Tightening and fixing structure of test tank rear cover

A technology for fixing structures and test objects, applied in the direction of measuring devices, instruments, measuring electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

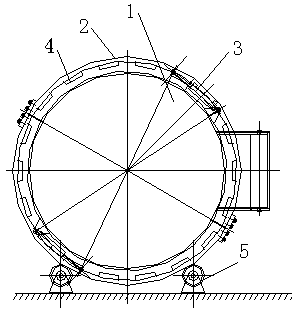

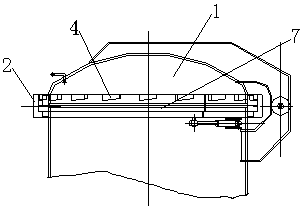

[0016] 18 oblique wedges 4 are evenly distributed on the circumference of the test tank rear cover 1 and the concave groove 2 of the present invention, and the oblique wedges 4 are entities with a certain inclination. Both oblique wedges 4 are symmetrically distributed, and the length of the vacant part is greater than the length of the oblique wedge 4 entities.

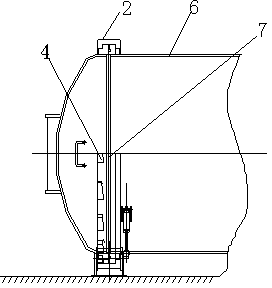

[0017] The rear cover 1 and the tank body 6 of the sample tank are fixed by a central axis 7, and the two central axes 7 form a line, which can be opened and closed freely. The concave groove 2 can rotate at a certain angle on the circumference, and the direction of rotation is realized by two hydraulic cylinders 3 on the tank body 6 . The bottom of the concave groove 2 is provided with a guiding device 5 to ensure that the concave groove 2 can rotate smoothly.

[0018] In the present invention, the rear cover 1 is manually closed at first, and the concave groove 2 is driven to rotate through the hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com