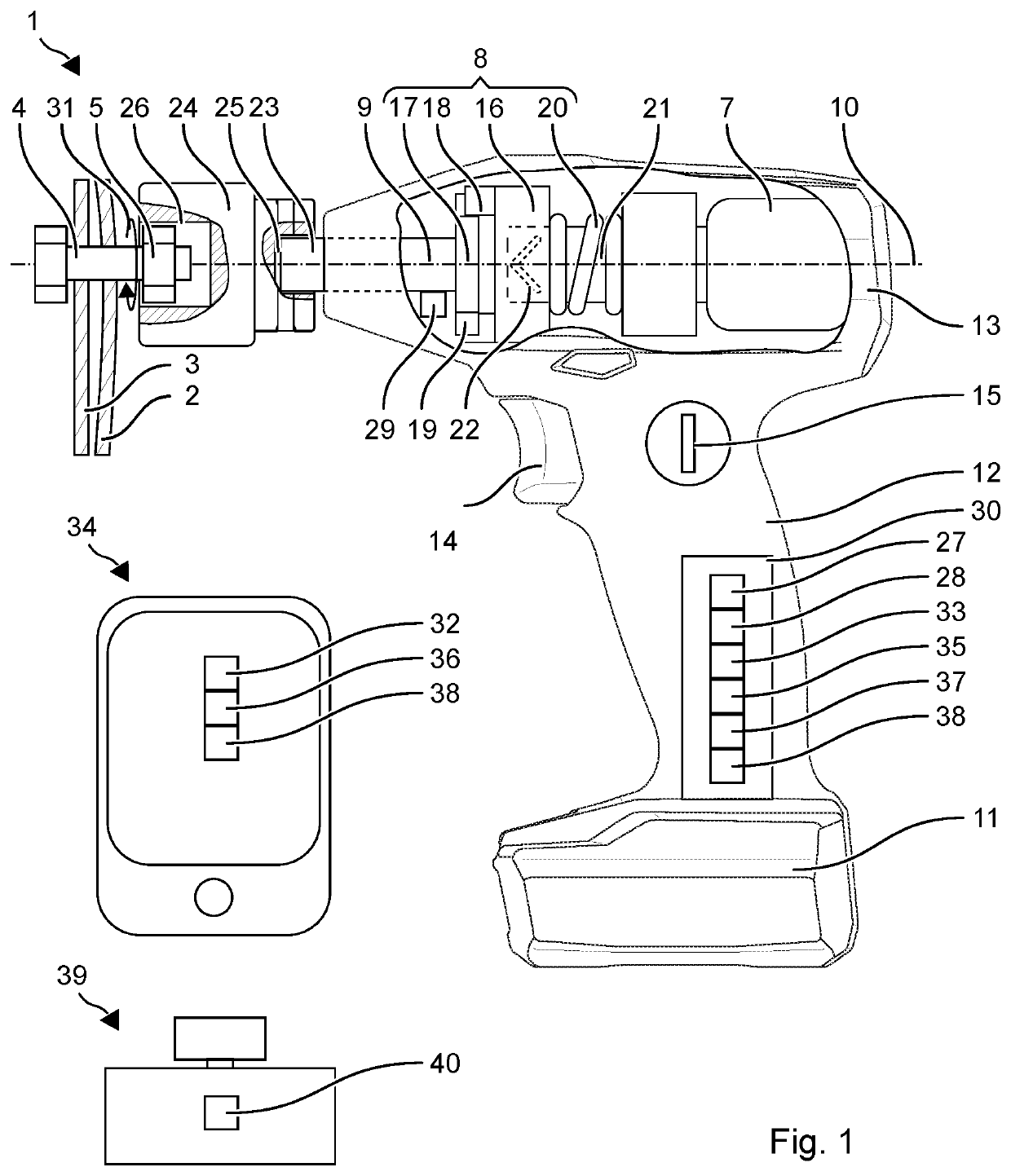

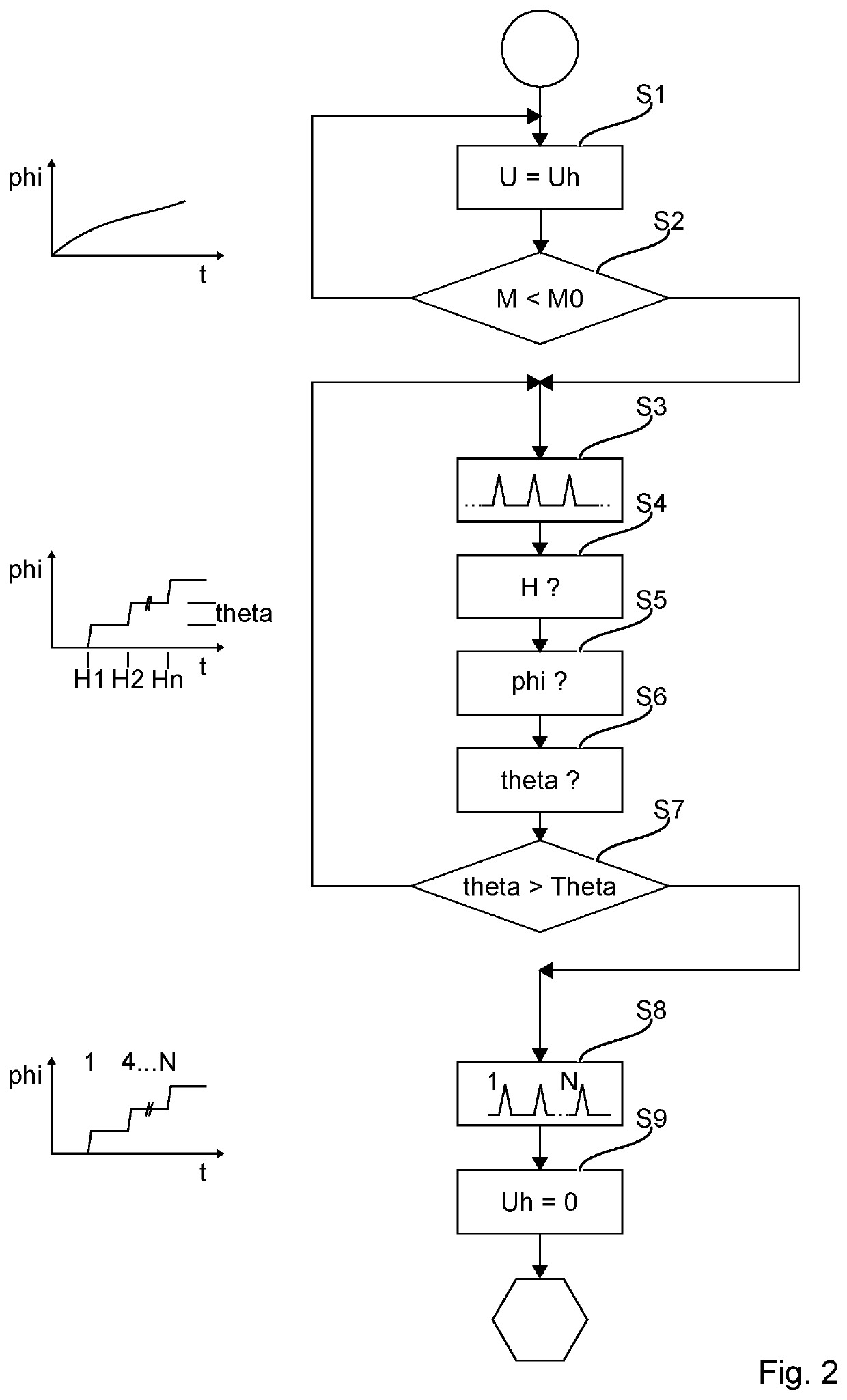

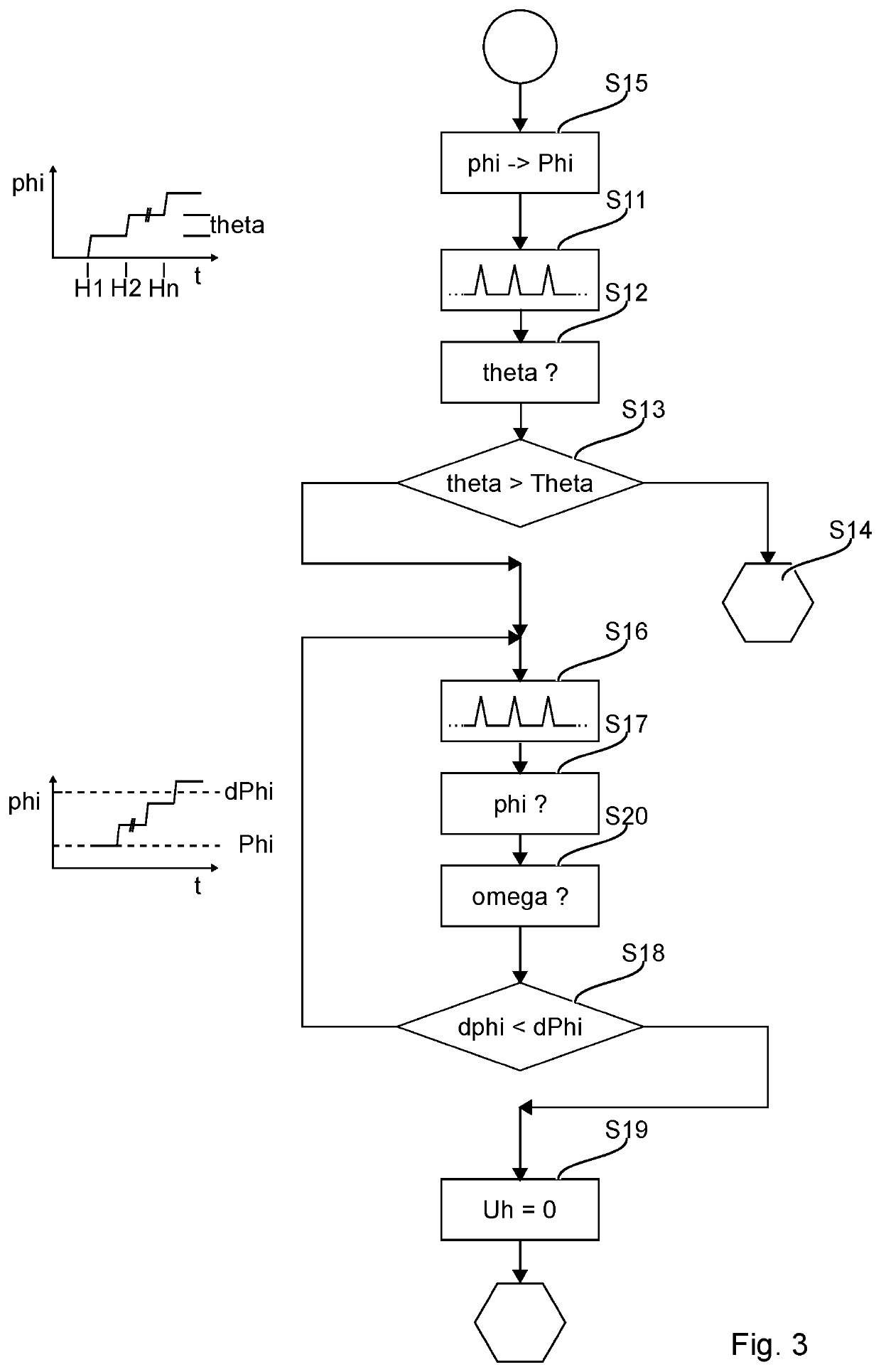

Control method for an impact wrench

A control method includes two operating modes carried out in response to a position of a selector switch. The first operating mode provides: carrying out first impacts of the hammer onto the anvil; detecting the event of an impact of the hammer onto the anvil with an impact sensor; detecting an angular position of the anvil with an angle sensor; estimating an individual impact angle of the anvil due to the last detected impact, based on the angular position of the anvil before the last detected impact and the angular position of the anvil after the last detected impact, and comparing the individual impact angle with an individual impact setpoint angle. The first operating mode is ended when the individual impact angle drops below an individual impact setpoint angle. The second operating mode provides: detecting the angular position of the anvil with the angle sensor as the initial position; carrying out second impacts of the hammer onto the anvil; and detecting a relative rotation angle of the anvil with respect to the initial position during the second impacts. The second operating mode is ended when the relative rotation angle exceeds a standard angle.

Owner:HILTI AG

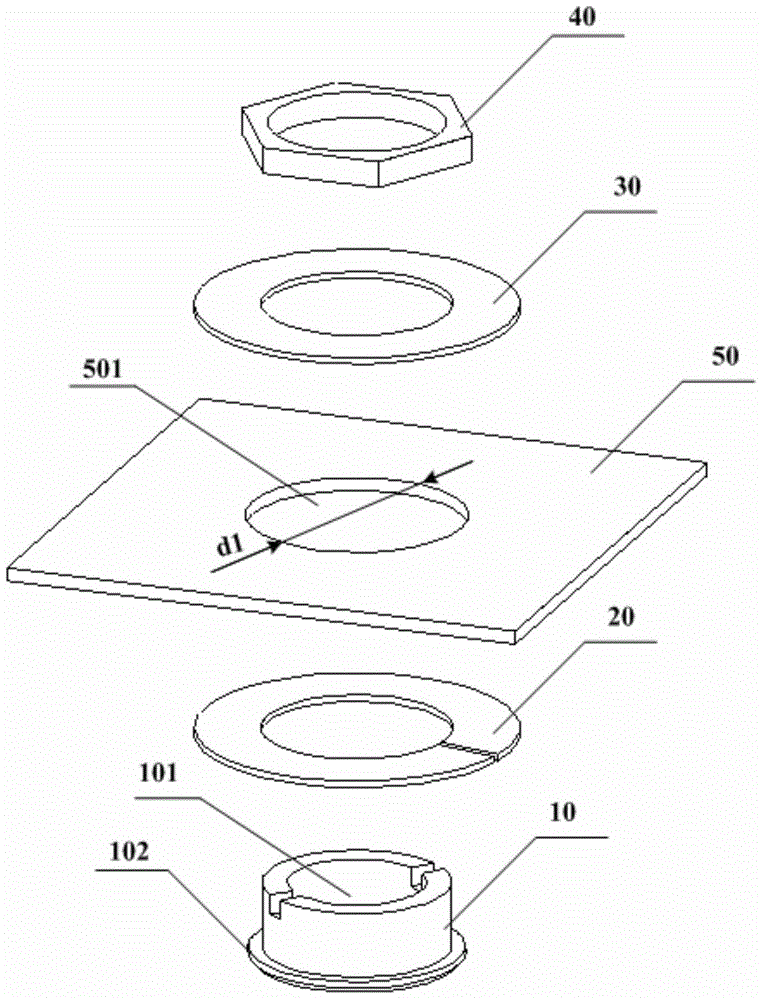

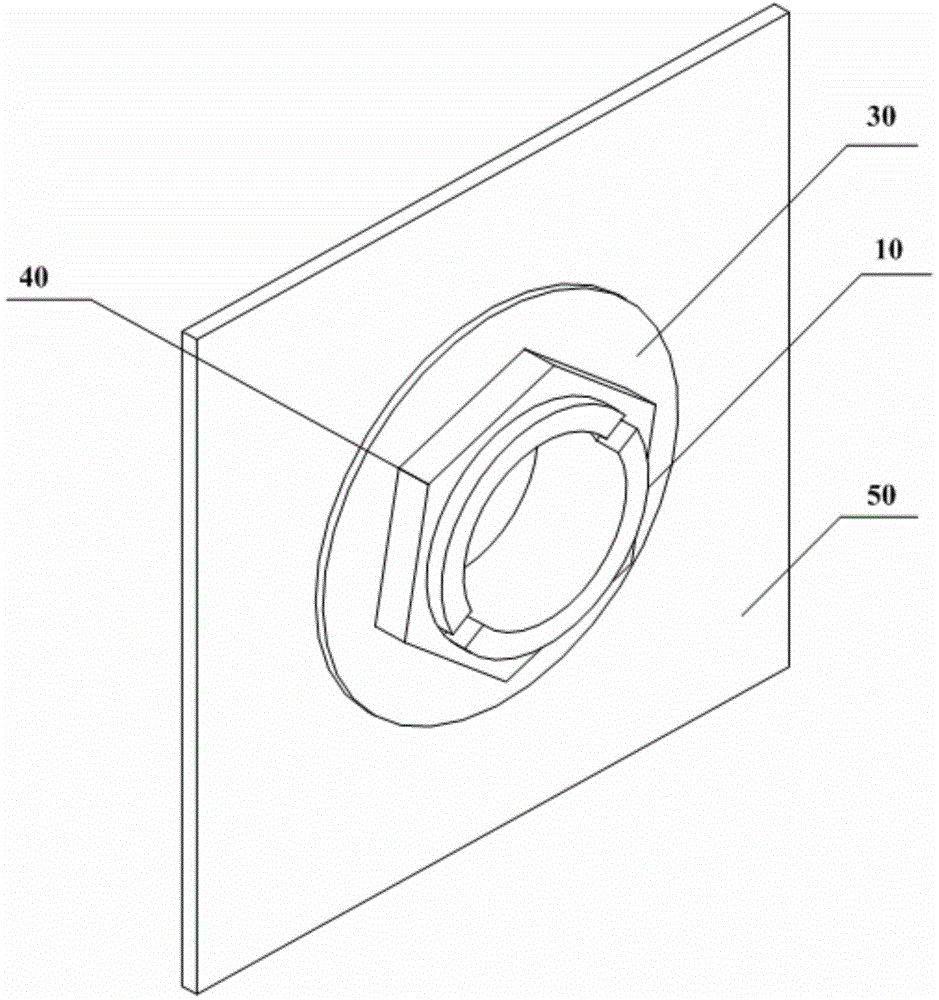

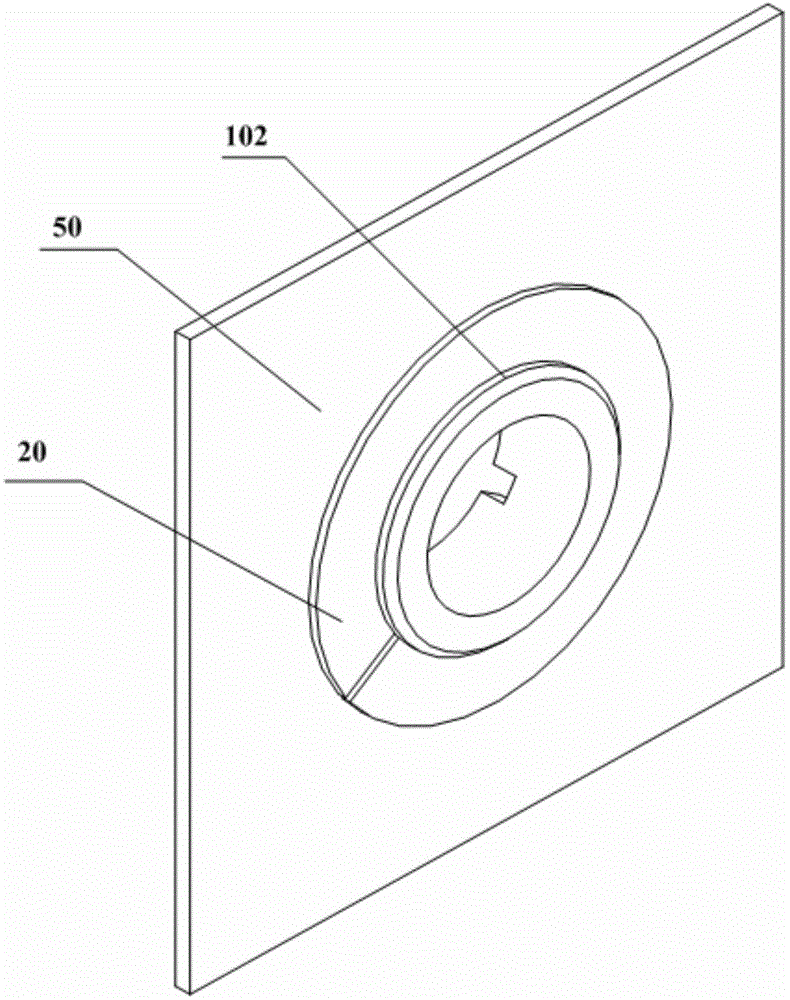

Pipe joint assembly and transportation equipment

InactiveCN103939686ASimplify the installation processImprove reliabilitySleeve/socket jointsBranching pipesFastener

The invention relates to the technical field of transportation equipment, in particular to a pipe joint assembly and a set of transportation equipment. The pipe joint assembly comprises a pipe joint with a through hole, an inner press piece, an outer press piece and a fastener, wherein the inner press piece, the outer press piece and the fastener are arranged on the pipe joint in a sleeved mode. A trapezoidal face is arranged on the outer side face of the pipe joint, and one end of the pipe joint penetrates through an opening of a pipeline wall. The inner press piece is located between the trapezoidal face and the inner wall of the pipeline wall. The outer press piece is located on the outer side of the pipeline wall. The fastener is connected with the pipe joint through threads, and the inner press piece and the outer press piece are made to clamp the pipeline wall. According to the pipe joint assembly, by screwing down the fastener, the inner press piece and the outer press piece located on the two sides of the pipeline wall respectively can be made to clamp the pipeline wall, a set of special equipment can be further connected with the pipe joint of the pipe joint assembly, and therefore, the process of installing the special equipment on a pipeline can be simplified through the pipe joint assembly, the application range of the pipe joint assembly can be wider, and the installing reliability is improved.

Owner:陈瑾

Anti-skid wrench

The invention discloses an antiskid wrench. The antiskid wrench is characterized in that the antiskid wrench comprises a wrench body, a compression bar handle, a plunger and a pressing assembly; the wrench body is sequentially divided into a nut connecting part, a handle mounting part, a plunger part and a holding part from left to right; the nut connecting part is provided with a nut sleeve holepenetrating through the front and back of the nut connecting part; a sliding block mounting hole penetrating through the interior and exterior of the nut connecting part is formed in the upper part ofthe nut connecting part; a pressing sliding block of the pressing assembly is arranged in the sliding block mounting hole of the nut connecting part in a sliding manner; a handle mounting seat is arranged on the upper side of the handle mounting part; the compression bar handle is hinged with the handle mounting seat; the plunger part is provided with a plunger hole penetrating through the upperpart and lower part of the plunger part; the plunger is arranged in the plunger hole in a sealing and sliding manner; a first cavity in the wrench body penetrates through the nut connecting part, thehandle mounting part, the plunger hole of the plunger part and the holding part; liquid plastic is arranged in the first cavity; and the compression bar handle gest close to the holding part and presses the plunger downwards, and the liquid plastic is extruded by the plunger to allow the pressing sliding block to be contracted inward in the radial direction to clamp six surfaces of a nut.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

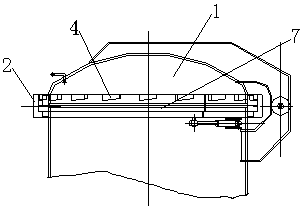

Fluid operated torque tool for and a method of tightening a nut on a plate on railroad crossings

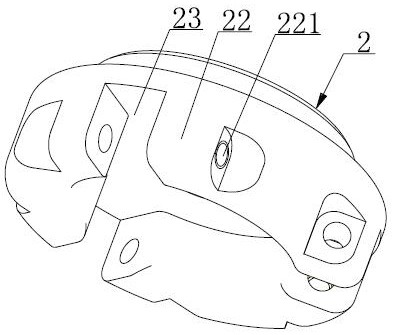

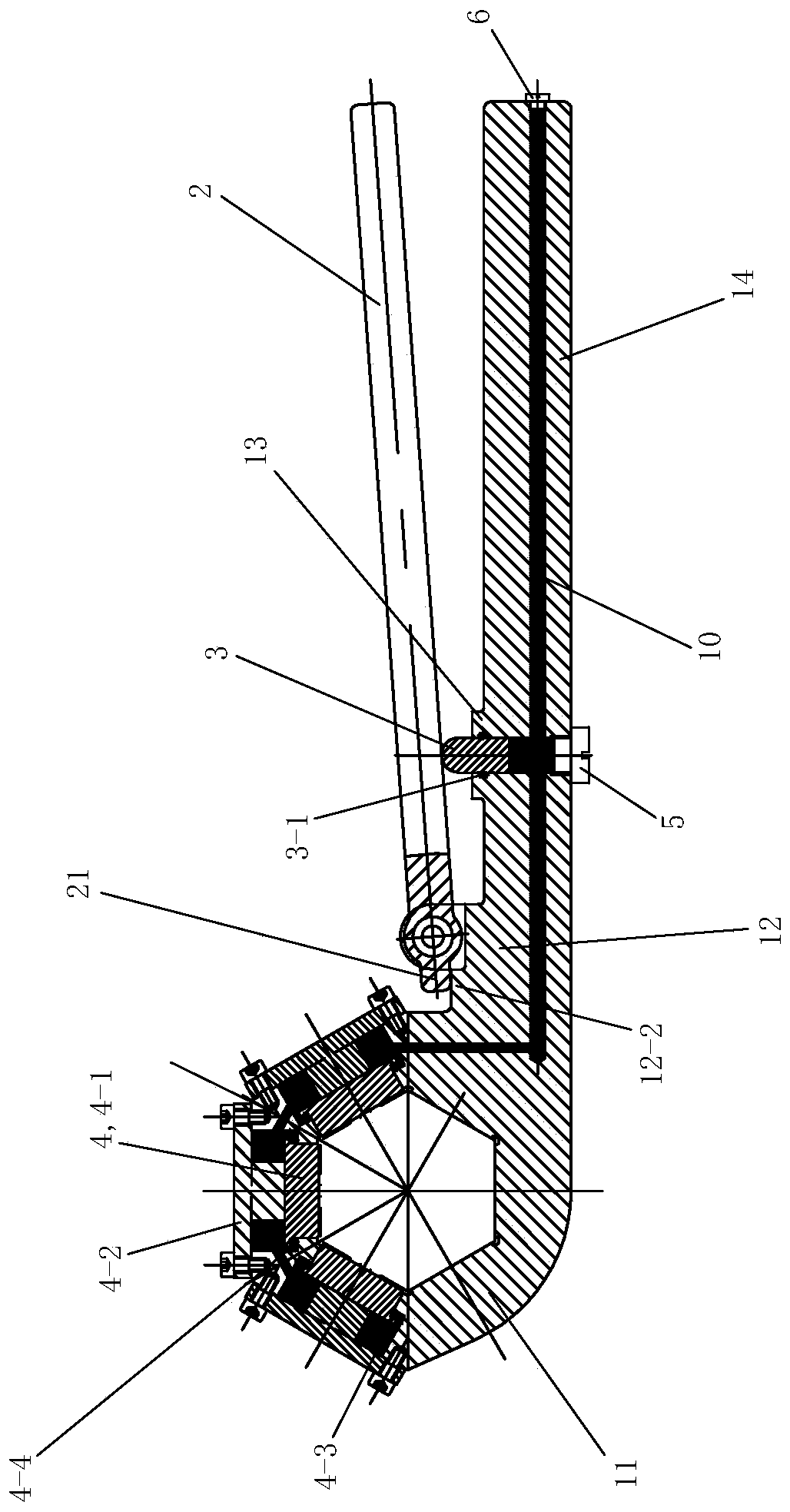

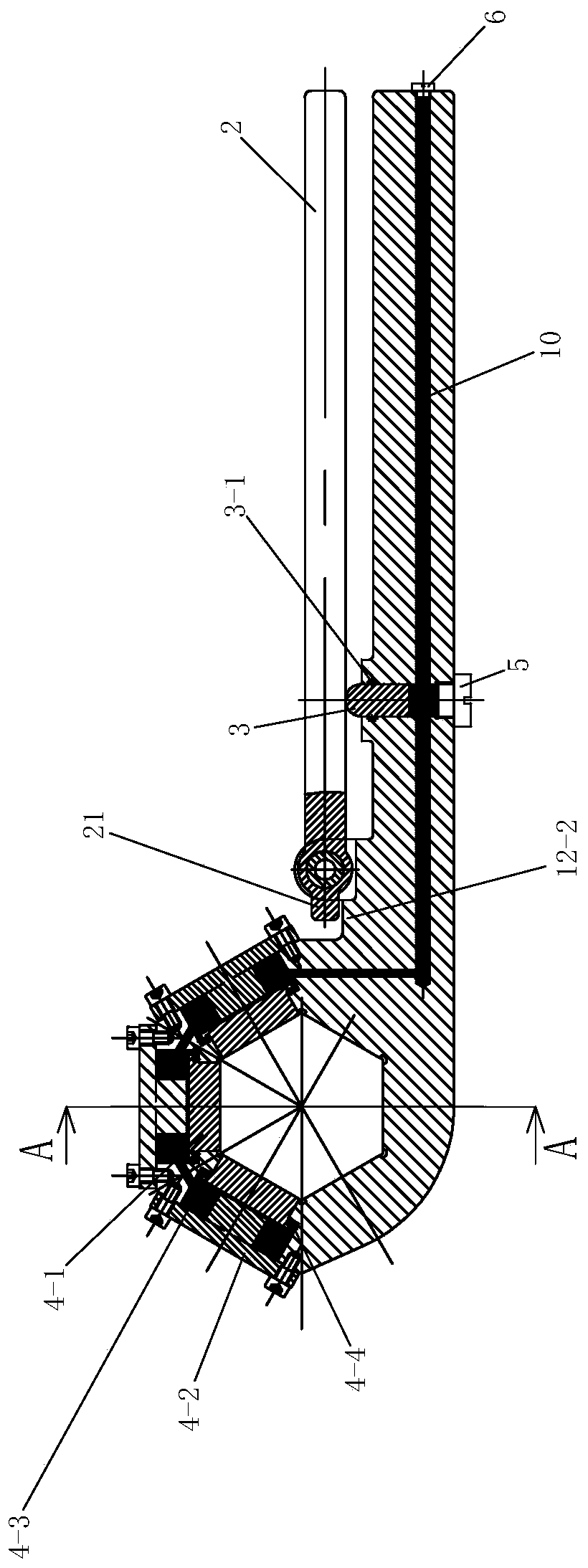

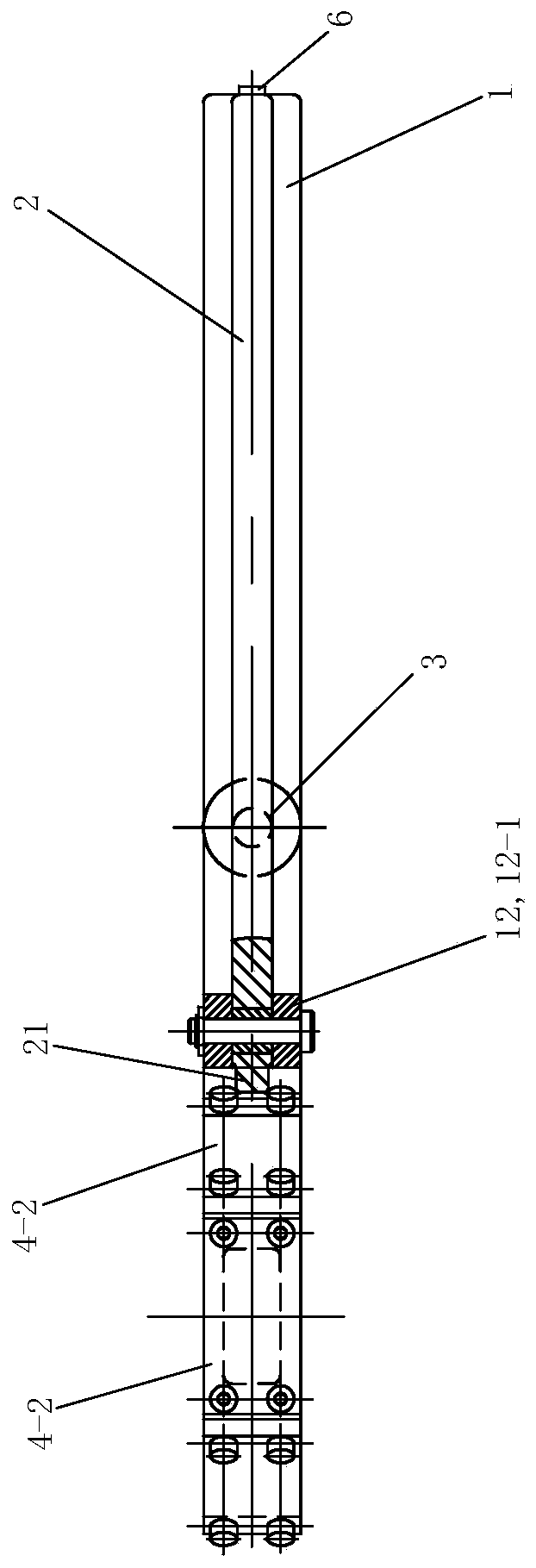

ActiveUS20090223326A1Reliable tighteningSpannersPortable power-driven toolsLevel crossingEngineering

A fluid operated torque tool tightens a nut through a spring washer on a plate on a railroad crossing, and has a housing, two coaxial drives applying equal turning forces in opposite directions around an axis, with one of the two coaxial drives located around the other of the two coaxial drives, a first socket attached to the one coaxial drive and configured to fit on the rectangular plate, and a second socket attached to the other coaxial drive inside the first socket and configured to fit on the nut, with the washer being not engaged by the sockets, so as to tighten the nut and to tighten up the spring washer onto the plate while the first socket and the housing stand still.

Owner:HYTORC DIV UNEX CORP

Control method for an impact wrench

Owner:HILTI AG

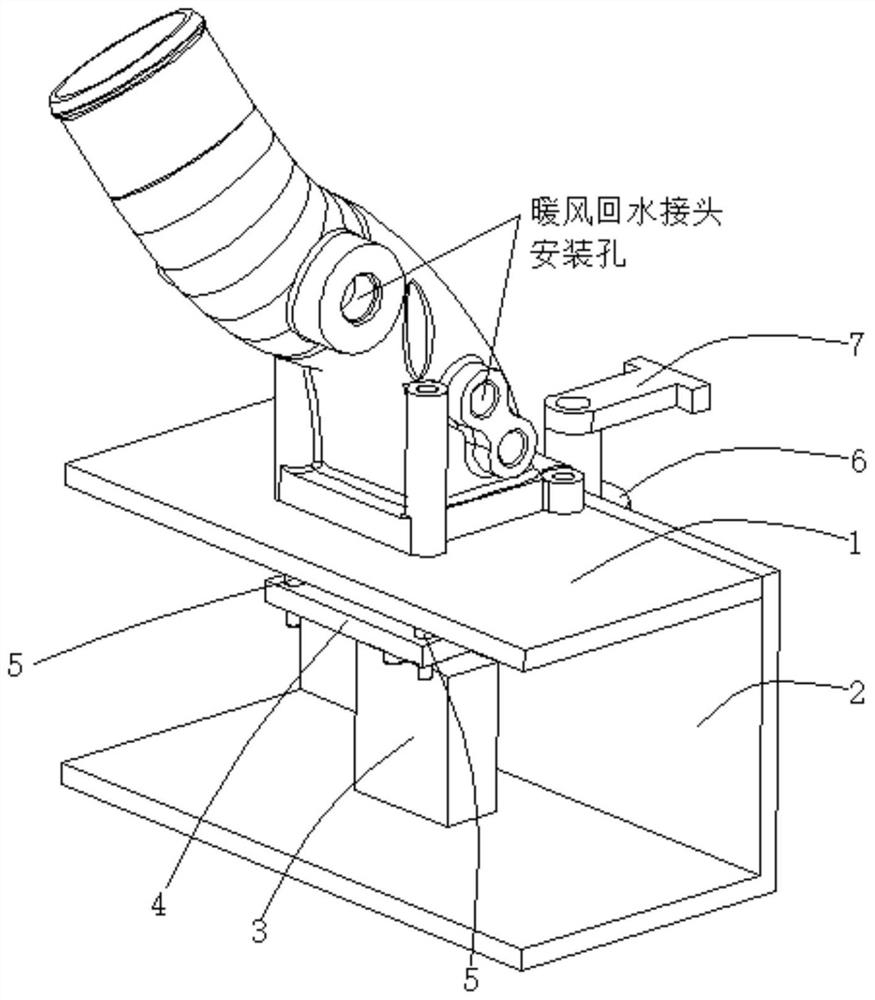

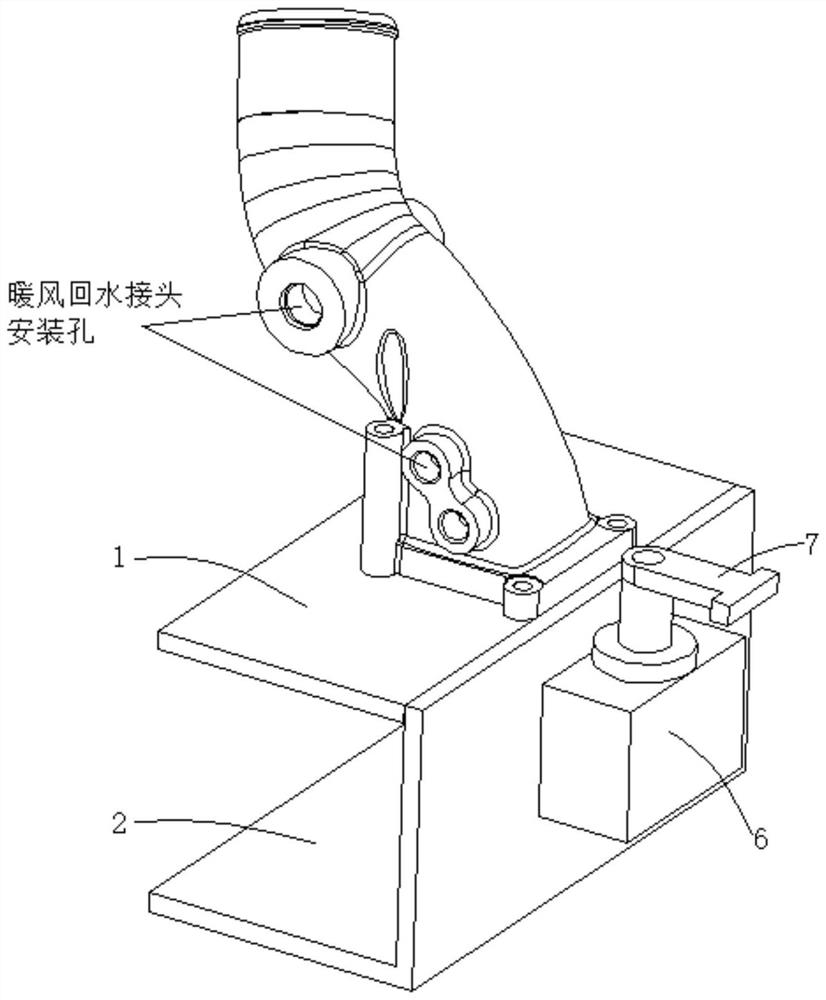

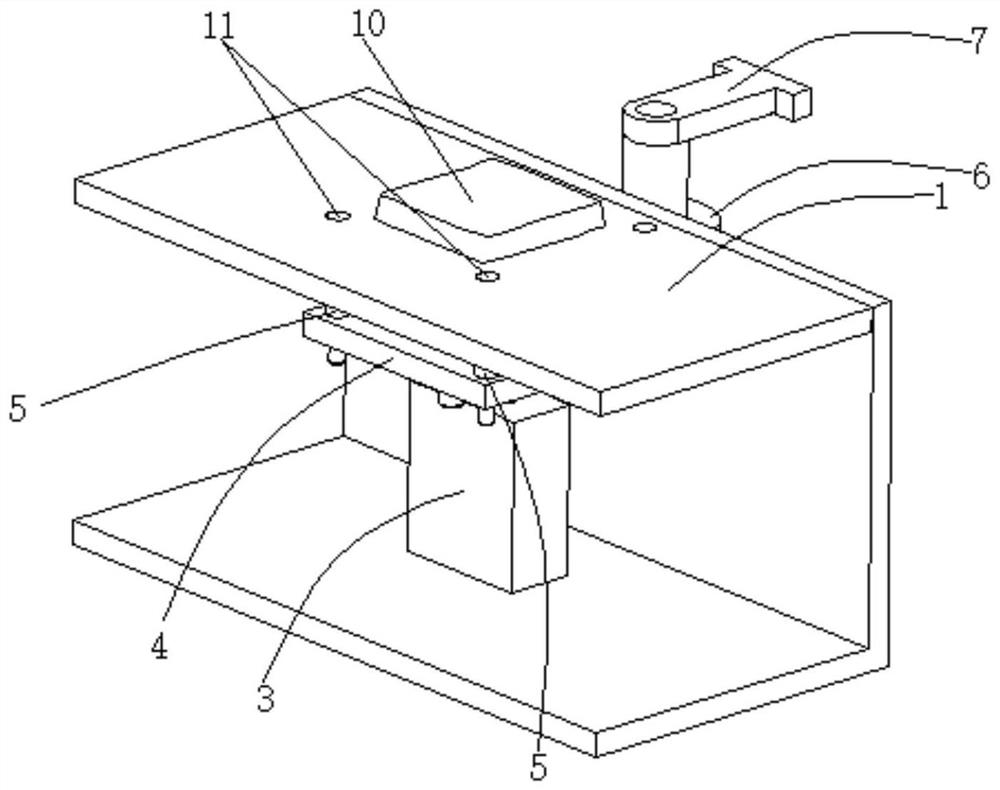

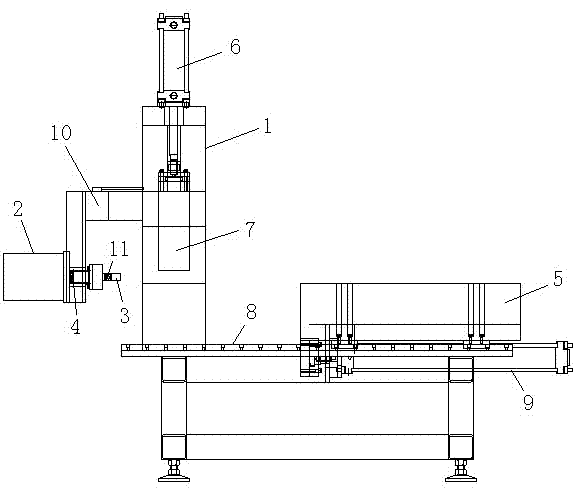

Screw-up tool for air heater backwater joint on engine water inlet pipe

PendingCN111716271AClamp firmlyEasy to tightenWork holdersMetal-working hand toolsMarine engineeringStructural engineering

The invention discloses a screw-up tool for an air heater backwater joint on an engine water inlet pipe. The screw-up tool comprises a platform plate, a side frame plate, a telescopic air cylinder, alifting plate, positioning pins, a rotary clamping air cylinder and a clamping head. The side frame plate and the side face of the platform plate are in fastening connection, and the telescopic air cylinder and the lower end of the side frame plate are in fastening connection. The lifting plate and the end of a piston rod of the telescopic air cylinder are in fastening connection, the positioningpins and the lifting plate are in fastening connection, the rotary clamping air cylinder and the side wall of the side frame plate are in fastening connection, and the clamping head and the end of a piston rod of the rotary clamping air cylinder are in fastening connection. The clamping and fixing stability of the water inlet pipe is guaranteed, the air heater backwater joint can be screwed up conveniently, time and labor are saved, and screwing up is reliable.

Owner:Y & C ENGINE

Adjustable multishaft screwing mechanism

The invention discloses an adjustable multishaft screwing mechanism, which comprises angle adjusting mechanisms, radial adjusting mechanisms, single-shaft screwing machines, a frame and a driving control unit, wherein the angle adjusting mechanisms are fixed on the upper disc of the frame, the radial adjusting mechanisms are installed on a lower disc, adjusting link rods are used for connecting the angle adjusting mechanisms with the corresponding radial adjusting mechanisms, the single-shaft screwing machines are installed on the radial adjusting mechanisms, and the driving control unit is installed on the top cover of the frame. By adopting the invention, the screwing speeds, moments and directions of different single-shaft screwing machines are controlled; and the adjustable multishaft screwing mechanism disclosed by the invention has the advantages of high regulation precision, simple structure, convenience for adjusting and the like, and can realize rapid screwing of bolts at different positions.

Owner:AIR FORCE UNIV PLA

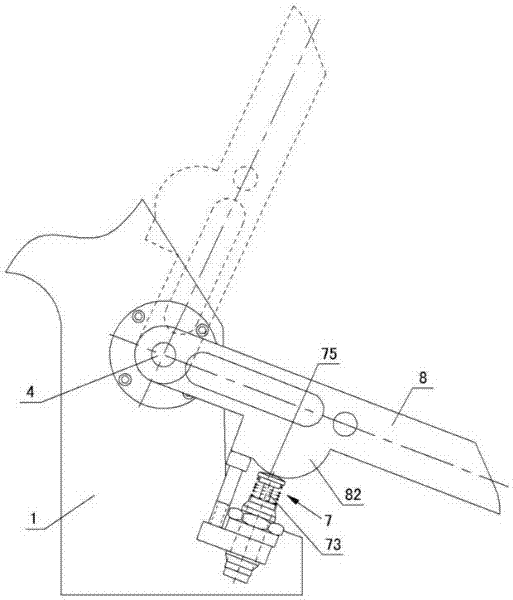

Improved impact head for shock absorber of aluminum die casting spraying machine

ActiveCN102562937BExtended service lifeReduce impactNon-rotating vibration suppressionDie castingEngineering

An improved impact head for a shock absorber of an aluminum die casting spraying machine comprises a bracket mounting base of the aluminum die casting spraying machine, wherein the bracket mounting base is connected with a spraying case base and a spraying machine assembly; the spraying machine assembly is connected with a spraying pipe and a power bracket; the power bracket is driven by an air cylinder and is connected with one end of a long lateral arm and one end of a short lateral arm; the other ends of the long lateral arm and the short lateral arm are connected onto the spraying case base through rotating shafts; the shock absorber is mounted below the spraying case base and comprises a machine body bracket and a shock absorber main body mounted on the machine body bracket; a bufferrod is arranged in the shock absorber main body; the head of the buffer rod is connected with an impact cap; and a spring is mounted between the impact cap and the shock absorber main body. The improved impact head is characterized in that bearings are mounted on the long lateral arm and the short lateral arm and are contacted with an upper plane of the impact cap.

Owner:台州市宗拓自动化设备有限公司

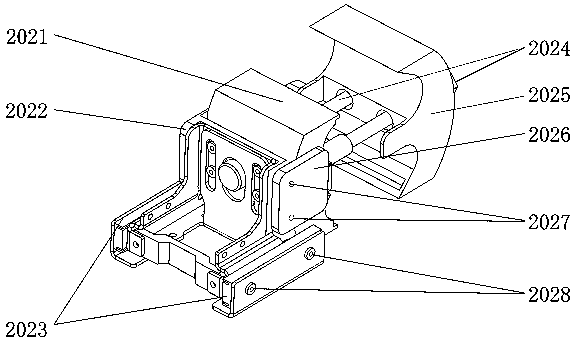

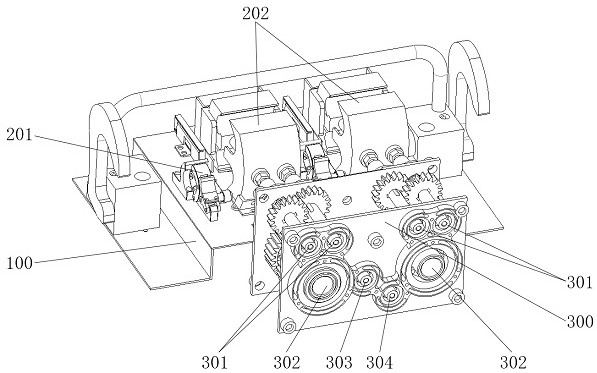

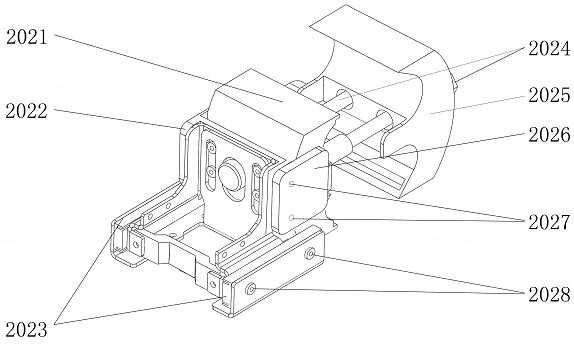

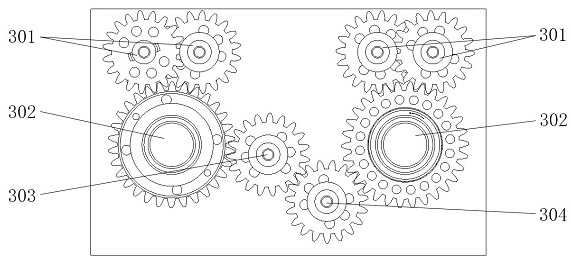

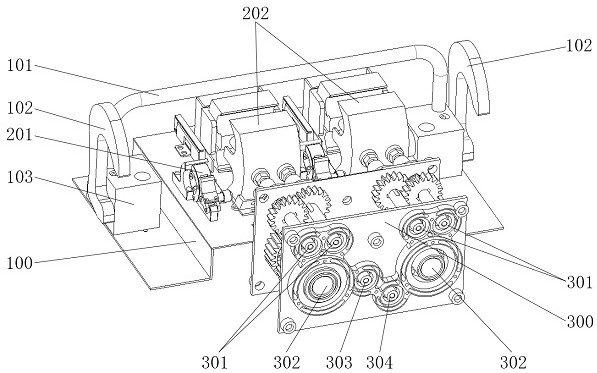

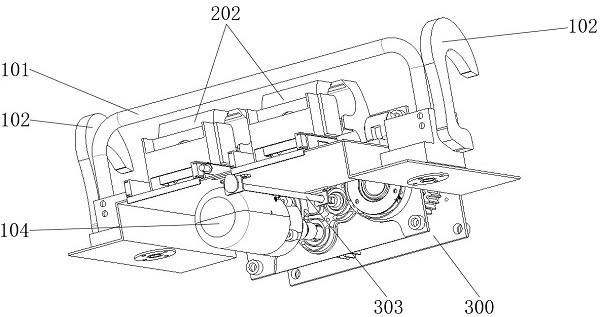

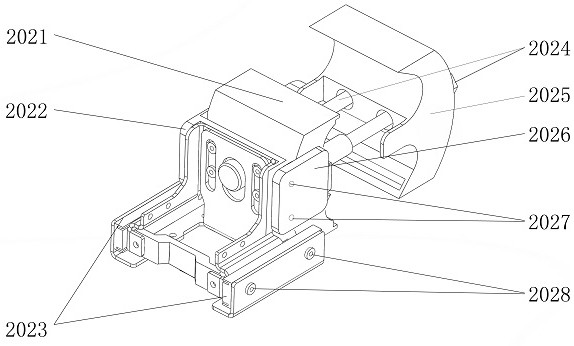

A high-safety puncture wire clip tightening device suitable for live working robots

The invention relates to the technical field of distribution network operation and maintenance equipment, in particular to a high-safety puncture clamp tightening device suitable for live working robots, which includes four tightening shafts, a motor and a gear box, and the motor is connected to the tightening shaft through the gear box One end is driven and connected, and the other end of the tightening shaft is set on the clamp screw of the puncture clamp; the gearbox includes a box body, two sets of driving gears, four tightening gears, a driving gear, a driving shaft and a reversing gear, and the driving gear includes a main gear , auxiliary gear, gear shaft and one-way transmission device, the main gear is connected to the gear shaft through the one-way transmission device, the auxiliary gear is fixedly connected to the gear shaft, the driving gear is connected to the motor, one group of main gears meshes with the driving gear, and the other The main gear of the group meshes with the reversing gear, and the reversing gear meshes with the driving gear. The substantive effect of the present invention is: when the motor is in the forward and reverse direction, one puncture wire clip is tightened respectively, so that the puncture wire clip can be tightened more reliably, and the reliability and safety of the branch line are improved.

Owner:STATE GRID ZHEJIANG HANGZHOU XIAOSHAN POWER SUPPLY CO +1

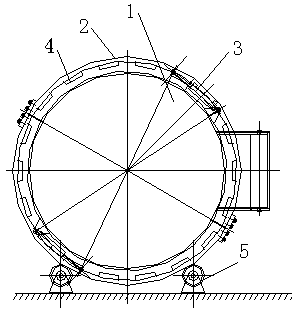

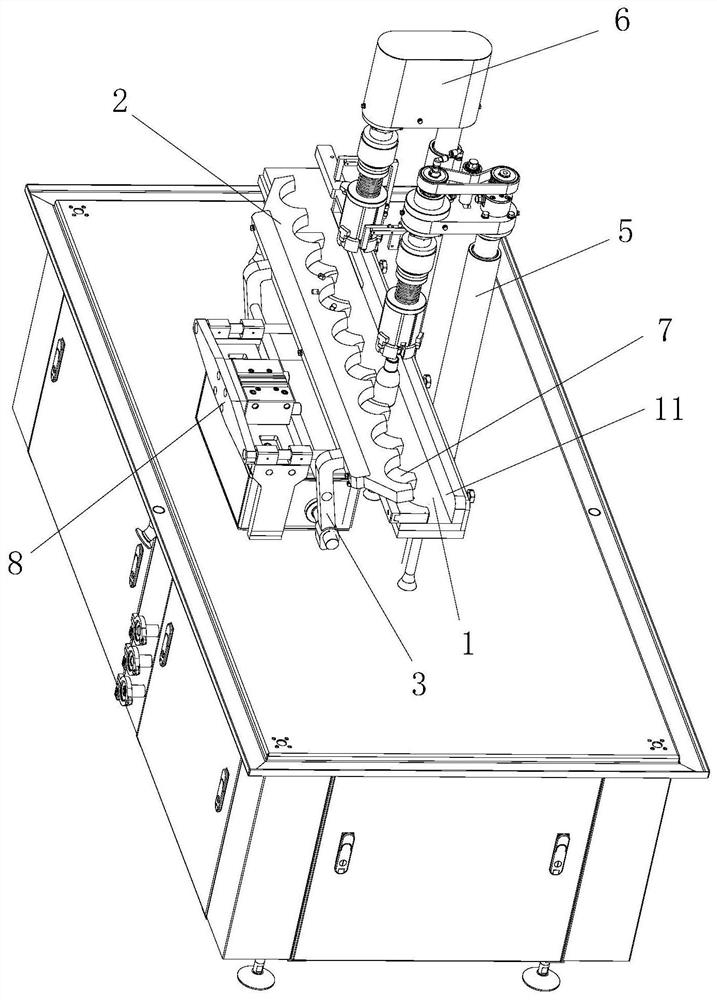

Barrel tightening machine

ActiveCN103143925BEasy to operateImprove work efficiencyMetal working apparatusElectric machineryEngineering

Owner:贺州市八步区市场监督管理局

Tightening and fixing structure of test tank rear cover

InactiveCN103792395AIncrease frictionAvoid damageElectrical measurement instrument detailsElectrical testingHydraulic cylinderClassical mechanics

Owner:JIANGSU QIYUAN LEIYU ELECTRICAL TECH

Top pushing type water pipe connecting tool and use method thereof

InactiveCN107414739AEasy to useReliable tighteningMetal-working hand toolsPipingArchitectural engineering

The invention discloses a top pushing type water pipe connecting tool and a use method thereof. The connecting tool is provided with a casing pipe of a hollow structure, a thread rod capable of stretching into the casing pipe and capable of sliding in the casing pipe, two guide grooves arranged on the casing pipe, a sliding rod fixedly arranged on the thread rod, a supporting rod, a check block and a butterfly nut; the sliding rod is fixedly arranged on the thread rod, the two ends of the sliding rod stretch out of the two guide grooves and can slide in the guide grooves, the supporting rod is fixedly arranged at the position, close to the first end, of the casting pipe, the check block is fixedly arranged at the first end of the casing pipe, the butterfly nut is arranged at the second end of the casing pipe and is in thread fit with the thread rod, use is convenient, and screwing is reliable.

Owner:芜湖金智王机械设备有限公司

A pipe joint assembly and a transport device

InactiveCN103939686BSimplify the installation processImprove reliabilitySleeve/socket jointsBranching pipesEngineeringScrew thread

The invention relates to the technical field of transportation equipment, in particular to a pipe joint assembly and a set of transportation equipment. The pipe joint assembly comprises a pipe joint with a through hole, an inner press piece, an outer press piece and a fastener, wherein the inner press piece, the outer press piece and the fastener are arranged on the pipe joint in a sleeved mode. A trapezoidal face is arranged on the outer side face of the pipe joint, and one end of the pipe joint penetrates through an opening of a pipeline wall. The inner press piece is located between the trapezoidal face and the inner wall of the pipeline wall. The outer press piece is located on the outer side of the pipeline wall. The fastener is connected with the pipe joint through threads, and the inner press piece and the outer press piece are made to clamp the pipeline wall. According to the pipe joint assembly, by screwing down the fastener, the inner press piece and the outer press piece located on the two sides of the pipeline wall respectively can be made to clamp the pipeline wall, a set of special equipment can be further connected with the pipe joint of the pipe joint assembly, and therefore, the process of installing the special equipment on a pipeline can be simplified through the pipe joint assembly, the application range of the pipe joint assembly can be wider, and the installing reliability is improved.

Owner:陈瑾

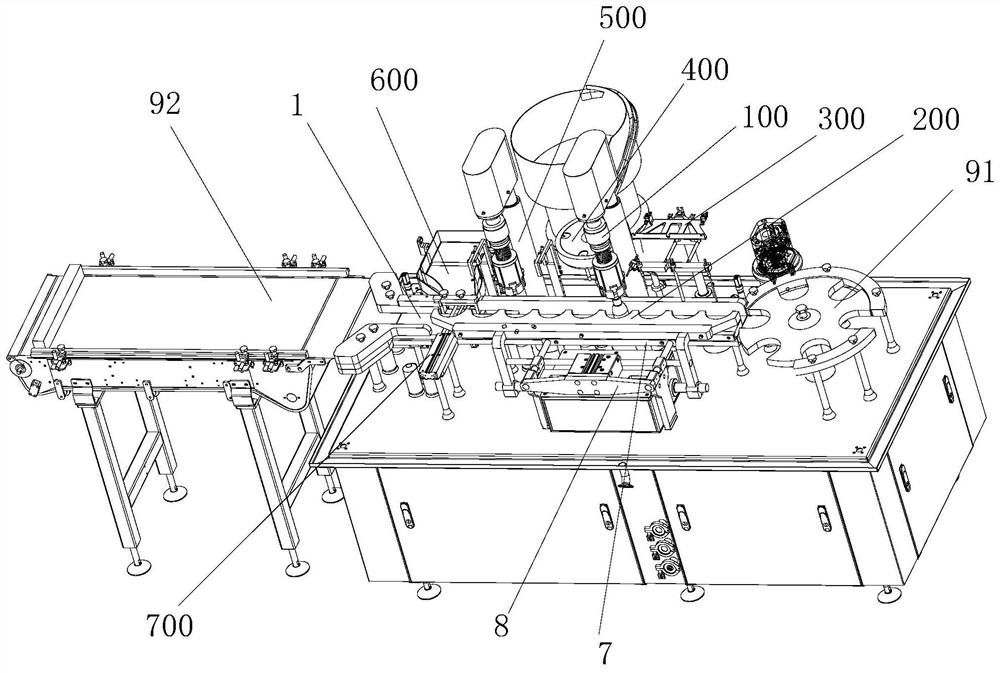

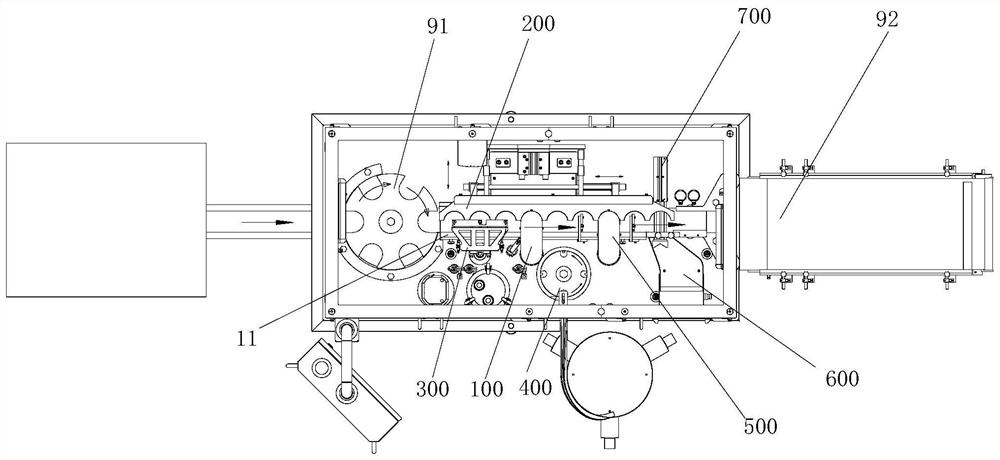

A filling and capping machine and a filling and capping method

ActiveCN109231131BReasonable layoutReduce space consumptionThreaded caps applicationBottle-handling machinesProcess engineeringBottle cap

A filling and capping machine, comprising a bottle conveying track, a bottle infeed part located upstream of the bottle conveying track and a bottle outlet part located downstream of the bottle conveying track, both sides of the bottle conveying track are provided with bottle conveying fences and intermittent The bottle conveying device, below or above the intermittent bottle conveying device, is provided with a positioning piece for positioning the medicine bottle. In the conveying direction, the side of the bottle conveying fence far away from the bottle conveying track is provided with a filling device, a pre-capping device and a capping device in turn, and a cap unscrambling device for providing bottle caps is provided on the side of the pre-capping device, and the bottle conveying Downstream of the fence, there is a rejecting channel, and the rejecting channel is equipped with a rejecting bottle pushing part, and the rejecting bottle pushing part and the rejecting channel are relatively arranged on both sides of the bottle conveying track. The filling and capping method comprises the steps of: bottle feeding; filling; pre-capping; capping; rejecting. The invention has the advantages of reasonable layout, small occupied space, reliable screw cap and the like.

Owner:TRUKING TECH LTD

A high-efficiency live working robot for distribution network and branch line

ActiveCN111446601BReliable tighteningImprove reliabilityUnstripped conductor connection apparatusClip conductor connectionRemote controlVideo image

The present invention relates to the technical field of robots, in particular to a high-efficiency distribution network connection branch line live working robot, including a chassis, a boom, a wire clamp seat, a wire clamp tightening device, a camera and a remote control, the boom and the wire clamp seat Both are installed on the chassis, and there are two wire clip seats, the two wire clip seats are arranged side by side along the extending direction of the target wire, and the puncture wire clips are installed on the two wire clip seats, and the target wire passes through the puncture Wire clip, the wire clamp tightening device is fixedly connected with the chassis, the wire clamp tightening device is connected with the puncture wire clip, the camera is installed on the chassis and aligned with the puncture wire clip, and the camera takes pictures of the puncture wire clip The video image, the camera and the clamp tightening device are all connected to a remote controller with a display screen. The substantive effects of the invention are: the wiring of two branches can be completed at one time, and the work efficiency is high; the control is carried out by remote control, the deployment is simple and flexible, and it can adapt to the complex distribution network environment.

Owner:STATE GRID ZHEJIANG HANGZHOU XIAOSHAN POWER SUPPLY CO +1

Improved impact head for shock absorber of aluminum die casting spraying machine

ActiveCN102562937AFirmly connectedEven by forceNon-rotating vibration suppressionDie castingEngineering

An improved impact head for a shock absorber of an aluminum die casting spraying machine comprises a bracket mounting base of the aluminum die casting spraying machine, wherein the bracket mounting base is connected with a spraying case base and a spraying machine assembly; the spraying machine assembly is connected with a spraying pipe and a power bracket; the power bracket is driven by an air cylinder and is connected with one end of a long lateral arm and one end of a short lateral arm; the other ends of the long lateral arm and the short lateral arm are connected onto the spraying case base through rotating shafts; the shock absorber is mounted below the spraying case base and comprises a machine body bracket and a shock absorber main body mounted on the machine body bracket; a bufferrod is arranged in the shock absorber main body; the head of the buffer rod is connected with an impact cap; and a spring is mounted between the impact cap and the shock absorber main body. The improved impact head is characterized in that bearings are mounted on the long lateral arm and the short lateral arm and are contacted with an upper plane of the impact cap.

Owner:台州市宗拓自动化设备有限公司

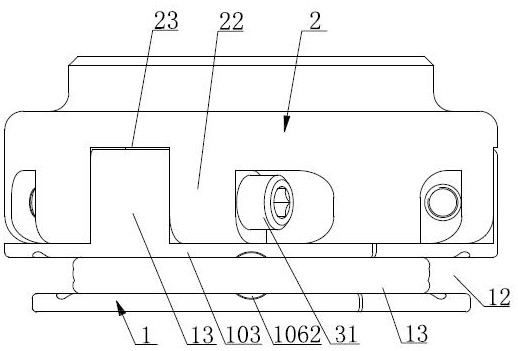

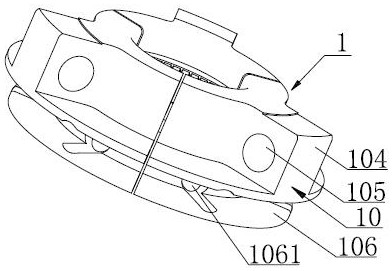

A gear hobbing fixture for clamping multiple large ring gear parts

ActiveCN103706892BModerate numberReliable tighteningGear-cutting machinesGear teethHobbingEngineering

The invention discloses a hobbing clamp for clamping a plurality of parts with big gear rings. The hobbing clamp for clamping the parts with the big gear rings comprises a pressing portion and a centering portion, wherein the centering portion comprises a base, a first spring, a locating sleeve, force transmission blocks, a lower pull rod and the like, a support is arranged on the top surface of the base, the support is sleeved with a supporting disk, the pressing portion comprises an upper pull rod and a press plate, the upper pull rod is sleeve with a disk spring and a pressing sleeve in sequence from top to bottom, the disk spring and the pressing sleeve are sleeved with a bushing in a spaced mode, a supporting plate is arranged at the bottom of the press plate, the top surface of the supporting plate is a big-end-down conical surface, the conical surface is attached to the bottom surface of the press plate, the lower end of the supporting plate is fixedly sleeved with a gland, the lower end of the upper pull rod is provided with a T-shaped portion, and the T-shaped portion penetrates through a small-diameter section of a center hole of a taper sleeve and a center hole of a reset spring, and then is clamped into a large-diameter section of a cylindrical hole formed by inner surfaces of all the force transmission blocks. According to the hobbing clamp for clamping the parts with the big gear rings, centering of workpieces with big gear rings can be well carried out through expansion blocks, the workpieces can be tightly pressed at the same time, and centering accuracy can be ensured.

Owner:CHONGQING MACHINE TOOL GROUP

Cap grabbing head

The invention discloses a cap grabbing head. The cap grabbing head comprises a cap grabbing die, wherein the cap grabbing die comprises at least two independent arc-shaped cap grabbing die petals, each cap grabbing die petal structurally comprises an arc-shaped petal body, a top plate and a supporting plate are arranged on the inner side and the outer side of the petal body respectively, and the top plate is located at the top of the inner side of the petal body; a mounting base sleeves the cap grabbing die, a check ring is arranged on the inner wall of the mounting base, the top plate of each petal body is positioned at the bottom of the check ring of the mounting base, the supporting plate of each petal body is positioned at the bottom of the mounting base, each petal body is hinged to the mounting base, a space for each petal body to rotate around the corresponding hinge center is reserved between the mounting base and the petal body, and when the top plate of any petal body is pressed and blocked by a bottle cap, the lower end of the petal body can rotate towards the inner side of the mounting base around the corresponding hinge center. The cap grabbing head has the advantages that errors between the bottle cap and the cap grabbing die can be overcome, and the cap screwing efficiency is greatly improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

non-slip wrench

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

High-safety puncture wire clamp tightening device suitable for live working robot

ActiveCN111438511AImprove work efficiencyImprove safety and reliabilityMetal working apparatusElectric machineryWheel drive

The invention relates to the technical field of power distribution network operation and maintenance equipment, in particular to a high-safety puncture wire clamp tightening device suitable for a liveworking robot. The live working robot comprises four tightening shafts, a motor and a gear box, the motor is in transmission connection with one ends of the tightening shafts through the gear box, and the other ends of the tightening shafts are arranged on wire clamp screws of puncture wire clamps in a sleeving mode; and the gear box comprises a box body, two groups of drive gears, four tightening gears, a driving gear, a driving shaft and a reversing gear, each drive gear comprises a main gear, an auxiliary gear, a gear shaft and a one-way transmission device, the main gears are connected with the gear shafts through the one-way transmission devices, the auxiliary gears are fixedly connected with the gear shafts, the driving gears are connected with the motor, the main gear of one groupis engaged with the driving gear, and the main gear of the other group is engaged with the reversing gear, and the reversing gear is engaged with the driving gear. The live working robot has the substantial effects that when the motor rotates forwards and backwards, the puncture wire clamps are respectively screwed down, so that the puncture wire clamps can be screwed down more reliably, and the reliability and the safety of branch wires are improved.

Owner:STATE GRID ZHEJIANG HANGZHOU XIAOSHAN POWER SUPPLY CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com